Helm TMG-1200 User manual

Helm Instrument Company, Inc.

361 West Dussel Drive

Maumee, Ohio 43537 USA

419/ 893-4356

Fax: 419/ 893-1371

www.helminstrument.com

Non Contact Fault Detector

For Cold Heading Machines

Force Measurement and Control Solutions

Page 1

TMG-1200 Instruction Manual

Table of Contents

Introduction................................................................................................2

Basic Operation

Description of Component Parts..................................................................3

Normal Operation.........................................................................................6

Changing Preset Range...............................................................................7

Operation of Counter ...................................................................................8

Specifications...............................................................................................9

Applied Operation

Mean Value and Absolute Value..................................................................10

Details of Detection......................................................................................13

Slowdown Detection ....................................................................................13

External Timing............................................................................................13

Details of System Setting.............................................................................14

Maintenance

Connection of Terminal Block......................................................................16,17

Sensor Installation .......................................................................................18

Sensor Adjustment.......................................................................................19

Troubleshooting Guide.................................................................................20

We would like to thank you for purchasing the TMG-1200 non-contact monitor. This guide

consists of four parts: Introduction, Basic Operation, Applied Operation and Maintenance. Prior

to operation, please read the TMG-1200 guide thoroughly.

Introduction

The TMG-1200 detects the “Front Dead Center” (FDC) positions of the cold former using a

proximity sensor and sends a fault signal to the output when the difference between FDC

positions at each stroke exceeds the preset range. The TMG-1200 will send a fault signal to the

output when the revolutions (rpm) of the cold header or cold former fall below the preset range

when slowdown detection is set to On.

Fault detection of FDC position is performed in two modes - Adaptive (mean value) comparison

and Trend (absolute value) comparison. For each of these modes, it is possible to preset the

operating range. Slowdown detection can be set in units of 1% in the range of –5% to –49%.

Header

Former Sensor Signal Header

Former Monitoring by both Absolute

value and Mean value

Slowdown monitoring

Fault Detection Signal

(Stop Signal)

This device meets the requirements for the single, double and multi modes according to the types

of cold header and cold former.

The single mode is for single stroke, single die machines.

The double mode is for single stroke, double die machines.

The multi mode is a multi-slide or progressive header (Two sensors are necessary only in the

case of using the multi mode.) The TMG-1200 can be setup for operation in any of these modes.

Refer to the contents of Section “System Setting”.

One Stroke

One Die

One Stroke Two

Two Die One Stroke

Two Die

Multi-Slide or

Progressive

Header

The device is factory set in the double mode. The set point setting and system setting are preset

at the factory. System can start at installation.

Page 2

TMG-1200 Instruction Manual

Description of Component Parts

TMG Monitor

RIKEN OPTECH CORPORATION

ON/OFF

INSTRUMENT CO., INC.

MAUMEE, OHIOU.S.A.

B.C RESET

SAMPLING

ADAPTIVE/TREND

P.C SELECT

P.C SELECT

SETUP

SETUPDIAL

CONTRAST

RESET

ADAPTIVE/TREND

ON/OFF

ADAPTIVE

+ 0 0

+ 0 0

BATCH C

321

PRESET COUNTER

87654321

R.P.M

1000 PARTS COUNTER

87654321

ADAPTIVEADAPTIVE

TIMING

SAMPLING

14

19

15

16

17 20

5

987

6

11

11

12

13 10

4

12

14

18

3

1. Deviation display (unit: µm)- Displays the deviation detected by the proximity sensor. It is

factory set for adaptive (mean value ) display.

2. Set point display - Displays the monitoring range between the upper and lower limits. When

the display shows a deviation exceeding the limit values, the TMG-1200 displays a fault

condition.

3. Bar display – Displays the deviation from the set point. The left side of the bar display is the

“-“ (negative) side of the set point and the right side the “+” (positive) side. The center square

is the “0” position, and the two sides are divided each into five equal parts. For example,

when the set point is 10, the display is as shown below:

-10 -8 -6 -4 -2 0 +2 +4 +6 +8 +10

Bar Display Scale (Unit: µm)

When the set point is less than 5, the display will show 5.

