H.E.R.O. Industries PW-3540-AC Pressure Washer Owners Manual

Page 10

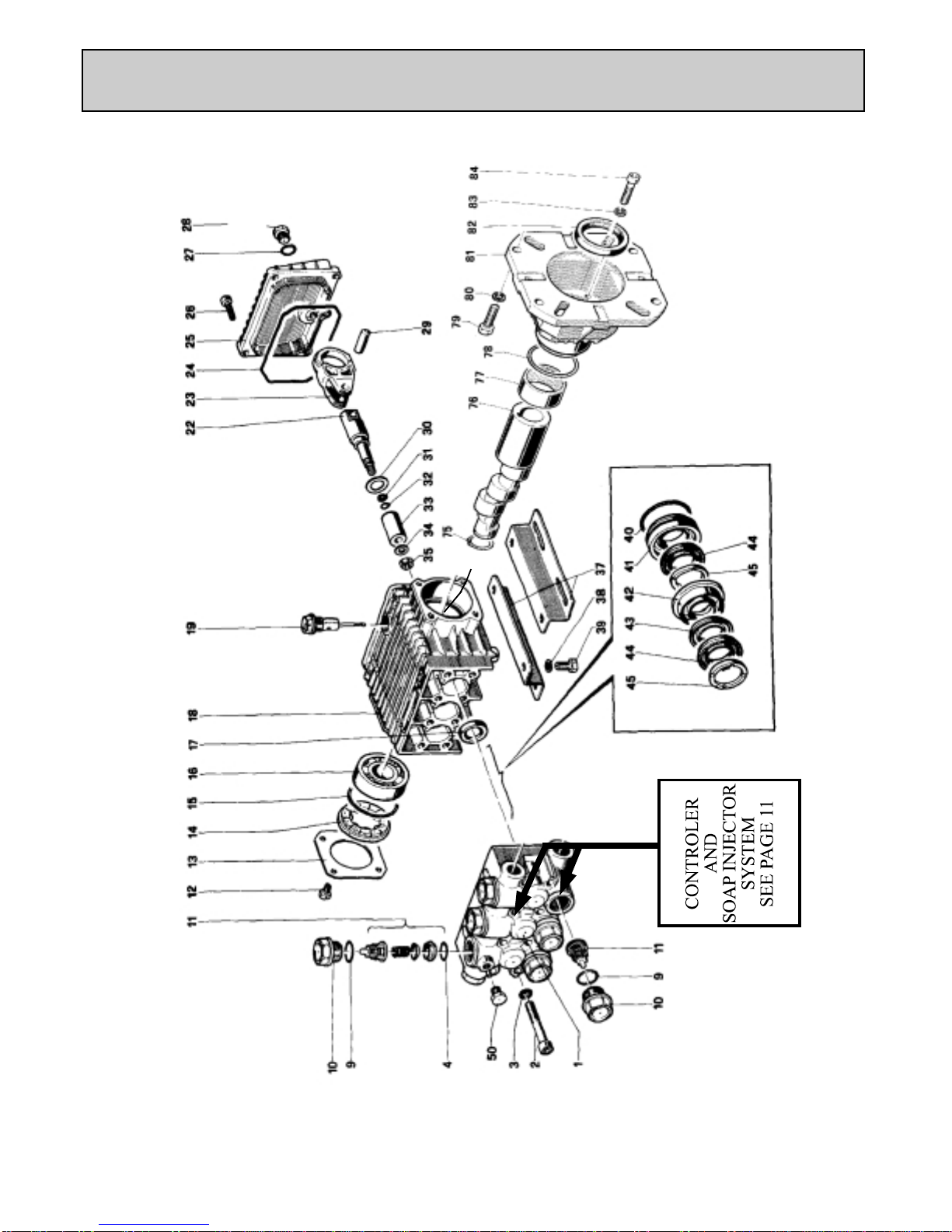

33 PW-44.0402.66 Plunger ( Ø 13 Piston ) 3

37 PW-50.2000.74 Foot 2

38 PW-96.7016.00 Washer 4

39 PW-99.3037.00 Screw 4

40 PW-90.3612.00 O-Ring

Kit 125, 130, 152 - 156 3

41 PW-44.0803.70 Packing Retainer Ø 13 Kit 152, 156 3

42 PW-44.2162.70 Intermediate Ring Ø 13

Kit 154 – 156 3

43 PW-90.5076.00 Backup Ring Ø 13 Kit 153 – 156 3

44 PW-90.2602.00 Packing Ø 13 Kit 153 – 156 3

45 PW-44.10002.51 Head Ring Ø 13 Kit 155 – 156 3

46 PW-98.2100.00 Cap 1

47 PW-98.2176.00 Cap 1

48 PW-96.7380.00 Washer 1

49 PW-96.7514.00 Washer 1

50 PW-98.1966.00 Cap 1

51 PW-90.2603.00 Low Pressure Seal Ø 13

Kit 153 – 156 3

52 PW-1075 Valve, Thermal Protection, 1/2, 1

53 PW-1405 Tubing, P.R.V. 1

75 PW-90.0635.00 Circlip 1

