Heinrichs KDSE User manual

Heinrichs Messtechnik GmbH

EX-Supplementary Operating Manual KDSE

January 2021

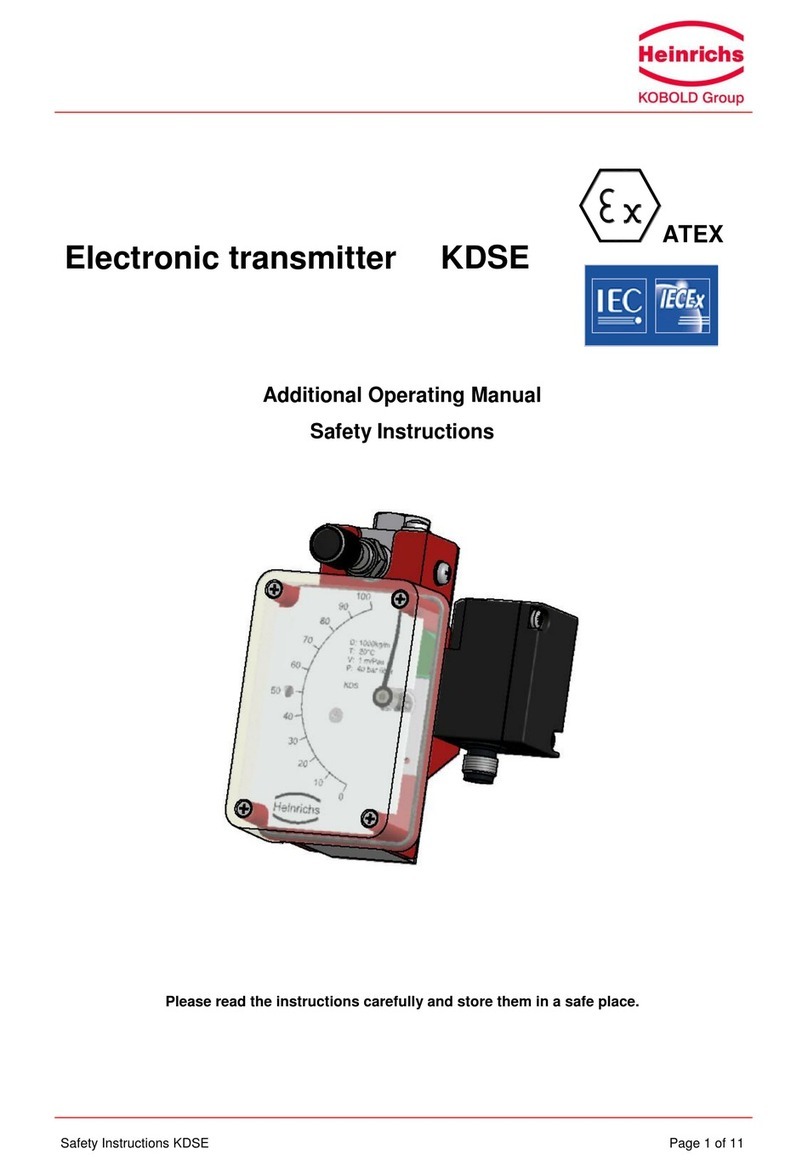

Electronic transmitter

KDSE

EX-Supplementary Operating Manual for Hazardous areas

Safety Instructions

This operating manual is a supplement to the manuals for the

Flow-meters KDS und BGK.

Please read the instructions carefully and store them in a safe place.

Heinrichs Messtechnik GmbH

Page 2 of 14

Ex-Supplement operating manual KDSE

CONTENTS

Introduction.......................................................................................................................................................3

I. Shipping and storage; product inspection......................................................................................................................3

II. Warranty...................................................................................................................................................................................3

III. Validity of this operating manual ......................................................................................................................................3

IV. Returning the device for repairs or servicing.................................................................................................................3

1. Steps prior to operation ...................................................................................................................4

1.1 Installation, mounting, commissioning and maintenance ........................................................................................4

1.2 Hazard warnings....................................................................................................................................................................5

1.3 Proper use of the device......................................................................................................................................................5

2. Identification .......................................................................................................................................6

3. General information about explosion protection ......................................................................7

4. Applications .........................................................................................................................................8

5. Operational mode and system design .........................................................................................8

6. Electrical connection .........................................................................................................................9

6.1 Electrical and thermal parameters ...................................................................................................................................9

