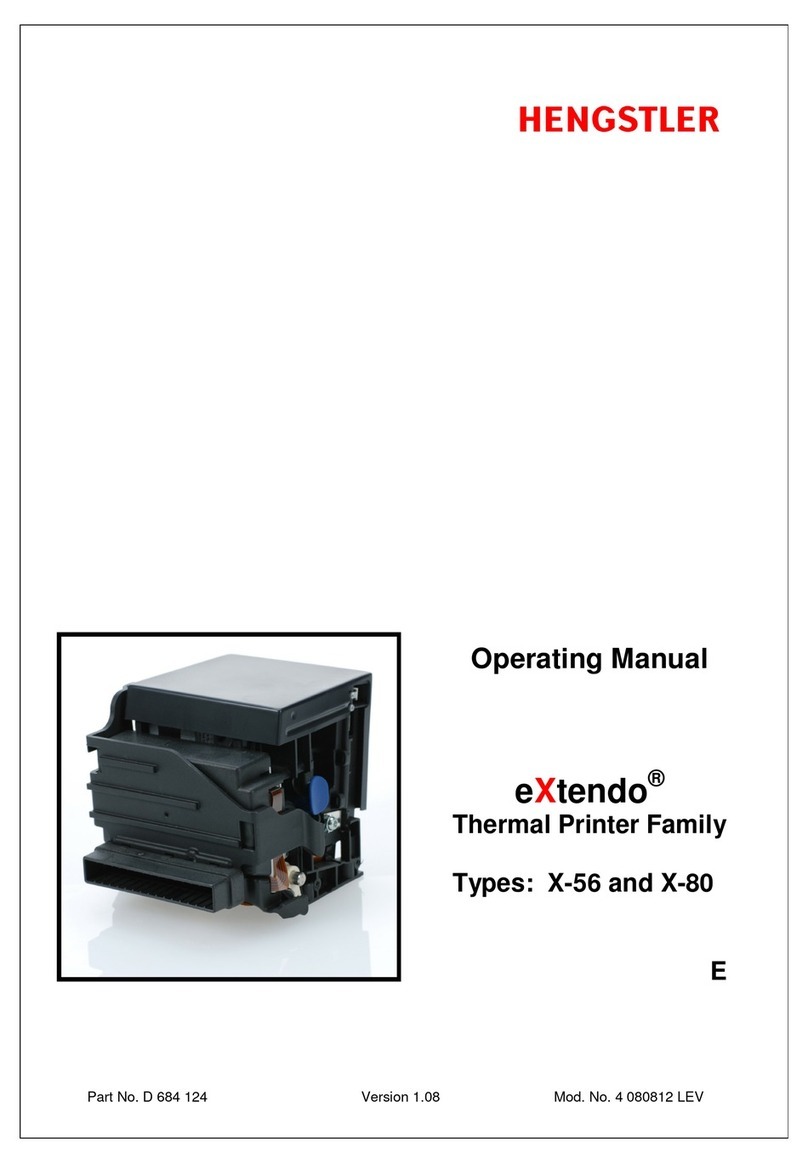

Hengstler eXtendo X-56 User manual

Part No. D-684-124 Version 1.10 Mod. No. 4 270919 HW1

Operating Manual

eXtendo®

Thermal Printer Family

Models: X-56 and X-80

E

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 2 of 33

© 2008-2019 by HENGSTLER

Hengstler GmbH has created the text and diagrams contained in this document with care. However, we

cannot accept responsibility for any errors or omissions. Notification regarding any errors and suggestions

for improvement are welcome. We reserve the right to make technical and other changes at any time in the

interest of continual product development.

All information contained in this manual is given without regard to any possible patent protection.

All rights reserved. Reproduction, translation and/or distribution of this document, or extracts thereof, are

permitted only by express authorization from Hengstler GmbH. The Hengstler name, “eXtendo” and the

Hengstler logo are registered trademarks of Hengstler GmbH and the Danaher Corporation. “Windows”and

“Microsoft”are registered trademarks of Microsoft Corporation. Other brand and product names are

trademarks or registered trademarks of their respective companies.

HENGSTLER GmbH

Uhlandstrasse 49

78554 Aldingen

Germany

Tel. +49 (0) 7424-89 0

Fax +49 (0) 7424-89 500

www.hengstler.com

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 3 of 33

Document History

Revision

Date

Init

Status

Description

1.00

2008 Jan 28

CBL

Closed

Initial version

1.01

2008 Mar 31

CBL

Closed

Removed excessive warranty value entries under “Features Selected

at Time of Order”. Corrected figure ref. no. under Wiring, Interfacing.

Removed “Heading” format for word “Serial” under Wiring,

Interfacing.

1.02

2008 June 27

CBL

Closed

Add note re 15 mm minimum paper length. Removed Basic Firmware

option and 130 mm/sec option. Add print speed of 130 mm/sec max.

for 12/10-36 VDC models. Change 10-39 VDC to 10-36 VDC. Change

Printhead Position description to describe three positions.

Troubleshooting section expanded. Black Mark text clarified. Cutter

Operation text clarified. Change sleep mode current spec to 50µA.

1.03

2009 Jan 25

CBL

Closed

Corrected formatting of columns in serial and USB cable pinout

tables. Company logo changed from graphics to text. Add duty-cycle

specification. Add photo of USB and Multivoltage version for

connector positioning. Add description of connectors on gear side.

Modify paper roll holder text. Modify text to match new photos. Add

note re specifications under Power Supply section. Update paper roll

holders in option chart. Added paper roll holder drawing reference.

Add schematic fragment for PVE/Aux. sensor connection. Add

registered trademark symbol (®) to “eXtendo”.

1.04

2009 Feb 20

CBL

Closed

Revise printhead position to two positions (three positions used in

prototypes only). Add “printhead up” status to LED Indicators. Revise

Head Status Sensor to reflect no printing when printhead is up.

