Heatcraft BOHN User manual

No.: 20070206

页数. 1 of 20

日期:02/06/2007

西克制冷(无锡)有限公司生产

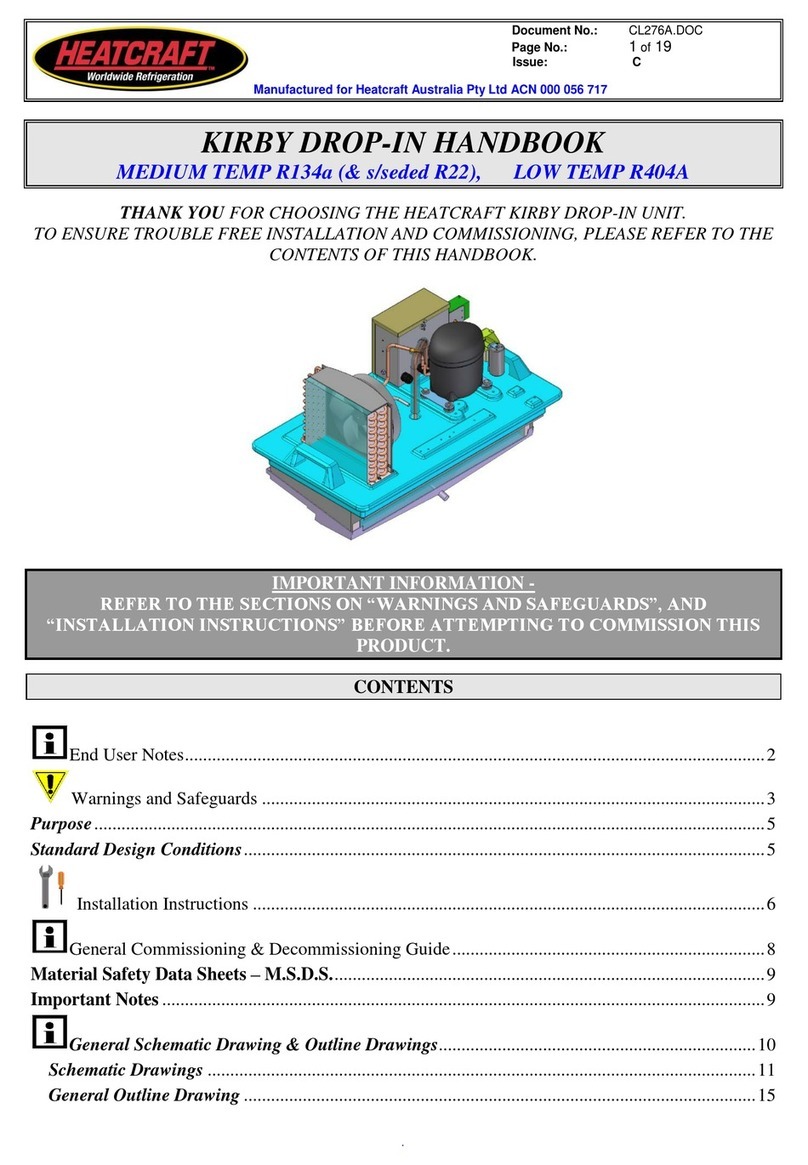

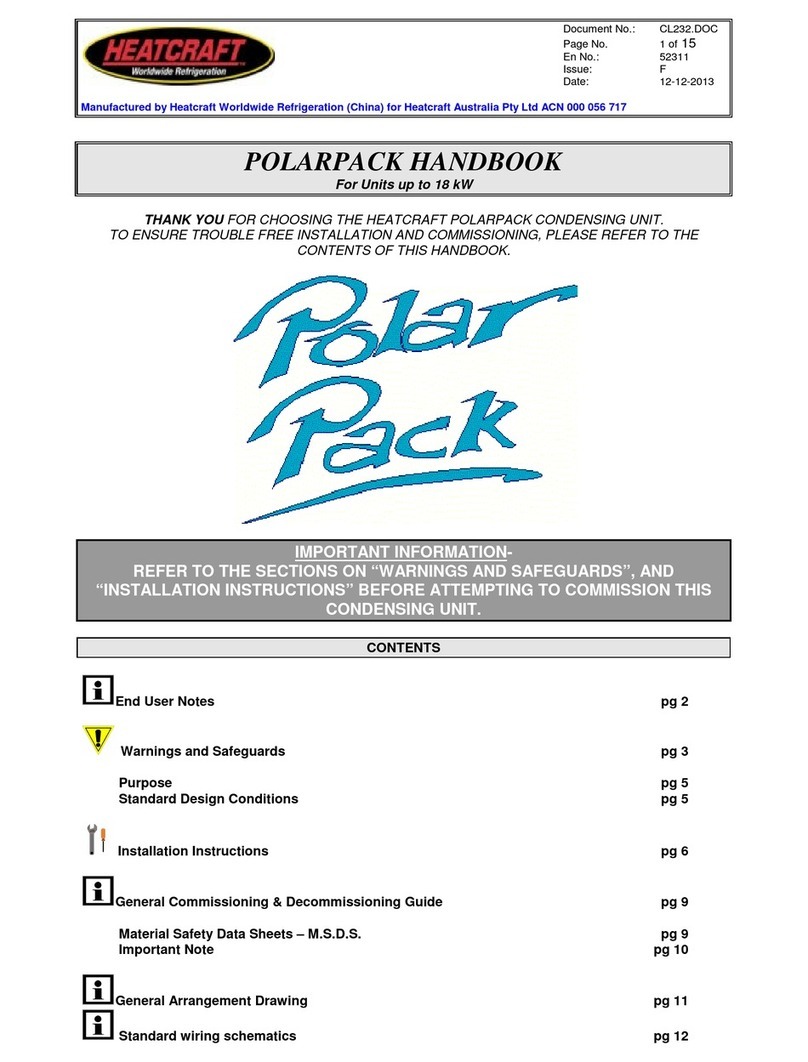

BOHN Heavy Duty Evaporator HANDBOOK

For Units up to 70 kW

BOHN

工

业

型

冷

风

机

操

作

手

册

单台最大冷量到

70 kW

IMPORTANT INFORMATION 重要信息

REFER TO THE SECTIONS ON

“WARNINGS AND SAFEGUARDS”, AND “INSTALLATION INSTRUCTIONS”

BEFORE ATTEMPTING TO COMMISSION THIS EVAPORATOR.

