Hengstler C-56 User manual

Operator Manual

Thermal Printer

C-56

E

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 2of 17

Release

Release 1.0

C.Bernhart Mar 03th, 2005

Approved Hengstler E.Link

Approved

Changes

Date Rev Additional Content

09 Nov 2004 1.0 First Release

03 Jun 2005 1.1 RS 232 extension

26 Jul 2005 1.2 Update technical data, troubleshooting

17 Jul 2006 1.3 Update USB cable spec; add safety hint

21 Jan 2008 1.4 Update spare parts; add EMC hints; adding sensor options

15 May 2009 1.5 Revise EMC specs.

5 Aug 2009 1.6 Add 12 volt specs, chute sensor, hardware PPE sensor. Add reference to short

chute shroud.

17 Oct 2011 1.7 Add limitation on reversing paper. Added German paper specification. Removed

reference to German operating manual with wrong P/N.

3 Apr 2013 1.8 Clarify serial pinout; add wiring diagram for serial connectioncable; correct height-

width-depth abbreviations; modified warning definition;

30 Jul 2015 1.9 Addition of chapter 2.3 and power supply pinout; various minor corrections

© 2005 - 2015 by HENGSTLER

This document is protected by copyright by HENGSTLER GmbH.

This document may not be changed, altered, duplicated or reproduced in any manner, or provided

or transmitted to any third persons or organizations, without the prior written approval of

HENGSTLER.

We reserve the right to make technical changes, modifications or improvements without prior

notice.

Hengstler and the Hengstler logo are registered trademarks of Hengstler GmbH. Other brand and

product names used herein are trademarks or registered trademarks of their respective companies.

HENGSTLER GmbH

Uhlandstr. 49

78554 Aldingen / Germany

Tel. +49 (0) 7424-89 0

Fax +49 (0) 7424-89 500

www.hengstler.com

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 3of 17

Contents

RELEASE.............................................................................................................................. 2

CHANGES............................................................................................................................. 2

1.0Introduction ..................................................................................................................... 4

1.1ADDITIONAL LITERATURE.......................................................................................... 4

2.0Important Information and Safety Instructions.............................................................. 5

2.1GENERAL INFORMATION........................................................................................... 5

2.2SYSTEM-SPECIFIC SAFETY INSTRUCTIONS AND SYMBOLS....................................... 5

2.3PRINTER INSTALLATION........................................................................................... 6

3.0Layout and Function........................................................................................................ 7

3.1STRUCTUREOFTHEC-56THERMALPRINTER ............................................................... 7

3.2FUNCTIONS OF THE PRINTER..................................................................................... 8

4.0Operation........................................................................................................................ 10

4.1START UP OF THE SYSTEM ..................................................................................... 10

4.2LOADING OF PAPER ............................................................................................... 10

5.0Troubleshooting............................................................................................................. 11

5.1CLEARING PAPER JAMS ......................................................................................... 12

5.2REPLACEMENT OF COMPONENTS............................................................................ 13

6.0Technical Data............................................................................................................ 14

6.1GENERAL DATA..................................................................................................... 14

6.2CONFIGURATION OF THE INTERFACES...................................................................... 15

6.3PAPER SPECIFICATIONS......................................................................................... 16

6.4DATA SPECIFIC TO PRINTING................................................................................... 16

6.5ORDER NUMBERS FOR SPARE MODULES:................................................................ 16

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 4of 17

1.0 Introduction

Thank you for selecting the Hengstler C-56 printer! We are proud of this feature-rich product, which was

designed using all our expertise and experience, and we are confident that you will be pleased withthe

advanced features and outstanding performance.

This Operator Manual is designed to help you with the proper installation, connectionto your host computer

system and start-up of the C-56 thermal printer system. All necessary details will be further explained in the

following sections. Please read this manual carefully before starting up the thermal printer. If you have any

further questions, please do not hesitate to contact our head office or one of our branch offices.

The thermal printer does not require any servicing and isintended primarily for printing documents and receipts,

at a printing speed up to 220 mm/sec for the 24 VDC version, and up to 160 mm/sec for the 12 VDC version,

when powered by an appropriate power supply and when printing on endless thermal paper with paper weight

ranging from 50 to 60 g/m2. The paper width may vary from 58 to 60 mm (2.28" to 2.36"). Whiledocuments may

be any length greater than 120 mm, most documents will fall in the range of 120 to 297 mm.

The horizontal andvertical print density is 203 dpi sothat graphics, such as logos etc. can be printed with good

quality.