The bar display during set point setting serves as a clearance gauge to indicate the FDC

position (refer to section “Sensor Adjustment”).

Page 3

TMG-1200 Instruction Manual

Page 4

TMG-1200 Instruction Manual

4. RPM Display

Displays the rpm's of the cold header and cold former in real time.

5. Batch counter

A 3-digit counter which counts the number of times that the preset counter has counted up.

6. Parts counter

An 8-digit preset counter which does not perform counting while detection is off.

7. Preset counter set point

Shows the set point of the preset counter.

8. Trend value sampling display

Indicates that sampling of Trend data, for absolute value detection, is not complete or

sampling is being performed.

9. External timing indicator

Indicates when the external timing is on.

10. Comment column

Shows the current fault or operational state.

11. ON/OFF button

The button to turn on or off fault detection by deviation. When fault detection is off, “OFF” is

shown on the set point display.

12. Batch counter reset button

Push this button to reset the batch counter to “0”.

13. Sampling button

Press Sampling button to start sampling Trend data for reference data during operation.

During sampling, “Sampling” appears on the screen.

14. Adaptive/Trend button

The button to select whether to cause the deviation display to show the absolute value or

mean value. Which of them is selected is indicated by “Adaptive” or “Trend” on the lower

side of #2 – Set point display. The button is factory set for mean value display.

15. Preset counter reset button

Push this button to reset the preset counter to “0”.

16. Preset counter select button

Push this button to set the point of the preset counter (refer to section “Operation of

Counter”).

17. Setup button

Push this button to change the set point (refer to section “Changing Preset Range).

18. Setup dial

Used to change the set point or to change settings in the system mode.

19. Contrast control

Used to adjust the contrast of the Liquid Crystal Display (LCD) screen. The contrast control

is factory adjusted. Readjust it when the screen is difficult to see.

Page 5

TMG-1200 Instruction Manual

20. Reset button

When a fault is detected, the red lamp goes on to notify of a fault condition. Pushing this

button cancels the fault condition and causes the red lamp to go off. In normal operation,

pushing this button causes the red lamp to flash and turns off fault detection. Pushing it

again stops flashing of the red lamp and cancels the bypass state.

Page 6

TMG-1200 Instruction Manual

Normal Operation

Normal operation does not require any special procedure. However, some procedures need to

be performed when detection is by-passed for setup or for turning on/off wire feed during

continuous operation. The procedures are described below.

1. At setup for material supply, etc., press the Reset button to cause the TMG-1200 to go to the

by-pass state. Push the reset button again cancels the bypass state.

2. When the machine is operated in the continuous mode, the TMG-1200 automatically starts

detection after 10 strokes. During the initial 10 strokes after the start of the machine, fault

detection is automatically by-passed to prevent erroneous detection due to the initial

instability of the machine. (The number of times that detection is turned off can be changed

by system setting.)

3. When the deviation exceeds the set point during continuous operation, the TMG-1200 issues

a machine stop fault condition and red lamp of the reset button goes on indicating that the

machine has stopped.

4. Pushing the reset button turns off the red lamp and cancels the fault detection condition. The

numerical display of abnormal value etc., is maintained as it is.

5. To change the set point, refer to the next section “Changing Preset Range”.

Changing Preset Range

The set point can be changed when necessary by pushing the setup button, regardless of

whether the machine is in the stop state or in continuous mode. The black and white colors on

the set point display are inverted, so turn the setup dial to change the display to an arbitrary

value.

In this case, “Adaptive” or “Trend” appears on the lower side of the set point display, indicating

the respective set points.

Set the set point display to the display type to which you wish to change it, and then turn the

setup dial.

To change from mean value (adaptive) display to Trend (absolute value) display or vice versa,

push the “Absolute/Trend” button on the right side of the respective displays.

Page 7

TMG-1200 Instruction Manual

ADAPTIVE/TREND

SETUP DIAL

ADAPTIVE/TREND

ADAPTIVE

10

10

ADAPTIVEADAPTIVE

G Monitor

CH1 Set point Display

CH2 Set point Display

CH2 Trend/Adaptive Button

CH1 Absolute Value/Mean Value Display

CH2 Absolute Value/Mean Value Display

CH1 Trend/Adaptive Button

Trend/Adaptive Setup Dial

Set table range: Absolute Value: 0 to 500 µm (in units of 10 µm.)