调试蒸发器前请先参看“警告及安全防护”和“安装说明”这两部分

CONTENTS 内容

Warnings and Safeguards 警告及安全防护 pg 2

Purpose 目的 pg 2

Standard Design Conditions 标准设计工况 pg 3

Recommended Placement and Clearance 推荐的安装位置及间距 pg 3

Installation Instructions 安装说明 pg 4

a) Lifting of Unit 设备吊装 pg 4

b) Unpacking of Unit 包装拆除 pg 4

c) Mounting the Unit 设备安装 pg 4

d) Condensate Drain Line 排水管 pg 5

e) Refrigerant Distributor and Nozzle 制冷剂分液器及节流环 pg 5

f) TX Valve, Sensor Bulb and

External Equalisation Line 热力膨胀阀,感温包及外平衡管 pg 5

非常感谢您购买西克无锡制冷产品,为了更

好的使用您所购买的产品,请仔细阅读并按

照下面的步骤操作,该手册仅适用于西克

BHDC/BHDF 系列工业型冷风机。

THANK YOU for purchasing refrigeration

products from Heatcraft Wuxi. Please

read and apply the following procedures

carefully in order to fully utilize the

equipment you purchased. This

instruction booklet is only applicable to

Kirby Heavy Duty Evaporators marketed

as the Kirb

y

BHDC / BHDF ran

g

e.

西克制冷(无锡)有限公司 文件号: 20070206

页数 2 of 20

g) Refrigerant Piping 制冷剂管道 pg 5

Electrical Connection 电气连接 pg 6

General Commissioning Guide 调试指南 pg 6

Advisory Defrost Guidelines 除霜指南 pg 7

a) Defrost Termination Requirements 除霜终止要求 pg 7

b) Control Setting Guidelines 控制设置指南 pg 8

Routine Maintenance of Unit 设备日常维护 pg 8

General Decommissioning Guide 关机指南 pg 9

Material Safety Data Sheets – M.S.D.S. 制冷剂安全数据表(M.S.D.S)pg 9

Important Note 特别提示 pg 9

General Arrangement Drawing 安装布置图 pg 10

General Electrical Schematic Drawings 电气原理图 pg 11

西克制冷(无锡)有限公司 文件号: 20070206

页数 3 of 20

Warnings and Safeguards

警告及防护

Under no circumstances should anyone

other than a qualified person attempt to

gain access to the interior of the unit

without first ensuring electric power is

在没有保证切断电源前,除了具备

资质的技工其他任何人决不允许接

触设备内部。

•Personal Protective Equipment such as gloves,

eyewear and footwear should be used during any work

carried out on this product.

•Installation, commissioning, testing,decommissioning

and service maintenance should be performed only by

qualified personnel (refrigeration mechanics and/or

electricians) who have sufficient knowledge in this type

of equipment. It is the purchaser’s responsibility to co-

ordinate with qualified personnel as required.

•All units are pressurised with dry air or Nitrogen gas.

Care must be taken to discharge the pressurised gas

carefully prior to installing or commissioning the

equipment.

•Avoid contact with sheet-metal edges and the coil

fins. They can be sharp and are a potential personal

injury hazard.

•Refrigerant can be harmful if it is inhaled and/or

makes contact with exposed skin. Refrigerants used in

this equipment are controlled substances, and must be

used and recovered responsibly. It is against the law to

deliberately discharge controlled substances into the

environment. Extreme care must be taken when

handling refrigerant, as personal injury or death may

occur.

•All field wiring must conform to the requirements of

the equipment and all applicable National and Local

Codes. All power sources must be disconnected before

the commencement of any service, maintenance or

electrical work.

•Avoid contact refrigerant pipes and heat transfer

surfaces when the equipment is operating. Their

extreme hot or cold surfaces ma

y

result in skin burns.

•在操作该设备时应该配备个人防护用品,例

如:手套、眼镜、鞋。

•安装、调试、测试、关机和维修服务等应该

由对该类设备具有足够知识经验的有资质的人

员(制冷机械工和/或电工)来操作。客户有

职责配备操作的人员进行作业。

•所有的设备都充有高压的干燥空气或者氮

气。在设备安装或者调试前一定要小心的排放

压缩气体。

•避免接触钣金的边缘和盘管的翅片,锋利的

边缘可能会引起人员受伤。

•如果吸入和/或皮肤直接接触制冷剂都会造

成伤害。该设备所用的制冷剂对人和环境都会

造成危害,在使用和回收中必须要负责任。制

冷剂排放到周围环境中是违法的。要非常小心

的处理制冷剂,否则,可能发生人身伤害或死

亡。

•所有现场接线必须符合设备的要求和通用的

国家和地方编码。在任何维修服务或者电气操

作之前必须先切断电源。

•当设备在运行过程中避免接触制冷剂管道和

热交换表面。高温或低温的表面会导致您的皮

肤受到伤害。

•WARNING: Do not insert any object into operating

fans. Ignoring this warning may result in personal injury

and/or severe equipment damage and consequences.

•Fans operate continuously even when the

refrigeration system has ‘cycled off’. The exception is

on freezer models where the fans will cycle off during

defrost.

•Keep the floor of refrigerated rooms dry. Slippage

due to ice formation on the floor is a potential personal

injury hazard.

•警告:不要把任何物体插入运行的风扇中,

否则会导致人员的损伤和/或机械的损害.

•当制冷系统循环停止时,风扇会继续运转,

除了在制冷模式下的除霜期间风扇会停止运

行。

•保持库房地面的干燥。潮湿的地面因为结冰

而较滑,可能会造成人身伤害。

西克制冷(无锡)有限公司 文件号: 20070206

页数 4 of 20

Purpose 目的

Standard Design Conditions 标准设计工况

Recommended Placement and Clearance 建议安装位置和间距

Some general rules for evaporator placement shall be followed: 冷风机得布置规则如下:

These Heavy Duty Evaporator ranges are standard

OEM products of Heatcraft Australia; they comprise

both ‘medium’ and ‘low’ temperature ranges. They are

intended for typical commercial sized cool room and

freezer applications for the storage of vegetables, fresh

meat, general foodstuffs, beverages, etc. They are not

intended for environments that may have harmful,

corrosive or flammable atmospheres or for the storage

of corrosive or flammable chemicals. ‘Marine’

environments are considered corrosive; please consult

Heatcraft before installing in this environment.