The printer mechanism has been designed in particular for application in self-service gasoline pumps in service

stations, in terminals and vending applications. The modular design enables the main components to be

replaced in less than 2 minutes. The controller integratedin the printer mechanism controls all printing functions

and is provided with an USB 1.1 port for the host computer. Driver software is available that supports the

Windows XP/7/8/10 and Linux operating systems. In addition, the printer can also be activated directly in ASCII

mode through ESC/FS sequences; a detailed description of the different sequences is contained in the

Emulation Manual.

1.1 Additional Literature

C-56 Emulation Manual D 684 017

Paper Specification (English)

Paper Specification (German) D 684 012

D 684 010

Dimensional Drawing D 684 048 etc; see the C-56 download area at www.hengstler.de

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 5of 17

2.0 Important Information and Safety Instructions

2.1 General Information

The company Hengstler GmbH will not accept any liability for direct or consequential damages arising due to

improper use of the thermal printer and, in particular, due to non-compliance with this operating manual or to

improper handling and maintenance. Thesupply of technical documentation does not imply any authorization by

Hengstler GmbH to make additions, repairs or modifications.

This documentation may not be copied, norshall its contents be disclosed or used commercially unless this has

otherwise been explicitly agreed. The user is responsible for proper handling and installation of the printer. The

printer should only be shipped in its original packing.

2.2 System-Specific Safety Instructions and Symbols

Hengstler GmbH will not accept anyliability for the safe operation ofthe C-56 thermal printer unless Hengstler

original products are used exclusively and the following instructions andrecommendations are heeded.

If unauthorized persons perform any repairs ormodifications to theprinter mechanism andthe

controller, HENGSTLER will not accept any liability andthe guarantee shall be void.

Unapproved types of thermal paper may dramatically reduce the life of the print head and may

void the guarantee. For pre-printedthermal paper make sure that only appropriate inks are

used. Details can be found in the Hengstler Paper Specifications D 684 012.

The connector for the power supply must not be plugged in or disconnected under load in order

to avoid damage to the electrical components and the thermal printhead.

Avoid strong vibration, shocks and impacts since they may damage or even destroy sensitive

electronic and mechanical components. Do not touch the surface of the printer control board in

order to prevent static electricity from damaging sensitive components.

The thermal printer must not be used nearto high-frequency apparatus or strong magnetic fields

in order to prevent undefinedmagnetic disturbance.

Do not make any attempts to service this printer (e.g. change paper) whilethe printeris printing.

Installing or uninstalling the printer must only be done while using adequate ESD protection.

The following symbols on the system and in the manual remind you to follow the relevant safety

instructions:

General warning for cases where the useror service personnel may be in danger.

General notes and hints for operating thesystem safely.

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 6of 17

2.3 Printer Installation

The C-56 printer uses electrically conductive housing materials which help to eliminate electrostatic charging

during printing. In order to protect the printer from damages caused by externally applied charges, e.g. when

electrostatically charged customers grabthe receipt at the printer chute,the printer must be grounded.

The mounting holes of the printer’s base unit can be utilized for this where a ground wire with lug may be

inserted in one ofthe two screw points.

If the printer is mounted in an electrically conductive and already grounded panel, additional wiringcan be

omitted if sufficient electrical contact is ensuredthrough the mounting points.

Caution:

The C-56 printer mouting must ensure permanent electrical connection of the printer’s base unit to

ground. This measure serves the draining of externally applied electrostatic charge.

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 7of 17

3.0 Layout and Function

All modules of the C-56thermal printer mechanism are delivered in operating condition. After connecting the

printer to a USB 1.1 or 2.0 port on the host system (PC)and to a properly rated 24 VDC or 12 VDC power supply

(depending upon the model), and installing the driver software (if needed), the printer is ready for operation.

This thermal printer is a built-in module to be operated only as part of an overall system like e.g.

a vending application. Please, also consider the storage and operating conditions (see also

under chapter 6- Technical Data).

