Heath Company Heathkit H9 User manual

,,'"..'t'. '

::, .:.,r .

H

MANUAL

for the

VIDEO

TERMINAL

Model

H9

ASSEMBLY 5e5-1se6-05

\,

\

HEATH

COMPANY

. BENTON

HARBOR,

MICHIGAN

HEATH

COMPANYPHONEDIRECTORY

Thefollowing

telephonenumbers

aredirectlines

tothe

departmentslisted:

Kit

orders

anddeliveryinformation ...... (616)

982-3411

Credit. ......(616)982-3561

ReplacementParts.. .. (616)

982-9571

TechnicalAsslstance

Phone Numbers

8:00A.M.to 12

P.M.and 1:00

P.M.to 4:30P.M., EST,Weekdays

Only

RZC,Audio,

andElectronic

Organs. .... (616)

982-3310

Amateur

Radio

TestEquipment,

WeatherInstruments

and

Home

Clocks

Television

Aircraft,

Marine,Security,

Scanners,Automotive,

Appliances

andGeneralProducts .... . (616)

982-3496

Computers ... (616)

982-3309

YOUR HEATHKIT 90 DAY LIMITED WARRANTY

If you ae not satisfied with our sewice - warranty or otherwise - or with our products, write directly to our Director of Custoner

Services,Heath Company, Benton Harbor, Michigan 49022.He will make certain your problems receive immediate, personal

attention.

Our attorney, who happens to be quite akitbuilder himself, insists that we describe our warranty using all the necessary legal

phrases in order to comply with the new wananty regulations. Fine. Here they are:

For a period of ninety [90) days after purchase, Heath Company will replace or repair free of chmge any parts that are defective

either in materials or workmanship. You can obtain parts directly from Heath Companyby miting us at the addressbelow orby

telephoning us at [616] SB2-3571.And we'll pay shipping chmges to get those parts to you - anywhere in the world.

We wmrant that during the first ninety (90) days after purchase, our products, when correctly assembled, calibrated, adiusted

and used in accordance with our printed instructions, will meet published specifications.

If a defective part or error in design has caused your Heathkit product to malfunction during the wailanty period through no

fault of yours, we will service it free upon proof of purchase and delivery at your expense to the Heath factory, any Heathkit

Electronic Center (units of Schlumberger Products Corporation), or any of our authorized overseasdistributors.

You will receive free consultation on any problem you might encounter in the assembly or use of your Heathkit product. |ust

drop us a line or give us a call. Sorry, we cannot accept collect calls.

Our wananty does not cover and we ile not responsible for damage caused by the use of corrosive solder, defective tools,

incomect assembly, misuse, fire, or by unauthorized modifications to or uses of our products for purposes other than as

advertised. Our warranty does not include reimbursement for customer assembly or set-up time.

This warranty covers only Heathkit products and is not extended to allied equipment or components used in conjunction with

our products. We are not responsible for incidental or consequential darnages. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This waranty

gives you specific legal rights, and you may also have other rights which vary from state to state.

HEATH

COMPANY

BENTONHARBOR,MI.49022

(616)

982-3296

(616)

e82-3315

(616)

982-3307

d5

o<J

-ir

.fJ

=-

Prices

andspecifications

subjectto changewithoutnotice. ffirdtffbTbTbllThtllK

Heathkit@

Manual

for the

VIDEOTERMINAL

ModelH9

ASSEMBLY 5e5-1ee6-05

HEATH COMPANY

BENTON HARBOR, MICHIGAN

Copyrlght@ 1977

HeathCompany

Nl RightsReserved

Printed

inthe

UniledStatesofAmerica

49o 22

Pase. @

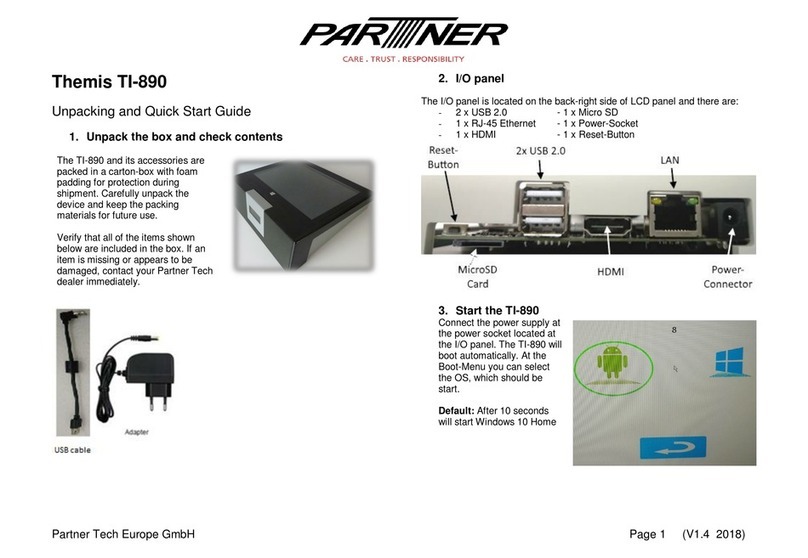

TABLE OF CONTENTS

INTRODUCTION.

