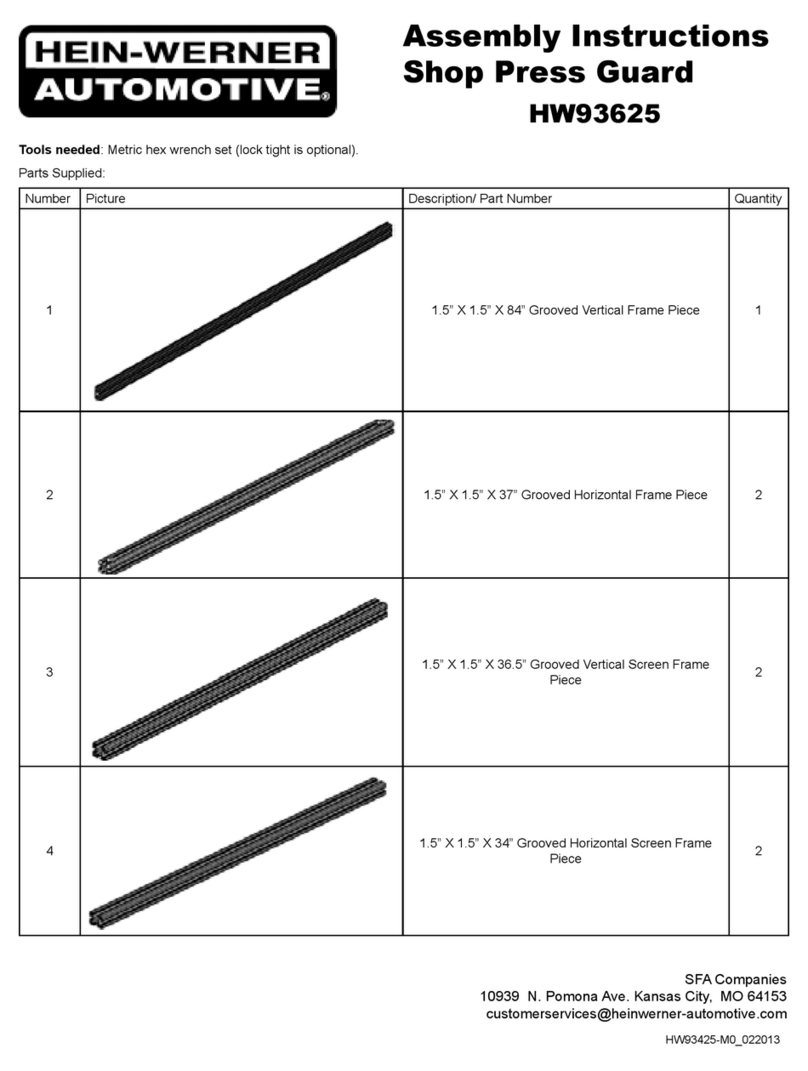

HEIN-WERNER AUTOMOTIVE HW93400 Instructions for use

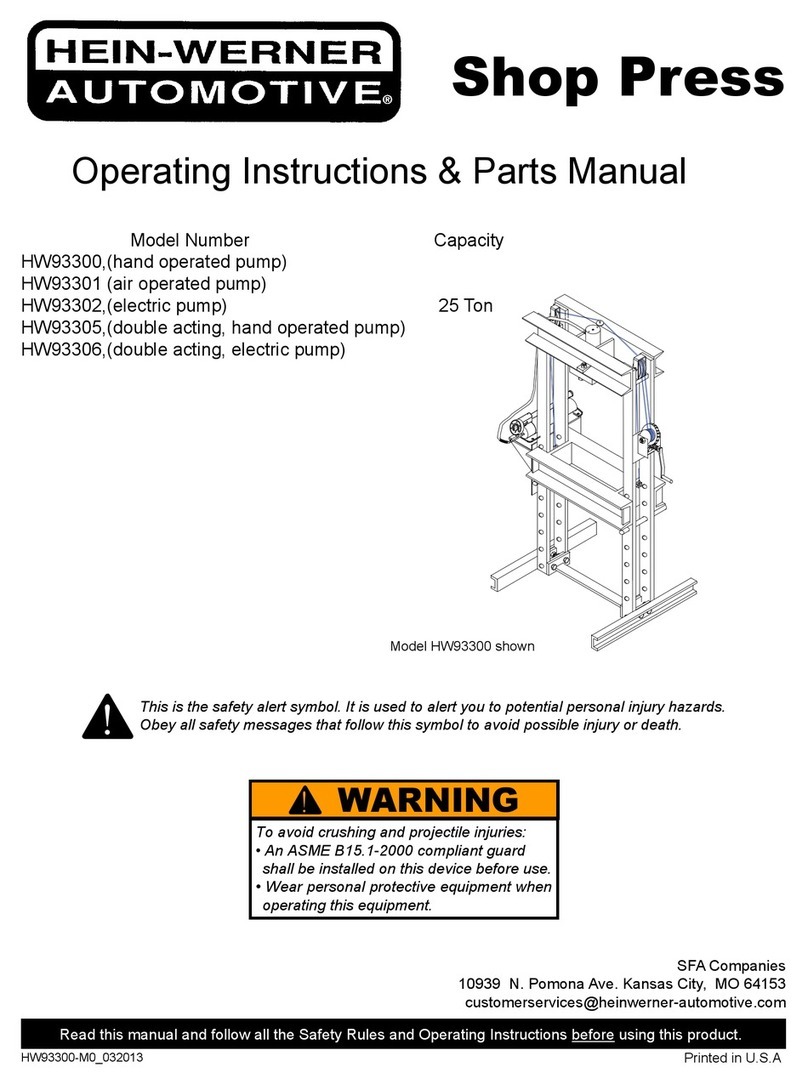

Operating Instructions & Parts Manual

Model Number Capacity

HW93400 thru HW93404 55 Ton

HW93610 100 Ton

Shop Presses

Model HW93610

Model HW93400, HW93401, HW93402 & HW93404

SFA Companies

10939 N. Pomona Ave. Kansas City, MO 64153

Read this manual and follow all the Safety Rules and Operating Instructions before using this product

HW93400-M0 rev 09/07

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

!

2

SAFETY and GENERAL INFORMATION

Save these instructions. For your safety, read, understand, and follow the information provided with and on this product

before using. The owner and/or operator of this equipment shall have an understanding of this equipment and safe operating

procedures before attempting to use. The owner and/or operator shall be aware that use and repair of this product may

require special skills and knowledge. Instructions and safety information shall be conveyed in the operator's native language

before use of this product is authorized. If any doubt exists as to the safe and proper use of this wheel dolly, remove from

service immediately.

Inspect before each use. Do not use if there are broken, bent, cracked or otherwise damaged parts (including labels). If

the press has been or suspected to have been subjected to a shock load (a load dropped suddenly and unexpectedly upon

it), discontinue use until checked out by an authorized factory service center. Owners and operators of this equipment shall

be aware that the use of this equipment may require special training and knowledge. It is recommended that an annual

inspection be done by qualified personnel and that any missing or damaged parts, decals, warning/safety labels or signs be