这些工业型冷风机是西克标准的 OEM 产品;

包括中温和低温两个应用范围。专为保存蔬

菜,鲜肉,常规食品和饮料等典型的商业冷藏

及冷冻库而设计。不能用于储藏有害,腐蚀,

易燃物的冷库,也不能用于储藏腐蚀,易燃化

学品的冷库。海洋环境是有腐蚀的;如果要安

装在这样的环境中请在安装前咨询西克。

Medium temperature range evaporators (Kirby KHDC

series) are designed at -4°C saturation suction

temperature (SST) and 6 KTD to suit room temperature

from -6°C to +20°C (refer to technical data for

maximum and minimum allowed KTD for specific SST),

for use in ‘heavy duty’ commercial cool room

applications. For rooms below 2°C, additional

defrosting means may be required. R507/R404A and

R22 are recommended refrigerants. For other

refrigerants, please refer to sales data sheet for

capacity variations.

Low temperature range evaporators (Kirby KHDF

series) are designed at -24°C SST and 6 KTD to suit

room temperatures from –4°C to –32°C (refer to

technical data for maximum and minimum allowed KTD

for specific SST), for use in ‘heavy duty’ commercial

freezer room applications. R507 or R404A are the

recommended refrigerants. For other refrigerants,

please refer to sales data sheet for capacity variations.

For lower temperatures design variations may be

required.

中温工业型冷风机(BOHN BHDC 系列)其设

计的饱和吸气温度为-4°C,温差为 6K,适用

于室温从-6°C 到20°C 商用冷库(特定的饱和

吸气温度下允许的最大和最小温差请参照技术

资料)。室温低于 2 °C 时需额外的除霜方

法。该蒸发器推荐使用的制冷剂有

R507/R404A 和R22。对于其他制冷剂,请参

照数据表查不同的制冷量。

低温冷风机(BOHN BHDF 系列)其设计的饱

和吸气温度为-24°C,温差为 6K,适用于室温

从-6°C 到-32°C 商用冷库(特殊饱和吸气温度

允许的最大和最小温差请参照技术资料)。该

蒸发器推荐使用的制冷剂有 R507/R404A 和

R22。对于其他制冷剂,请参照数据表查的不

同的制冷量。更低的库温必须重新设计。

These standard evaporators cannot use Ammonia

(NH3) as refrigerant.

For special design requirements (non standard

conditions and/or refrigerants such as Glycol,

Hydrocarbons, etc), please inquire with your local

representatives and/or Heatcraft Wuxi local branches,

or call our national telephone number 0510-85282020

for your nearest available information resources

这些标准的蒸发器不能用氨(NH3)作为冷媒。

对于非标设计(非标准工况和/或乙二醇、碳

氢化合物等作为冷媒)请咨询西克当地代表和

/或西克无锡,或者拨 0510-85282020 为您

提供最新的信息。

•The air pattern shall cover the entire room or

effective area.

•Do NOT locate evaporators over doors.

•Locate aisles, racks, etc so as not to hinder the

discharge or return airflow of the evaporator.

•Locate relative to compressors for minimum pipe

runs.

•Locate condensate drains for minimum pipe runs.

•气流组织应覆盖整个房间或者有效面积。

•禁止将蒸发器安装在门的上面。

•过道和货架的布置不能阻碍蒸发器的送风和

回风的流道。

•蒸发器到压缩机的管道距离尽量短。

•排水管的走管距离尽量短。

西克制冷(无锡)有限公司 文件号: 20070206

页数 5 of 20

S2S2

S2

S1

S2

S1

S1S1

Minimum clearance shall be guaranteed: 所允许的最小安装间距

Where one side of wall mounting is satisfactory.

满足所有蒸发器安装在同一侧墙上的情况

A)

S2

S1

S2

B)

S2S2

S1

A) is preferred

placement.

A)优先推荐的布置方

位。

B) is an alternative,

because it discharges

air at the door.

(However, it is still

better than mounting

over the door)

B)次之的选择,因为

送风正对门(但比直接

安装在门上面要理想)

C)

S2

S1

S2

S1

C) is preferred

placement.

C)优先推荐的安装方

位。

D)

S2

S1

S2

S2

S1

S2

D) is an alternative for

the same reason as B).

D)次之的选择,等同

于B)。

Where one side of wall mounting will not accommodate all required units or air

throw distance must be considered.

所有蒸发器不能容纳在同一侧墙上,或者必须考虑冷风射程的情况

S1 S1

S1 S1

S2

S2

Preferred Placement

优先推荐的布置方位

Second Choice due to possible airflow collision and

defrost difficulties

第二种选择,因为可能发生扰流或除霜困难

•S1 - Allow 500mm or more between the wall and air

on side of the coil, for airflow.

•S2 - Allow 400mm or more between the wall and the

access panel for service convenience.

•S1-墙壁到盘管空气侧之间的距离至少

500mm。

•S2-为了方便维修,墙壁到端板之间的距离

为至少 400mm。

西克制冷(无锡)有限公司 文件号: 20070206

页数 6 of 20

Installation Instructions

安装说明

a) Lifting of Unit a)设备的吊装

b) Unpacking of Unit b)包装的拆除

c) Mounting the Unit c)设备的安装

The weight of the unit ranges from 70 to

350kg. Always use the appropriate

mechanical handling equipment to lift the unit

into

p

lace.

设备的重量在 70~350Kg 之间,用合适的设备

吊起到适当的位置。

When unpacking, check for any damage to

packing material or the unit itself, which may

affect the unit’s performance. If any such

damage is evident, please contact your

Heatcraft branch.

拆包装的时候,检查设备和包装材料是否受

损,任何受损可能会影响运行效果。如果发现

有明显的受损部位,请您联系西克各地办事

处。

These evaporators can be mounted with

threaded rods and bolts. As a general rule,

the single 5/16” rod, and bolts and washers

can lift the weight up to 110kg (250 lb), 3/8”

for up to 270kg (600 lb). However it is the

installer’s responsibility to ensure the

evaporators mounted securely and

professionally.

To comply with HACCP and/or relevant

regulations for food safety, the area above

the evaporator must be sealed or exposed in

such a way to facilitate hand cleaning without

the use of tools. So depending on the end

user’s preference, the evaporators can be

installed either,

•Using threaded rod and allow sufficient

space between the top of the evaporator

and the ceiling for cleaning, or

•Flush mount the evaporator to the ceiling,

seal the gap between the top and the ceiling

with food benign sealant to prevent

accumulation of any foreign matter.

All evaporators shall be mounted

professionally and levelled properly so that

condensate drains from the evaporator

efficiently. Adequate support must be

provided to hold the weight of the evaporator

plus the weight of the refrigerant and any

frost that may accumulate on the coil surface.

The use of weight lifting equipment is highly

recommended whenever possible.

