10 EHW-Series | Version 1.02

Commissioning

Press the Turtle button (item 18, fig.7) to switch

to slow speed mode. Drive slowly by moving

the gas button (item 14, fig.7), press the turtle

button again to return to normal mode.

Press and hold the Turtle button for 2 seconds

to activate the drive function with tiller in vertical

position when working in confined spaces. The

drive function is only active when the turtle but-

ton is pressed (speed is reduced); releasing the

turtle button stops immediately. Activating the

gas button in less than two seconds after the

turtle button is pressed will not activate the

drive function, but will repeat the operation cy-

cle from the beginning. The gas pedal button

should remain in the neutral position for two se-

conds.

The electric lift truck is controlled by moving the

tiller to the left or right

Step 8: Press the lowering button (item 17, Fig. 7) care-

fully. Lower the load until the forks are free of

the pallet and then carefully drive the lift truck

out.

7.2.2Brake function

The brake function can be activated in various ways:

1. The regenerative braking is activated by pushing the

gas button (item 14, Fig. 7) to the initial position "0" or

by releasing the button. The lift truck brakes to a

standstill.

2. By moving the accelerator pedal (pos. 14, Fig. 7) from

one direction of travel directly in the opposite direction,

the vehicle brakes until it moves in the opposite direc-

tion.

3. The electric lift truck brakes when the tiller is moved

up or down in the braking zones ("B"). When the tiller

is released, the tiller automatically moves into the up-

per baking zone ("B") and the electric lift truck brakes

to the stop.

4. The safety button (pos. 1, fig. 5) prevents the operator

from being squeezed. When this button is activated,

the vehicle decelerates and/or begins to travel in re-

verse ('Bw.') for a short distance and stops. Please

note that this button also works when the vehicle is not

moving and the tiller is in the working area.

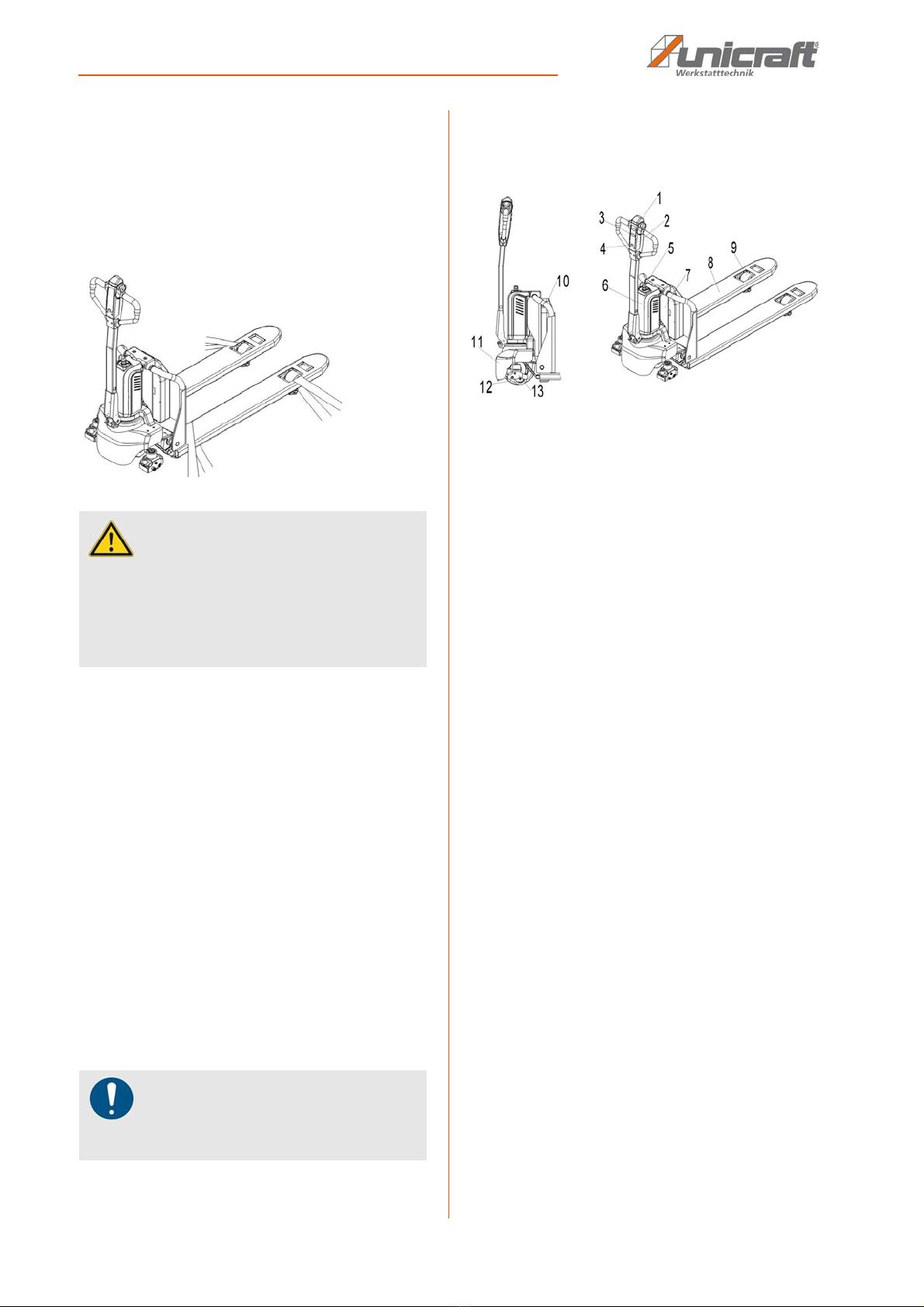

7.3 Pin-Code-Display

The electric pallet truck EHW 15 is

equipped with a pin code control panel

(3). It can only be operated if the cor-

rect password is entered.

The electric lift truck EHW 20 is equip-

ped with a pin code control panel (3)

and ID cards. It can only be operated if

the correct password is entered or a valid ID card is

used.

The pin code control panel is an electronic system simi-

lar to an electronic alarm system. The lift truck can only

be operated after a correct password has been entered.

The main function is to prevent unauthorized operation.

Main functions

The Pin Code Control has two passwords, one is the de-

fault user password 1234, which you can use immedi-

ately.

The other is the administrator password 3232, which

allows you to set a new user password according to the

steps below:

Step 1: Enter "3232", click on "√".

Step 2: Enter the previous user password, click on "√".

Step 3: Enter a new password and click on "√", the pre-

vious password will be replaced.

If you want to reset the password, please proceed as de-

scribed below:

Step 1: Enter "123", click on "√".

Step 2: Enter "123" again, click on "√". The password is

now "1234".

If you need to add more ID cards (EHW 20 only), please

proceed as follows

Step 1: Enter "3434", click on "√".

Step 2: Insert the new ID card for about 5 seconds.

DANGER!

The electric pallet truck is equipped with an electro-

magnetic, fail-safe holding and parking brake.

Always lower the forks completely. Press the emer-

gency stop switch (pos. 5, fig. 5).

Do not park the lift truck on inclined surfaces.

NOTE!

- Please determine the braking distance of the

electric lift truck before starting up.

- The braking power depends on the track conditions

and the load conditions of the lift truck.

NOTE!

The pin code control panel supports a maximum of

five cards.