Troubleshooting section revised re printhead up operation. Added

printing current specs under Technical Specifications.

1.05

2009 May 15

CBL

Closed

Add section on low current operation. Add FCC Part 15 statement.

Add EN55022, EN55024 statements. Add two “General Information”

points. Add “Function” section. Add cable length limitation to

interface specs. Add warning with photo about damaging cutter

bracket when improperly mounted. Remove “Available soon” from

Linux driver reference in intro. Add fanfold paper reference in “Paper”

section. Add explanation for moving cutter blades manually.

1.06

2010 July 19

CBL

Closed

Add note about no serial handshaking with sleep mode. Add

explanation of chute sensor/partial-cut. Add mounting hole diagram

and expand mounting comments. Update cover photo. Add

installation of paper guide.

1.07

2011 April 21

CBL

Closed

Changed P/N of paper spec document. Correct voltage in print speed

specifications. Increase 24 VDC print speed to 350 mm/sec.

1.08

2012 Aug. 8

CBL

Closed

Add clarifying statement re Class B emissions. Add statement about

sunlight on chute sensor. Add definition of area in line with black

mark where only certain inks may be used. Added drawing of PPE

sensor.

1.09

2015 Oct. 5

Eli

Closed

Serial data cable pinout corrected. 12V and 10-36V options removed

for X-80. Sensor position 3 in X-56 moved left.

1.10

2019 Sep. 12

Eli

Closed

Updating photographs; various corrections, formatting. Added:

polarity information, cutter types, spares, accessories, hints for

grounding and more. Removed multi-volt options.

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 4 of 33

Table of Contents

1. Introduction ......................................................................................................................................6

1.1. Additional Documentation ........................................................................................................6

2. Important Information and Safety Instructions ...................................................................................7

2.1. Systems Specific Safety Instructions and Symbols......................................................................7

2.2. General Information..................................................................................................................7

3. Overview ...........................................................................................................................................8

3.1. Overview of Thermal Printing Technology..................................................................................8

3.2. X-56 versus X-80 ........................................................................................................................8

3.3. Functional View ........................................................................................................................9

3.4. Description of Components and Operation ................................................................................9

3.5. Location of Controls and Connectors .......................................................................................10

3.6. Operation of Sensors and LEDs................................................................................................11

3.6.1. Paper Entrance / Black Mark Sensor.....................................................................................11

3.6.2. Paper Pre-End (Paper Low) Sensor Option ...........................................................................12

3.6.3. LED Indicators.....................................................................................................................14

3.6.4. Printhead Status Sensor......................................................................................................14

3.6.5. Chute/Jam Sensor ..............................................................................................................14

3.7. Graphic Printing vs. Printing with Printer’s Fonts......................................................................15

3.8. Features Selected at Time of Order ..........................................................................................16

5. Installation......................................................................................................................................17

5.1. Unpacking ..............................................................................................................................17

5.2. Function.................................................................................................................................17

5.3. Mounting Printer.....................................................................................................................17

5.4. Installing Paper Guides............................................................................................................18

5.5. Wiring.....................................................................................................................................19

5.5.1. Power.................................................................................................................................19

5.5.2. Data Interfacing ..................................................................................................................19

5.6. Paper Supply ..........................................................................................................................21

5.6.1. Hengstler Paper Roll Holders...............................................................................................21

5.6.2. Designing Your Own Paper Roll Holder.................................................................................21

5.7. Power Supply Specifications ...................................................................................................22

5.8. Electrical Design Aspects .........................................................................................................22

6. Operation........................................................................................................................................23

6.1. Loading Paper ........................................................................................................................23

6.2. Printhead Position Control ......................................................................................................23

6.3. Paper Advance Wheel..............................................................................................................23

6.4. Print Speed.............................................................................................................................24

6.5. Cutter Operation.....................................................................................................................24

6.5.1. Partial Cut with Chute Sensor ..............................................................................................24

6.6. eXtendo® Digital Tools.............................................................................................................25

7. Low Current Operation ....................................................................................................................26

7.1. Print Speed.............................................................................................................................26

7.2. Graphics/Bar Codes ................................................................................................................26

7.3. Inverse Printing.......................................................................................................................26

7.4. Dot History Factor...................................................................................................................26

7.5. Multi-Strobe Factor .................................................................................................................26

7.6. Print Density Adjustment.........................................................................................................26

8. Troubleshooting..............................................................................................................................27

9. Maintenance....................................................................................................................................27

10. Repair and Support.....................................................................................................................27

11. Buying Paper ..............................................................................................................................28

11.1. Sourcing Paper .......................................................................................................................28

11.2. Converting Paper ....................................................................................................................28

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 5 of 33

11.3. Black Mark Sensor Locations ...................................................................................................28

12. Technical Specifications..............................................................................................................30

12.1. General Specifications (X-56 and X-80) .....................................................................................30

12.2. X-56 Specifications..................................................................................................................31

12.3. X-80 Specifications..................................................................................................................31

12.4. Electromagnetic Compatibility ................................................................................................32

12.4.1. FCC Part 15 Class B Device...............................................................................................32

12.4.2. EN55022 –Emissions.......................................................................................................32

12.4.3. EN55024 –Electromagnetic Susceptibility........................................................................32

13. Spare Parts and Accessories ........................................................................................................33

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 6 of 33

1. Introduction

Thank you for selecting the Hengstler eXtendo® Thermal Printer! We are proud of this feature-rich product,

which was designed using all our expertise and experience, and we are confident that you will be pleased

with the advanced features and outstanding performance.

This Operator Manual is designed to help you with the proper installation, connection to your host

computer system and start-up of the eXtendo® thermal printer system. All necessary details will be

explained in the following sections. Please read this manual carefully before using the printer. If you have

any further questions, please do not hesitate to contact us.