UNPACKING

.. ..

CHASSIS

Partslist .....5

Assembly

Notes ... .. 8

Step-by-StepAssembly ...71,

POWER

SUPPLY

CIRCUIT

BOARD

PartsList

Assembly

Notes .

Step-by-StepAssembly

PowerSupply Checkout

CHARACTERGENERATOR

CIRCUIT

BOARD

Parts

List

Step-by-StepAssembly

CharacterGeneratorCircuit

BoardCheckout

VIDEOCIRCUIT

BOARD

Parts

List

Step-by-Step

Assembly

Video Circuit BoardCheckout

CRTInstallation.

KEYBOARD

CIRCUIT

BOARD

Partslist ....85

Step-by-StepAssembly ... 87

Keyboard

Circuit

Board

Checkout ..... 99

RAM AND COUNTERCIRCUIT

BOARD

Partslist ...103

Step-by-StepAssembly .. 105

Ramand CounterCircuit

Board

Checkout .. 1.12

INPUT/OUTPUT

CIRCUIT

BOARD

Partslist ...1.17

Step-by-StepAssembly ..119

I/OCircuitBoard

Checkout .. .. 728

TIMING AND PROCESSING

UNIT

CIRCUIT

BOARD

Partslist ...732

TPUCircuit

Board

Checkout ... 734

ADIUSTMENTS. ... 't37

FINAL

ASSEMBLY ....... 139

33

36

38

46

52

54

61

62

64

73

75 CUSTOMERSERVICE .... Insiderear

cover

WARRANTY

.... .. Insidefront

cover

-

Page3

L@

INTRODUCTION

The Heathkit Model H9 Video Terminal can display

information coming from a computer or enter infor-

mation into acomputer. The information is displayed

ort a 72" (diagonal) cathode ray tube (CRT) which is

capableof displaying 960charactersatone

time in 12

rows with 80 characters per row.

A sixty-seven key ASCII keyboard permits you to

composeand edit directly onto the CRT with a capa-

bility of 64 different characters and 24 different func-

tions. This messageor program canthen betransmit-

ted through the standard serial I/O interface [EIA,

TTL, or 20 mA current loop) to a digital computer or

through the parallel I/O interface to a paper tape

punch.

The Video Terminal can be used with any digital

computer in dedicated, stand-aloneapplications, or

in time-sharing systems. It lets you communicate

with a digital computer in higher-level languages,

such as Basic, Assembler, etc., rather than in just

machine language.The Video Terminal is also

much

faster (up to 9600 baud) than the standard electro-

mechanical teleprinter systems. You can select any

data rate between 110 and 9600 baud.

Other important features include:

o Automatic scrolling.

a Cursor controls.

o Erase

to end of line.

. Erase

page.

o Short form (four 12-line columns of 2O

characters).

o Automatic line carryover.

o Plot mode.

o Built-in speaker

(audible bellJ.

These features, along with the attractively-styled

cabinet, make the Video Terminal a very versatile

peripheral to your computer system.

TJNPACKING

Inside the shipping carton there is a box stamped

"PKS 1-6," and a numberof loose

parts.

After you

remove

theboxstampedPKS1-6, all theremaining

parts

will beconsideredthe"final pack."

The

cathode

ray tube is separate

in its own shipping carton.

Remove

the box stamped

PKS 1-6- Remove

the

cathoderay tube carton and set it asideuntil it is

calledfor in aPartsList.WARNING:

Donot openthe

cathode

raytubecarton

until you areinstructed

to do

soin a step.Improper

unpacking

canresult

in per-

sonalinjury or tube damage.

Whenyou openthebox stampedPKS1-6, you will

find a PackIndex Sheet

in the top of the box. This

sheetshows

howthe

boxhas

been

divided into differ-

entcompartments

which arereferredtoin theManual

as"packs."Youwill bedirected

toopeneach

ofthese

"packs" asit is needed.

CAUTION: No partsshould

be removed from the boxes or their compartments

until theyarespecificallycalledforby aPartsList in

the Manual.

Each

assembly

section

oftheManualcontains

itsown

"Parts List" and "Step-by-Step

Assembly" instruc-

tions.

At thebeginning

ofeach

"Parts

List,"you will

beinstructed

to open

oneof the packs.

You will also

be directed,in somePartsLists, to remove certain

parts

from the final pack.

