Herutu WCL-426R User manual

LAN Connection TypeAndon Receiver

WCL-426R

INSTRUCTION MANUAL V1.30

Please use this operation manual correctly on reading well.

Please keep it carefully to be able to read immediately, when required.

Table of Contents

1.Overview..................................................................................................................................... 1

1-1.Introduction ......................................................................................................................... 1

1-2.Main Unit and Accessories ................................................................................................ 1

1-3.Safety Precautions (Be Sure to Read This)...................................................................... 2

1-4.Outline.................................................................................................................................. 4

2.Specification............................................................................................................................... 5

2-1.Radio Part Specification..................................................................................................... 5

2-2.General Specification ......................................................................................................... 5

3.Part Names and Descriptions................................................................................................... 6

4.Drawing....................................................................................................................................... 7

5.Prepare to Start Communication.............................................................................................. 8

5-1.Installation of "Device Installer"........................................................................................ 8

5-2.Factory Default IP Address................................................................................................ 8

5-3.IP Address Settings and Procedure.................................................................................. 8

6.Settings..................................................................................................................................... 15

7. Communication Command Function..................................................................................... 17

7-1.Information Acquisition Command................................................................................. 17

7-2.Setting Command ............................................................................................................. 17

7-3.Command Execution Result............................................................................................ 17

8.Installation Procedure............................................................................................................. 21

8-1.Receiver Installation......................................................................................................... 21

8-2.LAN connector .................................................................................................................. 22

9.Description of Operation......................................................................................................... 23

9-1.Basic Operation................................................................................................................. 23

9-1-1.Opening....................................................................................................................... 23

9-1-2.Receive Data from Transmitter................................................................................. 23

9-2.LED Monitor....................................................................................................................... 24

9-3.Processing at Power ON.................................................................................................. 26

10. After Service and Warranty ................................................................................................... 27

1

1.Overview

1-1.Introduction

This instruction manual describes the information required for using this product including overview,

installation, and operation of this product. Read this manual carefully before using this product. Keep this

manual handy so that you can take it out immediately.

▪Do not use this product for the application that may cause harm to human body or damage to other

devices and equipment.

Do not use this product near the devices that may malfunction due to radio waves emitted from this

product.

▪Because the communication performance is changed depending on the surrounding environment, be

sure to confirm the communication is established before installation of this product and then use it.

1-2.Main Unit and Accessories

■Receiver

Receiver main unit “WCL-426R”×1

AC adapter “ADB24050” x1

Cable Approx. 1.5 m

Antenna “TK-1842”×1

2

1-3.Safety Precautions (Be Sure to Read This)

This section describes the matters to be observed in order to prevent harm to the users and other persons

and damages to the property.

■The following marks and displays classify and describe the extent of harm and damage caused by failing

to observe the display content and using this product wrongly.

This display column shows "a failure to do observe it could result in death or

serious personal injury".

This display column shows "a failure to do observe it could result in only the

personal injury or property damage".

■Common matters in handling

●Avoid using this product in the humid or dusty place. Dusts or water enters the product,

which may cause the fault, fire, or electric shock.

■Handling this product

●This product is the wireless communication equipment made of precision parts. Do not

disassemble or modify it. Or the accident or fault may occur.

■Handling this product

●Do not use this product for application that requires the extremely high reliability affecting

the human life.

●Do not use this product in the area which the radio wave reaches or not.

■Handling the power supply

Be sure to observe the followings in order to prevent the accidents such as heat generation, damage, or

ignition ofAC adapter and power cord.

●Do not place the AC adapter and power cord close to fire or insert them into fire. Or they

may be burst and ignited, resulting in the accident.

●Use the AC adapter and main body only at the specified power supply voltage in order to

prevent burst and ignition accidents.

! Warning

! Caution

! Caution

! Warning

3

●Do not use the AC adapter and main body at the location where they easily get wet. Or the

accidents including heat generation, ignition, or electric shock and faults may occur.

●Do not touch the AC adapter, main body, power cord, and outlet with wet hands. Or the

accident such as an electric shock may occur.

●Do not damage the power cord. Short-circuit or heat generation may cause fire or electric

shock.

●Do not use the power plug with dusts attached. Short-circuit or heat generation may cause

fire or electric shock.

●Do not give a strong shock to theAC adapter.