The eXtendo® thermal printer family does not require any servicing and is intended primarily for printing

and cutting documents and receipts from continuous thermal paper. The X-56 version is for narrower paper

(49 –60 mm), while the X-80 handles wider paper (60 –86 mm). Various paper cutters are available to handle

a wide range of paper stocks up to 250 g/m² and more. Powerful motors allow the use of large paper rolls to

maximize time between paper replenishment. If documents are to be printed on preprinted forms or with a

predetermined length, 'Black Mark' control is available. The horizontal and vertical print density is 203 dpi

so that graphics, such as logos etc. can be printed with good quality.

The eXtendo® printer family has been designed for use in a wide variety of applications, including ticketing,

parking, banking, transit, reverse-vending, kiosk, car wash, fuel dispensing, and vending applications. In

order to provide the optimal cost/benefit ratio, the eXtendo® family of printers allows you to choose and buy

only the features that you need for your application! This extreme customization insures that you have just

the right amount of printer for your task; not too much, and not too little.

Available in both USB and Serial (RS-232) configurations, the eXtendo® printer family is one of the most

versatile we’ve ever produced! Driver software is available that supports Windows and Linux operating

systems. In addition, the printer can also be operated directly in ASCII mode through ESC sequences a

detailed description of which can be found in the eXtendo® Emulation Command Set Reference.

We’re glad you chose the eXtendo® thermal printer family. Once you’ve used it, we’re sure you will be, too!

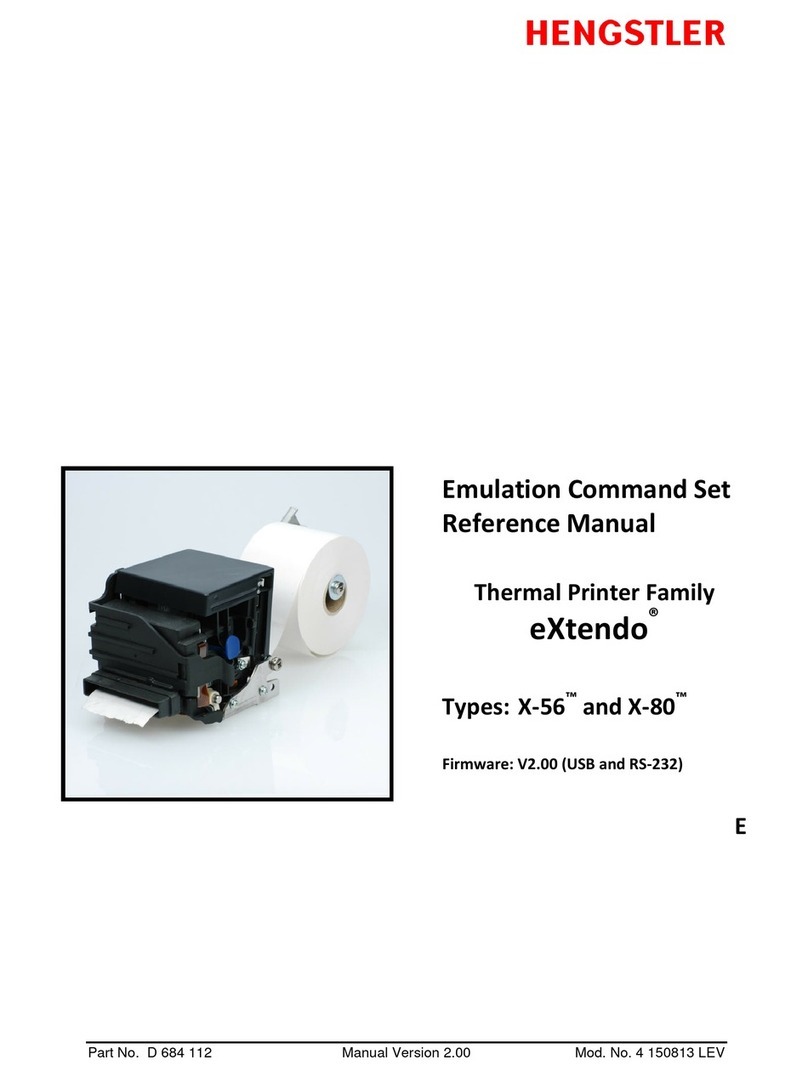

1.1.

Additional Documentation

1

Document No.

Description

D 684 112

eXtendo® Emulation Command Set Reference

D 684 128

eXtendo® Paper Specification

D 684 090

D 684 098

X-56 Dimensional Drawing –Twincut Cutter

X-56 Dimensional Drawing –Rotary Cutter

D 684 091

D 684 099

X-80 Dimensional Drawing –Twincut Cutter

X-80 Dimensional Drawing –Rotary Cutter

D 684 152

D 684 154

100 mm Paper Roll Holder Drawing

150 mm Paper Roll Holder Drawing

1

All listed documents can be found in the download area on our webpage under Thermal Printers. If any of these are

missing, please contact our technical support (section “

10 Repair and Support”

).

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 7 of 33

2. Important Information and Safety Instructions

Hengstler GmbH accepts no liability for any damages, direct, indirect or consequential, arising from

improper use of this thermal printer, and, in particular, due to non-compliance with this operating manual

or any other available documentation or due to improper handling or maintenance. Should Hengstler

GmbH choose to make technical documentation available, this does not imply any authorization, implied or

stated, for the making additions, repairs or modifications to this printer.

This documentation may not be copied, nor shall its contents be disclosed or used commercially unless

such use has otherwise been explicitly agreed to by a duly authorized Hengstler representative in writing.

The user is responsible for proper handling and installation of this printer. The printer should only be

shipped in its original packing.

2.1.

Systems Specific Safety Instructions and Symbols

The following symbols on the system and in the manual remind you to follow the relevant

safety instructions:

General warning for cases where the user or a service person may be in danger.

General notes and hints for operating the system safely.

Cross Reference

2.2.

General Information

Hengstler GmbH accepts no liability for the safe operation of the eXtendo® thermal printer family

unless Hengstler original products are used exclusively and the following instructions and

recommendations are heeded.