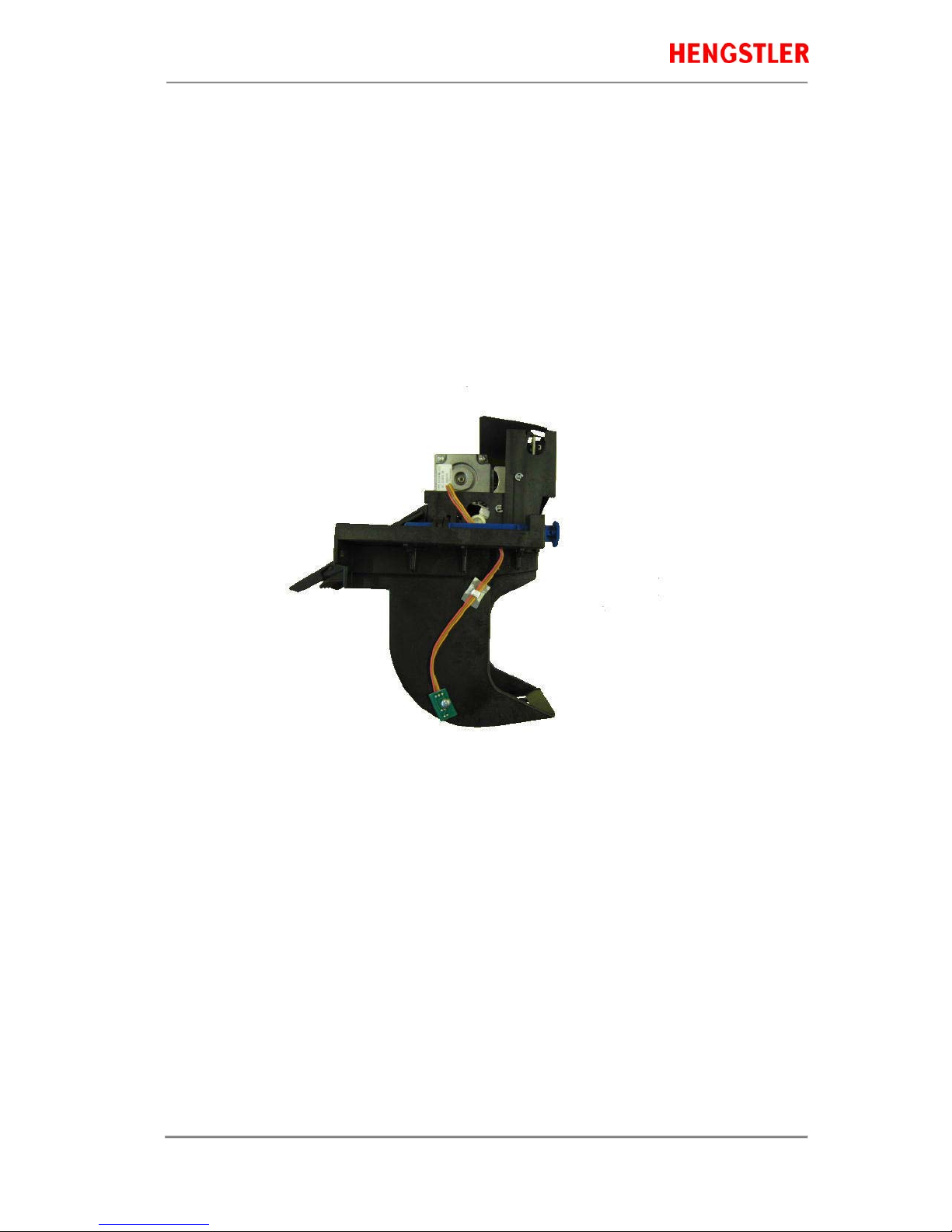

3.1 Structure of the C-56 Thermal Printer

Fig.1 Thermal printer, front view left hand

The C-56 Thermal Printer is composed ofthree main units:thermal printer with integrated Controller, basic unit

with paper tray and two hinge pins, and an eject chute supported by the basic unit. These hinge pins securethe

printer mechanism on the basic unit. If both hinge pins are retracted in part, the printer mechanism can be re -

moved. If only one hinge pin is retracted, the printermechanism can be pivoted around the remaining hinge pin.

The Eject Chute is provided with guides that engage in the basic unit firmly and with high dimensional accuracy.

The paper roll liesin the paper tray loosely. The sensitive side of the thermal paper must be outside or be

directed upward.

Note: A shorterEject Chute is also availablefor OEM applications. When this shorter chute is

used, an external, customer-supplied shroud must be used! Failure to usethis shroud will

cause increased paper jams. Contact Hengstlerfor details ofthe shroud design.

In Fig. 1, the protective plastic cover has been removed (also see Fig. 2) to provide a view of the

controller board. But for operation, this plastic cover must be in place.

USB or RS232 Interface,

DC power connector on controller board

Thermal printer mechanism

Hinge pin

Thermal paper roll

Mounting holes

Eject chute

Base unit with paper tray

Optional Paper Pre-End

Sensor connection

Printhead up lever

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 8of 17

3.2 Functions of the Printer

The printhead of the C-56 printer mechanism has a horizontal resolution of 203 dpi (dots per inch). Thus, the 448

dots allow printing of lines with a maximum width of56 mm. The stepper motor affects the paper feed by means

of a platen that is rotated via gearing. The transmission ratio of this gearing has been selected insuch a way that

the vertical dot resolution is also 203 dpi; this corresponds to a paper movement of 0.125 mm. All functions of the

printer mechanism are controlled by the integrated Controller.