replaced with factory authorized replacement parts only. Press that appears to be damaged in any way, is worn or operated

abnormally shall be removed from service immediately. Labels and Manual are available from manufacturer.

PRODUCT DESCRIPTION

Hein-Werner Shop Presses are designed for automotive, truck, implement, fleet, and industrial repair shops where press-

ing, bending, straightening, forming, holding is required. Each press includes a cylinder, an electric pump with pendant

switch, a winch assembly which provides safe and fast way to raise and lower the bed frame, and a pressure gauge which

provides for monitoring the applied press force.

Typical applications include installation and removal of alternator and power steering pump bearings, axle bearings,

transmission bearings, seal, driveshaft bearings and u-joints and others. It is not intended for use as an assembly table or

as fixture stand used to secure a large, final assembly component. Refer to Cylinder and Pump manuals for more information.

!WARNING: To reduce the risk of personal injury and/or property damage, ensure that the rated working pressure of

each pressurized attachment be equal to or greater than the rated working pressure developed by the hydraulic pump.

TWO YEAR LIMITED WARRANTY

For a period of two (2) years from date of purchase, SFA Companies will repair or replace, at its option, without charge, any

of its products which fails due to a defect in material or workmanship under normal usage. This limited warranty is a

consumer's exclusive remedy.

Performance of any obligation under this warranty may be obtained by returning the warranted product, freight prepaid, to

SFA Companies Warranty Service Department, 10939 N. Pomona Ave., Kansas City, MO 64153.

