Heathkit Q MULTIPLIER User manual

Other Heathkit Receiver manuals

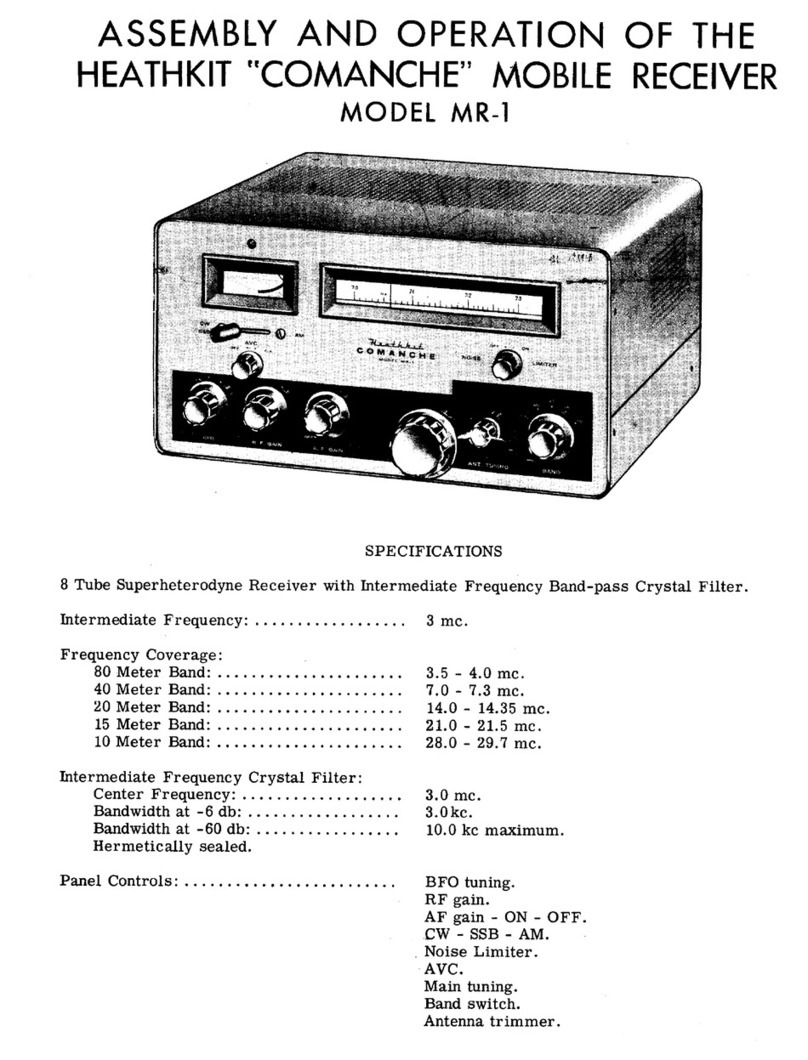

Heathkit

Heathkit RA-1 Guide

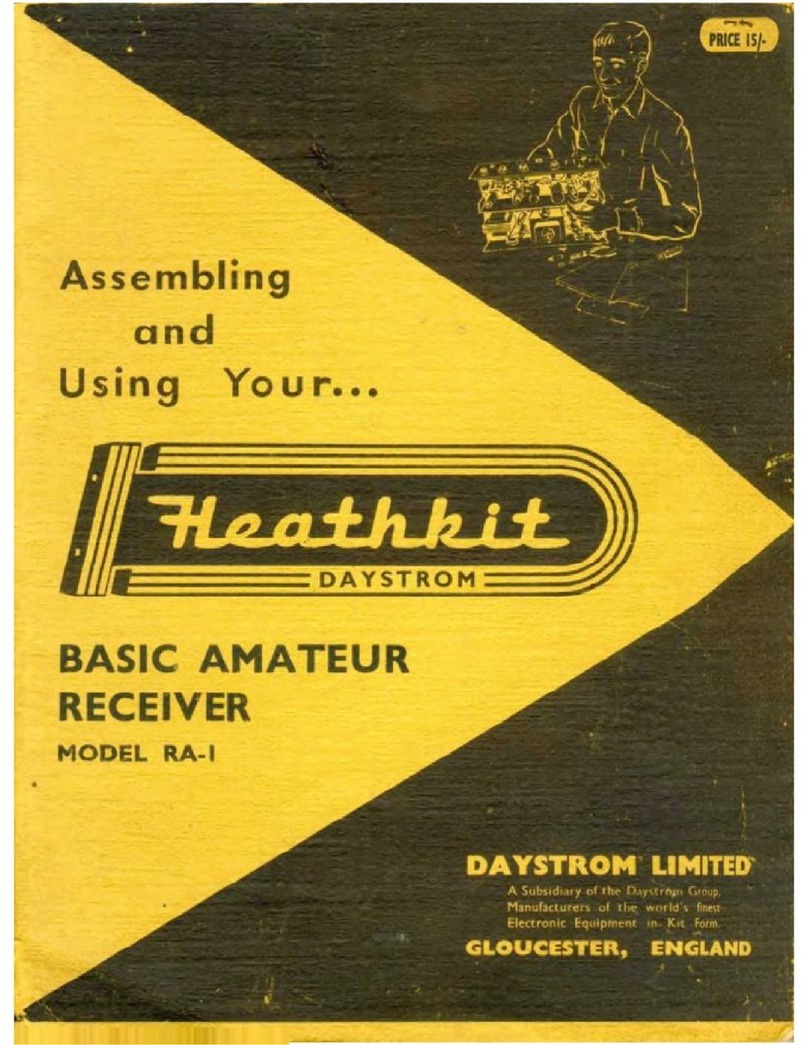

Heathkit

Heathkit Heathkit HD-3006 User manual

Heathkit

Heathkit SB-300 Installation instructions

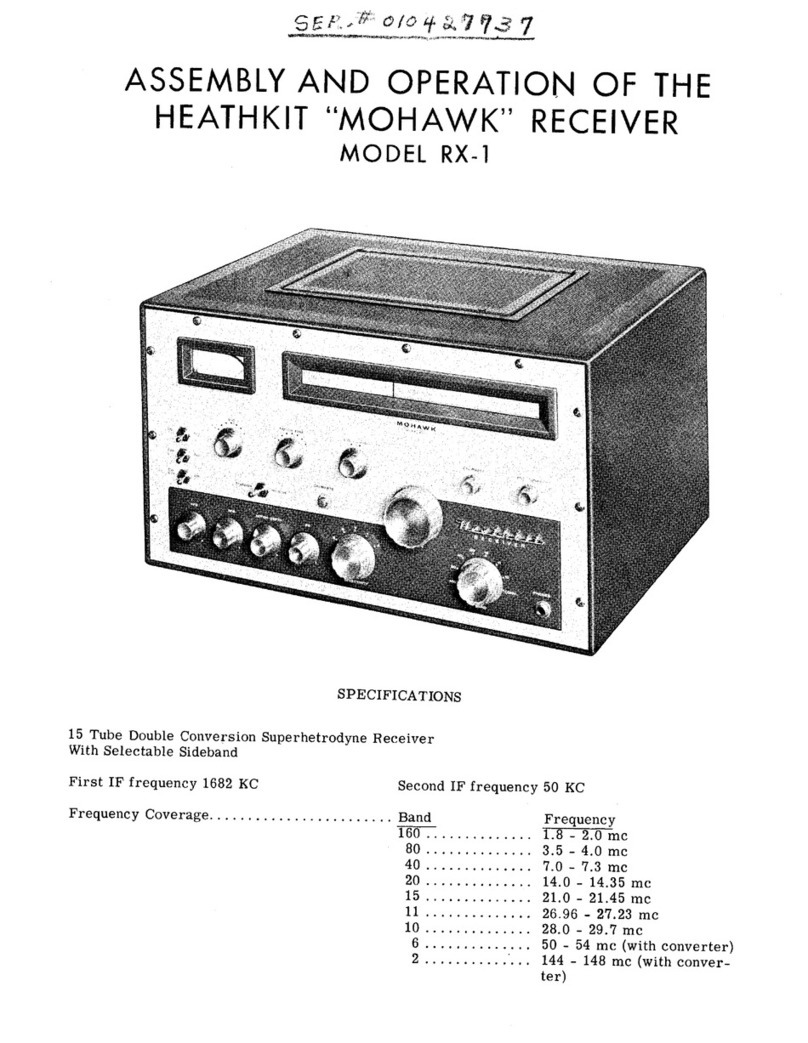

Heathkit

Heathkit Mohawk RX-1 Installation instructions

Heathkit

Heathkit Delux SWL GR-54 Installation instructions

Heathkit

Heathkit HD-3030 User manual

Heathkit

Heathkit SB-3000 Installation instructions

Heathkit

Heathkit GR-64 Installation instructions

Heathkit

Heathkit SW-717 User manual

Heathkit

Heathkit UXR-1 User manual