If unauthorized persons perform any repairs or modifications to the printer mechanism

and the controller, HENGSTLER will not accept any liability and the guarantee shall be

void.

Unapproved types of thermal paper may dramatically reduce the life of the print head and

may cause the guarantee to expire. For pre-printed thermal paper make sure that only

appropriate inks are used. Details can be found in the Hengstler Paper Specifications

document D 684 122.

The DC power connector must not be plugged in or disconnected under load in order to

avoid damage to the electrical components and the thermal printhead.

Avoid strong vibration, shock and impact since they may damage or destroy sensitive

electronic and mechanical components. Do not touch the surface of the printer control

board in order to prevent static electricity from damaging sensitive components.

This thermal printer must not be used near to high-frequency apparatus or strong

magnetic fields in order to prevent undefined magnetic disturbance.

Do not make any attempts to service this printer (e.g. change paper) while the printer is

printing.

Installing or uninstalling the printer must only be done while using adequate ESD protection.

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 8 of 33

3. Overview

3.1.

Overview of Thermal Printing Technology

A brief overview of thermal printer technology might be helpful to understand how the eXtendo®

thermal printer family works. In most direct thermal printers, paper is fed over a soft, rotating

platen and under the thermal printhead. The platen acts as a roller to advance the paper at the

same time it acts as a surface against which the spring-loaded printhead presses the paper to

insure good thermal conductivity. Circuitry in the printer determines which heating elements to

activate (“fire” or “burn”) to form the next row of dots on the paper.

The thermal paper is coated with several compounds. At room temperature, these compounds are

white in color and do not react with each other. The heat from the thermal printhead acts as a

catalyst in the areas where the small printhead dots are fired, causing these compounds to react

with each other and form a new compound which is a contrasting color, usually black. The platen

then advances the paper to the position of the next dot row, and the process is repeated.

You may note immediately several of the advantages of thermal printing. First, since the printing is

done with heat, there is no noise from the printing process itself. Thermal printing is inherently

quiet compared to most other technologies, such as impact dot matrix. Also, there is only one

moving element in the thermal printer: the platen. This provides increased reliability and life when

compared to other technologies.

3.2.

X-56 versus X-80

The X-56 and X-80 thermal printers are based on a single design concept and share many

components. The difference between them is primarily in the width of paper that they will print and

cut. The X-56 handles paper of between 49 and 60 mm in width, while the X-80 accepts paper from

60 to 86 mm wide. Narrower paper than the widest specified above is accommodated by the use of

paper guides to provide additional positional guidance.

This causes one specific minor difference between the two printers. The maximum paper width the

X-56 will accept is 60 mm, and paper guides are not needed for paper in this width range. 58 mm

and 60 mm paper widths are very common, and are considered standards. Paper guides are not

needed to handle these two paper widths.

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 9 of 33

The X-80 has a maximum paper width of 86 mm. While 86 mm wide paper may sometimes be used,

the most common larger paper widths are 80 mm and 82. 5 mm (3¼ inches). These do require a

paper guide to use. This is why the X-80 is always shipped with paper guides, since they are needed

for the most common paper widths.

3.3.

Functional View

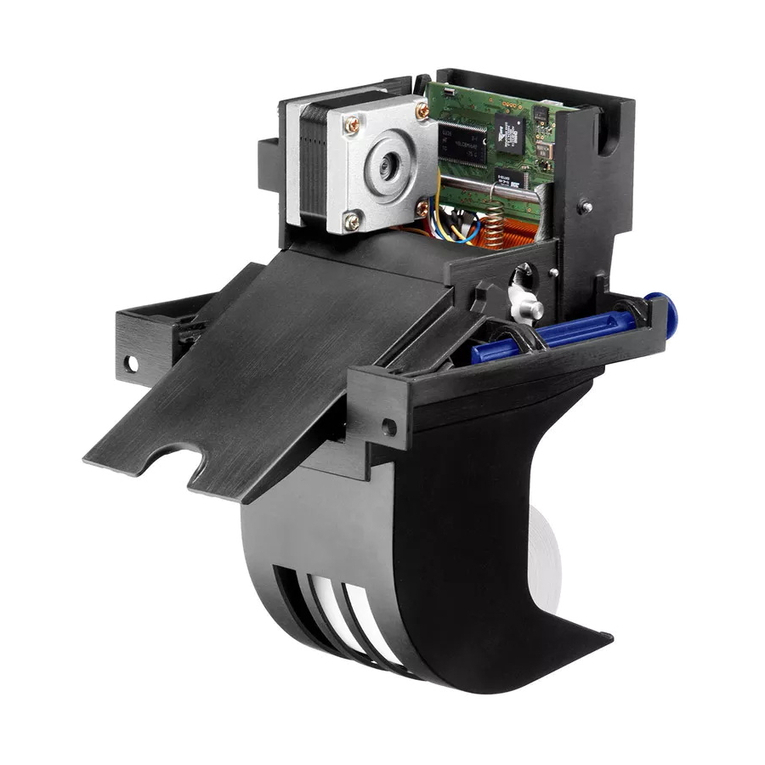

Figure 1

3.4.

Description of Components and Operation

There are several key components or modules to the eXtendo® family of thermal printers (Fig. 1).

The thermal printhead is positioned above the platen. The platen acts as a roller to advance the

paper at the same time it acts as a surface against which the spring-loaded printhead presses the

paper to insure good thermal conductivity. The interface, motor used to turn the platen, sensors,

printhead, and paper cutter are all connected to the controller, which controls all these

components to function at the proper time and which also communicates to the host. The cutter

separates the paper from the paper roll when instructed to do so. Several sensors monitor progress

as the printed document is created. All these items are mounted in a conductive plastic housing to

discharge any static and to provide electrical noise shielding.

The paper chute is a short chute protruding from the front of the printer. It snaps in and out without

tools. The paper chute should be present for most normal printing applications, but it should be

removed for applications where the printed document is expected to fall freely into a chute or other

pathway. In these cases, the chute may interfere with the free fall of the printed document.