Or the accident or fault may occur.

●If you find a deformation in theAC adapter, do not use it.

Or the accident or fault may occur.

●Do not charge the main body at the location where the flammable gas is generated.

Or the ignition accident may occur.

●Never disassemble the AC adapter.

Or the accident or fault may occur.

■Never disassemble the AC adapter.

Remove the power plug from the outlet because it may cause fire and electric shock. Request the dealer

or our company to repair it.

●When smoke comes or there is a strange smell, immediately stop usage and remove the

power plug from the outlet because it may cause fire and electric shock. Request the dealer

or our company to repair it.

●If the cord is damaged, do not use it. Using the cord damaged continuously may cause fire

or electric shock.

■Reliability of wireless communication

As wireless communication has properties that are different from those of wired communication,

communication errors may occur due to the following.

・Exceeds the communication distance.

・Enters a dead zone.

・Interfered by strong jamming

If signals are often jammed, or being jammed leads to operational problems, stop using the systems and

restart using the systems after removal of the cause.

Radio waves may not be received due to various reasons other than the above. Please understand this

before using the systems.

* A dead zone is an area where the radio wave transmitted from the transmitter becomes extremely weak

due to radio waves reflected from walls or other objects.

4

1-4.Outline

WCL-426R is a LAN connection typeAndon*1 receiver (hereinafter called “receiver”).

The receiver can wirelessly receive in real-time trouble occurrence reports transmitted from theAN426TⅡ

transmitter installed at the workstations and machines of the production line.

In addition, the receiver can externally output the received reports of trouble occurrence via LAN.

By utilizing and analyzing the information of trouble occurrences on the production line with applications on

computers, tablets and in the cloud, the receiver can be useful for visualizing and improving the operation

status of the production line.

Using the Windows application “Production Process Support Software for WCL Series WCL plus,” you can

save the trouble occurrence history received by up to 10Andon receivers in the CSV format.

1. At the transmitter, there are two selectable input methods for reporting trouble occurrences: one for

workers with four push-buttons (orange, red, green, and white) and one for machines with four external

inputs (orange, red, green, and white).According to possible trouble occurrences in the production line,

you can assign each color a meaning, such as red for an exception occurrence, orange for parts out of

stock, green for requesting transportation of finished products, or white for trouble solved.

2. When using the receiver linked to a wireless Andon seriesAN426Ⅱ, one receiver can wirelessly

communicate with up to 800 transmitters and a maximum of 10 receivers can be used in a factory. This

enables trouble occurrence reports to be collected from up to 8,000 locations in a factory.

When using the receiver with the transmitter without linking to a wirelessAndon seriesAN426Ⅱ, each

receiver can wirelessly communicate with up to 1,000 transmitters and a maximum of 10 receivers can

be used within a factory. This enables trouble occurrence reports to be collected from up to 10,000

locations in a factory.

*1:A system to notify management, maintenance, and other workers of a quality or process problem.

5

2.Specification

2-1.Radio Part Specification

Item

Specification

Frequency Band

426.0250MHz~426.1375MHz

Modulation Band

Direct 2-value FSK modulation

Modulation Speed

Approx.977bps

Channel Step

12.5kHz(Step 10Wave)

Antenna

External Whip Antenna

Communication

Method

Receive only

2-2.General Specification

Item

Specification

Interface

Ethernet IEEEE802.3 10Base-T/100Base-TX Auto switching

Connector: RJ-45 ×1

Indication for network 2-color LED ×2

Display

Red LED × 1 (Power supply monitor)

Red/Green 2-color LED × 1 (Monitor for wireless communication)

Red/Green 2-color LED × 1 (Monitor for wired communication)

Power Source

DC24V (Available at AC100-240V with supplied AC adapter.)