7. Special conditions for safe use.................................................................................................... 10

7.1 Environmental influences on the electronics ............................................................................................................. 10

7.2 Atmospheric conditions .................................................................................................................................................... 10

7.3 Ground connection ............................................................................................................................................................. 10

7.4 Electrostatic charge of non-conductive parts............................................................................................................ 10

7.5 Mechanical strength .......................................................................................................................................................... 10

8. Marking.............................................................................................................................................. 11

9. Declaration of Conformity ............................................................................................................ 12

Heinrichs Messtechnik GmbH

Ex- Supplement operating manual KDSE

Page 3 of 14

Introduction

I. Shipping and storage; product inspection

The device is to be safeguarded against moisture, dirt, impact and damage.

Product inspection

Upon receipt of the product, the consignment should be checked for completeness. The data of the device have

to be compared with the packing slip and the order documents

Notify us of any shipping damage immediately upon receipt of the product. Any damage claim received at a later

time will not be honored.

II. Warranty

Your flow meter was manufactured in accordance with the highest quality standards and was thoroughly tested

prior to shipment. However, in the event any problem arises with your device, we will be happy to resolve the

problem for you as quickly as possible under the terms of the warranty which can be found in the terms and

conditions of delivery. Your warranty will only be honored if the device was installed and operated in accordance

with the instructions for your device. Any mounting, commissioning and/or maintenance work is to be carried

out by qualified and authorized technicians only.

III. Validity of this operating manual

The present instructions apply to explosion-proof transmitter type KDSE as of year of construc-

tion February 2021

These instructions are supplementary operating manual for non-explosion proof meters. If you

do not have a copy of the latter instructions, please request one from Heinrichs Messtechnik

GmbH or download the instructions from our website.

The instructions herein pertain primarily to explosion proof magnetic-inductive flow meters. The technical data

in the mounting and operating instructions for non-explosion proof magnetic-inductive flow meters still apply

insofar as the present instructions do not replace them or exclude their application.

IV. Returning the device for repairs or servicing

Note: According to German waste disposal legislation, it is the owner’s or customer’s responsibility to dispose

of hazardous waste. Thus, before any devices are returned to Heinrichs Messtechnik for servicing or repairs the

following measures must be performed:

When returning the unit for an inspection, please enclose as detailed a description as possible of the fault

and the specific application, as well as the chemical-physical properties of the measurement medium.

Remove all residue of measurement medium which may be present. paying special attention to the gasket

grooves and crevices. This is especially important if the medium is detrimental to health and safety, for

example: corrosive, poisonous, carcinogenic or radioactive etc.

Costs, which result from insufficient cleaning, (disposal and/or personal injuries) will be invoiced to the cus-

tomer.

Heinrichs Messtechnik GmbH

Page 4 of 14

Ex-Supplement operating manual KDSE

1. Steps prior to operation

Prior to installation and operation, it is essential that the operator familiarizes himself

with all of the instructions and information contained in the manual for non-explosion

proof as well as the present instructions. If any part of either manual is missing, contact

Heinrichs Messtechnik GmbH to request a new manual. These manuals can also be

downloaded from our website.

1.1 Installation, mounting, commissioning and maintenance

Installation, mounting, commissioning and maintenance are to be performed by a technician trained to work

with explosion-proof devices, or by a Heinrichs Messtechnik service technician.

Warning

Any maintenance or repair which is safety relevant in terms of explosion-protection is to be

carried out by the manufacturer, an authorized Heinrichs Messtechnik GmbH service center

or under the supervision of an expert in explosion proof devices.

Heinrichs Messtechnik GmbH accepts no liability for any loss or damage of any kind arising from improper

operation of any product, improper handling or use of any replacement part, or from external electrical or

mechanical effects, overvoltage or lightning. Any such improper operation, use or handling shall automatical-

ly invalidate the warranty for the product concerned.

In the event of a problem please contact the service center of Heinrichs Messtechnik:

Contact our customer service department if your device needs repair or if you need assistance in diagnosing a

problem with your device.

Heinrichs Messtechnik GmbH

Ex- Supplement operating manual KDSE

Page 5 of 14

1.2 Hazard warnings

The purpose of the hazard warnings listed below is to ensure that device operators and maintenance personnel

are not injured and that the flow meter and any devices connected to it are not damaged.