76 PW-44.0221.65 Crankshaft, WW965, 1

77 PW-91.8568.00 Bushing 1

78 PW-90.4097.00 O-Ring 1

79 PW-99.2755.00 Screw 4

80 PW-96.7020.00 Washer 4

81 PW-10.0518.22 Motor Flange 1

82 PW-90.1690.00 Oil Seal 1

83 PW-96.6938.00 Washer 4

84 PW-99.1912.00 Screw 4

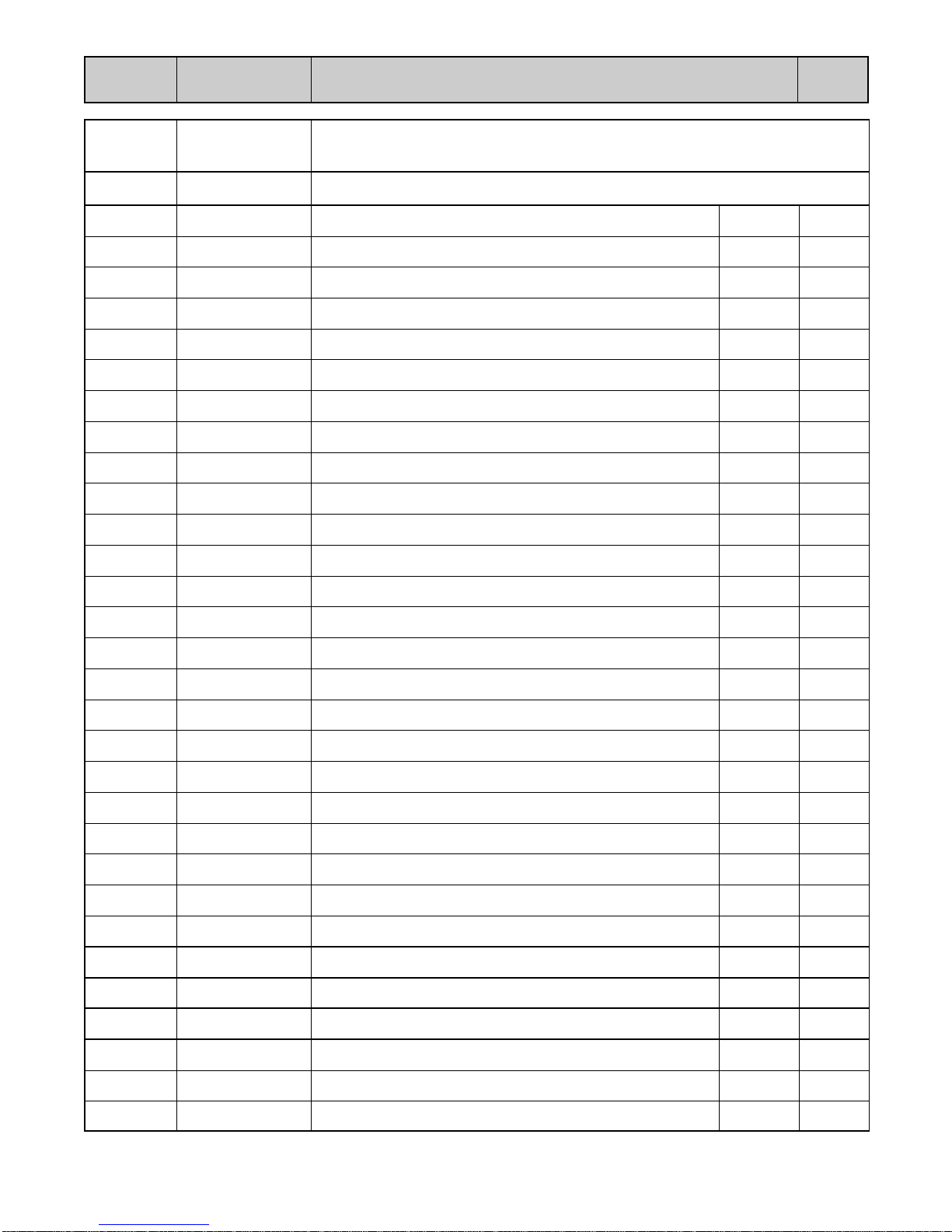

REF # PART # DESCRIPTION QTY

Part # Description Kit Ref# Included # Pieces

PW-RKI023 Repair Kit, Oil Seal, 2500, 3000 23 17 3

PW-RKI123 Repair Kit, Valve, 123 4,5,6,7,8,11 6

PW-RKI124 Valve Cap ( Brass ) & O-ring, 124 9, 10 6

PW-RKI125 Low Pressure Brass Ring & O-Ring 125 40, 41 3

PW-RKI152 Repair Kit, Packing, 13mm, 152 40, 41 3 each

PW-RKI153 Repair Kit 153 43, 44, 51 3 each

PW-RKI154 Repair Kit 154 42 3 each

PW-RKI155 Repair Kit 155 45 3 each

PW-RKI156 Repair Kit 156 40, 41, 42, 43, 44, 45, 51 3 each