冷风机可以用螺栓和螺母固定。一般来说,单

个M8 的螺栓和螺母能承受重达 110Kg(250lb)

的重量,M10 的能承受重达 270Kg(600lb)的

重量。尽管是这样,但安装人员有责任确保蒸

发器安全的、专业的安装在指定位置。

为了遵守 HACCP 和/或有关的食品安全标

准,蒸发器的上面必须密封,或者不密封的话

请留出一定的空间方便手工清洗。以上两种方

式根据终端用户的实际需要而定。

•用螺栓固定蒸发器,并在顶板到天花板之

间留有足够的空间以便于清洗。

•将冷风机对齐安装在天花板上,采用亲食

品的密封材料密封天花板和冷风机顶部间的空

隙。

冷风机安装要得当,位置要适中,以保证凝结

水能有效地排出冷风机。支撑必须有足够的能

力承受冷风机自身的重量,冲注的制冷剂重量

及盘管表面寄居的霜的重量. 可能的话推荐使

用起重设备来吊装。

西克制冷(无锡)有限公司 文件号: 20070206

页数 7 of 20

d) Condensate Drain Line d) 排水管

e) Refrigerant Distributor and Nozzle e)制冷剂分液器及节流环

f) TX Valve, Sensor Bulb and External Equalisation Line

f)热力膨胀阀, 感温包及外平衡管

Ensure that the installation complies with

HACCP and/or relevant regulations for food

safety, and the end user’s preferences when

choosing copper, stainless steel or PVC

material for condensate drain lines. For low

temperature applications, proper insulation

and heating cable shall be provided to

prevent the drainpipe from freezing. Provide

a minimum 300mm per meter pitch to

condensate drain lines for proper drainage.

Drain lines should be at least as large as the

evaporator drain connection. All condensate

drain lines must be trapped to prevent

outdoor air and odours entering the

refrigerated room, and must never be

connected directly to the sewer system. All

traps must be located in a warm ambient to

prevent water from freezing. It is

recommended that the drain line be kept to a

minimum length within the refrigerated room.

请确认排水管的安装符合食品的 HACCP 及相

应的安全规范,材料可选择铜管,不锈钢管或

PVC 管,根据客户而定。对低温应用工况,

需提供保温及加热丝以防止排水管结冰。推荐

每1米300mm 的坡度正确安装排水管。排水

管的尺寸至少和冷风机的积水盘接头一样。所

有的凝结水排水管必须要安装 U型弯以防止

外界空气及异味进入冷库,绝对禁止直接和排

污系统相连。所有 U型弯置于温暖的环境以

防止结冰。建议排水管在冷库内的长度要尽可

能短。

To obtain the best performance of the

evaporator, the distributor body shall be

mounted vertically to ensure refrigerant liquid

being distributed evenly to all the circuits.

For each unit through the whole range of

BOHN Heavy Duty Evaporators, a carefully

selected Sporlan-type orifice will be factory-

fitted in the distributor based on your request

of refrigerant type before delivering the

completed unit to your preferred site.

为保证冷风机达到最佳的制冷效果,分液器必

须竖直安装,确保制冷剂均匀地分配到各个制

冷回路中。

对于 BOHN 工业型冷风机中每一个型号,在

发往客户指定的地点前,根据客户所采用的制

冷剂,我司已在工厂安装了和分液器配套的

Sporlan 孔板。

For best performance, the TX valve should

be installed as close to the distributor as

possible.

Locate the TX valve sensor bulb on the

horizontal section of suction line and close to

the suction header. For a satisfactory TX

valve operation, good thermal contact

between the sensor bulb and the suction line

is essential. Follow TX valve manufacturers

recommendations when positioning TX valve

and sensor bulb. Incorrect installation may

result in poor evaporator performance.

The external equalisation line should be used

to link the TX valve external equalisation port

and the suction line, near the suction header.

A ¼” tube brazed to the suction line is

supplied for that purpose.

为了达到最佳的制冷效果,热力膨胀阀应尽可

能安装在离分液器近的位置。

将热力膨胀阀的感温包放置在吸气管的水平位

置,并且离吸气集管比较近的位置。为了达到

良好的运行效果,必须保证感温包和吸气管之

间达到良好的热接触。热力膨胀阀及感温包的

放置请遵循生产厂家的指示。不正确的安装会

导致制冷效果变差。

外平衡管用于连接热力膨胀阀的外平衡口和吸

气集管附近的吸气管。连接到吸气管的 1/4 英

寸铜管就是所说的外平衡管。

西克制冷(无锡)有限公司 文件号: 20070206

页数 8 of 20

g)Refrigeration Piping g)制冷管路

Note: With modern high quality TX valves,

refrigerant leakage through the equalisation

line is at a minimum and the TX valve

operation is not affected. Thus the external

equalisation connection could be made either

upstream or downstream of the sensor bulb

注意:目前热力膨胀阀的质量比较好,外平衡

管上很少会出现制冷剂泄漏,热力膨胀阀的运

行不受影响。 因此,外平衡管连接位置既可

以在感温包前,也可以在感温包后。

Refrigeration piping work shall be carried out

professionally by qualified refrigeration

mechanics in accordance with applicable

national and local regulations and in

conformance with good engineering

practices required for the proper operation of

the refrigeration system

制冷管路的设计,安装必须由专业的制冷技工

依照国家和当地的规范,同时符合良好的制冷

工程运行实际。

All the evaporators supplied by Heatcraft

Wuxi are supplied clean and internally

charged with dry nitrogen to prevent

oxidation and ingress of moisture or foreign

matter. Care shall be taken during installation

of the piping to prevent entrance of foreign

matter or moisture by minimising the time

that the piping is uncapped.

The interconnecting refrigeration pipe size is

not necessarily the same size as the outlet

on the unit. The pipe sizes shall be

selected/calculated based on the best

compromise of minimizing refrigerant

pressure drop and refrigerant velocity to

ensure efficient oil return. Heatcraft can

provide a software program to assist in the

calculation of pipe sizes.

Horizontal suction lines shall slope away

from the evaporators to allow the oil return

freely to the compressor by gravity. A 1:100

slope is considered sufficient. It is a good

engineering practice to fit an oil trap when

the suction line rises above the evaporator.

If in doubt during the installation, please

consult with your local sales representatives

and/or application engineers from Heatcraft

Australia for technical support.