Current Consumption

Approx. 120mA

Operating

Environment

Temperature:0-+40℃(32-104°F)

Humidity:35-80% (without condensation)

External Dimensions

(W × H × D) 135 × 90 × 35mm (5.3 × 3.5 × 1.4″) (excluding protrusions)

Weight

Approx. 380g (13.4 oz)

Switches

2P DIP switch × 1 (For normal operation settings)

16P rotary switch × 1 (For channel settings)

Accessory

1 AC adapter, 1 Antenna

6

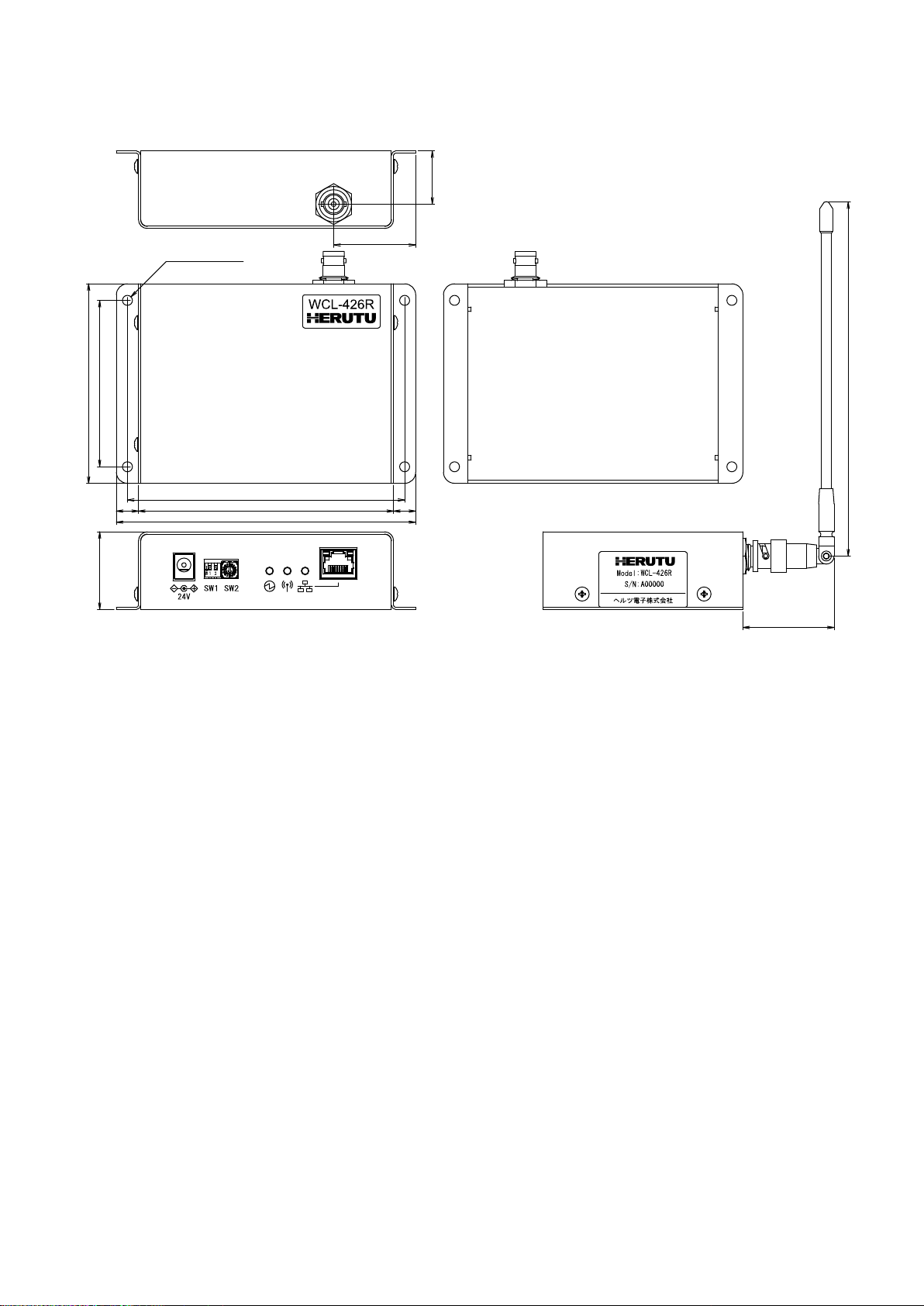

Setting switch

Connector for antenna

LED monitor

LAN Connector

DC jack

Mounting hole

3.Part Names and Descriptions

Name

Function

Connector for

antenna

Connector for connection to the antenna. (BNC-J Connector)

Attach the supplied antenna.

Mounting holes

Mounting hole of φ4.5 × 4

DC jack

DC jack for connection of the included AC adapter.

Setting switch

DIP switch and rotary switch for settings.