-

Page5

r@

CHASSIS

PARTSLIST

Unpack the following parts from the final pack and

checkeach

partagainst

thefollowing PartsList.The

keynumbers

correspond

tothenumbers

ontheChas-

sisParts

Pictorial

(Illustration

Booklet,

Pages1and2).

Any partthat is packaged

in anindividual envelope

with apart

numberonit should

be

placed

backin the

envelope

afterit isidentified until it is called

forin a

step.

NOTE:

You shouldplace

theparts

in alocation

other

thanyour work area.

Many of these

parts

will not be

useduntil later in the assembly

and will be in your

way if placedon your work area.

Some

parts

aremarkedwith a"77L-"or"172-"pack-

agingnumber.These

numbersare

usedfor packaging

only anddonotappear

in theManualPartsList.Save

all packagingmaterial until all partshavebeenlo-

cated.

To order a replacement part, always include the

PART

NUMBER.

UsetheParts

Order

Formfurnished

with this kit or at the rearof this Manual. If a Parts

Order Form is not available,referto "Replacement

Parts"insidetherear

cover.

Your Warranty

is inside

thefrontcover.For

prices,

refer

totheseparate

"Heath

PartsPriceList."

Each

circuit componentin this kit hasaCircuit Com-

ponent

Number

(R2,

C4,

Q1,etc.).This is a specific

number

for onlythatone

partin thekit. Thepurpose

ofthese

numbers,

which are

especially

usefulif apart

everhasto bereplaced,

isto help you easilyidentify

the same

part in eachsectionof the Manual. These

numbers

will appeal

In the Parts

List.

At the

beginningofeach

stepwhere

acom-

ponentis installed.

In someillustrations.

In the Schematic.

In the sectionsat the rearof the Manual.

IMPORTANT:TheTPUcircuit boardassemblyhasbeenwired andtestedatHeath

Company.

If it malfunctions

during the90-day

period,

returnthecompletecircuitboardassemblytoHeath

CompanyoraHeathkitElectronic

Center.It will be promptly repaired and returned. Individual replacement parts are not supplied under

warranty. DONOT attempt

to servicethis circuit boardassembly

yourself

during thewarrantyperiod;

todo so

voids the warranty.

KEY

No. HEATH QTY.

DESCRIPTION

PartNo.

CIRCUIT

COMPONENTS

CIRCUIT

Comp.No.

c1

T2

T1

L1

D2

D1

SW1,SW2

SPKRl

A1 6470-12

A1 6-15'l

A2 2't-96

M 21-17

A3 25-810

A4 25-156

A5 25-822

A6 51-194

A7 g-943

A8 58-8

A9 56-26

A9 56-56

A10 60-2

All 401-163

A13 417-894

414 421-23

INSULATORS

81 73-92

82 73-132

73-23

83 75-30

84 75-52

85 75-728

86 75-734

75-124

87 75-704

47 A, 1|4-watl(yellow-

violet-black)resistor

150

O, 1/2-waft

(brown-

green-brown)

resistor

36 pFceramiccapacitor

270 pF ceramiccapacitor

500pF electrolytic

capacitor

4000pF electrolytic

capacitor

12,@O

y"F

electrolytic

capacitor

Flyback

transformer

Powertransformer

Deflection

yoke

1N191

diode

(brown-

white-brown)

1N4149diode

Slideswitch

Speaker

1 BU180A

transistor 01

1 l-ampere,3AG,

slow- Fl

blowfuse

1 314'

x 5"foam

tape

1 Small

rubber

grommet

1 Largerubber

grommel

1 Line

cordstrainrelief

'l Slideswitchinsulator

'12 Circuitboardstandoff

4 Circuitboardholder

1 4-112'

x d'fish

paper

1 Transistorinsulator

R'l

c5

@

c3

c2

1

1

1

1

'l

1

1

1

2

1

WARNING:Donotremovethecathoderaytube

fromits

cartonuntilyou areinstructed

to do so in a step.

A1z 411-830 1 310GJB4

cathoderay

tube CRTl

NOTE:Atransistorcanbemarkedforidentificationinoneof

thefollowing

fourways:

1. Partnumber.

2. Typenumber.

3. Partnumber

andtypenumber.

4. Part

numberwith

a

typenumber

otherthanthe

one

listed.

Paseo @

KEY HEATH QTY.

DESCRIPTION

No. Part

No.

CONNECTORS

_ SHELLS

- PLUGS

CIRCUIT

Comp.No.

HARDWARE

NOTE:

The

hardware

may

be

packed

in

morethan

one

packet.

Open

allthehardware

packets

(marked

HDW)

before

you

check

thehardware

against

theParts

Ltst.