Mean Value: 0 to 99 µm (in units of 1 µm.)

•Setting the absolute value to "0" turns off absolute value detection.

Page 8

TMG-1200 Instruction Manual

Operation of Counter

This device incorporates an 8-digit counter which uses the sensor signal to count one per stroke.

The operating procedure is described below.

1. Setting of preset value

a) Push the counter setup button to set the device in the preset setup mode. (Black-white

inversion occurs at the highest order digit of the preset set point.)

b) With each push of the setup button, the digit with black-white inversion shifts to the lower

order, so set digits to which you wish to set the set point.

c) Turn the setup dial to set to an arbitrary value. Set digits one by one.

d) After setting all digits, don’t fail to push the counter setup button and bring to the position

of the digit with no black-white inversion (the position at which setting is turned off). 8th

digit→7th digit→6th digit→5th digit→4th digit→3rd digit→2nd digit→1st digit→setting Off→8th

digit ….. The digit position shifts with each push of the setup button. Setting the preset

set point to “0” turns off setting, so the preset counter operates as the total counter.

2. Resetting of preset counter

To reset the preset counter to “0”, push the preset counter reset button. In this case, the fault

output cannot be cancelled even when the fault detection signal is being output.

3. Batch counter

The batch counter is a 3-digit total counter to count the number of times that the preset

counter has counted up.

4. Resetting of batch counter

When you wish to reset the batch counter to “0”, push the batch counter reset button. In this

case, the fault output cannot be cancelled even when the fault detection signal is being

output.

Page 9

TMG-1200 Instruction Manual

Specifications

•Power supply and output section

Power supply 100-240 VAC, 50 or 60 Hz

Power consumption Less than 15W

Output contact 1A-1B (fault signal output, counter signal output)

Output contact capacity less Less than 250 VAC, less than 5A

CosØ=1

•Detection section

Number of channels 2 channels (channel 2 in case of using multi mode)

Detection range 1mm to 3mm

Repeating accuracy 1 µm

Preset range Mean value ±99 µm, Absolute value ±500 µm

Sensor type Sanksu GS-14M

•Display section

Display LCD with back light (128 x 48 pixels)

Operating temperature range 0 to 50°C

Retention temperature range -20 to 60°C

Humidity 10-0-% RH max. (wet bulb temperature shall be less

than 29°C for prevention of dew condensation).

Temperature compensation circuit incorporated

Contrast control Externally attached

•Others

Backup EPROM is used; backup time more than 10 years

Backup contents All contents

Maximum speed 1,200 rpm

Operating temperature range –10 to 50°C

Retention temperature range –20 to 75°C

Humidity 10-85% RH max. (Wet bulb temperature shall be less

than 29°C for prevention of dew condensation.)

•Accessories

Sensor 2 (Sanksu GS-14M)

User’s guide 1

Mean Value and Absolute Value

This device is capable of performing absolute value detection and mean value detection. These

detection modes are performed at the same time. For each of these modes, it is possible to set

the set point individually. Details of each detection mode are given below.

•Absolute value detection

When the machine is operated in the continuous mode, detection is kept turned off for a while

during the initial 10 strokes (the initial number of bypasses or the number of times that

detection is turned off can be changed by system setting) and begins with the 11th stroke.

After the end of this bypass state, sampling of reference data for absolute value detection is

repeated 10 times. (The number of times that absolute value sampling is performed can be

changed by system setting.) During sampling, “Sampling” appears on the left side of the

screen. Mean value comparison is made during sampling. After completion of sampling the

mean value of sampled data is determined as the reference value with which the subsequent

data are compared at all times.

Trend Mode

(Learned Sample "Benchmark")

Trend Mode

(Learned Sample "Benchmark")

•

•

•

•

Compares present Sensor-to-target displacement

to Average of Displacement for Initial strokes

during "Benchmark" sampling.

Monitoring limits established for plus / minus

deviation based on preset values

Bypass function at start of operation inhibits

alarms during machine stabilization.

