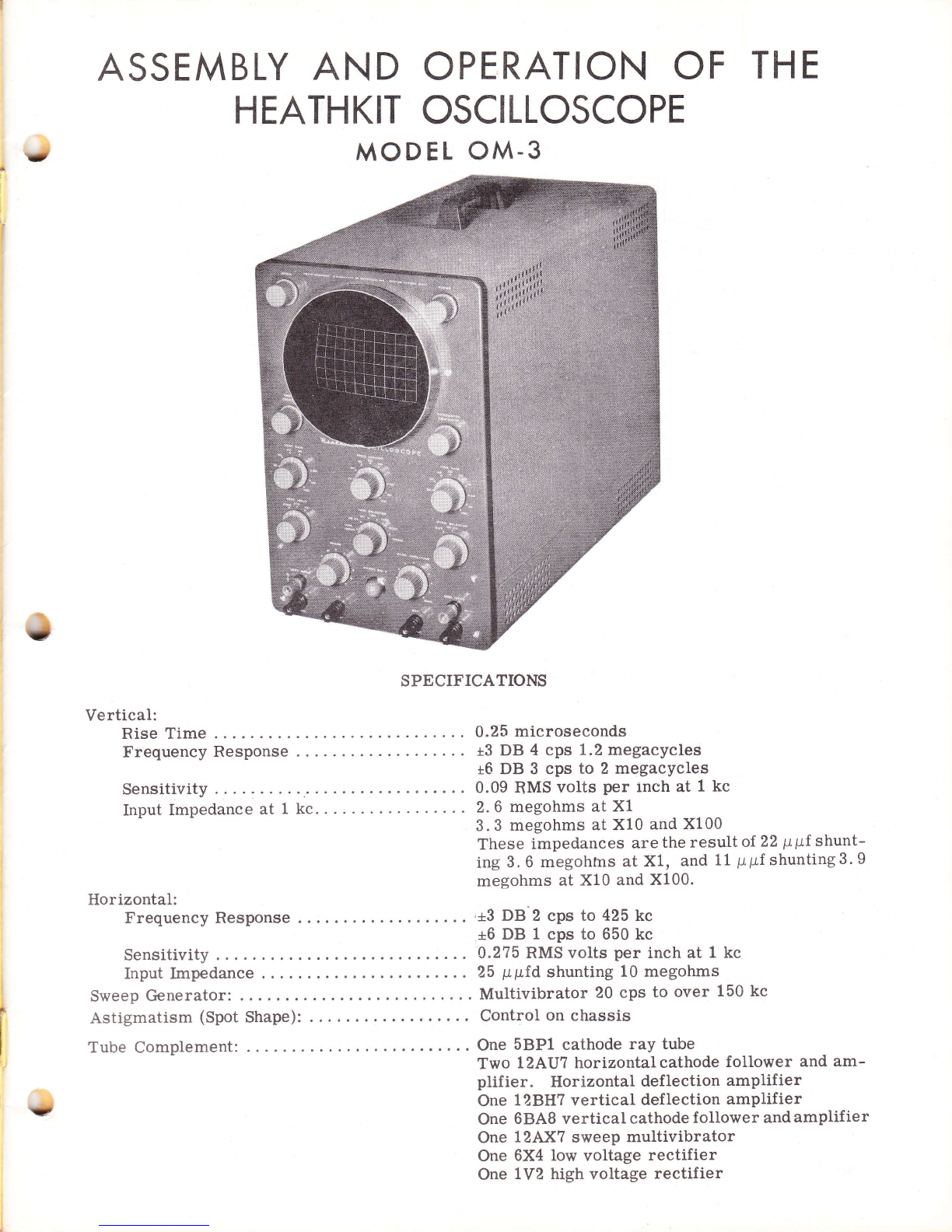

Power Requirements:.. ...105-125 volts AC, 5A/6C cycles, 65 watts

Dimensions:.... ... I 5/8" wide xr4lf9" high x lB" deep

Net Weight:. 18 lbs.

Shipping Weight:. ... 22 lbs.

INSTRUMENT DESCRIPTION

The Heathkit model OM-3 Oscilloscope is a relativelywide band, general purposeoscilloscope,

designed primarily for radio service, audio engineering, industrial electronics, production line

testing, amateur radio, and hobbyist, in fact, and application where a stable., sensitive oscil-

loscope is needed, but where the more expensive, broadband oscilloscope is not required.

Featuring a wide vertical response, down approximately 6 DB at 2 megacycles, and a modern

tube line-up, the model OM-3represents aconsiderable advantage in performance foran oscil-

Ioscope in this price range.

The cathode ray oscilloscope is, without a doubt, one of the most versatile electronic instru-

ments available today. It has earned this reputation because of its ability to display, in usable

form, the instantaneous relationshipsbetween anytwoelectrical quantities, no matterhow com-

plex, or between an electrical quantity and time. The oscilloscope can be used to evaluate dif -

ferentials in voltage, current flow, phase, frequency, waveform and time. With the unlimited

number of transducers available to the engineer today, it is a simple matter to convert any dy-

namic motion or static or dynamic physical quantity into an electrical signalwhich may then be

displayed upon the screen of the oscilloscope.

Probably the major use of most oscilloscopes is in the study of transient or recurrent electrical

phenomena" Since the oscilloscope is a voltage-operated device, these phenomena must first

be converted into voltage excursions.