LED monitor

LEDs for power supply, wireless communication and wired communication.

LANConnector

Connector for LAN connection. (RJ-45)

7

24

37

90

75

4-φ4.5取付穴

125

115

135

10 10

35

(41)

(160)

4.Drawing

4-φ4.5 Mounting hole

8

Link LED

Activity LED

RJ-45

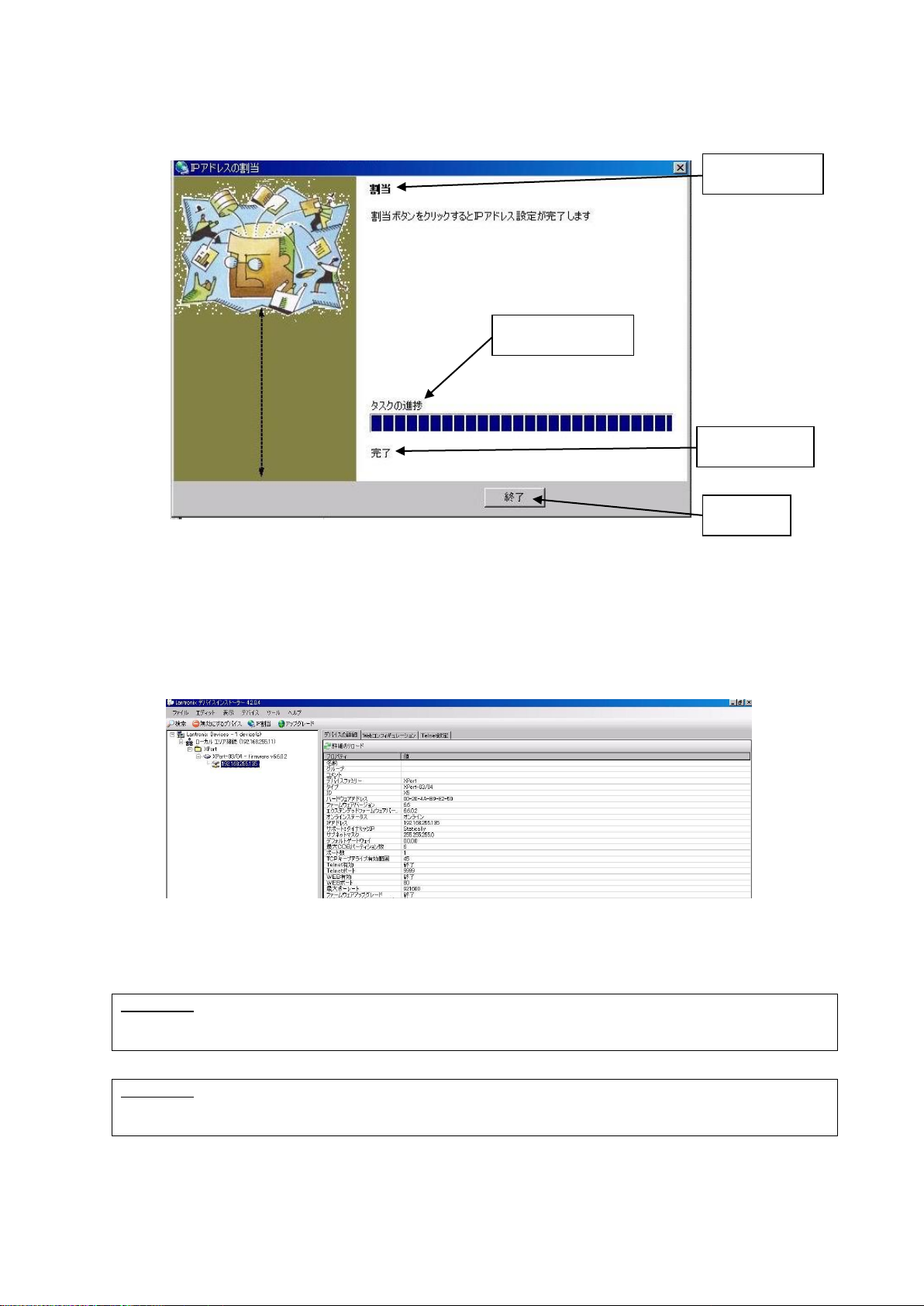

- Fig. 1 Screen to start Device Installer -

5.Prepare to Start Communication

Before use of the receiver, set each receiver according to the use environment.