西克提供的所有冷风机都是干净的,并且内部

预先充注有干燥氮气以防止氧化及湿气和外界

杂质进入。在安装时,尽量减小接管暴露在空

气中的时间,以防止外界杂质和湿气的进入。

制冷连接管路不一定要和冷风机的出口管路一

致,管路尺寸的选择和计算应基于最小压降和

流速衰减的原则。西克可提供管路计算软件。

水平吸气管需以一定的倾斜度离开冷风机,确

保冷冻油由重力作用回到压缩机。1:100 的斜

率是足够的。当吸气管高于冷风机时,最好安

装回油弯。

如果在安装过程中有疑问,请咨询我们当地的

销售代表或应用工程师。

西克制冷(无锡)有限公司 文件号: 20070206

页数 9 of 20

Electrical Connection 电气连接

General Commissioning Guide 调试指南

All electrical connections must be carried

out by a licensed electrical technician and

in accordance with the relevant

regulations. Without prior permission

from Heatcraft Wuxi, all the provided

electrical wiring shall NOT be modified.

Failure to follow this procedure may

cause death and void warranty.

所有电器连接必须遵循相应的规范,并由专业

的电气技工来实施。未得到西克认同的情况

下,不允许修改电气连接。若不遵循该要求,

将会导致人身伤害,并且我司也将因此不提供

任何质保。

The BHDC-H series, the medium

temperature evaporators fitted with heater

elements, and the BHDF series, the low

temperature evaporators, are supplied pre-

wired to “WAGO” terminal block located in

the external electrical box of the evaporator

(Note: the BHDC series, the medium

temperature evaporators, is not pre-wired).

The wiring diagram for each pre-wired

evaporator is located on the inside of the

electrical box cover. Refer to the sales data

sheets for all the information regarding

voltage and current for fan motors and

element heaters.

During field wiring, fan motors shall be wired

up in star connection. After electrical

installation, units should be tested for correct

current draw and rotation of fan motors.

BHDC-H 系列中温冷风机安装有加热丝,

BHDF 系列低温冷风机在外置电器接线盒

上”WAGO”接线端子上预先接线 (注: BHDC

系列中温冷风机无预先接线)。每个预先接好

线的冷风机的电气接线图放在接线盒的盖子

内。对于风扇马达和电热丝的详细信息请参看

样本。

在现场接线时,风扇马达采用星型连接。电气

接线完毕后,请检查电流及风扇马达的运转方

向是否正确。

Refrigeration system commissioning shall be

carried out professionally by qualified

refrigeration technicians in conformance with

good engineering practices required for the

p

ro

p

er o

p

eration of the refri

g

eration s

y

stem.

制冷系统的开机调试需符合正确的制冷运行实

际,由资质的制冷技工操作。

After all installation and electrical work is

completed, the entire refrigeration system

must be leak tested. After satisfactory testing

the refrigeration system, then necessary

refrigeration lines shall be insulated. The

insulation located in outdoor environments

shall be protected from UV exposure.

Before charging the refrigerant, the entire

refrigeration system shall be evacuated by

connecting a good, high vacuum pump to

both the high-pressure side and low-pressure

side service valves or ports.

在所有的安装和电气连接完毕后,整个制冷系

统需先检漏,确认系统无泄漏后,所有的制冷

管路需保温,室外的保温同时需满足防止 UV

暴晒。

在充注制冷剂前,必须在高压侧和低压侧的维

修阀件处连接高性能的真空泵对整个系统抽真

空。

西克制冷(无锡)有限公司 文件号: 20070206

页数 10 of 20

Advisory Defrost Guidelines 除霜指南

SST 饱和吸气温度 -42 -36 -30 -24 -18 -12

DEFROSTS AT MAX. KTD 最大温差下的除霜次数 6 7 7 7 6 6

DEFROSTS AT 6KTD 6K 温差下的除霜次数 6 5 5 4 4 4

DEFROSTS AT MIN. KTD 最小温差下的除霜次数 5 5 4 3 3 4

Advisory defrost timing for -18°C room 建议的除霜时间 (-18℃冷库)

KTD

温差

LIGHT LOAD

轻负荷

HEAVY LOAD

重负荷

LIGHT LOAD

轻负荷

1 2 3 4 5 6 7 8

10 X X X X XX X

8 X X X X X X

6 X X X X

4 X X X

Vacuum must be maintained sufficiently so

as to minimise the occurrence of leaks when

the system is charged. Refrigerant must not

be charged into a system with known leaks.

Should vacuum not be maintained, check for

leaks with Nitrogen gas at a suitable

pressure prior to charging.

Installing a liquid line drier and a sight glass

in a refrigeration system is sound

engineering practice. The liquid line drier will

ensure all refrigerant supplied to the

refrigeration system is clean and dry. The

sight glass is a useful device to ensure

sufficient refrigerant is supplied to the

refrigeration system.

Refrigerant charging shall be in liquid form at

the high-pressure side of the system such as

condenser or liquid receiver. If the refrigerant

charging must be carried out through the

suction side of the compressor, charge in

vapour form only.

系统必须维持足够的真空度,这样在充注制冷

剂时不会出现泄漏现象。如果系统已有泄漏,

决不允许再充注制冷剂。如果系统不能保持真

空状态,那么在充注制冷剂前,用氮气在一定

压力下检漏。

制冷系统中安装液路干燥器和视液镜是比较好

的工程应用。液路干燥器可以确保系统中的制

冷剂是干净及干燥的。视液镜用来检查系统中

是否有足够的制冷剂。

采用液态制冷剂进行充注,一般在系统的高压

侧,比如在冷凝器或储液器。如果必须在压缩

机的吸气侧进行充注,必须以气态的方式充

注。

In order to maximise efficiency and airflow,

the following advisory defrost data has been

compiled. Defrost data is minimum number of

defrosts required per 24 hrs for average

room loads.

为了能使客户在使用我公司蒸发器时得到最高

的效率和最大的风量,建议根据以下除霜参数

进行除霜。

Double-check all field wiring connections and

factory terminals. Factory connections can

vibrate loose during shipment. Ensure

correct fan motor rotation, airflow is induced

from coil side and forced out of fan motor

side.

Check the room thermostat for normal

operation and adjust if necessary.

由于运输可能导致工厂接线松动,请再次确认

出厂前的接线及现场的接线。检查风扇马达的

运转方向是否正确,气流是否是从盘管处吸

入,从风机侧排出。

检查库房的温控器是否运行正常,有必要时可

对参数进行调整。

西克制冷(无锡)有限公司 文件号: 20070206

页数 11 of 20

a) Defrost Termination Requirements a) 除霜终止要求

Each column represents a 3-hour period

during the day. An X indicates the hour that a

defrost should commence. “Heavy Load”

represents the nominal ‘working period’ of

each da

y

.