Slow changes over time NOT canceled.

•

•

Fault detection range set wider (±20 microns typ.)

to prevent nuisance alarms.

Changes over time detected (loss of lubrication,

machine heat up / cool down, changes in material

hardness, etc.)

Page 10

TMG-1200 Instruction Manual

The deviation displayed is calculated by the equation:

Deviation = Detected Value – Reference Value

Ex) Detected value: 1,823mm Reference value: 1,798mm

1,823 – 1,798 = 0.025 Display value: 25

The monitoring range depends on the set point. When the set point is 100, the monitoring

range is ±100 (m relative to the reference value. Absolute value detection is characterized in that

the value right after start is taken as reference for comparison with detected values, so slow

changes such as overload by temperature can be detected. To recommence sampling of

reference data for absolute value detection during operation, push the sampling button. Then

sampling is recommended with the appearance of “Sampling” on the left side of the screen.

Mean value detection is performed during sampling.

•Mean Value Detection

When the machine is operated in the continuous mode, detection is dept turned off for a while

during the initial 10 strokes (the initial number of bypasses the number of times that detection

is turned off can be changed by system setting) and begins with the 11th stroke. Mean value

detection is a detection mode which makes comparison with the mean value of 10 previous

data (the number of averages taken can be changed by system setting) when the device gets

into the detection condition after the end of the bypass state. However, right after the start of

detection, 10 previous data are not available. Therefore, after the end of the bypass state,

the 1st data is compared with the last detected value at the end of bypass, the 2nd data with

the 1st detected value, the 3rd data with the mean value of the 1st and 2nd data, and the 4th

data with the mean value of the 1st, 2nd and 3rd data. Thus the data up to the 10th are

compared each with the mean value of previous data and the 11th and subsequent data are

compared each with the mean value of 10 previous data at all times.

Adaptive Mode

(Stroke-to-Stroke "Rolling Average")

Adaptive Mode

(Stroke-to-Stroke "Rolling Average")

Page 11

TMG-1200 Instruction Manual

Adaptive Mode

(Stroke-to-Stroke "Rolling Average")

•

•

•

•

•

•

Compares present Sensor-to-target displacement

to Mean Value of Displacement for previous two

strokes.

Monitoring limits established for plus / minus

deviation.

Bypass function at start of operation has

progressively closer alarm limits during machine

stabilization.

Slow changes over time canceled.

Fault detection range set very small (±5 microns

typ.) without nuisance alarms.

Sudden changes (dropped parts, short feeds,

chipped or broken punches) easily detected.

The deviation displayed is calculated by the equation:

Deviation = Detected Value – Average of 10 Previous Values

Ex) Detected value: 1,823mm Average of 10 previous values: 1,820mm

1,823 – 1,820 = 0.003 Display value: 3

The monitoring range depends on the set point. When the set point is 10, the monitoring

range is ±10 (m relative to the mean value of 10 previous data. Mean value detection is

characterized in that slow changes are cancelled and only sudden changes such as punch

abnormality, shorter size, etc., can be detected.

In addition, the detection range can be made smaller so this detection mode is suitable for

minute fault detection.

Page 12

TMG-1200 Instruction Manual

Details of Detection

This device can select three detection modes. Which detection mode is to be used, depends on

the type of machine.

•Single mode

This mode is for single stroke, single die headers. The screen display is limited to one

channel only.

•Double mode

This mode is used for such machines which perform two work with punches 1 and 2 in one

stroke. In this case, detection is made for two punches at the same time, using one sensor

(2-die & 2-blow, 2-die & 3-blow). The device is factory set in this mode.

•Multi model (multi-stage type)

This is the detection mode for multi-state headers and formers. Detection is performed using

two sensors. With one each sensor installed at the left and right sides of the slide, fault

detection is made based on the inclination of the slide.

These detection modes can be selected by system setting. (Refer to Section “Details of System

Setting”.)