Except where such limitations and exclusions are specifically prohibited by applicable law:

(1) THE CONSUMER'S SOLE AND EXCLUSIVE REMEDY SHALL BE THE REPAIR OR REPLACEMENT OF DEFECTIVE

PRODUCTS AS DESCRIBED ABOVE.

(2) SFA COMPANIES SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGE OR LOSS

WHATSOEVER.

(3) ANY IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, SHALL BE LIMITED TO TWO YEARS, OTHERWISE THE REPAIR,

REPLACEMENT OR REFUNDAS PROVIDED UNDER THIS EXPRESS LIMITED WARRANTY IS THE EXCLUSIVE REMEDY

OF THE CONSUMER, AND IS PROVIDED IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

(4) ANY MODIFICATION, ALTERATION, ABUSE, UNAUTHORIZED SERVICE OR ORNAMENTAL DESIGN VOIDS THIS

WARRANTY AND IS NOT COVERED BY THIS WARRANTY.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

3

SPECIFICATIONS

Manual Pump (Hand pump):

Air Pump:

Electric Pump:

Cylinder:

1st Stage 2nd Stage 1st Stage 2nd Stage

PE0501T 1 293 18 0.5 8 58

PE1002T 2 397 37 1 15 63

Model

Usable

Oil

Capacity

Pressure Rating Oil output Flow Rate Weight

(lb.)

580 10,000

Manual,

4-way,

3-position

115

Valve Type

Motor

Size

(hp)

Current

Draw

(A)

Motor

Voltage

(V)

Model Load

Capacity

Cylinder

Stroke

Cylinder

Model

Pump

Model

Pump

Type

Bed

Width

Press Size

(H x W x L)

Min.

Working

space

Max.

Working

Space

HW93400 P2001 Manual

HW93401 PA2000 Air

HW93402 PE0501T Electric

HW93403 PA3801 Air

HW93404 PE0501T Electric

HW93610 100 Ton 10" H10010 PE1002T Electric 16" 89 1/2" x 63" x 30" 11 1/4" 51"

55 Ton

6 " H5506

13 3/4" 79 1/8" x 56" x 30" 14" 55 1/2"

13" H5513

Model Capacity

.

.

(ton)

Stroke

.

.

(in)

Cylinder

Effective

Area

(in2)

Oil

Capacity

.

(in3)

Collapsed

Height

.

(in)

Extended

Height

.

(in)

Outside

Dia

.

(in)

Ram

Plunger

Dia.

(in)

Saddle

Dia.

.

(in)

Collar

Thread

Collar

Thread

Length

(in)

H5506 6.22 68.34 11.14 17.36

H5513 13.27 145.77 18.15 31.42

H10006 100 10.24 20.57 210.6 17.68 27.93 3.97 4.13 6 7/8"-12 1.73

5"-12 2.1755 10.99 5 3.15

2.76

1st Stage 2nd Stage 1st Stage 2nd Stage

P2001 122 200 10,000 0.81 0.14 3/8"-18NPTF 21

Model

.

.

Usable Oil

Capacity

(in3)

Pressure Rating

(psi)

Oil Displacement

(in3)

Oil Outlet Port

.

.

Weight

.

(lb.)

.

No Load Load

PA1500 91.5 65 11 18

PA2000 122.1 65 12 20

PA3801 232 65 11 27

Input Air

Pressure Range

(psi)

Weight

(lb.)

10,000 90-175

Model

.

Usable Oil

Capacity

(in3)

Pressure

Rating

(psi)

Oil output Flow Rate

(in3/min)

Figure 1: Model HW93400 thru HW93404 Components Figure 2: Model HW93610 Components

Cylinder

Winch

Pressure

Gauge

Electric Pump

Control Valve Knob

Support

Pin

Base

Bed Frame

Lower Cross

Member

Arbor Plates

(not included)

Upright

Channel

Upper Cross Member

Cylinder

Winch

Upright

Channel

Support

Pin

Base

Upper Cross Member

Electric Pump for

Model HW93402 &

HW93404

Pressure Gauge

Control Valve Knob

of Electric Pump

Bed Frame

Arbor Plates

(not included)

Lower Cross

Member

Hand/ Manual Pump

for Model HW93400

Air Pump for

Model HW93401

Air Pump for

Model HW93403

4

1. Inspect before each use. Do not use if bent, broken or cracked components are noted. Check for and tighten any loose

assemblies.

2. Verify that the product and the application are compatible, if in doubt call Hein-Werner Technical Service (816) 891-6390.