每列代表了每天时段中的 3个小时。X显示了

除霜应该开始的时间。"重负荷"显示的是通常

意义上每天的“工作时段”。

温度终止—温度终止的设定主要根据除霜的频

率和结霜的状况,另外还取决于温度传感器/

温度开关的位置。如果使用的是电子除霜控制

器,对于每个安装环境下的冷风机,其温度终

止的设定点必须单独确定,设定点应不低于

12℃切断。温度传感器的位置应根据各个不

同的安装环境进行优化摆放。将传感器放置于

盘管上时通常需要更高的设置点,一般为 20

℃或者更高。

压力终止—可采用多种方式用于除霜。不论采

用何种方式,必须注意翅片表面的温度总是比

制冷剂饱和压力对应的温度要低,应此,必须

考虑在设定压力控制时,制冷剂的温度设定要

高点。请参看下面的表。西克制冷不推荐通过

压力来控制风机延时,因为在采用热力膨胀阀

的系统中,当风机停止时,除霜结束后系统迅

速进入低压状态。对风机延时控制上,建议对

采用压力中止的除霜方式基础上采用时钟。

电加热丝热保护—西克生产的冷风机标准产品

中不带电加热丝热保护装置。客户负责安装合

适的该保护装置以防止在控制器和传感器失灵

的情况下,由于过高的温度和压力引起的冷风

机及周围环境的过热。

Defrost time for average loads should be

approx. 20 - 25 minutes including drainage.

Time will vary with varying degrees of ice

build up.

Time Termination – should be set to ensure

complete defrost at the heaviest load

condition. Typically allow 25 - 30 minutes

with safety reset at 35 minutes.

对于正常负荷的系统来说,平均的除霜时间大

约为 20-25 分钟(包括滴水时间)。这个除霜

时间将随着结霜的程度有所变化。

时间终止—时间终止是为了能够保证在最重负

荷的情况下仍然能够除尽盘管上的霜。通常的

时间设定为 25 - 30 分钟,安全关断时间为 35

分钟。

西克制冷(无锡)有限公司 文件号: 20070206

页数 12 of 20

b) Control Setting Guidelines b)控制设置

Termination Type

终止方式

Sensor Location

传感器位置

Setting

设置

Fan Delay

风机延时

Time

时间

n/a

无

25 – 30 mins

25-30 分钟

5 mins (max)

5分钟(最长)

Temperature

温度

Position & temperature settings must be determined for individual case

根据不同的应用,设置不同的传感器位置和温度控制点

Pressure (Gauge)

压力

Header

集管 770-790kPa R404A n/a

无

800-820kPa R507 n/a

无

630-650kPa R22 n/a

无

690-710kPa R407C n/a

无

340-360kPa R134a n/a

无

Fan Delay Requirements – may vary with

application, conditions and control method,

but should not be more than 5 minutes.

Coils – 4FPI (for Low Temp.) and 6FPI(for

medium Temp.) coils (standard coils), should

be operated to the above guidelines unless

otherwise indicated on the installation

concerned.

风机延时要求—风扇延迟需要根据不同的应用

场合而定,但一般来说不应超过 5分钟。

盘管—4FPI(低温) 和6FPI(中温)盘管(标准盘

管) 除非有特殊安装指示,一律按上述的指导

进行安装运行。

Each application should be treated on its

merits, however the following is given as a

guide. During the commissioning, this data

should be used as a reference initially. It is

then necessary to fine-tune the control

settings to achieve the satisfactory defrost

results.

不同的应用需区别对待,请遵从下面的安装指

南。在开机调试时,下面的参数应作为首选参

考值,然后根据实际做相应的调整,达到最佳

的除霜效果。

The above guidelines allow for relatively

heavy defrost loads. Shorter times or lower

settings must be verified on the installation.

Pressure termination given for R407C and

R404A corresponds to the mid point at the

required temperature. Refer to the applicable

Heatcraft Pressure / Temperature Chart.

All data given is for defrost without refrigerant

pump down.

Pump-down is not recommended for electric

defrost using pressure and/or temperature

control. There is clear evidence in testing that

positive defrosting of the distributor, leads,

header and suction line, can not be achieved

without refrigerant being present in the coil.

Additional means, such as heater tape

around these components, may be needed if

using pump-down.

上面的设置参数同样适用于重除霜负荷的工

况。在安装时必须修改时间及温度设定。对

R407C 和R404A 压力设定点取要求温度对应

的中间点。具体请参看西克的压力温度对应

表。

所有给定的除霜参数在无抽空循环的情况下

的。西克制冷不推荐在抽空情况下使用电加热

化霜的方式。根据我们多年积累的经验,分液

器、分液管、吸气集管上的霜如果在盘管内没

有制冷剂存在的情况下是很难除掉的。可能还

会需要其它诸如在这些零部件上加装发热管等

辅助方式。

西克制冷(无锡)有限公司 文件号: 20070206

页数 13 of 20

Routine Maintenance of Unit 设备的日常维护

Longer defrosting time and / or more frequent

defrosting may also be necessary to ensure

long-term ice built up does not occur.

Pump-down may be used with time

termination. The defrost time will be longer

and requirements must be determined on

individual systems.

Data above based on R507/R404A

refrigerant. For other refrigerants, it may be

necessary to vary the number of defrosts per

day to maintain efficient performance.

可能还必须采用延长加热时间,提高加热次数

的方法以避免霜堵。

抽空最好和时间中止一起使用。除霜时间会相

应变长。

上面的数据是基于 R507/R404A 制冷剂的。

对于其他制冷剂,西克建议变化每天的除霜次

数来最佳的除霜效果。

BHDC-H Unit

The advisory defrost data has not been

compiled for the BDHC-H range, the medium

temperature application with factory fitted

heater elements. But generally you should

use above low temperature application data

as a guideline to start with, and make

necessary alterations based on observation

and monitoring during the commissioning

BHDC-H 冷风机

推荐的除霜参数不适用于 BHDC-H 冷风机,

对于中温应用工况,工厂已预装了加热丝。在

开机时还是应使用上面低温工况的参数为指

南,在调试时,根据实际情况来进行必要的调

整。

All BOHN Heavy Duty Evaporators are

designed to have low service maintenance

requirements. Based on normal operation

conditions and working environment, a

service maintenance schedule shall be

established after the successful completion

of commissioning, to ensure the evaporators

operate efficiently and running costs are kept

at a minimum. The following items shall be

checked and recorded during service

maintenance,

•Visually inspect the evaporators looking for

corrosion, unusual vibrations, oil stains and

drain tray blockage. The drain tray should be

cleaned regularly with warm soapy water.