Set the IP address and other required items of the receiver by using Lantronix’s Windows-based software,

“Device Installer”.

5-1.Installation of "Device Installer"

Download “Device Installer” from Lantronix’s WEB site (https://www.lantronix.com/products/deviceinstaller/)

to install it on your PC.

Connect the receiver to the HUB capable of communicating with the PC on which “Device Installer” is

installed.

CAUTION

To connect the receiver to the PC with “Device Installer” installed using a LAN cable, be sure to

use a cross LAN cable.

Check the left LED on the LAN connector (RJ-45) of the receiver to see if the Link LED is ON.

When connected to 10Base-T, the Link LED lights up in orange. When connected to 100Base-TX, the Link

LED lights up in green.

If the Link LED is not ON, the receiver cannot communicate with the network. Confirm if the LAN cable and

HUB are correctly connected.

5-2.Factory Default IP Address

The factory default IP address of the receiver is as follows:

IPAddress 192.168.3.100

Subnet Mask 255.255.255.0

Default Gateway 0.0.0.0

Port No. 50001

5-3.IP Address Settings and Procedure

Check that the power of the receiver is ON and that the receiver is properly connected to the HUB or PC,

and then start “Device Installer” from the start menu.

The connected receiver is displayed on the main window (Fig.1).

IP address of the receiver connected to the LAN

IP address

9

- Fig. 2 Select IP address of Xport to change -

- Fig. 3 IP address assignment -

To change the IP address, select the address of the X port on the left of the screen.

Click “IP assignment button”, and the screen is displayed as shown in Fig.3. Select to assign an IP address

automatically or specify an IP address directly. This document explains about specifying an IP address.

Check “Assign a specific IP address” and click the “Next” button.

IP assignment button

Select IP address to change

IP address assignment method

Automatic IP address acquisition

Allocation of specific IP address

Device details

Next

10

- Fig. 4 IP address input screen -

- Fig. 5 Assignment input screen -

Enter the IP address, subnet mask and default gateway.

*Before setting an IP address, obtain permission from the network administrator.

Click “Next” button.

Click “Assignment” button.

IP settings

IP address

Subnet mask

Default gateway

Next

Assignment

11

- Fig. 6 Input end screen -

- Fig. 7 IP address display screen after change -

When the setting is completed, the “Exit” button becomes active.

It may take some time before the setting is completed. Please wait until the setting is completed.

Click the “Exit” button, and the screen is displayed as shown in Fig.7. Confirm if the IP address has changed

properly.

CAUTION

If the IP address set by the customer is already used on the network, the signals will run into each

other. Set another IP address.

CAUTION

This product is intended to be used on a closed network that is not connected to the internet. Do

not use this product in an open network environment that is connected to the internet.

Assignment

Task progress

Completed

Finish

12

Navigate button

- Fig. 8 WEB configuration setting screen -

- Fig. 9 Password input screen -

■Change Password

The WEB screen (Web Manager) inside X port requires user authentication by password.

Change the default password in the following procedure.

CAUTION

Leaving the default password can cause a security risk to the product. Be sure to change the

default password.

Click the “WEB configuration” tab on the screen in Fig.7, and the screen in Fig.8 is displayed.

Click the “Navigate” button and the password entry screen in Fig.9 is displayed.

Please leave the user name blank.

Enter the following password. When the entry is completed, click the “OK” button.

Initial password NuM7?FrC@nVT8Z1Q

Web Configuration

User name

Password

13

“Server” button.

- Fig. 10 Web Manager initial screen -

On the “Web Manager” screen in Fig.10, click the “Server” button.

14

- Fig. 11 Server settings initial screen -

Click the “Server” button, and the “Server Settings” screen in Fig.11 is displayed.

①Set the “Enhanced Password” radio button to “Enable”.

②Enter a new password (up to 16 characters) in the “Telnet/Web Manager Password” field.

③Enter the same password as ②in the “Retype Password” field.

④Click "OK" button. If the passwords entered in ②and ③match, "Done!" will be displayed to the right of

the "OK" button. If the passwords entered in ②and ③are different, an error message "Passwords do

not match. Please retry again." is displayed. Retry ②and ③again.