#4 Hardware

c1 432-866 15

c2 432-753 15

c3 432-855 38

u 432-9il 1

c5 432-970 2

c6 432-821 1

c7 432-183 1

c9 432-924 |

c10 432-951 1

c1l 432-832 13

D1 250-213 1

D2 252-2 3

D3 2U-9 4

D4 253-703 1

#6 Hardware

D5 250-4s2 16

D6 250-381 I

D7 250-1264 10

D8 250-89 10

D9 2fi-475 6

D10 2fi-162 1

D11 250-569 6

D12 250-13 4

D13 252-3 16

D14 252-22 4

D15 252-708 2

D16 252-195 16

D17 253-60 2

D18 2*-1 16

D19 259-1 12

#8 Hardware

D20 250-137 4

D21 250-585 4

D22 2524 8

D23 2V-2 6

D24 2*-28 6

Smallspringconnector

Largespringconnector

Female

connector

4-conneclor

socketshell

s-connector

socketshell

6-connector

socketshell

g-connector

socketshell

24-connector

socketshell

4-pin

plug

6-pin

plug

12-pin

plug

4-40

x 5/16'screw

440 nut

#4 lockwasher

Plastic

shciulder

washer

6-32

x 114'

blackscrew

6-32

x 3/8'blackscrew

6-32

x 3/8'hexhead

screw

6-32

x 3/8'screw

6-32

x 318'

hex

head

self-tappingscrew

6-32

x 1/Z screw

6-32

x 3l4i blackscrew

6-32

x 1"

screw

5-32nut

#6 square

push-on

nut

#6 round

push-on

nut

6-32self-retainingnut

#6 flatwasher

#6 lockwasher

#6 solder

lug

8-32

x 3/8"screw

8-32

x 1/2'screw

8-32nut

#8 internal

toothlockwasher

#8 externaUinternaltooth

lockwasher

#8 solderlug

D25 259-2

KEY

No. HEATH QTY.

DESCRIPTION

PartNo.

LINE

CORD

- HARNESSES

- WIRE

-

CABLE- SLEEVING

CIRCUIT

Comp.

No.

89-54 1

134-1001 1

134-1002 1

134-1009 1

134-1016 1

340-8 10',

344-15 z',

344-59 10',

344-94 3g'

347-1 8',

346-1 12',

METALPARTS

E1 204-2325 2

E2 204-135 2

E3 206-1247 1

E4 206-1248 1

E5 203-1886-1 |

E6 204-2324 1

E7 207-86 1

E8 207-63 1

E9 200-1321 1

E10 203-1887-1 1

E11 203-1885-1 1

MISCELLANEOUS

Linecord

Mainharness

Busharness

2'l

-wire

cable

assembly

8-wire

cable

assembly

Barewire

Blackwire

Whitewire

Yellow

wire

8-wirecable

Sleeving

CRT brace

Anglebracket

Highvoltagetopshield

Highvoltagebottomshield

Rear

panel

CRT bracket

Capacitorclamp

Capacitorstrap

Chassis

Frontpanel

Bottompanel

Rollmaskingtape

Cabinetshell

Assembledtimingand

processing

unit

(TPU)

circuitboard

F1 74-6

90-'t2't0-1

181-2679-2

I

1

1

KEYHEATH OTY.DESCRIPTION

No. Part

No.

Miscellaneous

(cont'd.)

CIRCUIT

Comp.

No.

F2 260-16

203-1894

F3

F4

F5 205-778

F6 258-33

F7 258'79

F8 261-21

F9 352-13

F10 3y-7

390-147

390-1382

F11 390-1387

F12 391-61

1

F13 423jt1

F14 431-604

F15 431-42

446-686

406-664

Fl6 490-5

490-1

85

F17 490-189

Fl8 490-168

391-34

597-260

4

1

1

't

2

6

4

1

6

1

2

'l

1

1

1

I

1

1

1

'1

1

1

1

1

1

1

Alligator

clip

Cabinet

side panel

set consistingof:

Leftside (#203-1889)

Rightside

(#203-1890)

Screwdriver

blade

Coil

spring

Tensionspring

Rubber

foot

Silicone

grease

Cabletie

High

voltage

label

Chassis

plug

label

Modellabel

Modellabelholder

Fuseholder

3-lug

terminalstrip

s-lugterminalstrip

Cabinetwindow

Magnitying

glass

Plasticnut starter

De-solderwick

(braid)

Integratedcircuit

(lC)puller

Wrench

Blueandwhite

label

PartsOrderForm

Solder

Manual

(See

Page1

for part

number.)

lllustration

Booklet

Operation

Manual

(See

Page1forpart

number.)

Pases @

ASSEMBLYNOTES

TOOLS

Youwill needthesetoolstoassemble

vour

kit.