The paper entrance sensor detects if paper is approached in the entry area. The controller causes

the motor to turn the platen to draw paper into the printer. As soon as the paper reaches the

platen, the paper is pulled under the printhead and printing can begin.

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 10 of 33

While printing, the paper continues to advance and enters the paper cutter, where it passes

between the cutter blades and out the print chute and passes the chute/jam sensor. Once printing

is completed, the paper is advanced and a command sent to the cutter to cut off the paper. The

paper then retracts to a park position to avoid wasting the paper between the printhead and cutter.

When the printer runs out of paper, the entrance sensor detects the fact. The controller then

immediately stops printing and backs the paper up so it protrudes from the back of the printer. This

is to allow the operator to raise the printhead, remove the partially printed document, and lower

the printhead before loading a new roll of paper. If this were not done, it would be possible for

short pieces of paper to remain in the paper path without the operator’s knowledge, eventually

causing an obstruction and a paper jam.

The chute/jam sensor located at the paper exit monitors whether there is paper in the chute. A

more detailed description of this sensor can be found in chapter 3.6.5.

3.5.

Location of Controls and Connectors

The following figures below show the locations of connectors, indicators and controls on the

eXtendo® series.

Figure 2 shows a USB version of the eXtendo® but also shows the alternative serial connector

when using a printer with RS232 serial interface.

Figure 3 shows the upper portion with details about the polarity of the power connector and

cable.

Figure 4 shows the opposite side of an eXtendo®, showing the Paper Advance Wheel and the

Paper Low and Auxillary Sensor connectors.

Please note that the Paper Pre-end/Paper Low Sensor connectors are optionally duplicated on the

wheel side of the printer to make connection convenient regardless of which side of the printer

might be near the cabinet side wall.

Figure 2

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 11 of 33

Figure 3

Figure 4

3.6.

Operation of Sensors and LEDs

3.6.1. Paper Entrance / Black Mark Sensor

The basic function of the paper entry sensor in the paper entrance area has been described

above. But the same sensor is also used to detect Black Marks. Black Marks are blackened

areas placed on the paper during the converting process. They are generally used, in

conjunction with appropriate printer commands, to advance the paper to a specific

position after each print job. One common reason for this is to so that preprinted

information is properly located with respect to information printed by the printer itself, for

example, printing inside a preprinted box. Black marks can be located on the thermally

coated side of the paper (where printing takes place) or on the back of the paper,

depending upon the location of the sensor.

The eXtendo® series of printers is designed to allow for numerous Paper Entrance/Black

Mark sensor locations during manufacturing (The location of this sensor cannot be

changed once the printer is built). Also, two different sensor types can be used. The most

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 12 of 33

common is the reflex or reflective sensor, where the light source and detector are located

on a single chip. Basically, the light strikes the white paper surface and reflects back into

the sensor. If enough light reflects to activate the sensor, the printer concludes that paper

is present. If there is not enough light reflected, the printer assumes that this area is black,

meaning the printer is on a black mark or the printer is out of paper. There are six (6)

different possible positions for this sensor in the X-56 and ten (10) in the X-80. Half of these

positions sense the coated side of the paper, while the other half sense the back of the

paper. The positions of these sensors are detailed in the Paper section of this document.

The eXtendo® can also use a through-beam sensor in OEM applications. This type of sensor

has a light source on one side of the paper and the detector on the other side of the paper.

When the light is blocked and cannot reach the detector, the printer concludes that paper

is present. When the light does reach the sensor, the printer concludes that there is no

paper present.

The through-beam sensor can also be used in a manner similar to a Black Mark sensor.

Instead of a Black Mark, a hole is used in the paper. The through-beam sensor is located on

the centerline of the paper path. This is the only location it may use.