⑤Click "Apply Settings" button.

When the process is completed, the password entry screen is displayed. Enter the set password and

press the "OK" button. (Please leave the user name blank.) If login is successful, the settings are

complete. Press the “x” button on the top right of the screen and the application exits.

CAUTION

When reconfirming the changes made to the settings, the changes may not be reflected in the

display. In that case, reboot the software (Device Installer) and check the changes again.

■About settings various parameters

Various parameters can be set on the WEB screen (Web Manager) inside X Port. However, do not change

the settings of the parameters. The default values are set to work properly.

①

②

③

⑤

④

15

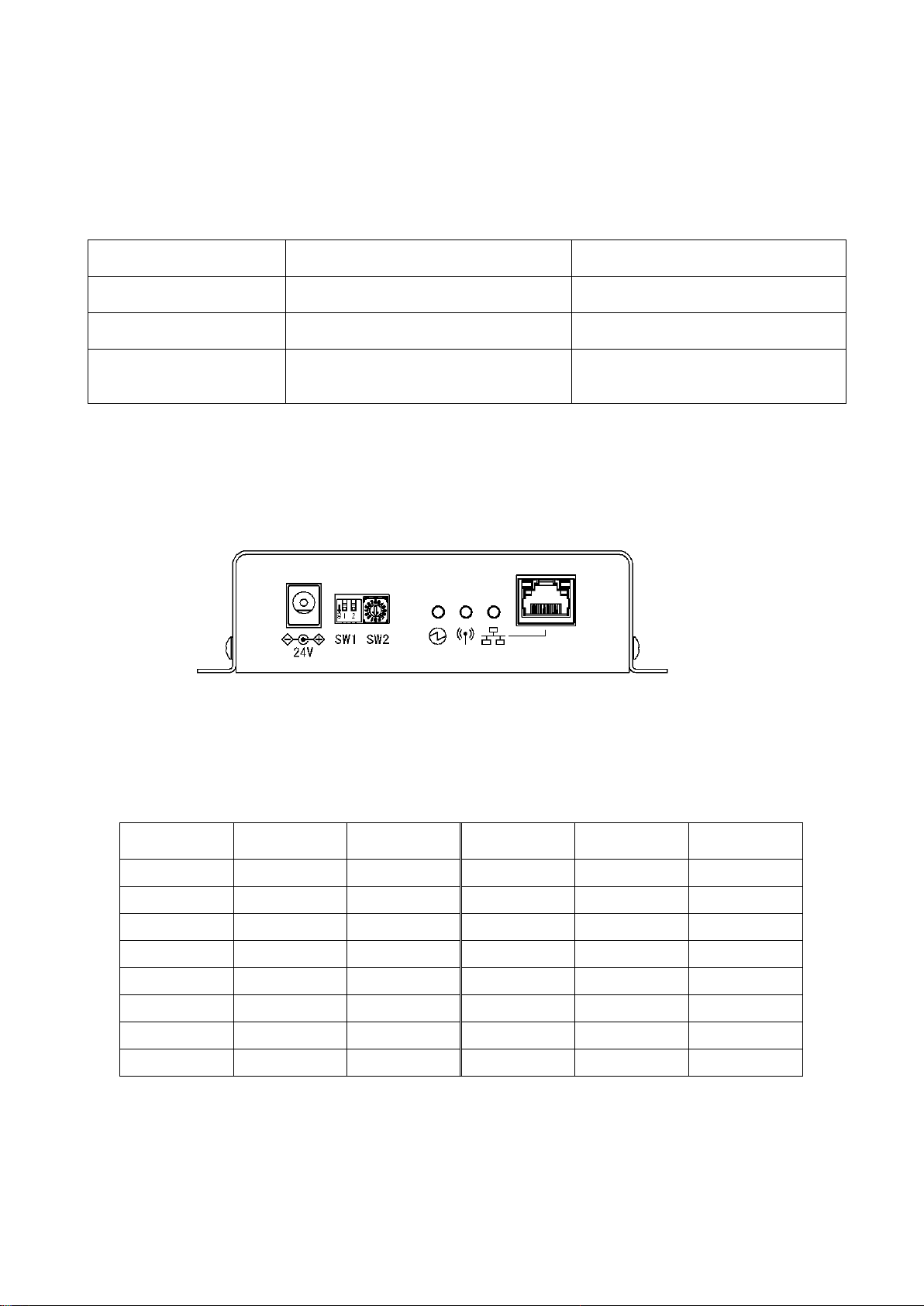

6.Settings

Use the rotary switch, DIP switches or Ethernet communication command to set the receiver.