Fig. 2 Diagram of paper transport

The paper is inserted into the printer through the upper and lower paper guides and led over the platen. As soon

as the reflective LED sensor L1a in the upper guide detects the front paper edge, 'automatic paper insertion' will

start and the paper is transported until its front edge can be seized in the eject chute. The LED L2 signals that

the printer is ready by flashing slowly.

In the event the paper edge is not detected within approximately 5 seconds, the printer will

assume a malfunction and LED L2 (on the component side of the controller board) will flash

rapidly, indicating 'No paper/paper end'. The paper loading process is then aborted and must be

repeated.

As an alternative, the reflective LED sensor L1b may be installed instead of the sensor L1a. It will detect the

paper edges and recognizeposition identificationmarks (Black Marks) on the back side ofthe paper. The

ejected paper is cut when the user pulls it from the printer, thereby tearing it straight over the cutter. The shape of

the triangle cutter knife provides for a clean cut. The further paper transport will be carried out by program

control.

Optional reflective LED sensor L3 detects the presence of paper in the eject chute. The status of L3 can

determined via the Query command and is reported as part of the C-56 status bytes. See the C-56 Emulation

Manual D 684 017 for details on querying this sensor and theformat of the response.

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 9of 17

Optional reflective LED sensor L4 is located on the left outside of the paper reservoir and detects when the

diameter of the paper roll decreases below afixed dimension, indicating that paper is low. This is a hardware

alternative to the default paper low system, which requiresthermal paper with black marks atthe end of the

paper roll. The status of L4 can determined via the Query command and is reported as part of the C-56 status

bytes. See the C-56 Emulation Manual D 684 017 for details on querying this sensor and the format of the

response.

In case of any trouble during paper feed, the printhead can be lifted from the platen manually

using the “printhead up” lever so that the paper can be pulled out of the printer mechanism.

Caution !

Do not lift the printhead during printing or the thermal printhead may be damaged or destroyed

by overheating.

Fig. 2a C-56 with Hardware Paper Low Sensor

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 10 of 17

4.0 Operation

Once the C-56 thermal printer is connected to the power supply and the host's interface port, and the driver (if

needed) is installed, the printer is ready for use.

4.1 Start up of the System

Fig. 3 Connections of the thermal printer to the system

1.

The connection to power supply is to be done

exclusively by means of the supplied cable.

Make sure that the power supply is always

switched off before the connector is plugged in or

removed. The locking tab of the connector should

always be directed towards the paper insert side.

2.

Connect the a) mini - USB port of the printer

mechanism with a USB – interface, or b) micro -

RS232 port with a RS232 interface of your PC,

using the supplied USB / RS232 cable.

On USB, Windows will then automatically

recognize the new connected device and install

the appropriate driver software.

3.

Install the driver software on the host system (PC).

Please, consider the coordination of the drivers with

the operating systems and respect the current

instructions supplied together withthe drivers.

4.2 Loading of Paper

Please only use paper of the recommended quality. Thermal paper with other specifications or poorer

quality may reduce theservice life of the thermal printhead considerably and will invalidate the printer's

warranty.

Fig. 4 Loading of the paper roll

1. Pull the protective sheathingfrom the paper roll

and cut the paper end at right angles to the

direction of feed as far as possible. Truncated,

lacerated or folded paper edges can produce a

paper jam duringautomatic insertion. Also

perforations of the paper web or rounded edges

are not acceptable.

2. Lay the paper roll into the paper tray as shown in

the illustration. The thermal sensitive paper surface

must be situated outside or on top.

3. Insert the paper into the printer mechanism. As

soon as the sensor in the paper guide detects

paper, the controller starts the automatic paper

insertion.

4. Cut off the paper appearing in the eject chute by

pulling it straight out.

Mini - USB

Locking tab

Connector

Power Supply

Micro – RS232

Be sure to use the supplied

cable tie to secure the RS-

232 cable and avoid possible

damage to this connector.

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 11 of 17

5.0 Troubleshooting

The paper path inthe printer mechanism is almost straight so that proper paper feed andguiding will prevent

paper jams (see also Fig. 2). The following malfunctions if any will be recognized and signaled by the integrated

controller:

Paper Insert Error In case the 'Automatic Paper Insertion' starts, but the paper has been held

back by hand too long time or has been fed in skewed, the paper path can

indicate a ‘Paper Insert Error’ caused by a time out of the sensor routine.