Slowdown Detection and External Timing

•Slowdown detection

The TMG-1200 has a slowdown detection function. When the rpm of the machine has

decreased due to machine trouble, this function stops the machine. The rpm when the

machine was started in the continuous mode is kept in memory. When the rpm becomes

lower than that at the start by more than the set value, a fault signal is produced and the

screen display shows that the machine has stopped due to slowdown. The function is used

mainly for prevention of motor burnout. The set table range is from –5% to –49% in units of

1%. Slowdown detection is factory set in the off state. This function is set by system setting.

(Refer to Section “Details of System Setting”.)

•External timing

This device has an external timing input. In the case of double detection, detection is made

for punches 1 and 2, using one sensor. Therefore, this input is used to make it recognized by

an external signal that the timing is for punch 1.

By turning on (short circuiting) the external timing input with the timing for punch 1 as

mentioned above, this device discriminates between punches 1 and 2. (Set the time, during

which the input stays on, to more than 20 msec.) In case punches 1 and 2 are different in

load, the punch of smaller load is automatically set as punch 1, and the punch of larger load

as punch 2, without connecting the timing signal.

Page 13

TMG-1200 Instruction Manual

Page 14

TMG-1200 Instruction Manual

Details of System Setting

The operation of the TMG-1200 can be varied by system setting to enable the device to be used

in various ways. Being preset, system settings items do not need to be changed. How to change

them is described below.

•Starting the system setting mode:

Push the Reset button while pushing the Setup button. The menu screen for system setting

appears. There are a total of 9 menu items.

•Changing settings

To change settings, turn the setup dial on the menu screen to select an item to which you

wish to make a change.

After selecting the item, push the reset button to obtain the data screen for the item.

When the data screen has appeared, turn the setup dial to change the setting.

After changing the setting, push the reset button again to restore the menu screen for system

setting.

To change the setting of another item, repeat steps 1-4.

After completing all changes, turn the setup dial clockwise to select the end of setting and

push the reset button to terminate the system setting mode.

Symbol “TMG” appears on the screen and the normal mode is restored.

Items of system setting

End of setting

The item for terminating the system setting mode. Pushing the reset button returns the

screen to the normal mode, terminating the system setting mode.

1. Number of initial bypasses

Set the number of bypasses at the start

(10 to 200) Initial value: 10

2. Absolute value sampling frequency

Set the frequency with which to sample the reference value for absolute value detection.

(1 to 100) Initial value: 10

3. Number of mean values taken

Set the number of times that mean value detection is made.

(1 to 100) Initial value: 10

4. Setting of slowdown

Set the set point for slowdown detection

(-5 to –50%) Initial value: -50% (OFF)

The set point can be set in units of 1%. When it is set to -50%, slowdown detection is turned

off.

5. Setting of operation mode

Set the operation mode.

(single, double and multi) Initial value: Double

Page 15

TMG-1200 Instruction Manual

6. Setting of detection sensitivity

Set detection sensitivity.

(High, Normal and Low) Initial value: Normal

7. Setting of key protection

Set control buttons in the disabled state. Push the button, whose operation is desired to be

disabled, to indicate the corresponding mark (P→). The position marked is the position at

which the operation has been disabled. To return to the former state (to enable the

operation), push the button again to remove the mark (P→). Note that each reset button

cannot be disabled. After completing the change, push the reset button to restore the menu

screen for system setting.

Initial value: All enabled

8. Setting the reset mode

Set the reset mode, i.e., select whether the device is to be reset manually by pushing the

reset button when fault detection is made or is made to be automatically reset one second

after fault detection.

Initial value: Manual

9. Setting of counter output timer

Set the output time (one shot) of the counter output relay which provides an output signal

when the preset counter value agrees with the preset set point. The set table time is 0.5-25

seconds in units of 0.1 second.