•Clean the evaporator fins by using a soft

brush, low pressurised water and/or

commercially available evaporator coil

cleaner. Never use an acid based cleaner.

Follow label directions for appropriate use.

Flush and rinse coil until no residue remains.

•Coils supplied with ‘Koil Kote’ need special

care so as not to damage the coating. The

coils should not be cleaned with strong

Alkaline Cleaners and/or with stiff brushes.

Mild soapy solutions that are well rinsed after

cleaning should be satisfactory.

所有 BOHN 冷风机都是基于维护较少的前提

下设计的。根据正常的运行工况和环境,在调

试成功后,应准备一份维护时间表,以确保冷

风机在最佳效率下运行,同时保证运行成本最

低。在做维护时,请检查并记录下列各项参

数:

•检查冷风机是否有腐蚀,不正常的振动,油

堵及排水管脏堵。排水管需要经常用温肥皂水

清洗。

•用柔软的刷子清洗冷风机翅片,用低压清水

冲洗盘管或者用市面上买得到的盘管清洗器。

禁止使用酸性清洗剂。请遵循标识的使用指

南。冲刷盘管直至无任何残留物。

•“Koil Kote”盘管需要特殊注意,不要破坏其

涂层。不要用碱性清洁剂或坚硬的刷子来清洗

这类盘管。清洗后最好用中性肥皂水进行冲

淋。

西克制冷(无锡)有限公司 文件号: 20070206

页数 14 of 20

General Decommissioning Guide 关机指南

•Check that each fan rotates freely and

quietly, fan guards are free of airflow

obstructions and fan screws are tight.

•Inspect electrical wiring, connections and

components looking for damaged wiring,

loose connections and worn components.

•Check that all coil heaters are in their

original positions and properly secured, and

that drain tray heater is in proper contact with

the tray and located by the brackets.

•Ensure even coil frost formation pattern on

the air off (fan) side of the coil during

operation. An uneven frost pattern may

indicate a distributor blockage or incorrect

refrigerant charge. The air on side tubes may

contain superheated vapour and may not

frost completely.

•Look for abnormal accumulation of ice

patterns and adjust the defrost cycles

accordingly.

•Check the superheat and adjust TX valve

accordingly.

•检查每个电机风扇转动是否正确,风扇罩是

否有堵塞,螺栓是否拧紧。

•检查电线,接头及其他元件是否有电线损

坏,接线是否松动,元件有无磨损。

•检查所有的盘管加热丝是否在原始位置,是

否安装牢固,检查积水盘管的电加热丝是否和

托盘接触良好,位置是否在托架上。

•在运行时检查在排风侧盘管上的结霜是否均

匀。不均匀的结霜说明分液头有堵塞物或者制

冷剂充注的不正确。在吸风处的盘管上可能因

为有过热气体而无任何结霜现象。

•寻找不正常的结霜状况,根据情况调整除霜

循环。

•检查过热度,相应的调整热力膨胀阀。

All power must be disconnected before cleaning

and/or service maintenance. The condensate

drain tray also serves as a cover of hazardous

(hot, cold, electrical and moving) parts. Operation

of evaporators without condensate drain tray

constitutes a safety hazard.

The service maintenance record as well as this

“BOHN Heavy Duty Evaporators Handbook” shall

be kept together in a safe place as a future

f

在清洗和维修时必须断电。积水盘也是

需要维修的部件(热,冷,电气及运动部

件)。如果冷风机在不安装积水盘情况下

运行是存在安全隐患的。

维护记录和”BOHN 工业型冷风机的操

作手册” 应好好保管以便将来做参考。

In order to remove the evaporator from its

mounting place, the following procedures

need to be carried out professionally by

qualified personnel. Failure to do so may

result in personal injury or death, property

damage by fire or explosion. Discharge of

refrigerant to atmosphere is illegal and may

result in heavy fines by relevant regulatory

authorities.

将冷风机从原来的安装位置移走,必须由专业

的制冷技工遵循下面的程序来进行拆卸。不遵

循该程序将引起操作人员受伤或死亡,并且由

于失火或爆炸引起财产损失。直接将制冷剂排

放到大气中是不合法的,并且会受到监控部门

的严厉罚款。

西克制冷(无锡)有限公司 文件号: 20070206

页数 15 of 20

Material Safety Data Sheets – M.S.D.S. 制冷剂安全数据表-M.S.D.S

•Pump down the entire refrigerant charge

into the liquid receiver or appropriate

container such as reclaim cylinder, and shut

related valves. All reclaimed refrigerant that

is not re-used must be taken to an approved

refrigerant recycling or destruction facility.

•将全部充注的制冷剂抽到储液器或合适的储

液罐,如回收钢瓶,同时关闭相应的阀件。所

有回收的不能再用的制冷剂必须送往合格的制

冷剂再利用或销毁处。

•Disconnect the power supply. Remove all

necessary field electrical wiring and related

components, leaving the earth wire to the

last.

•Disconnect the drainpipe.

•Care must be taken when de-pressing the

Schrader valve core in order to balance the

pressure between the evaporator and

ambient. There may be a small amount of

refrigerant trapped in the oil, the pressure

rise in the evaporator will boil and vaporise

the refrigerant resulting in a potential

personal injury hazard.

•Cut and solder seal the refrigeration liquid

line and suction line pipe connections.

•Remove the evaporator from its mounting

place. Adequate support must be provided to

hold the weight of the evaporator. The use of

weight lifting equipment is highly

recommended whenever possible.

•切断动力供电。移走所有不要的现场接线,

相应的电气元件,最后切断地线。

•断开排水管

•为了平衡蒸发器和外界的压力,在打开针阀

阀心时必须特别小心。在润滑油中溶有一定量

的制冷剂,当冷风机的压力上升时制冷剂就会

沸腾并挥发,这可能会导致人员受伤。

•切断,并密封液管和气管的接头。

•将冷风机从安装位置移走。当需要时,建议

采用起重设备。

These are available from your nearest

Heatcraft Branch for all refrigerants that this

range of evaporators are approved for.

Important Note

•To ensure BOHN Heavy Duty Evaporators

operate efficiently and for a long working life,

always obtain genuine replacement parts

from your local Heatcraft Wholesale Branch.

Genuine replacement parts are covered by

the warranty. Refer to the Standard Terms &

Conditions of Sale in the Price Guide for

warranty statements.