As failure corrective action, pull the paper back. In case the paper has

already been transported by the platen, left the printhead, pull back the

paper and restart the loading procedure.

No Paper Insertion In case the ‘Automatic Paper Insertion’does not start andthe motor stalls,

with a characteristic rattling sound. If the printer has been left with no paper

inserted for a longer period (e.g. a day or more), the printhead can cause a

temporary depression of the platen and the motor will not start turning.

Lift the printhead using the head lift lever (see Fig. 5) and insert paper.

Release the headlift lever after themotor begins to runsmoothly and the

platen begins to pull the paper. Continue the auto loading procedure.

Paper Jam During operation, a paper jam may occur in the eject chute due to paper

scraps, etc. Jamming may also occur from reversingthe paper for morethan

the 150 mm specified maximum reverse distance.

As failure corrective action, tilt the printer mechanism open and remove

any paper scraps found at the entrance into the eject chute. In case the eject

chute has been clogged deliberately (vandalism), the chute will have to be

dismounted and cleaned. Afterwards repeat the paper loading routine.

Paper End The sensor L1 (a or b, depending upon thevariant of sensor placement) will

detect the end of the paper, e.g. in case of a torn paper web.

As failure corrective action, remove the document that has already partly

been printed (see Paper Jam) and repeat the paper loading routine. If

necessary, load a new paper roll.

Paper Pre-End The sensor L1 recognizes the 'paper pre-end mark' so that the controller can

transmit the status message 'Paper Pre-End' upon receipt of the Query

Status command. Alternatively, if so equipped, sensor L4 will detect that the

paper roll diameterhas decreased to thepoint that it is nolonger reflecting

the side of the paper roll when in the rest position, and will transmit the

‘Paper Pre-End” status message when queried. In either case, the printing

of further documents will not be blocked unless the printer detects 'Paper

End'. A new loading operation will cancel this message.

Undefined Error In case none of the above mentioned failures is detected, the printer may be

blocked by the operating system because e.g. the printer is not recognized

by the PC. If noother obvious disorder of the operating system is found, we

recommend as failure corrective action to disconnect the USB cable from

the PC. The operating system will then deactivatethe driver software. Re-

establish theUSB connection after aninterruption ofabout 1 minute inorder

to re-activate the driver software.

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 12 of 17

5.1 Clearing Paper Jams

In order to clear a paper jam, detach the document that is already present in the eject chute and retract the

remaining paper manually. Paper scraps remaining in the area between the print mechanism and eject chute can

be removedafter the printer is tilted open.

Fig. 5 Open paper path for removing paper

In case there is still paper between the printhead and the

platen, remove the friction between head and platen by

pressing down the lever andthen pull the paper back by

hand.

Never actuate this lever during the printing

operation or else the printhead will overheat.

Fig. 6 Tilt the printer mechanism open for paper removal

If a partly printed document remains in the printer

mechanism, e.g. in the event of a paper end signal due to

a tear, and it does not appear in the eject chute, the

printer mechanism will have to be tilted open and the

document be taken out by hand. Note that additional care

must be taken concerning wire routing if the optional

chute sensor or hardware paper-low sensor are installed.

1.

Pull the hinge pin back into its tilt position.

2.

Then tilt the printer open as illustrated. Now, the

partially printed document will be visible and can be

pulled out over the eject chute.

3.

Eject the document by twisting the motor pinion gear

clockwise untilthe document leaves the friction area

of the platen.

4.

Remove the partially printed document. Then again tilt

the printer mechanism back into its operating position

and secure it by snapping the hinge pin into its

operating position.

Push to lift printhead

Drive

pinion

Partly

printed

paper

LED L2

Hinge pin

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 13 of 17

5.2 Replacement of Components

The C-56 thermal printer does not require any servicing. It has been designed such that its main modules

represented in the illustration below can be replaced also by the operational staff aftershort briefing, within less

than 2 minutes. The modules do not require any adjustment. Note that additional care must be taken concerning

wire routing if the optional chute sensor or hardware paper-low sensor areinstalled.

Fig. 7 Modular structure of the C-56 thermal printer with 4 main components

The eject chute is pushed into the guiding supports on the basic unit and cannot be removed when the printer

mechanism is installed. It represents the only access to the printer for the customer. The hinge pins are inserted

into the collars onto thebasic unit in the sense illustrated above and then are pushed against the tilt position.