Initial value: 1 second

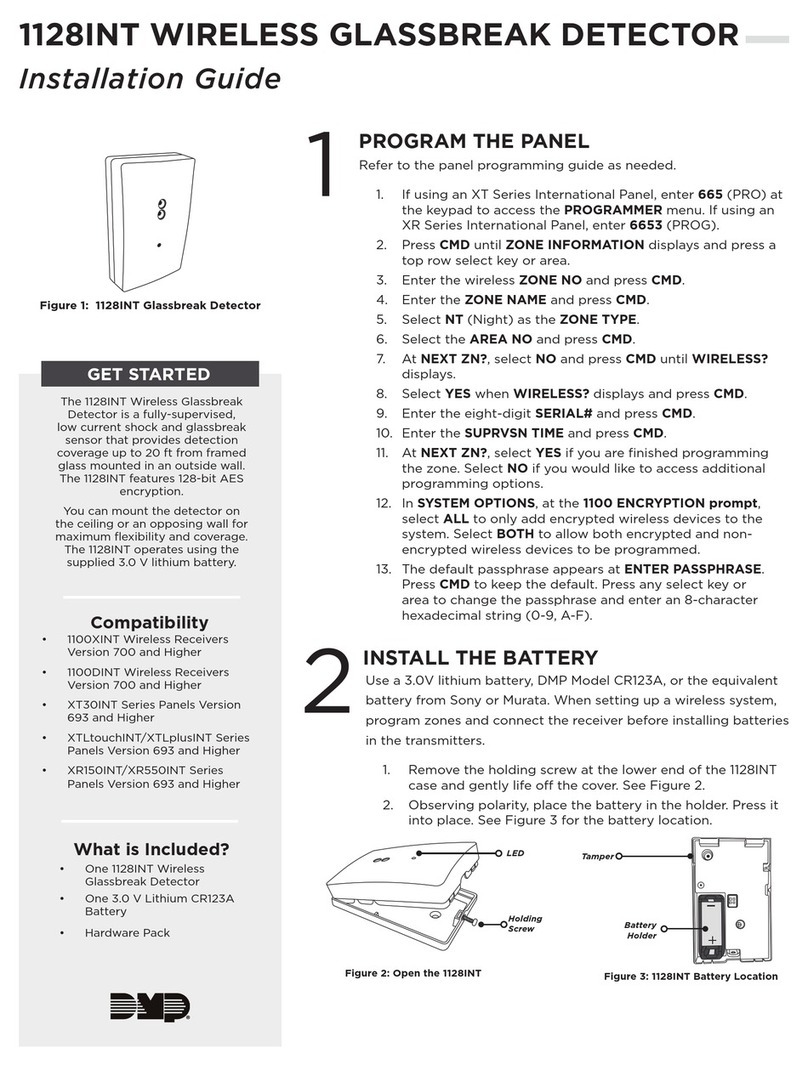

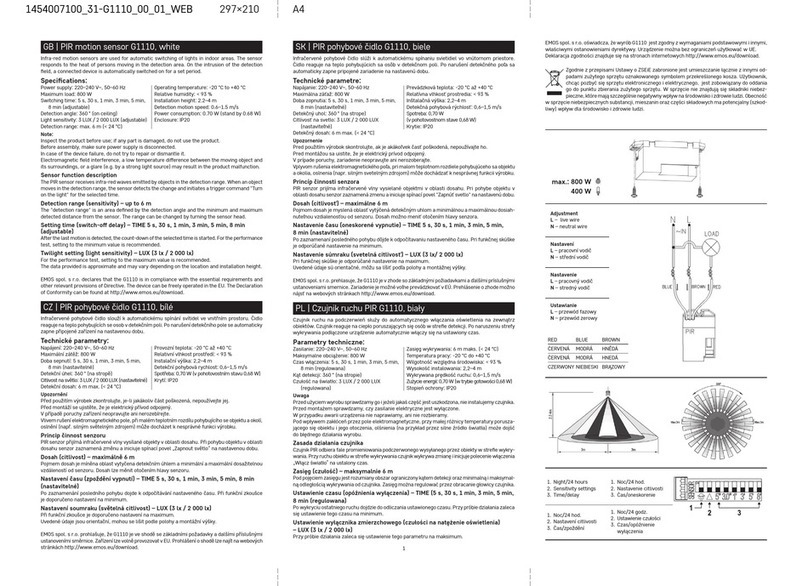

Connection of Terminal Block

External Signal External Signal

External Reset External Bypass External Timing Sensor 1 Sensor 2

Blank

R G M G +12V T G IN-1 G IN-2 G

Proximity Switch Etc Sensor 1 Sensor 2

Counter Output Fault Output A Fault Output B Earth Power

Blank

A1 A2 B1 B2 A1 A2 B1 B2 E S1 S2

Counter Counter Fault Output A Fault Output B Earth 100-240 VAC

Output A Output B

Kind Contact Power OFF Power ON Fault output being Counter producing

Produced coincidence ouptut

Fault output A1 OFF ON OFF

A2

B1 ON OFF ON

B2

Counter A1 OFF OFF OFF ON

output A2

B1 ON ON ON OFF

B2

Page 16

TMG-1200 Instruction Manual

Connection of Terminal Block

Counter Output Fault Output A Fault Output B Earth Power