•Continuous product improvement is our

company policy. Heatcraft Australia reserves

the right to make changes in product

specifications and/or this instruction manual

without notice.

从就近的西克办事处获取冷风机所使用的所有

制冷剂的数据表。

提示

•为了确保 BOHN 工业型冷风机运行经济,

使用寿命长,请向当地的西克办事处采购原装

的配件,并且这些配件也是有一定的质保期

的。对质保期的详细描述请参看西克标准销售

合同。

•不断的改进产品是我们公司的宗旨。西克保

留对未经许可对我司产品及操作手册改动的最

终解释权。

西克制冷(无锡)有限公司 文件号: 20070206

页数 16 of 20

Heatcraft Wuxi is dedicated to providing safe

products and protecting the environment by

complying with all applicable national laws

and regulations governing environmental

protection. New and used refrigerants cannot

be vented into atmosphere. Reclaim all used

refrigerants.

西克制冷致力于提供安全,并且符合

国家法律及环境保护法规的制冷产

品。新的或者使用过的制冷剂是不可

以直接排放到大气中的,回收所有使

用过的制冷剂。

西克制冷(无锡)有限公司 文件号: 20070206

页数 17 of 20

General Arrangement Drawing

安装布置图

AIR FLOW

AIRFLOW

TOP BRACKETS

OPEN SLOT

12 WIDE

REFRIGERATION

CONNECTIONS

TOP BRACKETS

CLOSED SLOT

12 X 20 FOOT MOUNTING NOT SHOWN IN THIS VIEW

ELECTRICAL ENTRY

Ø22 ENTRY (AT REAR)

ELECTRICAL BOX

(KHDC-H & KHDF ONLY)

FOOT MOUNTED.

ALLOW 1000 MM MIN. FOR AIRFLOW

REMOVABLE / OPENING

ACCESS DOOR

AIRFLOW LABEL

CEILING MOUNTED

ALLOW 600 MM MIN. FOR AIRFLOW

FOOT MOUNTED

ALLOW 1000 MM MIN. FOR AIRFLOW

ALLOW 520 MM MIN.

FOR ACCESS PANEL OPENING / REMOVAL

Ø32 MM DRAIN TUBE

1000 (1 FAN)

1300 (2 & 3 FANS)

1500 (4 & 5 FANS)

ALLOW MIN. FOR

HEATER ELEMENT REMOVAL

KIRBY HEAVY DUTY MODELS

KHDC (NORMAL TEMP.)

KHDC-H (NORMAL TEMP. + HEATER)

KHDF (LOW TEMP)

12mm 半开式

长圆孔

12x20mm 封

闭长圆孔

底座不可见

冷媒连结管

ø12mm 穿线

孔

电气盒

Ø32mm 接水

管

检查通道≥520mm

1000mm(1个风扇)

1300mm(2或3个风扇)

1500mm(4或5个风扇)

以上为拆卸电加热丝的最短距离

检查门

到固定板距离≥1000mm,

方便气流流动

≥600mm,方便气流流动

到固定板≥1000mm,方便

气流流动

标签

西克制冷(无锡)有限公司 文件号: 20070206

页数 18 of 20

General Electrical Schematic Drawings

电气原理图

1. FACTORY FITTED COMPONENTS & ASSOCIATED WIRING

1.工厂附带的零件及布线

无锡新加坡工业园区新都路 12 号

邮编:214028

电话:0510-85282020

传真:0510-85282242

西克制冷(无锡)有限公司

W2 U1 U2 V1 V2 W1 W2 U1 U2 V1 V2 W1

L1 L2 L3 E

3-Ph FAN MOTOR 1 3-Ph FAN MOTOR 2 (IF PRESENT)

3-Ph FAN MOTOR 3

(IF PRESENT)

FUSE, OR

CIRCUIT BREAKER

415 V, 3 Ph, 50 Hz

ISOLATION SWITCH

BLACK

BROWN

BLUE

G / Y

W2 U1 U2 V1 V2 W1 W2 U1 U2 V1 V2 W1

3-Ph FAN MOTOR 1 3-Ph FAN MOTOR 2 (IF PRESENT)

3-Ph FAN MOTOR 3

(IF PRESENT)

BLACK

BROWN

BLUE

G / Y

OPTIONAL LOW SPEED

CONNECTION BY JUMPERS

STANDARD HIGH SPEED

CONNECTION BY JUMPERS

STANDARD HIGH SPEED CONNECTION METHOD

OPTIONAL LOW SPEED CONNECTION METHOD

熔断器或断路器

隔离开关

三相风扇电机 3

(如果需要)

三相风扇电机 2(如果需要)

三相风扇电机 1

三角形连结

标准高速连结方式

可选的低速连结方式

三相风扇电机 3

(如果需要)

三相风扇电机 2(如果需要)

三相风扇电机 1

星形连结

西克制冷(无锡)有限公司 文件号: 20070206

页数 19 of 20

2.WIRING METHODS FOR SINGLE-SPEED FAN CONNECTION 2.单速风扇接线方法

NOTE: Heatcraft Wuxi supplies motor fan(s) only. All wiring & associated components are to be supplied

and fitted on final installation by customer.

注意:西克无锡仅提供风扇电机。所有的布线和相关零件的供应由最终客户确认。

L1

COIL HEATER 1

"WAGO"

TERMINALS

1

N

BLACK

COIL HEATER 2

2

BLACK

COIL HEATER 3

3

BLACK

TRAY HEATER

BLACK

4

L2

L3

COIL HEATER 4

BLACK

5

6

7

BLACK

BLACK

BLACK

BLACK

BLACK

(IF PRESENT)

8

E

ALL EARTH LEADS

TERMINATE HERE

EARTH POST

EARTH LEAD TO

"TERMINAL BLOCK COVER"

G / Y

G / Y

G / Y

FACTORY FITTEDSUPPLIED & WIRED

BY OTHERS

415 V, 3 Ph, 50 Hz

由他方供电和接线

工厂提供

盘管加热器 4(如果有)

盘管加热器 1

盘管加热器 2

盘管加热器 3

黑色线

接水盘管加热器

所有接地端在此

零线

地线

接地柱

绿/黄

绿/黄

绿/黄

壳体接地

“WAGO”

接线排

黑色线

黑色线

黑色线

无锡新加坡工业园区新都路 12 号

邮编:214028

电话:0510-85282020

传真:0510-85282242

西克制冷(无锡)有限公司

西克制冷(无锡)有限公司 文件号: 20070206

页数 20 of 20

Table of contents

Other Heatcraft Industrial Equipment manuals