Only in this position, the printer mechanism can be placed onto the basic unit, and when the hinge pins are

snapped into the operating position, the printer will be locked on the basic unit. The two holes on the front of the

basic unit serve for installing the C-56 thermal printer in vendingapplications etc.

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 14 of 17

6.0 Technical Data

6.1 General Data

Dimensions: Height-width-depth HxWxD (in mm): 184.5x 129.5 x 169.5

For opening the printer, a free space of height H = 45 mm and width W = 60 mm

must be provided. Please refer to the dimensional sheets at www.hengstler.com.

Weight: Net approx 0.56 kg

Operating Voltage: a) +24 VDC ±5 %, SELV (EN60950)

Current consumption stand by 0.1 A, operation upto 6 A

Recommended safety fuse: 6 A, delayed-action

b) +12 VDC ±5 %, SELV (EN60950)

Current consumption stand by 0.1 A, operation upto 6 A

Recommended safety fuse: 6 A, delayed-action

UL - Certificate: E174318

Interface: a) Mini USB 1.1 industrial; cable length < 3 meters

Transmission rate: 1.5 MBit/s and 12 MBit/s

Printer graphics driver forWindows XP/7/8/10 and LINUX

USB – interface cable

b) Micro RS232; cable length <3 meters

Communication protocol: Hardware DTR/CTS, None

Baud Rate: 4800, 9600, 19200, 38400, 57600, 115200 (default)

Parity: Off (default), On

Data Bits: 8

Stop Bits: 1 (default), 2

RS232 – interface cable

Noise Level: < 55 dB(A) according to ISO 3744

Operating Conditions: For guaranteed printing quality (limit values in brackets)

Temperature: +5 °C to +50 °C (- 30°C to + 70 °C)

Humidity: 20 % to 80 % (90 %), no condensation

Storage Conditions: Temperature: -40° C to + 85° C

Humidity: 5 % to95 %, condensation not permitted

During storage and storage intransit, leave paper inserted between

thermal printhead and platen

Operating Reliability: Printer mechanism: 100 km of paper, at aprinting density of 12.5% or 100 million

dot pulses

MTTR: 1.5 minutes (module exchange)

All data refer to processing of therecommended paper quality, in atemperature

range appropriate to yield the guaranteed printing quality.

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 15 of 17

EMC:

EN55022 - Emission

Warning! The C-56 thermal printer is a class "A" appliance.

It can produce radio interference in residential areas so that the user may be forced

to take adequate remedial measures.

When operating the printer from a DC building power supply, or when the DC

power cable exceeds 3 meters in length, appropriateEMI filters must be used.

EN55024 - EMS Immunity

Electrostatic discharges and burst effects may cause short printing interruptions.

But the automatic recovery function will restorethe original state of the thermal

printing mechanism.

Additional action regarding lightning andovervoltage protection will be needed, if

cables and wires are installed outside of a building.

However, this standard can be met only if original units, components, andcables

are applied and the installation instructions are respected.

External interference caused by ESD or EMI can temporarily cause corrupted

printing or data loss.