Blank

A1 A2 B1 B2 A1 A2 B1 B2 E S1 S2

Counter Counter Fault Output A Fault Output B Earth 100-240 VAC

Output A Output B

Connecting a stop circuit for a conveyor

*Note: If the conveyor has an ON/OFF switch, make connections at that

point.

Also make sure to size the relay correctly to handle the current passing

through.

Page 17

TMG-1200 Instruction Manual

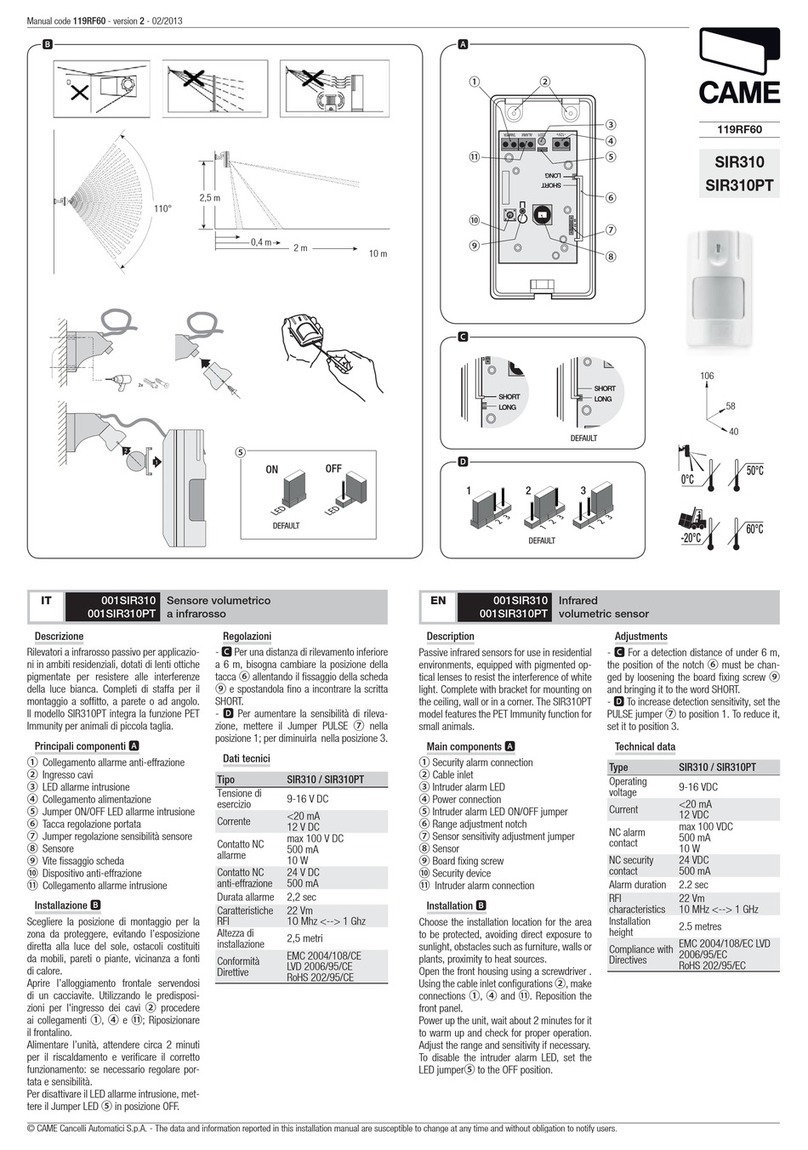

Sensor Installation

Sensor Location

Page 18

TMG-1200 Instruction Manual

HEADING SLIDE-FRONT VIEW

H

E

A

D

I

N

G

S

L

I

D

E

-

T

O

P

V

I

E

W

FRONT DEAD CETER POSITION

MACHINE FRAME HEADING SLIDE

(@ FRONT DEAD CENTER POSITION

)

MA

C

HINE FRAME

HEADING SLIDE TARGET SENSING AREA (TYPICAL)

Proximity element and sensor fittings are not attached.