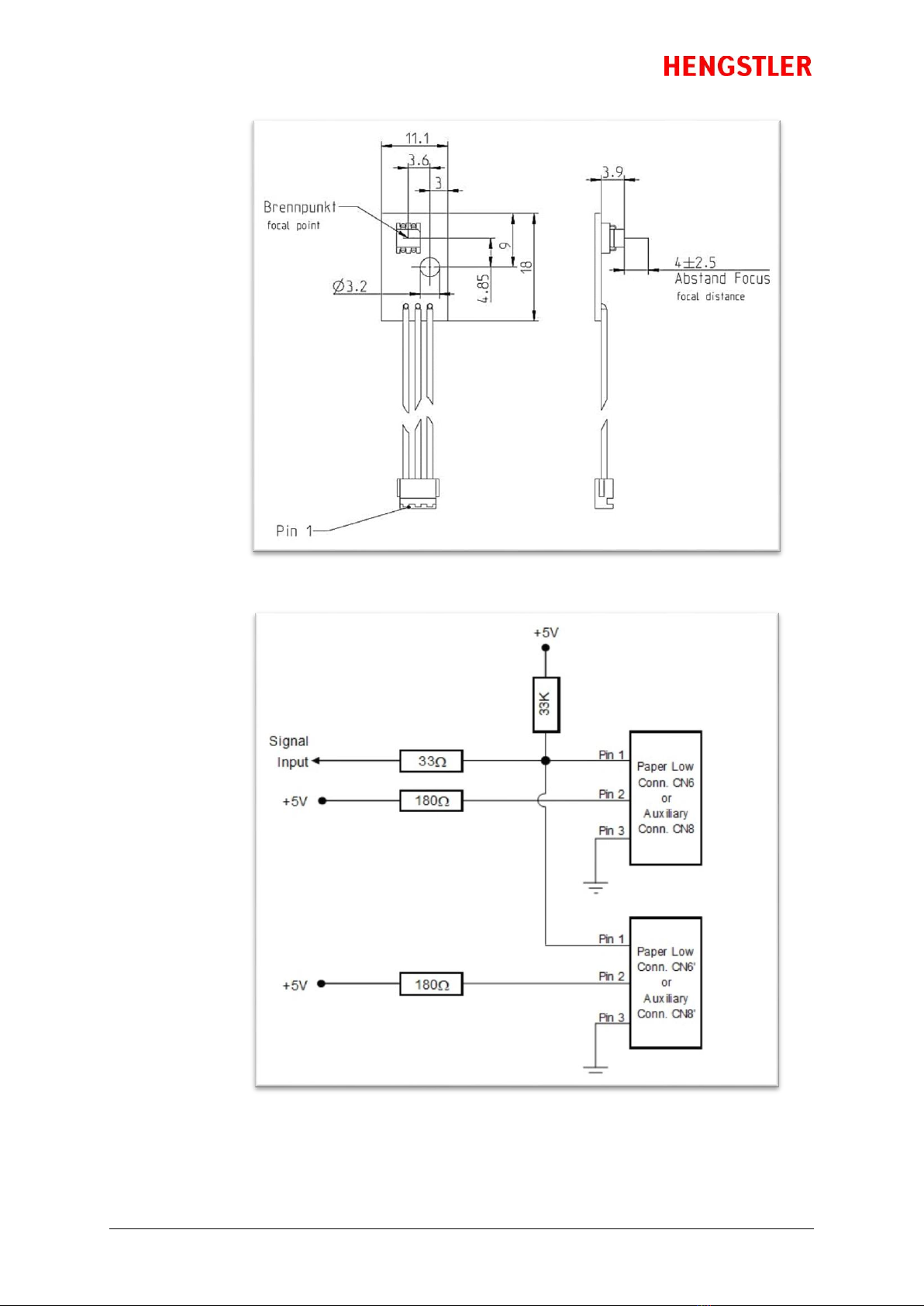

3.6.2. Paper Pre-End (Paper Low) Sensor Option

When ordered with the Paper Pre-End Sensor option, the eXtendo® will be shipped with a

paper pre-end sensor to be mounted by the customer. The sensor is a reflex type, meaning

that it senses paper by bouncing light off the paper and detecting its reflection. The sensor

is equipped with a 300 mm long cable to allow flexible mounting by the customer, and the

sensor itself is mounted on a small printed circuit board with a hole to be used for

mounting it. Simply mount the sensor where it will detect paper low (it is often mounted

facing the side of the paper roll, so that as the diameter of the paper roll decreases, it

eventually loses the reflection of the light and changes state), and plug the PPE sensor into

the upper sensor connector on the control board. While the exact distance of the sensor

from the paper varies from application to application, it is typically 2-5 mm for optimal

sensing.

If the printer with a paper roll holder is ordered, the sensor comes pre-mounted to the

paper roll holder and with the sensor connector plugged into the eXtendo® controller

board. Figure 5 below shows the PPE sensor itself, while Figure 6 is the input circuit to the

Paper Pre-End (Paper Low) input.

The lower sensor connector is for an Auxiliary Sensor, which can be mounted as desired by

the customer. The status of this sensor or it input voltage reading will be reported when

the printer’s status is requested via the interface. The Auxiliary Sensor connector is located

below the Paper Pre-End (Paper Low) Sensor connector.

Figure 6 shows the input circuit for these sensor connectors (Fig. 6 represents the circuit for

either the Paper Low or Auxiliary Sensor; these two inputs are wired identically). Please

note that each sensor input can have two connectors, a second one on the wheel side of

the printer. The Paper Pre-End (Paper Low) Sensor connectors are designated CN6 and

CN6’, while the Auxiliary Sensor connectors are CN8 and CN8’.

Note: Only one connector of each pair (for example, CN6 and CN6’) should be connected at

one time.

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 13 of 33

Figure 5 –Paper low sensor

Figure 6 –Sensor Input Circuit

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 14 of 33

3.6.3. LED Indicators

There are two LED indicators in the eXtendo® series printers, located as shown in Fig. 2 and

Fig. 3. The upper LED is red, and the lower one is green. These LEDs are used to signal

various status information concerning the eXtendo® printer. There are several flashing

speeds used in the printer LEDs. These are:

Slow: 0.5 Hz (LED is “on” for one second and “off” for one second)

Medium: 5 Hz (“on” for 100 ms and “off” for 100 ms)

Flicker (F): 10 Hz (“on” for 50 ms and “off” for 50 ms)

0: (off for 1 second)

1: ( on for 1 second)

Green

LED

Red

LED

Meaning

Slow

Off

Paper is loaded. Normal operation. Printer ready.

Medium

Off

Out of paper

Flicker

On

Data upload in progress (fonts, images, firmware, not

normal data communication). Do NOT disconnect or

power the printer off!

F 0F

On

Printhead raised, printer stalled or over voltage

F 010F

On

Paper error

F 01010F

On

Cutter error

Off

On

Boot failure

Flicker

Flicker

Initialization error

On

On

System “hung” during initialization

Please note that much more detailed information concerning the printer’s current state

and sensor conditions can be obtained by requesting the printer’s status ( eXtendo®

Emulation Command Set Reference D 684 112) or by using the eXtendo® Diagnostic Tool.

3.6.4. Printhead Status Sensor

An additional Head Status Sensor is used to determine whether the printhead is in the up

(do not print) or down position (ready to print). Normally, most of the heat generated by

thermal printing is transferred to the paper being printed and so is removed from the head

as the paper advances. When the printhead is in up position no printing or paper loading is

possible.

The output of this sensor as well as the current printhead temperature is also available

from various query functions.

3.6.5. Chute/Jam Sensor

The chute/jam sensor continually monitors whether there is paper in the chute, and can be

read via the Status function. This function is often used in conjunction with the host’s

peripherals to signal the user when a printout has not been taken. Examples where this is

important include when the information is confidential, or the printout can be redeemed

for cash or items of value. This function can also be used to prevent the host from sending

a new print job until the printout from the previous print job has been removed.