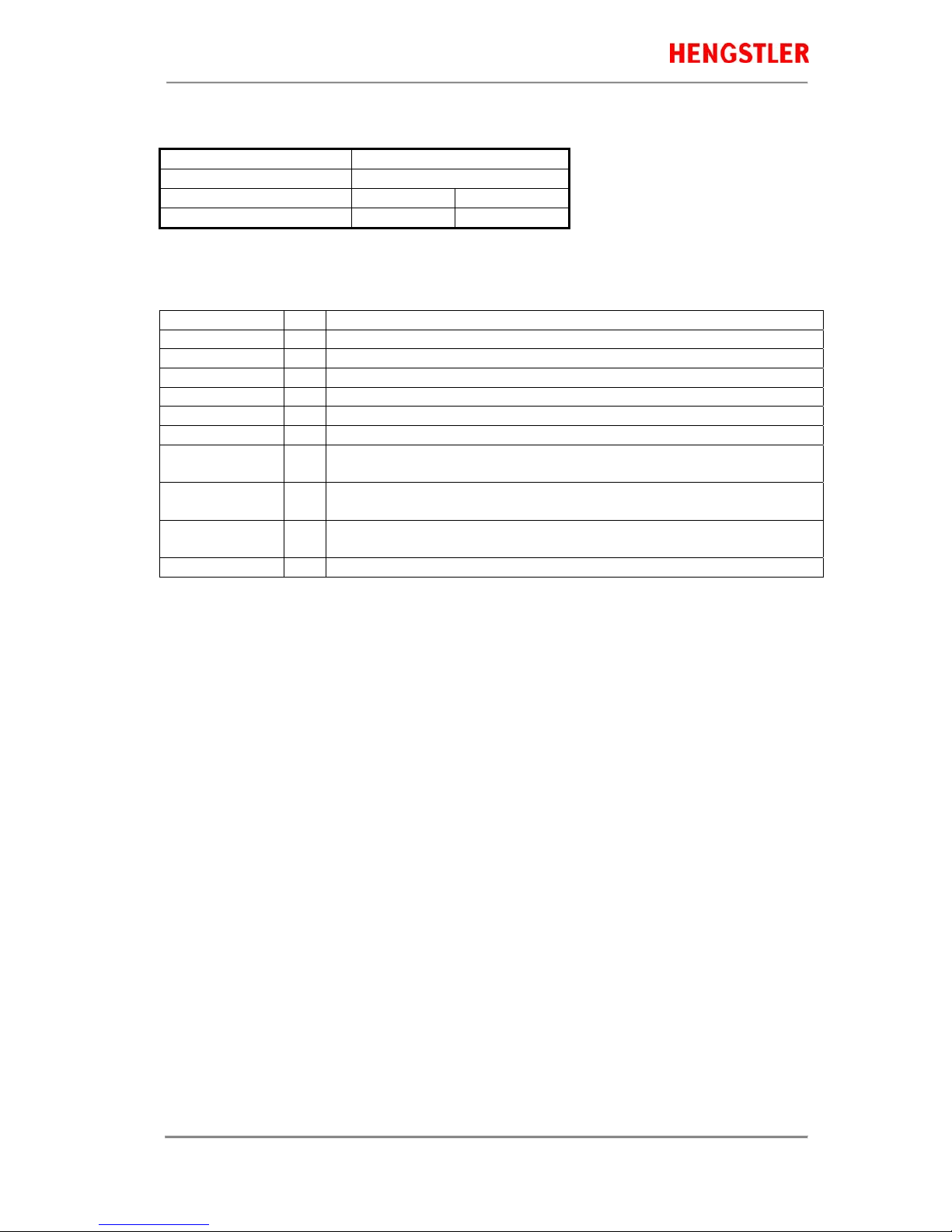

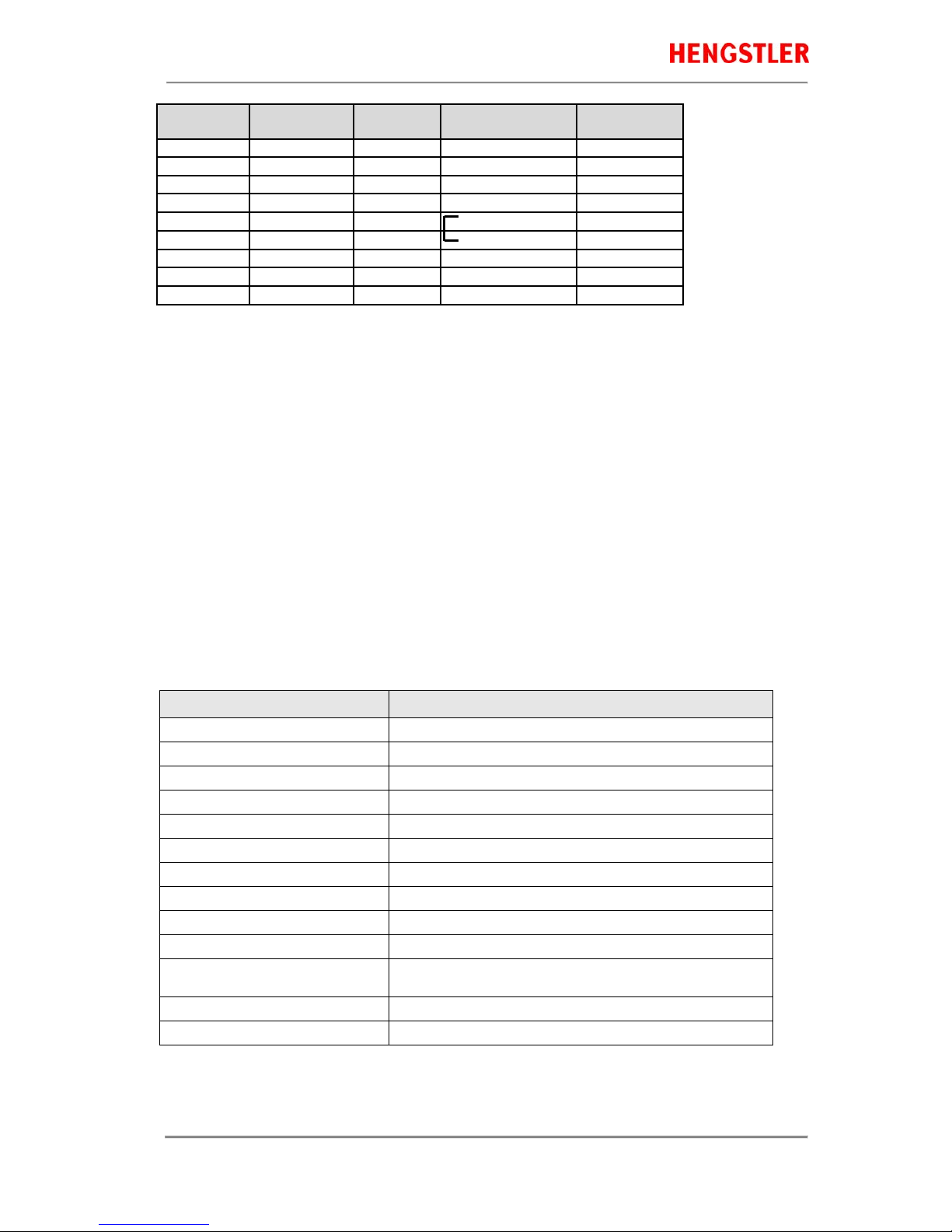

6.2 Configuration of the Interfaces

USB 1.1 Interface

Type A

(PC Side) Signal

Name mini-B

(C-56 Side)

1 +5V 1 Note: +5V is not connected on the C-56

2 D + 2

3 D - 3

4 GND 5

Metal housing Shield Metal housing

RS 232 Interface Power supply

8-pin micro

(C-56 Side)

Signal Name

(C-56)

Pin assignment

(CP35 series)

1RxD

2TxD

3CTS

4RTS

5GND

6GND

7GND

8N/C

housingshield

Wiring of the C-56 Serial Cable P/N 0684103

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 16 of 17

8-pin micro

(C-56 Side)

Signal Name

(C-56)Connection 9-pin Sub-D

(PC side)

Signal Name

(PC side)

1RxD 3TxD

2TxD 2RxD

3CTS 7RTS

4RTS 8CTS

5GNDN/C 4 (jumpered to 6) DTR

6GNDN/C 6 (jumpered to 4) DSR

7GND 5GND

8N/CN/C 1, 9 N/C

housingshield shell shield

6.3 Paper Specifications

Recommended

Paper Quality:

Thermal papers 50 to 60 g/m2;thermosensitive surface on outside;

see Paper Specification D 684012

Converting: Paper roll

Roll width: 58 to 60 mm (2.28" to 2.36")

Roll diameter: upto 100 mm (4")

Typical: 75 mm (3") or 100 mm (4")

The paper pre-end mark is to be printed on the coated paper side. For further data

regarding the printing of pre-end marks or 'Black Marks' please refer to the Paper