The safety advisories and hazard warnings in the present document that aim to avoid placing operators and

maintenance personnel at risk and to avoid material damage are prioritized using the terms listed below, which

are defined as follows in regard to the instructions herein and the advisories pertaining to the device itself.

Warning

means that failure to take the prescribed precautions could result in injury, substantial material

damage or even death. Always comply to these warnings and proceed with caution.

Caution

means that failure to take the prescribed precaution could result in material damage or de-

struction of the device. We advice always to abide to these instructions!

Note

means that the accompanying text contains important information about the product, handling

the product or about a section of the documentation that is of particular importance.

1.3 Proper use of the device

Warning:

The operator is responsible for ensuring that the material used in the sensor and transmit-

ter housing is suitable and that such material meets the requirements for the fluid being

used and the ambient site conditions. The manufacturer accepts no responsibility in regard

to such material and housing.

Caution:

In order for the device to perform correctly and safely, it must be shipped, stored, set up,

mounted operated and maintained properly.

Heinrichs Messtechnik GmbH

Page 6 of 14

Ex-Supplement operating manual KDSE

2. Identification

Manufacturer:

Heinrichs Messtechnik GmbH

Robert-Perthel-Strasse 9

D-50739 Cologne

Germany

Product type:

Electronic transmitter for small area flow meters

Product name:

KDSE

File name:

kdse-ex_ba_21.01_en.doc

Version:.

21.01,

Date, January 27th,2021

Heinrichs Messtechnik GmbH

Ex- Supplement operating manual KDSE

Page 7 of 14

3. General information about explosion protection

In accordance with directive 2014/34/EU (ATEX)

acc. EN / IEC 60079-0 ff

Example designation

0158

II

2G

Ex

d e [ia]

IIC

T6

Gb

Equipment groups

I

Equipment group I applies to equipment intended for use in under-

ground parts of mines as well as those parts of surface installations of

such mines endangered by firedamp and/or combustible dust.

II

Equipment group II applies to equipment intended for use in other

places liable to be endangered by explosive atmospheres. This group

is subdivided into three categories.

Equipment category

Designation

for gases

Designation

for dust

Definition

1G

(0)

1D

(20)

Equipment in this category is intended for use in areas in which

explosive atmospheres caused by mixtures of air and gases,

vapours or mists or by air/dust mixtures are present continu-

ously, for long periods or frequently.

2G

(1)

2D

(21)

Equipment in this category is intended for use in areas in which

explosive atmospheres caused by gases, vapours, mists or

air/dust mixtures are likely to occur.

3G

(2)

3D

(22)

Equipment in this category is intended for use in areas in which

explosive atmospheres caused by gases, vapours, mists, or

air/dust mixtures are unlikely to occur or, if they do occur, are

likely to do so only infrequently and for a short period only.

(The numbers in round brackets correspond to the IEC Zones.)

Ex = Explosion-proof electrical equipment

Electrical Types of protection examples

General requirements

IEC 60079-0

„d“

Flameproof enclosure

IEC 60079-1

„e“

Increased safety

IEC 60079-7

„i“

Intrinsic safety (ia, ib)

IEC 60079-11

„n“

Non-incentive electrical equipment

IEC 60079-15

„m“

Encapsulation

IEC 60079-18

Non-electrical types of protection

“h”

Basic Method and requirements

DIN EN ISO 80079-36

Explosion group

Examples: Gases and vapours

Minimum ignition power

[µJ]

IIA

Acetone, benzene, fuel oil, ethanoic acid

180

IIB

City gas, ethylene, isoprene

60

IIC

Acetylene, hydrogen, carbon bisulphide

20

Temperature classes

Maximum surface temperature

Temperature class

450 °C

842 °F

T1

300 °C

572 °F

T2

200 °C

392 °F

T3

135 °C

275 °F

T4

100 °C

212 °F

T5

85 °C

185 °F

T6

Equipment Protection Level (EPL)

Gas

Dust

“Very high” level of protection

Ga

Da

“High” level of protection

Gb

Db

“Enhanced” level of protection

Gc

Dc

Explosion protection designations [square brackets] refer to “Related electrical equipment or circuits.”

