Heat recovery unit KWLC 350

1

It is important for safety reasons, that you read and observe these instruc-

tions fully before proceeding.

RECEIPT

The consignment contains one of the following units including a three speed con-

troller and a summer-heat exchanger:

KWLC 350 __ __ __

S vertical installation

L horizontal installation

EH electric heater battery

WW water heater battery

Please check delivery immediately on receipt for accuracy or damage, please no-

tifiy carrier immediately of any damage. In case of delayed notification, any possi-

ble claim may be void.

STORAGE

When storing for a prolonged time the following steps are to be taken to avoid da-

maging influences: protection by dry air and dustproof packing (plastic bags with

drying agent and moisture indicators). The storage area must be free of water, vi-

bration and temperature variations.

When storing for years or non rotation of motor an inspection of the bearings with

possible replacement and an installation inspection in accordance with VDE 0530

are necessary before starting using the unit. Damage caused by incorrect storage,

transportation or installation are not valid warranty claims.

OPERATIO / USE

The unit is designed to ventilate a combination of living rooms, bathrooms and kit-

chens in a single dwelling. The unit is equipped with a heat recovery cube. It must

not be connected to kitchen hoods or laboratory extract systems. The standard

equipment has a working temperature range from -20°C up to 40°C. The ambient

temperature where the unit is installed must not be below 0°C. For operation un-

der unusual conditions, e.g. high humidity, long periods of standstill, high air pollu-

tion, extreem climatic conditions (e.g. operating temperature over 40°C), technical

or electronic inputs other than standard operation may affect the units performan-

ce. For this reason please enquire and obtain a quotation for a suitable unit, if avai-

lable.

U IT OPERATIO

In the heat exchanger the cold outside air and the warm extracted air “cross over”

and the temperature of the incoming air is raised. Through this method up to 80%

of the energy of the warm air is tranfered to the incoming air (Pic. 3). In addition a

thermostatically controlled heating element warms up the inlet air, in extreme cold

weather conditions, to the required temperature. Frost coditions are detected by a

Thermo-Humidity sensor which is positioned in the heat exchanger. The after heater

warms up the inlet air and the pre heating element is used as an additional heater to

avoid frost in the heat exchanger. The inlet air is directed to the living rooms and be-

drooms through ducts and dampers. The stale air is extracted from the bathrooms,

toilets and kitchens and flows back to the heat exchanger via the ducting system

and fan, transfering heat before being discharge into the open air.

PERFORMA CE DATA

To achieve the given performance, the unit must be correctly installed. The duct

system must be designed to be within the units pressure capablities and have

good flow into and out of the unit otherwise there will be a reduction in the units

performance. Noise figures are stated as sound power levels LWAin dB(A) (confor-

ming to DIN 45635 Pt.1). Sound pressure levels LPA depend on room specific con-

ditions.