The above figure is for reference only.

Sensor Adjustment

Adjust the sensor as follows:

1. Set the slide at FDC.

2. Push the setup button. The bar display serves as a clearance gauge between sensor and

proximity element.

The sensor detection range is 1-3 mm. The leftmost end of the bar display indicates a

clearance of less than 1mm and the rightmost end indicates a clearance of 3mm or more.

When the clearance is 2mm, only the center square is indicated. One point of the bar display

is equivalent to 0.2mm.

1 mm 2 mm 3 mm

3. Set clearance gap between sensor and proximity element to 1.5 to 2.0 mm (.059"~.078").

1.5 ~ 2.0 mm (.059" ~ .078")

4. Place material and operate the machine in the continuous mode. Confirm that the bar display

shows a value between 1.7 and 2.2mm. Placing material causes the FDC position to

displace a little, so make this confirmation without fail with material placed in the machine. If

the FDC position is displaced, stop the machine and adjust the proximity element and then

confirm again.

5. Push the setup button to cancel the setup mode.

When you push the setup button to get into the setup mode, the bar display operates as the

clearance gauge for the sensor. When the machine is in the stop state, the bar display

measures and shows the distance of clearance at all times. When the machine is operating,

it measures and shows the distance of the smallest clearance within one stroke.

Page 19

TMG-1200 Instruction Manual

Table of contents

Popular Security Sensor manuals by other brands

DMP Electronics

DMP Electronics 1128INT installation guide

Ksenia

Ksenia KSI5CLV-02.00W installation manual

TEKTELIC Communications

TEKTELIC Communications LoRa IoT Smart Room Sensor user guide

Honeywell

Honeywell FG-730 user manual

AJAX

AJAX GlassProtect Fibra user manual

Inficon

Inficon Sensistor Sentrac Service instructions

Bircher Reglomat

Bircher Reglomat Herkules 2E Original instructions

Smoke Guard

Smoke Guard M2500 Smoke Operation & maintenance manual

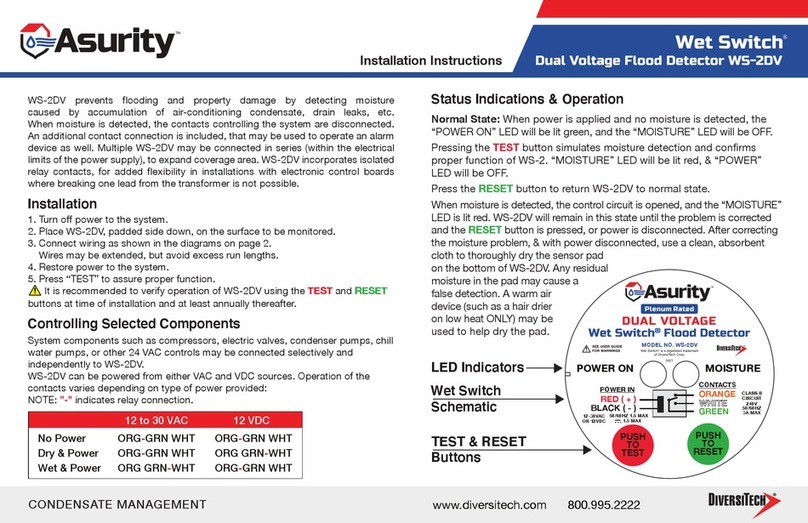

ASURITY

ASURITY Wet Switch WS-2DV installation instructions

Velleman

Velleman PIR416 user manual

Pfeiffer Vacuum

Pfeiffer Vacuum ASM 390 operating instructions

LEGRAND

LEGRAND EMOS G1110 manual