LONG.NOSE

PLITR

S

I

I

I

DIAGONAT

CUTTTRS

I

I

I

PLIERS

WIRT

STRIPPIRS I

4''-BLADT

DRIVTRS

@

l

l/8"&r/4'

SCRTWD

OTHER HELPFUL --+.

root,s 4 \ )

\, DiSOLDTRING

EIJLBT

! ilur

sTARTtR

1{MAY

Bt SUPPtItD

I WIIH KIT}

*I0 RtM0vt s0LDtR

FR0M

ctRcutT c0NNEcTt0NSI

-----J

ASSEMBLY

Follow the instructions

carefullyandreadthe

entirestepbefore

you performthe operation.

The illustrations in the Manual are called

Pictorials

and

Details.Pictorials

show

the

over-

all operation for a group of assembly

steps;

Details

generally

illustrateasingle

step.When

you aredirectedto referto a certainPictorial

"for thefollowingsteps,"continue

using

that

Pictorialuntil youarereferredtoanotherPicto-

rial for another

Sroupof steps.

3.1,

2.

4.

J.

Mostkits useaseparate

"Illustration Booklet"

that containsillustrations (Pictorials,

Details,

etc.)

thataretoolargefortheAssemblyManual.

Keepthe "Illustration Booklet" with the As-

semblyManual.The illustrations in it arear-

rangedin Pictorialnumbersequence.

Positionall parts

asshown in the Pictorials.

Solderapartora

groupofparts

onlywhenyou

areinstructed

to do so.

PHILLIPS

SCREWDRIVTR

PtNC

tr

SOTDERING

IRON

125

10 40 wATTS)

-

Page9

r@

Eachcircuit part

in anelectronic

kit has

itsown

component number (R2,C4, etc.).Use these

numbers when you want to identify the same

part in the various sectionsof the Manual.

Thesenumbers,which areespecially

usefulif a

part hasto bereplaced,appear:

In the Parts

List,

At the beginning of each step where a

component

is installed,

In someillustrations.

In the Schematic,

In the sectionat the rearof the Manual.

Whenyou areinstructedto cut somethingtoa

particular length, usethe scales

(rulers)pro-

vided at the bottom of the Manual pages.

SAFETY WARNING: Avoid eyeiniury when you cut

off excess

lead lengths.Hold the leadssothey cannot

fly toward your eyes.

6, SOLDERING

Soldering

isoneof

the

mostimportantoperations

you

will perform

while assembling

yourkit. A good

sol-

derconnection

will formanelectrical

connection

be-

tween two parts,such as a component lead and a

terminal strip lug. A bad solder connection could

prevent

anotherwise

well-assembledkit fromoperat-

ing properly.

It is easyto make a good solderconnectionif you

follow afew simplerules:

1. Usethe right type of soldering iron. A 25 to

40-watt pencil soldering iron with a 1/8" or

3/16"chiselor pyramid tip works best.

2. Keepthesoldering

irontip clean.Wipe it often

on awet spongeor cloth; thenapply solderto

the tip to give the entire tip a wet look. This

process

iscalledtinning, andit will protect

the

tip and enable

you to makegood connections.

When

soldertendsto"ball" ordoesnotetick

to

the tip, the tip needsto be cleanedand retin-

ned.

7.

Paselo @

A GOODSOLDER

CONNECTION

SOtDER

FLOWS

OUIWARD

AND GRADUALLY

BLENDS

WITH THTWIRI AND LUG. SOLDERING

IRON

POSITIONiD

CORRTCILY

,ur/

When

boththewire

andthelug

are

heated

atthesame

time,

thesolderwillflow

onto

the

wireandthelug

evenly.

Thesolderwillmake

a goodelectricalconnection

be-

tween

thewire

and

thelug.

Solder each connection as follows:

1. Pushthe soldering

iron

tipagainst

thewireand

thelug.

Heat

both

the

wireandtheluglortwoor

three

seconds. SOTDERING

IRON

2. Apply

soldertothe

wire

andthelug,

nottothe

solderingiron.

IMPORTANT:

Let

theheat

ofthe

wireandlugmelt

thesolder.

3. As thesolderbeginsto melt,

allowit to flow

around

the

connection.Thenremove

thesolder

andtheiron

and

let

the

connectioncool.

SOLDtRING

POOR

SOLDER

CONNECTIONS

SOTDER

DOTSNOI FLOW

LUG

ANOWIRT. A DARKoNTorHe

ROSIN

BEADSURROUNDS

AND

TATIS THt WIRI FROM INSUROSIN

THI CONNECTION

SOLDERING

IRON

POSITIONED

wlRE

iuConnEcriv

Whenthewireisnotheated

sufficiently,thesolderwill

not flow onto the wire as shown above.