Additionally, the chute/jam sensor is monitored while first printing after a cut. After a cut,

the printer “knows” where the end of the paper is. As printing takes place, the printer also

“knows” when the edge of the paper should reach the sensor. If the paper does not reach

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 15 of 33

the sensor when expected, the printer assumes that a paper jam has taken place and

signals this fact via the Status command.

Note: Care must be taken when mounting the eXtendo printers to insure that the sensor is

not exposed to direct sunlight. The multiple wavelengths of sunlight can cause false

readings from this sensor. Therefore, always shield the chute and sensor from direct

sunlight by the use of chutes, shrouds, covers and similar techniques.

3.7.

Graphic Printing vs. Printing with Printer’s Fonts

One area that causes frequent confusion with regard to printers in general is that of graphic

printing versus printing using the printer’s internal fonts. An explanation here may help clarify this

and make application of the eXtendo® easier for you.

All printers contain a set of commands that will cause the printer to perform different functions (For

the eXtendo® family of thermal printers, these commands are documented in the eXtendo®

Emulation Command Set Reference, p/n D 684 112). The functions are very diverse and there are no

standards for what these functions may be. This allows printer manufacturers to innovate and build

unique features into their products. These commands are often referred to as the printer’s “Native

Commands”.

A printer’s Native Commands are of many different types, but a few are of particular interest to us

here. One is the family of commands for printing graphics. It is these commands that allow pictures

and other graphic images of any type to be printed.

Another family of commands of interest to us here is the text commands. These commands involve

printing text in response to ASCII data sent to the printer. The printer itself contains one or more

character sets. In these character sets, one printable character corresponds to one ASCII character.

There are also commands for positioning and modifying the printout from these character sets,

such as tab and indent commands and commands to enlarge the internal characters by some

factor.

When printing from the internal character sets (we’ll call that “ASCII printing” here for

convenience), characters are sent to the printer and the corresponding characters from the

character set are printed. This has both advantages and disadvantages. The biggest advantage is

that the host need only send one character per printed character. So if 40 characters are being

printed on a line, for example, only 40 bytes of data (plus any overhead for formatting, indenting,

etc.) need be transmitted over the interface. In other words, you can print a lot of text and need

send only a little data. The downside is a lack of flexibility. In today’s Windows® world, we are all

used to printing exactly what we see on our computer screens, in the same font, size, etc. as we see

it. But with ASCII printing, what will be printed will be based on the printer’s internal character set.

The other type of printing we’ll call “Graphic printing”. This is what happens when you print to an

ink jet or laser printer from your PC. The information displayed on the screen is sent to a print

driver. This print driver, which is unique for each printer, translates what is on the screen as a

graphic into graphic Native Commands to be sent to the printer. Everything printed through a

print driver prints as graphics. It takes a lot more data to transmit graphics than to transmit ASCII.

In our 40 character example, assuming a 12 x 20 pixel character, the eXtendo® X-80 printer would

require 1,600 bytes (80 bytes/dotline * 20 dotlines) to print one “text” line (please note that these

are estimates, and that various compression routines also impact the amound of data bytes).

The advantage of Graphic printing, then, is the ability to print anything; pictures, text, photos, etc.

exactly as you see it on your screen. The disadvantage is that to do so, much more data must be

sent over the interface.

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 16 of 33

If you are doing ASCII printing, you can use USB or a serial interface. Both are fast enough to handle

the smaller amount of data being sent. But if you are doing Graphic printing, USB may be the better

choice due to its higher speed, and serial may increase the time to complete a printout to an

unacceptably long period.

3.8.

Features Selected at Time of Order

One of the strengths of the eXtendo® family of thermal printers is that it allows the designer to

select the features needed, rather than settling for performance less than desired or having to pay

for features that will never be used. The current set of available options is listed below.

Feature Description

Option 1

Option 2

Option 3

Basic Unit

X-56

X-80

Communications

Interface

USB

Serial (RS-232)

Cutter

Twincut, Full and

Partial Cut, up to

120 g/m²

Twincut, Full Cut Only,

up to 160 g/m²

Rotary, Full Cut Only,

up to 250 g/m²

Environmental Range

0 to +50ºC

25% to 80% RH,

non-condensing

-25 to +70ºC

20% to 100% RH

Voltage

24 VDC

12 VDC (only for X-56)

Paper Entry Sensor

Default BM Sensor

location:

Pos. 6 for X-56

Pos. 10 for X-80

(BM = black mark)

BM sensor located at

one of the positions

shown in Figure 13

Through-beam Sensor

in center position

Paper Guides1)

Note: Standard on X-80

Not included

Included

(2 pcs in a little bag)

Paper Roll Holder1)

(including a Paper Pre End

Sensor)

Not included

100 mm roll mounted

on data connector side

100 mm roll mounted

on gear side

150 mm roll mounted

on data connector side

150 mm roll mounted

on gear side

Paper Chute1)

Included

Not included

Paper Pre-End Sensor1)

Not included

Included

(12 inch cable)

Extended Warranty

Not included

3 year warranty

Other warranty

conditions on demand

1)

These components can also be ordered separately as accessories. See section “Spare Parts and

Accessories”.

Due to the wide variety of options possible, it is necessary to be able to identify what features are

included in each printer. Some features, such as the cutter or PPE sensor, are visually obvious.

Other features such as software configuration and extended warranty, are not. Therefore, this data

is stored as a code in each printer when it is manufactured.

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 17 of 33

5. Installation

5.1.

Unpacking

Care should be taken when unpacking your eXtendo® printer to preserve the packing material for

possible future use. eXtendo® packing is specifically designed to protect the printer from damage in

the harsh environment of trucks and aircraft.

Please be sure to use this packing if it ever becomes necessary to reship your eXtendo® unit.

5.2.

Function

Please note that the eXtendo® printer is a module designed to be integrated into a system and to be

operated only as a part of that system, for example, in a kiosk. All technical specifications and

instructions contained in this manual and related documentation must be considered and

complied with in order to achieve successful operation in the completed system.