Heinrichs Messtechnik GmbH

Page 8 of 14

Ex-Supplement operating manual KDSE

4. Applications

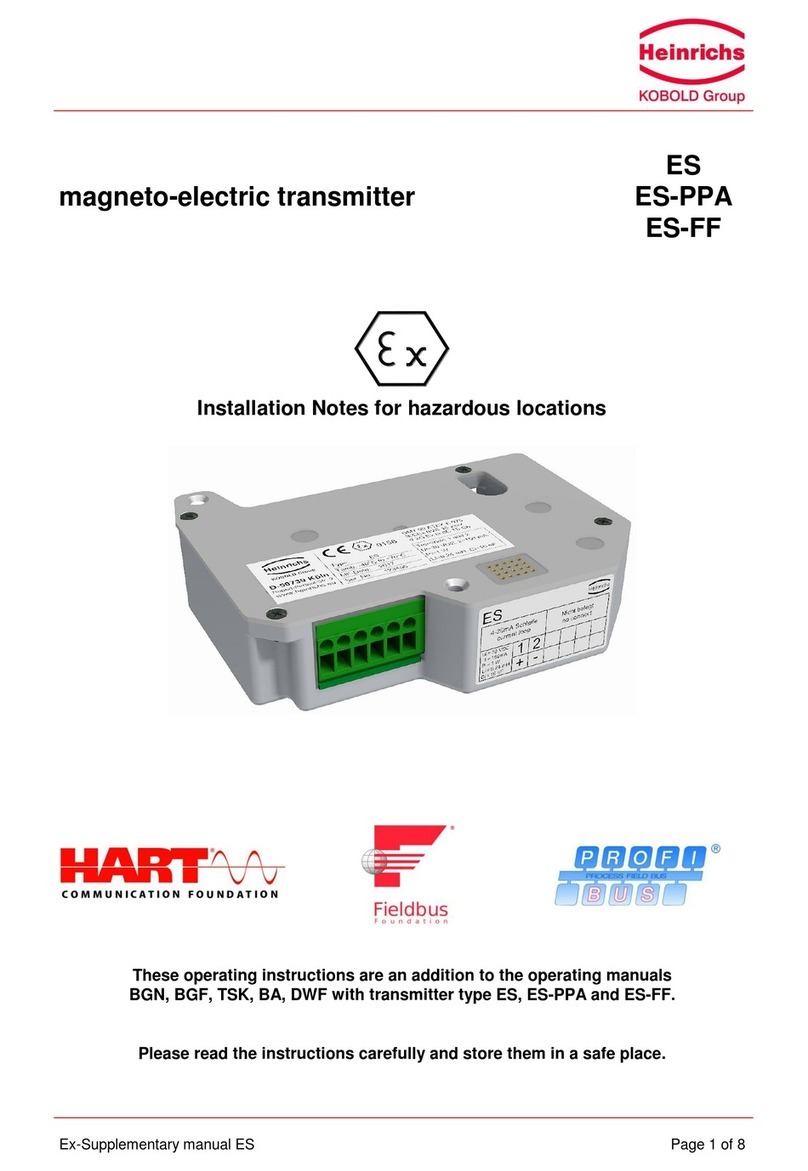

The electronic module type KDSE is a transmitter with integrated magneto electric measuring element for

measurement of floater’s actual position or and transmission of actual pointer position into an electrical signal.

The electronic module must be assembled in an enclosure possessing a minimum degree of protection of IP20

(EPL Gb) resp. IP54 (EPL Db). This enclosure and the connector should by sufficient for the applied (EPL).

5. Operational mode and system design

The electronic transmitter type "KDSE" is used to convert the pointer position of the mechanical measuring

system into a proportional 4-20mA signal.

The electronic module type KDSE is a "magneto-electrical angle sensor" used for recording the position or the

angular position of a magnet in the variable area flow meters series KDS and BGK. Either the position of the

float, in which there is a permanent magnet, or the angular position of a ring magnet, which is located on a

magnet tracking system, is detected directly. With the latter, the angular position of the axis with the follower

magnet serves as a measurement interface between the mechanical part and the electronics

The microprocessor controlled KDSE transmitter is used in flowmeters series KDS and BGK. The position of the

float is transmitted to the pointer axle by means of a magnetic system. The KDSE measures the field of a mag-

net mounted on the pointers axle and generates an output current of 4 to 20 mA from it.

The scale is generally non-linear and is linearized in the process with a minimum of 16 interpolation points. This

points and the measuring range is defined by manufacturer while calibrating the complete instrument.

The earth’ magnetic field and moderate homogeneous external magnetic fields are largely compensated.