To correct,

reheat

the

connectionand,ifnecessary,

applya small

amount

ofadditionalsolderto

obtaina

good

connection.

SOtDIR

INWARD

OF

LUG.

APPTARS

AND SIT IO FLOW

ONTOP

ROSIN s0tD

IRONR

ING

POSITIONED

INCORRECTLY

When

thelugisnotheated

sufficiently,thesolderwill

blob

on

thelug

asshownabove.To correct,

reheat

the

connectionand,ifnecessary,

applya smallamount

of

additional

solder

to obtaina goodconnection.

@ t"n"tt

STEP.BY.STEP

ASSEMBLY

NUT

DRIVER

ll o*

pusH

oowni

? ,r*$'Jl,(,*

/

@o iz

r'rur

druu LocKWAsHER

Detail t-tB

NOTE: Use the nut starter furnished with the kit to

pick up and start4-40 and 6-32 nuts on screws.

The

wrench supplied can be used to tighten hex head

screwsand nuts in hard-to-reachplaces.

( ,/) Refer

toDetail 1-18 and mount a 5-lug terminal

strip at AR. Use a 6-32 x 318' screw, two #6

lockwashers,

and a6-32nut. Besureto position

alockwasher on eachside of the mounting foot.

NOTE: Do not use the black or hex head

hardwareunlessit is specifically called for in a

step.

(i" ) Mount a #6 solder lug atAT with a 6-32 x 3lB"

screw,and a6-32nut. Position the solderlug as

shown.

STANDOFF

INSULATOR

CARTFULLY

WORK

INSULATOR

INTO

HOLE

Detail 1-1A

Refer

toPictorial 1-1

(IllustrationBooklet,Page

3)

for

the following steps.

(rA Position

thechassisbottom-side

up asshown.

(A Installasmall

rubbergrommet

in thechassisat

holeAA.

( rf) Placeall ofthe circuit boardstandoffsin warm

water and soakthem for 3 to 5 minutes.

( I ) Refer

to Detail1-1Aand install acircuit board

'' standoffat AB in the chassis.

( U Install circuit boardstandoffs

in the chassis

at

AC,AD,AG,

AH,AJ,AK, AM, AN, andAP.

Refer

to Pictorial1-2

(IllustrationBooklet,

Page

4)for

the following steps.

f fJ Turn thechassis

overandpositionit as

shown.

(r"

) Makealineacrossthechassis4-511,6'fromthe

backlip asshown.

(', ) On this line, make

amark 1"from the left side

andasecondmark

3-1,14'infromtheleft

sideof

thechassis.

(U) On

this

same

line,

make

a

mark1"from

theright

side

andasecondmark3-1/4"in fromtherieht

side

ofthechassis.

(

\/) Locate

a circuit boardholderandremove

the

protectivepaper

backing.

(;, ) Referto Detail1-2Aandpress

thecircuit board

holderontothechassis

at

P.

Makesuretheslot

in theholderisdirectly overtheline across

the

chassisandtheedgeofthe holderis onthe 1."

mark nearestthe left edgeof the chassis.

CIRCUIT BOARD

HOLDER

( 4 In thesamemanner,

press

circuit boardholders

to the chassis

at Q, at R, and at S.

( 4 Install circuit boardstandoffsat AE and AF

from the undersideof the chassis.

( ,) Mount two #6 solder

lugsatBE/BF

with a6-32

x 3/8"

screwanda

6-32nut. Position

thesolder

lugs

as

shown.

(,/) Mount

two#6 solderlugs

at

BG/BH

with a6-32

' x 3/8'screw anda6-32nut.

('l Mounttwo #6 solderlugs

atBI/gf with a6-32

x 318"

screwanda6-32nut.

( d' Mounttwo#6 solderlugsatBM/BNwitha6-32

x 318"

screwanda6-32nut.

( 4 Refer

to Detail1-28and cut eachleadof the

powertransformer

to its specifiedlength.Mea-

surethe leadsfrom wheretheycome

out ofthe

transformer.

Thenremove

theindicatedlength

of insulation from the end of eachwire.

|14" 3-rl2',

/"[r3^'

Ll4"

MEASURE

FROMHERE

Detail1-28

5

5

-112',

RID GRN

RTD ORG

6RN 0RG 4_rlT,

BLK-RED

BLK-YEL

l-

nr

Nt[.-/

Detail 1-2A

S

IX CONNECTOR

SOCKTT

RED

LARGISPRING

CONNECTOR

INSET

CRIMP OVERBARE

TND

OFLEAD

AND

StOTS

INSULATION

Detailr-2C

( 1 Refer

toDetail1-2Cand

crimpandsolderalarge

spring connectoronto one of the greenpower

transformer

leads.NOTE:

Besurethatyou do

not solderthe spring

part 9f theconnector

so

that it cannot move.