5.3.

Mounting Printer

The eXtendo® printer is built with four mounting holes for mounting from below, and four holes for

mounting from the side. These holes are molded into bosses which are part of the plastic frame.

Due to the very tough nature of the plastic used for the eXtendo®, we recommend the following

screws for mounting the printer.

Side Mounting Holes: EJOT Delta PT30, max. penetration into the printer 8 mm

Bottom Mounting Holes: EJOT Delta PT40, max. penetration into the printer 8 mm

These screws are available from Hengstler as a “mounting kit” to simplify your sourcing needs. Hole

layouts (viewed from above the printer) for mounting the X-56 and X-80 models with screws from

underneath are shown below. Please refer to the drawings specified in section 1. 1 for more

detailed dimensions and mounting hole locations for mounting from the side.

Figure 7a –X-56 Figure 7b –X-80

Note: The eXtendo® printer is designed with a cutter cover (cutter bracket) that is hinged and can

be tilted down to gain access to the cutter. However, the printer is designed such that this cover can

be tilted down only if the printer is mounted at the edge of a shelf (Fig. 8). Attempting to lower

this cover if the printer is back from the edge on a flat surface will likely damage the cutter cover!

Please be aware of this when selecting your printer mounting location.

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 18 of 33

Figure 8

5.4.

Installing Paper Guides

Depending upon the model and the options ordered, the eXtendo® family of thermal printers may

come with a pair of paper guides. Since the paper guides are only used for certain width papers,

and should not be used with other widths, they are not installed at the factory. Paper guides should

be utilized as follows.

Paper Width Paper Width

No. of Guides X-56 X-80

none 58-60 mm 84-86 mm

one 55-57 mm 81-83 mm

two 49-54 mm 60-80 mm

Use the following procedure to install paper guides. Please note that the cover has been removed

from the printer to make it easier to see the paper guide area.

1. Locate the paper guides in a small bag packed with the printer and remove them. Note that the

slotted, funnel-shaped opening it oriented towards the printer, and that the extended arms of

the paper guide (Fig. 9) should point towards the middle of the printer. The paper guides are

symetrical and can be use on the left and right side equally.

Figure 9

2. Note that the paper guide has four tabs that are intended to engage the printer. Two tabs are at

the end of the arms, and two tabs are near the slotted “funnel”. Locate the slotted area at the

back of the printer (Fig. 10). Position the tabs on the funnel end in the middle of the slotted

area of the side in which you will mount them, making sure to be clear of the gear teeth molded

into the printer, then press down until these two tabs snap into place.

Printer should not be

located further back

from edge than shown to

prevent interference

when pivoting the cutter

bracket

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 19 of 33

Figure 10

3. Slide the paper guide all the way to the outer edge of the slotted area. Press on first one, then

the other of the arms to snap these two tabs into place.

4. The paper guide is now installed. Push or pull on the end of the paper guide to position it where

desired (Fig. 11). You will hear the paper guide click as it locks into each position.

Figure 11

5.5.

Wiring

5.5.1. Power

Power is connected to the eXtendo® thermal printer via a JST connector. The connector

consists of a JST VHR-2N (RA 3. 96) shell and two SVH-21T-P1. 1 contacts. Wiring is as

follows:

Pin Function

1 0 VDC/GND (-) (blue )wire

2 24 VDC (+) (red wire)

The upper contact on the connector is common; the lower contact is the positive (+)

voltage (Fig. 3).

Note: USB GND and power GND are connected to each other.

5.5.2. Data Interfacing

Serial

The printer is shipped with the following serial settings as default: 115,200 baud, 8 data

bits, one stop bit, no parity, hardware flow control, and host transmission not blocked (this

last feature is intended for use with lower sophistication hosts that cannot read the

eXtendo® printer’s status data. It uses the hardware handshake lines to prevent the host

from sending more data if the printer registers “paper out”).

eXtendo® Thermal Printer Family

Part No. D-684-124 Mod. No. 4 270919 HW1 page 20 of 33

The serial versions of the eXtendo® printer use a JST ZHR-6 connector shell with

JST SZH-002T-P0.5 contacts to make the RS-232 connection. Hengstler can provide a serial

cable for direct connection to PCs with a DB-9 connector on one end (section

13 Spare

Parts and Accessories

). Connections are as follows, should you decide to make your own

connectors.

Serial Pinout

DB-9 female ZHR-6

Pin # Pin# I/O Function (Printer view)

8..........................1 RTS\

7..........................2 CTS\

5..........................3 GND

(internally connected to 0 VDC)

2..........................4 TXD\

3..........................5 RXD\

-- 6 n/c (leave unconnected)

1 n/c

4 jumper to pin 6

6 jumper to pin 4

9 n/c

Shell Earth Ground

Please note that the Hengstler cable is supplied with a flying pigtail on the printer end. This

pigtail is intended to be fastened under the grounding screw, as shown in Fig. 2, to provide

maximum reduction of radiated electrical noise.

For additional protection against accidental cable removal, the cable tie-downs (Fig. 2)

are provided as a point to which you may fasten cables using cable ties (not provided).

USB

The USB versions of the eXtendo® printer employ a standard digital camera USB interface

cable (5 pin Mini-B connector on the printer end) to communicate with the host. Be sure

that the Mini-B connector is fully engaged with the mating connector on the printer. The

other end of the cable plugs into a USB port on the host.

USB Pinout

Pin

Number Signal name I/O Function

1 NC no connection

2 D- I/O Data -

3 D+ I/O Data +

4 NC no connection

5 SGND I/O Signal Gnd

(internally connected to 0 VDC)

Please note that the shell of the USB connector automatically makes a connection to the

earth ground screw as shown in Fig. 2.

Other manuals for eXtendo X-56

2

This manual suits for next models

1

Table of contents

Other Hengstler Printer manuals