Details of the settings and methods for changing the settings are as follows:

Turn OFF the power of the main unit before changing the settings of the rotary switch or the DIP switch.

Setting contents

Setting by switch

Setting by Ethernet communication

command

Channel settings

〇*1

〇*2

Ethernet communication

command settings

〇

×

Terminal code settings of

Ethernet communication

command

×

〇*2

*1: This setting is available only when the Ethernet communication command is set to “Invalid”.

*2: This setting is available only when the Ethernet communication command is set to “Valid”.

For the setting by the Ethernet communication command, refer to "7. Communication Command Function".

■Channel settings

Set the channel settings according to the transmitter that will communicate with the receiver.

< Channel >

SW2

Channel

Frequency

(MHz)

SW2

Channel

Frequency

(MHz)

1

1

426.0250

9

9

426.1250

2

2

426.0375

A

10

(426.1375)

3

3

426.0500

B

10

(426.1375)

4

4

426.0625

C

10

(426.1375)

5

5

426.0750

D

10

(426.1375)

6

6

426.0875

E

10

(426.1375)

7

7

426.1000

F

10

(426.1375)

8

8

426.1125

0

10

426.1375

*When A to F are set, 0 (channel 10) is set for the channel.

16

■Ethernet communication command settings

Select Valid/Invalid for the Ethernet communication command.

When this setting is “Valid”, the devices are set to the setting of the Ethernet communication command. The

settings are stored until the power is ON next time.

When this setting is “Invalid”, the devices are set to the setting of the rotary switch or the DIP switch.

When this setting is “Invalid”, the receiver returns an error response after receiving the Ethernet

communication command and the command will not be reflected as the setting of the device.

SW1-1

OFF

ON

Ethernet communication

command settings

Invalid

Valid

*SW1-2 is not available.

17

7. Communication Command Function

The Ethernet communication command allows information acquisition and device settings of the receiver to

be changed.

To use the Ethernet communication command function, “Ethernet communication command settings” of the

DIP switch, SW1-1 must be valid.

7-1.Information Acquisition Command

@?Command<Space>[Param]<Terminal code>

1

First code

“@?” Fixed (40H, 3FH)

2

Command

Command for acquiring each information

3

Space

If an argument exists, separate the argument with spaces

(20H).

4

Param (Argument)

If there are multiple arguments, separate them with”,” (2CH).

5

Terminal code

Use one of CR/LF/CRLF.

(Value set by the command for setting the terminal code.

The default value is CRLF.)

7-2.Setting Command

@Command<Space>[Param]< Terminal code >

1

First code

“@?” Fixed (40H)

2

Command

Command for each settings

3

Space

If an argument exists, separate the argument with spaces

(20H).

4

Param (Argument)

If there are multiple arguments, separate them with”,” (2CH).

5

Terminal code

Use one of CR/LF/CRLF.

(Value set by the command for setting the terminal code.

The default value is CRLF.)

7-3.Command Execution Result

<At normal termination>

When the setting command terminates normally, the command execution result is as follows:

<First code>Command<Space>OK<Terminal code>

1

First code

“@?” Fixed (40H)

2

Command

Command for each settings

3

Space

Separate Command and OK with a space (20H).

4

OK (Execution result)

“OK” (4FH,4BH) ASCII string

5

Terminal code

Use one of CR/LF/CRLF.

(Value set by the command for setting the terminal code.

The default value is CRLF.)

Table of contents

Other Herutu Receiver manuals

Herutu

Herutu POKAYOKE TWF-600R User manual

Herutu

Herutu TW-800R-MCL User manual

Herutu

Herutu WCL-920R User manual

Herutu

Herutu TW-800R-EXS User manual

Herutu

Herutu TW-800 Series User manual

Herutu

Herutu AN426RM II User manual

Herutu

Herutu TW-800R-EXS User manual

Herutu

Herutu TW-800R-EXP User manual

Herutu

Herutu TW-510R User manual

Herutu

Herutu TW-800R-EXL User manual