Specifications D 684 012.

6.4 Data specific to Printing

Designation Specification

Printing method Thermal direct

Number of dots 448

Dot Resolution (horizontal resolution) 8 Dots/mm (203 dpi)

Paper Transport (vertical resolution) 0,125 mm / Dotline (in accordance with thehorizontal resolution)

Max. Printing Width 56 mm

Printing Speed Up to 220 mm / sec (24 VDC) or 160 mm / sec (12 VDC)

Paper Width 58 mm (2,28") to 60 mm (2,36")

Length of document 120 mm up to endless

Maximum ReversePaper Distance 150 mm; longer may leadto paper jams

Chute Sensor Optional chute sensor

Paper Pre-End Detection Printing mark onto the topside

Optional hardware paper pre-end sensor

Printhead Temperature Monitoring Thermistor

Workload Max. 20 documents/ min. (at 120 mm paperlength)

6.5 Order Numbers for Spare Modules

Thermal Printer C-56

Part No. 2 684 019 Rev. No. 4310715 eli page 17 of 17

Thermal Printer mechanism RS232 E2684001

Thermal Printer mechanism USB E2684002

Paper tray (contains 10 pieces) E2684009

Eject chute standard (contains 10 pieces) E2684005

Eject chute short (contains 10 pieces) E1684019

Hinge pin (contains 10 pieces) E2684012

DC power supply cable E1684009

USB Data Cable 0684102

RS232 Data Cable 0684103

Table of contents

Other Hengstler Printer manuals