Heinrichs Messtechnik GmbH

Ex- Supplement operating manual KDSE

Page 9 of 14

6. Electrical connection

The electrical connection of the intrinsically safe 2-wire 4-20mA power supply and signal circuit is via an M12

connector to pins 1 (+) and 3 (-).

This requires that the maximum electrical values (Ui, Ii, Pi, Li and Ci) are observed as described below.

6.1 Electrical and thermal parameters

Voltage Ui DC 30 V

Current Ii 150 mA

Effective internal inductance Li 0,24 mH

Effective internal capacitance Ci 15 nF

Power Pi in acc. with the following table:

Max. surface temperature for use in EPL Db 135 °C

When used in potentially explosive dust atmospheres, the device must be cleaned regularly in order to avoid

deposits exceeding 5 mm.

Use in

EPL Gb

EPL Db

Ambient temperature range

-40 °C up to +70 °C

-40 °C up to +40 °C

-40 °C up to +70 °C

Power Pi

1 W

750 mW

650 mW

Heinrichs Messtechnik GmbH

Page 10 of 14

Ex-Supplement operating manual KDSE

7. Special conditions for safe use

7.1 Environmental influences on the electronics

Environmental influences on the built-in transmitter type KDSE how the process temperature must be taken

into account. See Chapter 14 of the general operating instructions for the meter type or KDS BGK.

7.2 Atmospheric conditions

In accordance with EN 1127, a “potentially explosive atmosphere“ is defined as a mixture of air and combustible

gases, vapour, mist or dust under atmospheric conditions. Such conditions are defined in EN 13463-1, para. 1,

with values Tatm = -20 °C to +60 °C and Patm = 0.8 to 1.1 bar. Outside this range, safety parameters for most

ignition sources are not available.

Usually, variable-area flow meters operate under operating conditions outside the atmospheric conditions of

0.8 to 1.1 bar. Irrespective of the zone classification –safety parameters of explosion protection –are basically

not applicable to the inside of the measuring tube.

Therefore operation with combustible products is only allowed if a potentially explosive air mixture is not

formed inside the flow meter. Where this condition is not met, the operator will need to assess the ignition haz-

ard in each individual case and give due consideration to existing parameters (e.g. pressure, temperature, pro-

cess product, materials of construction for the measuring tube).

7.3 Ground connection

In variable-area flow meters, it is possible under operating conditions for charge separation to occur in the

measuring tube due to the transport of non-conductive fluids and/or when the flow comes into contact with

non-conductive internals (e.g. liners, floats). For this reason, variable-area flow meters must be permanently

grounded by the operator by way of the process connections (flanges) in order to discharge electrostatic build-

up. The operator is also responsible for extending the ground continuity of the process pipeline.

If grounding cannot be made via the process connections (plastic process connections or undefined connec-

tions), the flow meter must be connected to the local ground potential via the flanges. This connection only

ensures electrostatic grounding of the device and does not meet the requirements for equipotential bonding.

7.4 Electrostatic charge of non-conductive parts

In hazardous areas of protection class IIC pay attention to the risk of the electrostatic charge in a danger threat-

ening amount during cleaning work on the synthetic material housing and plastics. For cleaning purposes, use

only a damp cloth.

Devices where explosive electrostatic charges can be expected are marked with an adhesive label:

WARNUNG- / WARNING-

Gefahr elektrostatischer

Aufladung! Nicht reiben!

Danger of electrostatic charge!

Do not rub!

7.5 Mechanical strength

The flow meters have undergone an impact test to DNI EN ISO 80079-36 for a low level of mechanical hazard.

Additional protective measures are required if higher mechanical hazard levels are expected.

Heinrichs Messtechnik GmbH

Ex- Supplement operating manual KDSE

Page 11 of 14

8. Marking

Warning:

Only devices with ex marking may be operated within the explosive atmospheres range.

The electronic module is marked as follows:

When the module is assembled in a variable area flow meter is additional a mark on the scale of the device.