3. Before using this product, read the operator's manual completely and familiarize yourself thoroughly with the product, its

components and recognize the potential hazards associated with its use.

• Study, understand, and follow all instructions provided with and on this device before use.

• Do not exceed rated capacity.

• Burst hazard exists if hose or connection pressure exceeds rated pressure.

• Use the device only on a hard, level surface.

• Always monitor the pressure gauge while operating.

• Always inspect hoses and connections for damage prior to use.

• Always wear safety goggles when working on or near this equipment.

• Keep hands, feet and all other body parts away from loading area.

• Never leave loaded press unattended.

• Projectile hazard! Ensure workpiece is center loaded, and a safety shield is installed around workpiece to protect against

projectiles.

• Do not modify this device beyond installing a shield to protect against projectiles.

• Ensure the user is familiar with the controls and operational characteristics of this product and aware of the potential

hazards associated with its use.

• Failure to heed these markings may result in personal injury and/or property damage.

!WARNING

BEFORE USE

OPERATION

Refer to BVA owner's manuals for the cylinder and pump operation

Projectile Hazard! Ensure that workpiece is centerloaded and secure. Reduce risk of flying debris by carefully

following all operating instruction. Know your press and hazards associated with its use. Keep hands and feet from

bed area at all times.

Risk of serious eye injury from projected or blown debris. Reduce risk by wearing safety goggles when working with

or around press.

1. Insert the support pins to desired height, then lower the bed frame using the winch until the cable is slack and the bed

frame is resting fully on the support pins.

2. Place arbor plates on the bed frame. (optional)

3. Inset workpiece into bed frame, using every precaution necessary to ensure your safety and prevent property damage.

4. Operate the pump:

a) For HW93400 manual pump:

Close the release valve by turning clockwise, and pump the handle to extend the cylinder ram. To retract, simply

open the release valve of pump.

b) For HW93401 & HW93403 air pump:

Connect to suitable air supply, press on the foot pedal to extend the cylinder ram. To retract, simply press the

release valve by stepping on the raised, stirrup shaped portion of the foot pedal.

c) For HW93402, HW93404 & HW93610 electric pump:

Turn the ON/OFF switch to start the electric pump and let the pump idle for a few minutes before put into operation.

Use control valve knob to extend or retract the cylinder ram.

Note: Never operate pump with hose disconnected from cylinder. If operated in this condition, the hydraulic hose and

connections become pressurized. This increases burst hazard.

5. Apply load to workpiece. Do not overload the workpiece.

6. Stabilize workpiece in a manner which will not allow it to inadvertently fall from the bed once the load is removed.

7. Once cylinder has fully retracted, remove workpiece.

Note: To protect your cylinder, do not continue to operate pump after cylinder plunger is fully extended or retracted.

MAINTENANCE

Please refer to cylinder and pump's manuals for maintenance and how to add/change hydraulic oil. For best results,

change the oil once a year. Use only good quality hydraulic oil. We recommend Mobil HW93291 for manual and air pumps,

BVA hydraulic oil or equivalent for electric pump.

Lubrication

A periodic coating of light lubricating oil to pivot points and hinges will prevent rust and assure assemblies move freely.

Storage

Depressurize the hydraulic system, disconnect the hydraulic hose and lower the bed frame to lowest position.

5

ASSEMBLY

1. Ensure bed frame at lowest position and winch cable is slack.

2. Install the winch assembly to the press using 3 bolts, washers and nuts.

3. Secure cylinder to the cylinder adapter plate, and mount the adapter plate to upper cross member using 4 bolts and

washers.

Note: The cylinder comes with carrying handles, simply loosen the allen head socket screw to remove the handles.

4. Attach base sections to upright channels with 4 bolts and nuts.

5. Attach lower cross member to upright channels with 4 bolts and nuts.

6. For Model HW93400 thru HW93404 only, adjust the pump bracket to desire height and secure with bolts, nuts & washers

provided.

7. Connect the pressure gauge and the hydraulic hose to the gauge adapter, then connect the gauge adapter to pump.

Important: Ensure thread tape or compound is use on connections.

8. Place the pump on the pump bracket and connect the other end of hydraulic hose to cylinder.

!Before disassemble, slide bed frame section down, into its lowest position.

!

This manual suits for next models

5

Table of contents

Other HEIN-WERNER AUTOMOTIVE Power Tools manuals