In normal use, the signal to be observed is applied to the vertical input terminals of the oscil-

loscope. By means of attenuators and/or amplifiers this signal voltage is made to displace

vertically the electron beam in the cathode ray tube. Since, at the same time, the electron

beam is being displaced horizontallyand linearly with time bythe internal sweep generator, the

combined motion of the beam along both the X and Y axis traces out the instantaneous values of

the signal voltage with respect to time.

NOTES ON CMCUIT BOARD WIRING

hr line with the Heath Company's poticy of continualimprovementof its instruments, your Heath-

kit model OM-3.Oscilloscope utilizes circuit board, or "printed circuit" wiring. The Heath

Company was the first kit manufacturer to make use of this advanced technique i"n kit instru-

ments.

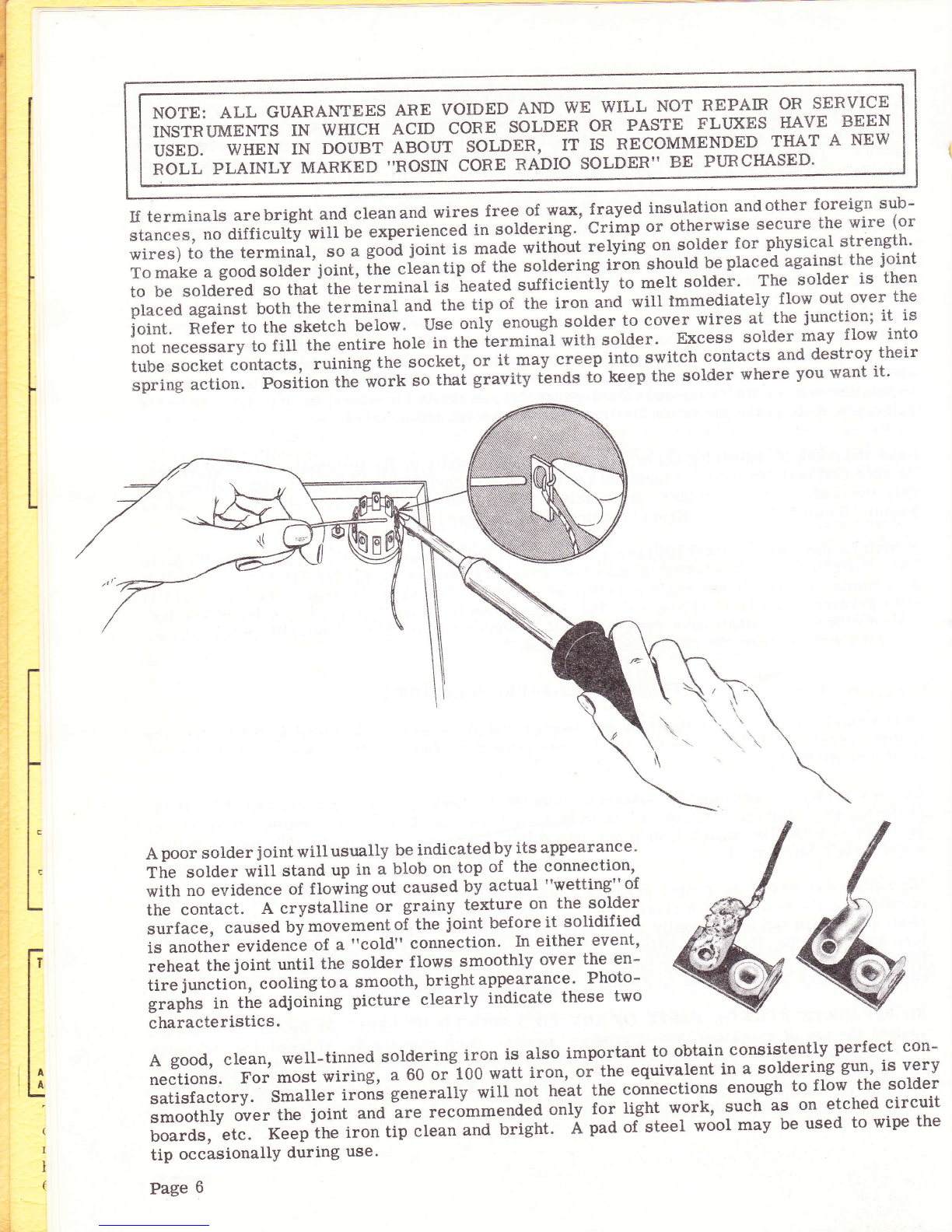

The process of etching, printing or silk screening a wiring pattern on a circuit board is not an

untried or experimental process. For years, one of the greatest hazards to quantity production

of electronic equipment has been the variable "stray" inductances and capacities caused by the

physicat plaeement of leads and components. Ir critical circuits, these variations become an

uncontrollable problem. During the first greatexpansion of televisionin the late 1940's, a tele-

vision tuner was developed using printed-circuit tuned circuits. It was so successful that the

technique was applied to millions of military electronic items where absolute uniformity, relia-

bility and low cost were paramount considerations. Today, the advantages of circuit board wir-

ing have made it an almost mandatory system for any commercial electronic mantrfacturer.

Since dip-soldering of manyconnections atone timereduceslabor cost, there is adecided econ-

omic advantage to the technique. In kit applications, dip-soldering is not practical of course.

But even more important is the absolute uniformity of each unit.

Page 3