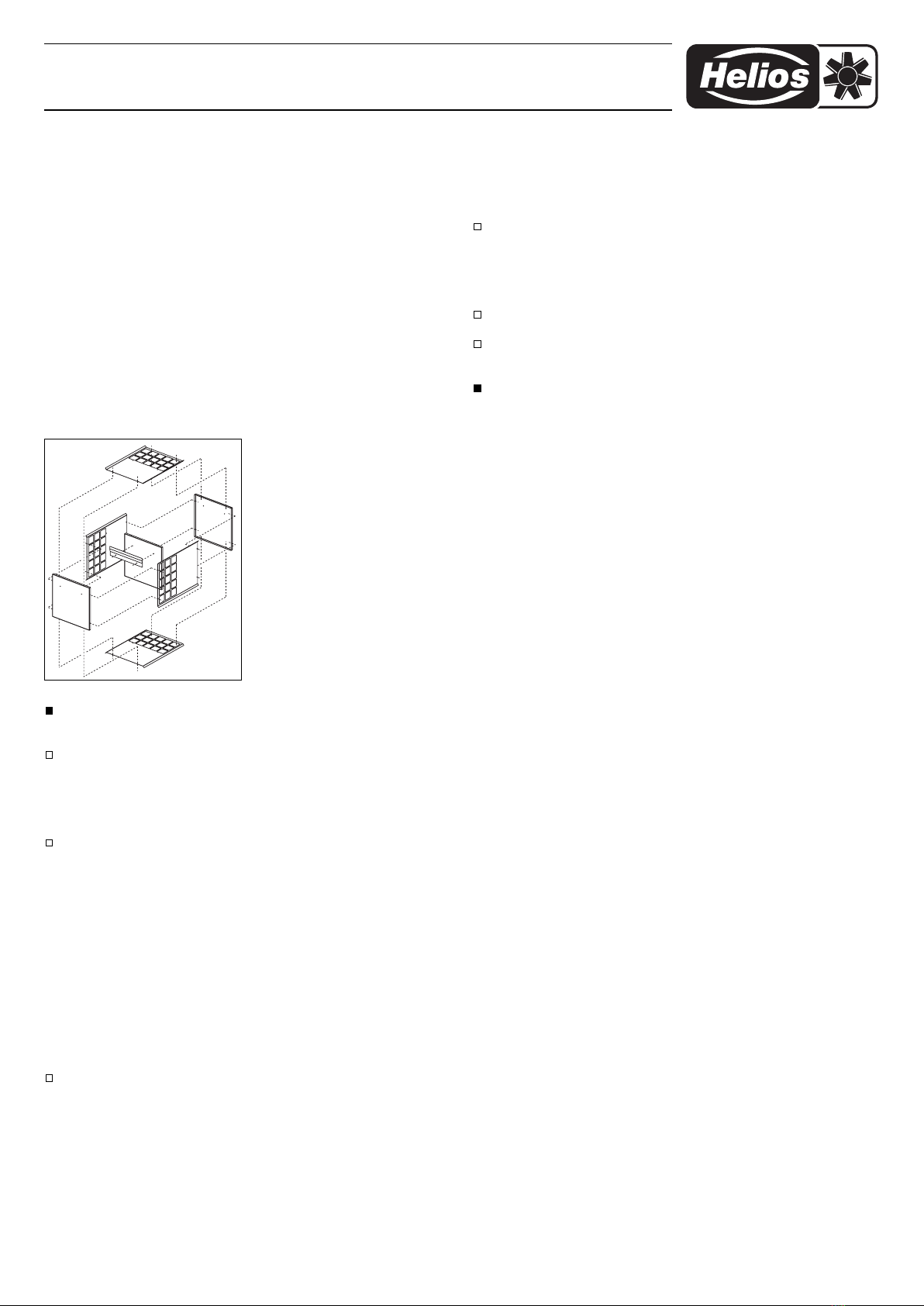

I STALLATIO -ASSEMBLY (picture. 3, page 4)

The KWLC 350 S is suitable for "vertical" installation wherever desired usually in the

loft space. As a base to mount the unit on we recommend chipboard on a secure

mineral wool board (approx. 60 x 120 cm) to prevent vibration transmission or use a

commercial anti vibration pad (approx. 60 x 120 cm). The mounting surface must

be level, flat and even. The KWLC 350 L is suitable for "horizontal" installation. For

effective condensate removal from the unit, the unit should slope down in the

direction of the drain pipe by 5° the init has differing height feet to acheive

this . The ducting should be as short as possible and tight bends should be avoided

as they can lead to a high pressure loss and airflow noise. The ductwork joints

should be fully sealed to prevent air loss. The supply and extract ducting should be

insulated to gain the best thermal efficiency. For maintenance and installation work,

instal the unit in an accessible position. When installed in areas with low ambient

temperature (e.g. roof space) the unit may require additional insulation.

The summer-heat exchanger and operating switch are supplied inside the

unit, these must be removed before installation. It is essential that the instal-

led unit tray has a drop in the direction of the condensate water flow.

General recommendation

The use of oil or gas burning devices e.g. boilers, gas heaters gas hobs and ovens

require a free flow of air. Used in combination with a heat recovery unit all national

regulations must be followed. A separate air inlet may have to be provided for.

– CO DE SATIO RU -OFF (picture 4/5)

The condensation pipe (4) is to be connected to the water run off by means of a

flexible pipe of 15mm diameter. If it is not in a room which is heated, it must be is-

sulated. A suitable drain trap is to be provided with a minimum height of 100 mm,

otherwise water could be drawn back through the fan.

Fill the drain trap with water before putting into operation to avoid smells

from the drain system. The regulations of the water board and other legislati-

on must be observed.

OTE: When connecting the condensation pipe by (cold) pressing avoid

any axial or radial forces on the unit drain pipe. The use of a flexible pipe is

recommended.

– AIR DUCTI G, VE TILATIO CIRCUIT (picture 4.)

When designing the ductwork, try to achieve the shortest possible runs. Use

smooth pipes (rigid plastic or steel ducting), to avoid high pressure loss, noise

etc. For the main ducting (outside air, extract air, inlet air, discharge collection) a

diameter 160 mm or 140 mm is recommened, for side pipes a diameter 80 mm to

125 mm. To reduce condensation in the extract pipes, the ducting has to be insu-

lated where appropriate. Also if inlet and extract ductwork cross unheated rooms

insulation must be provided to reduce heat loss.

Fresh air should be taken into living- and bedrooms, extraction from bathrooms,

toilets and kitchens. To regulate the whole system use adjustable Helios valves.

The extract from the kitchen needs to be filtered. A kitchen hood must not be

connected up to the unit (danger of grease carried into the heat exchanger). There

must be a good air flow (e.g. using door grilles) within the building between intake

rooms and extract rooms.