Heinrichs Messtechnik GmbH

Page 12 of 14

Ex-Supplement operating manual KDSE

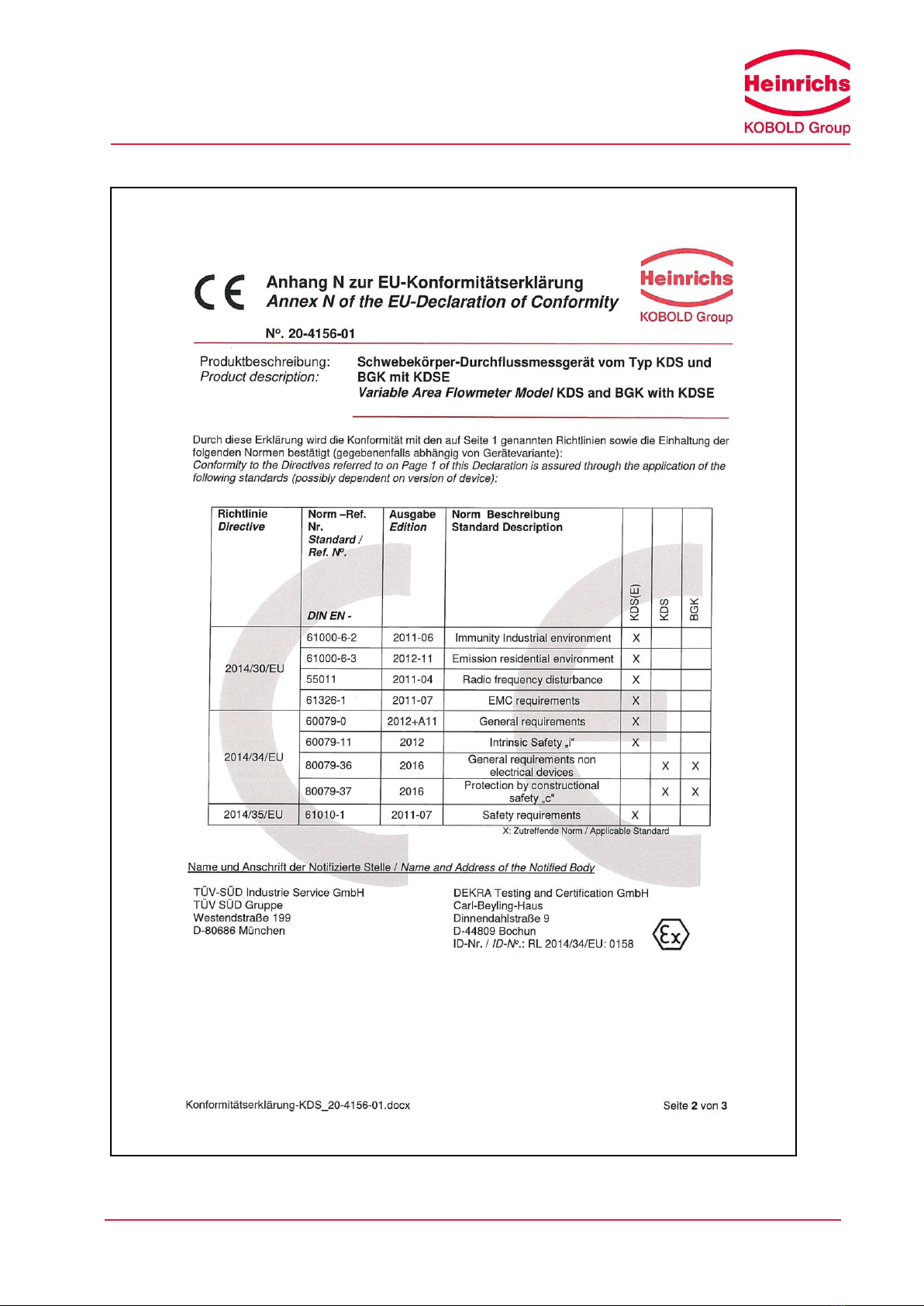

9. Declaration of Conformity

Heinrichs Messtechnik GmbH

Ex- Supplement operating manual KDSE

Page 13 of 14

Heinrichs Messtechnik GmbH

Page 14 of 14

Ex-Supplement operating manual KDSE

Other manuals for KDSE

1

Table of contents

Other Heinrichs Transmitter manuals

Popular Transmitter manuals by other brands

Elta

Elta ADT 406 AP User handbook

Fracarro

Fracarro HOME FIBRE OPT-TX 1510 operating instructions

Thies CLIMA

Thies CLIMA 5.4041 1.00 Series Instructions for use

FlowLine

FlowLine EchoTouch US01 Series quick start

Rexing

Rexing FMT2 user manual

Gill Electronics

Gill Electronics Teslink WPT503CM Installation information