( Vl Check

yoursolder

connectiontomakesurethat

theconnectionissolid.

The

connection

should

have

asmooth,

shinyappearance.Iftheconnec-

tion is dull or grainy, reheat

the connection.

tyl CrimpandsolderIarge

spring

connectorsonto

theother

green,

bothorange,andbothredtrans-

former leads.

( ,,4 Locate

the6-connectorsocket

shellandnotethe

numbers 1 and 6 stampedin the front of the

shell.This indicates

holes1 and 6.

Detail 1-2D

NOTE: If it is evernecessaryto remove a spring con-

nector from the socketshell, usea small screwdriver

and depressthe tab on the spring connector through

the slotin the connectorshell while you pull thewire

out. SeeDetail 1-2D.

( 4 Refer again to Detail 1-2C and insert the large

spring connnector on one of the green trans-

former leads

into hole 1 on the socket

shell. Be

sureto position the spring part away from the

slottedsideofthesocket

shell.Pushin until you

hear the connector snap into the shell.

Install the other transformer leads into the socket

shell in the samemanner as follows:

( ,) Other

greenlead

into hole2.

( i.l Either

orangeleadinto hole3.

( ,) Otherorangelead

into hole

4.

( ;) Either red lead into hole 5.

( \ Other red lead into hole 6.

SOLDER ENDOF

\ INSULATION

@:_

AFTER

CLIP HAS

COOLED,

BEND

OVIR

PUSH

IN ON

TABOF

SPRINGCLIP

'BEE

Page 14

K;fi

^M

8-32

x 318"

SCREW

6-32

x ll4"

BLACK

SCREW

Detail 1-3A

.t

o

Detail 1-28

(/) T1:

Refer

toDetail1-2E

andinsert

theother

four

power transformer leads down through grom_

met AA. Then mount the power transformerto

the chassis

with four g-32 x 3/g,,

screws,

four

#B lockwashers,

andfour g-32

nuts.Move the

transformer away from the rear panel asfar as

the mounting holeswill permit. Then tighten

the hardware.

@)a-lzNur

Set

the chassis

aside

temporarily.

Refer

toPictorial1-3(IllustrationBooklet,

page

4)for

the following steps.

( I Locate

therearpanel

andpositionit as

shown.

14f SWz:

Refer

to Detail 1-3A and install a 6-lug

slide switch SW2with two 6-32 x 1/4"black

screws.

h,4 SW1:

Install

a 6-lugslideswitch at SW1.

Use

only two 6-32 x 1/+"

black screws.

( ) F1: Referto Detail 1-3B and install the fuse-

holderatF1.

Use

thehardware

thatis supplied

with the fuseholder.Be sure to position the

fuseholder

lugsas

shown.NOTE:

Donot over_

tighten the hardware or the fuseholder mav

break.

6r(cv)z

(rNcHES)

%

3/A I3/t 1

7lA

@ t"n"tu

NUT

RUBBTR

WASHER

Detail 1-38

{ Xefer to Detail 1-3C and bend lug 1 of the

fuseholder

out slightly. Becarefulthatyou do

notapply

pressure

tothelugwhere

it comesout

of the fuseholder.

REIVIOVE

4" OFOUTER

I

IHAI YOU

DO

NOT

CUT

INNERLEADS.

NSULATION. BE CARFFL-

IHE INSULATI ON OF IHE

LUG

I

BEND

.IGHTLY

CUTIHT LEADS

TOTHEINDICAIEDLENGTHS

AND

RTMOVEI/4" INSULATION

FROM

THEENDOF

TACHLFA

D.

FINT

WIRE

STRAND

S

3, TW

I

STTHE

FI

NEW

I

RESTRANDS

ATTHETND

OF

EACHLEAD

AND

MFLTA VERY

SMAL!.

AMOUNT

OFSOTDER

TOTHFSTRA

NDSTOHOLD THEM

TOGETHER.

Detail 1-3D

(4 Refer

to Detail1-3D

andprepare

the end of the

line cordasshown.

(..1 RefertoDetail1-3Eandinstallthestrainrelief

onthelinecordwheretheouter

insulationbe-

gins.Then install the strainrelief into hole CB

from the backof the rearpanel.

PLACT

THT

LINE SQUEEZE

THETWO INSERTTHE

REAR

CORD

IN THE

SLOT, SEGMENTS

TOGETHER. HALFINTO

THE

HOLE.

NOT

I TH

IS

TOBEND

Detail t-eC Detail L-3E

RefertoPictorial1-4

(IllustrationBooklet,

Page

4)for

the following steps.

( ,4 Mount the rear panel to the chassiswith two

6-32 x 1/4"black screws.