Important: all fire protection regulations - where applicable- must be follo-

wed.

– Thermo-humidity sensor (picture 5)

The electronic thermo humidity sensor (3) is in the heat exchanger in order to de-

tect the humidity level of the fresh and extract air. This allows a more precise de-

tection of the risk of frost in the heat exchanger.

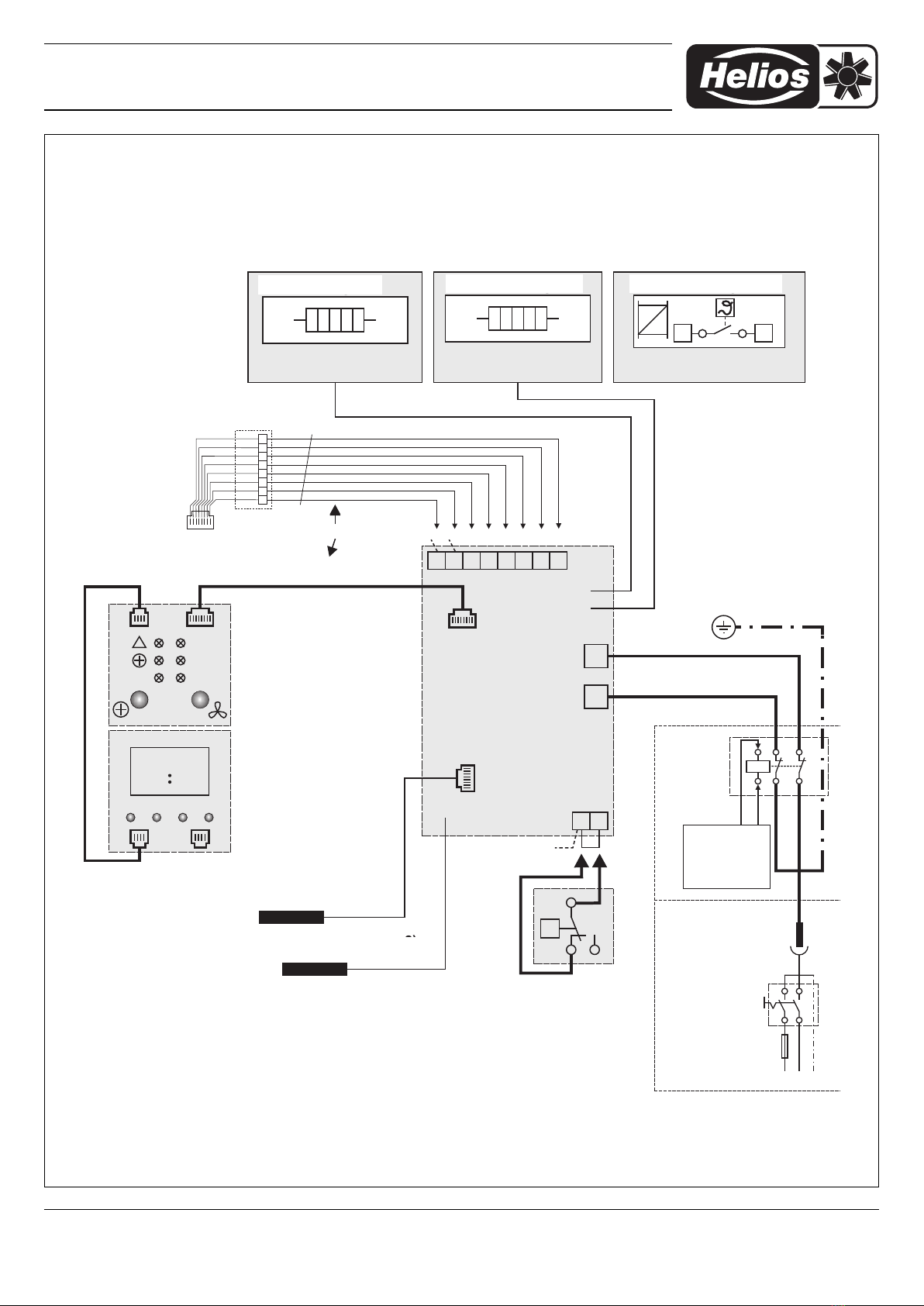

– ELECTRICAL CO ECTIO S (pic. 5/6)

Electrical connection may only be carried out by a qualified person. All electrical

work must only be carried out with the power supply off. A lockable isolator is re-

quired isolate from the mains with a minimum of 3 mm contact opening of each

pole.

All relevant safety and installation regulations (for example DI VDE 0100

and IEE regulations) are to be adhered.

Electrical connections are to be made according to wiring diagrams provided in

these instructions. The connection to the control panel are of plug in type using

the cables provided. The unit is designed for continous running and cannot be

switched off as a standard. To switch off please use mount a switch in the supply.