Do not install any

screws

in thetwo holes

nearthelargecutoutin

the rearpanel.

( I Referto insetdrawing #1.on Pictorial 1-4and

place

theslideswitchinsulatorover

thelugsof

switchSW1.

NOTE:Whenyou areinstructed

to prepare

stranded

wire asin the nextstep,cut the wire to the length

indicated and remove 714'of insulation from each

end.

Thentwistthe

finewire strandsat

theends

of

the

wireandmeltasmall

amountofsoldertothestrands

to hold the strands

together.

( ) Prepare

the following black strandedwires.

2_\14'

4"

NOTES:

1,. When you areinstructed to make a mechani-

callysecure

connection

as

inthe

nextstep,

form

a

hookin theendof

thewireand

insertthe

wire

throughthelug.Thencrimp the

hooksecurely

tothe

lug.

See

insetdrawing#2 on

Pictorialt-4.

2. Inthefollowingsteps,

(NS)

means

nottosolder

the connection

becauseother wires will be

added

later.

{S-),

with a number

suchas

(S-3),

meansto solderthe connections.The number

following the "S" tells how many wires areat

the connection.

( '/) Connect a 2-114x

black stranded wire from

switchSW1lug 5 (S-1)

to fuseholderF1lug 1

(S-1).

Makemechanically

secureconnections.

( t/) Connect

the

4"

blackstrandedwire from switch

SW1lug4(S-1)

toterminalstripARlug r (NS).

Makemechanically

secureconnections.

( ) Connectthe black lead from the line cord to

fuseholder

F1lug2(S-1).

Make

a

mechanically

secureconnection.

(, ') Connectthe green

leadfrom the line cord to

solder

lug AT (S-1).

Makea mechanically

se-

cureconnection.

(r,/) Connectthe white lead from the line cord to

terminal

stripAR,lug 5(NS).

Makeamechani-

callysecure

connection.

Connect

thepower

transformer

leads

toterminalstrip

ARin thefollowing steps.

Makemechanically

secure

connections.

(r ) Black-red

lead

tolug 1(NS).

( , ) Black-yellow

lead

to lug 2 (NS).

( rJ Black-green

lead

to lug a (NS).

(' ) Blacklead

tolug s (NS).

NOTE:Two sets

of line voltagewiring instructions

follow; one

for 120VAC line voltage,

andone

for 240

VAC

linevoltage.In

theU.S.A.,120VACis

mostoften

used,

while in othercountries24OVACis

morecom-

monly used.USEONLYTHEINSTRUCTIONS

THAT

AGREE

WITHTHE

LINEVOLTAGEINYOURAREA.

120VAC WIRING

Detail r-+A

Referto Detail1-4Afor thefollowing steps.

( "f Prepare

two 1,-314"blackstrandedwires.

(A Connect

a 1.-314"blackstrandedwire to termi-

nal strip AR betweenlugs 1 (S-3)

and 2 (S-2).

Make these

connections

mechanicallysecure.

( J' Connecta 7-314'black

strandedwire to termi-

nal stripAR betweenlugs4 (S-2)

and5 (S-3).

Make mechanicallysecureconnections.

( ,,)' Remove

the red cap from the fuseholderand

insert the 1-ampereslow-blow fuse.Then re-

placethe capinto the fuseholder.

24O

VAC WIRING

24oVA,CW|RING

Detail 1-48

Refer to Detail 1-48 for the following steps.

t ) Prepare a 2" black stranded wire.

f ) Connect

this2"blackstrandedwire toterminal

strip

ARbetweenlugs

2(S-2)

and

a(S-2).

Make

mechanically

secure

connections.

( ) Solder

lug 1 (S-2)

andlug 5 (S-2)

of terminal

strip AR.

( ) Removethe red cap from the fuseholderand

insert the 1/2-ampere slow-blow fuse (not

supplied). Then replace the cap into the

fuseholder.

PICTORIAL1.5

Refer

to Pictorial 1-5for the following steps.

( ) Setthechassisasidetemporarily.

NOTE;You may wish to placea soft cloth on your

work area

surfacefor theremainderofthekit assem-

bly. This will keep the side panels from getting

scratched.

( ' ) Locate

bothside

panels

andpositionthemona

softcloth.

( .l Referto the inset drawing and insert a self-

retaining nut into hole CB slotted end first.

Press

ortapthenut into theside

panel

until it is

flush with the surface.

t ) Turn a 6-32 x 3/8"hex head screwinto the

self-retainingnut to spreadthenut.Donotturn

the screwall the wav in. Then removethe

screw.

In thesamemanner,install self-retainingnutsin the

following holes.

CC

CD

CE

CF

CG

CH

cI ( )cN

cK ( )cP

CM

Table of contents