HES 8500 series User manual

8500 Series Electric Strike

Installation Instructions HES, Inc.

Phoenix, AZ

800-626-7590

www.hesinnovations.com

1

ASSA ABLOY, the global leader

in door opening solutions

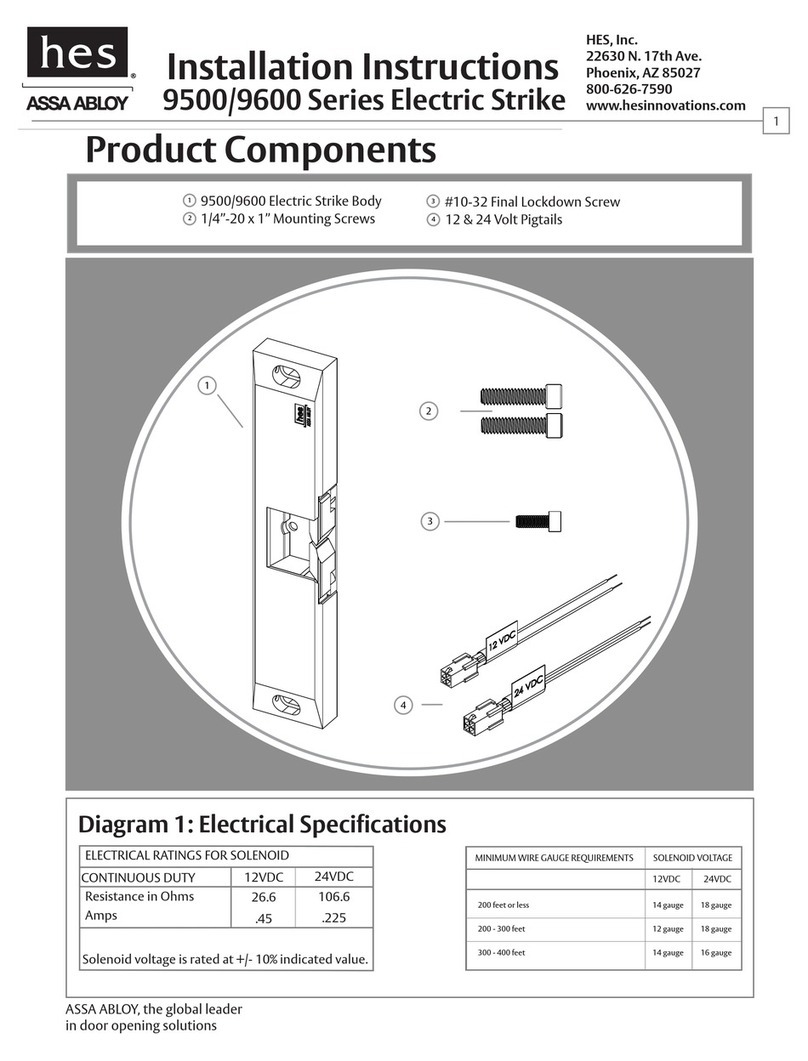

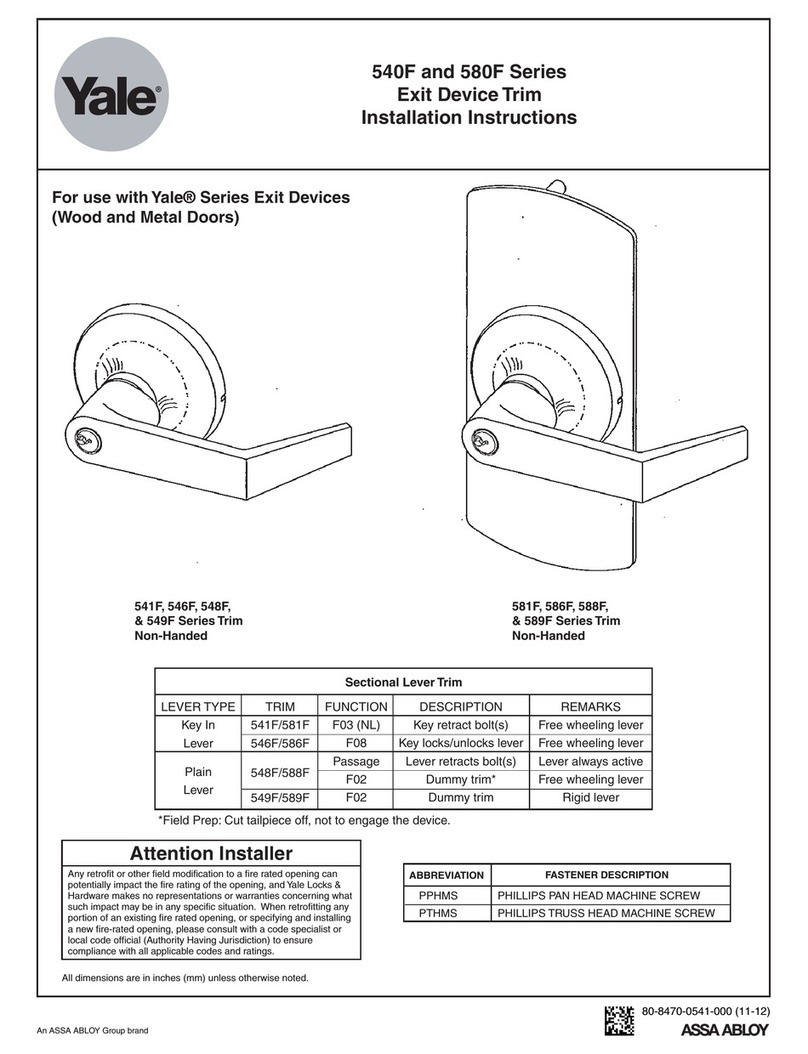

Product Components

1

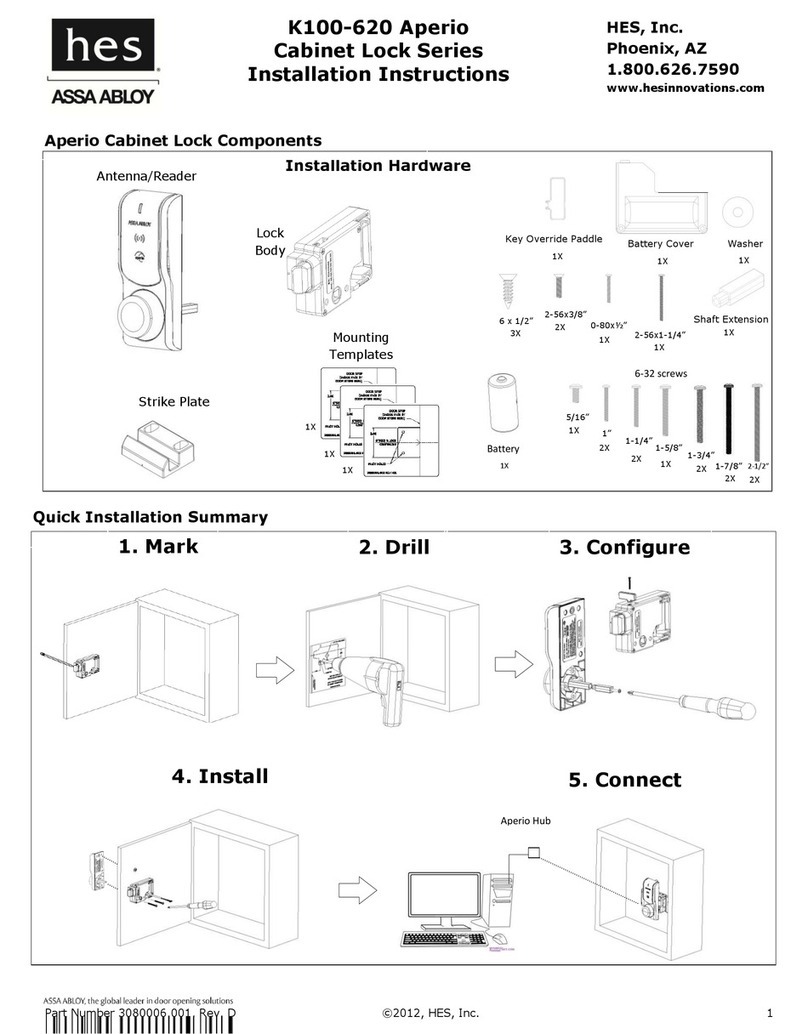

Electrical Specifications

MINIMUM WIRE GAUGE REQUIREMENTSSOLENOID VOLTAGE

12VDC 24VDC

200 feet or less

200 - 300 feet

300 - 400 feet

18 gauge

16 gauge

14 gauge

20 gauge

18 gauge

16 gauge

ELECTRICAL RATINGS FOR SOLENOID CONTINUOUS DUTY

12VDC

50

.24

24VDC

200 50 200

.12 .12

12-16VAC 24VAC

INTERMITTENT DUTY*

Resistance in Ohms

Amps

Solenoids are rated at +/- 10% indicated value.

*10% max duty cycle (2 min. max on time)

.24-.32

2

3

4

8500 Electric Strike Body

Horizontal Lockdown Shims

#4-40 Screws

3

12 & 24 Volt Pigtails

1

24

2

Installation Directions

CAUTION! Before connecting any device at the installation site, verify input voltage using a multimeter. Many power

supplies and low voltage transformers operate at higher levels than listed. Any input voltage exceeding 10% of the

solenoid rating may cause severe damage to the unit and will void the warranty.

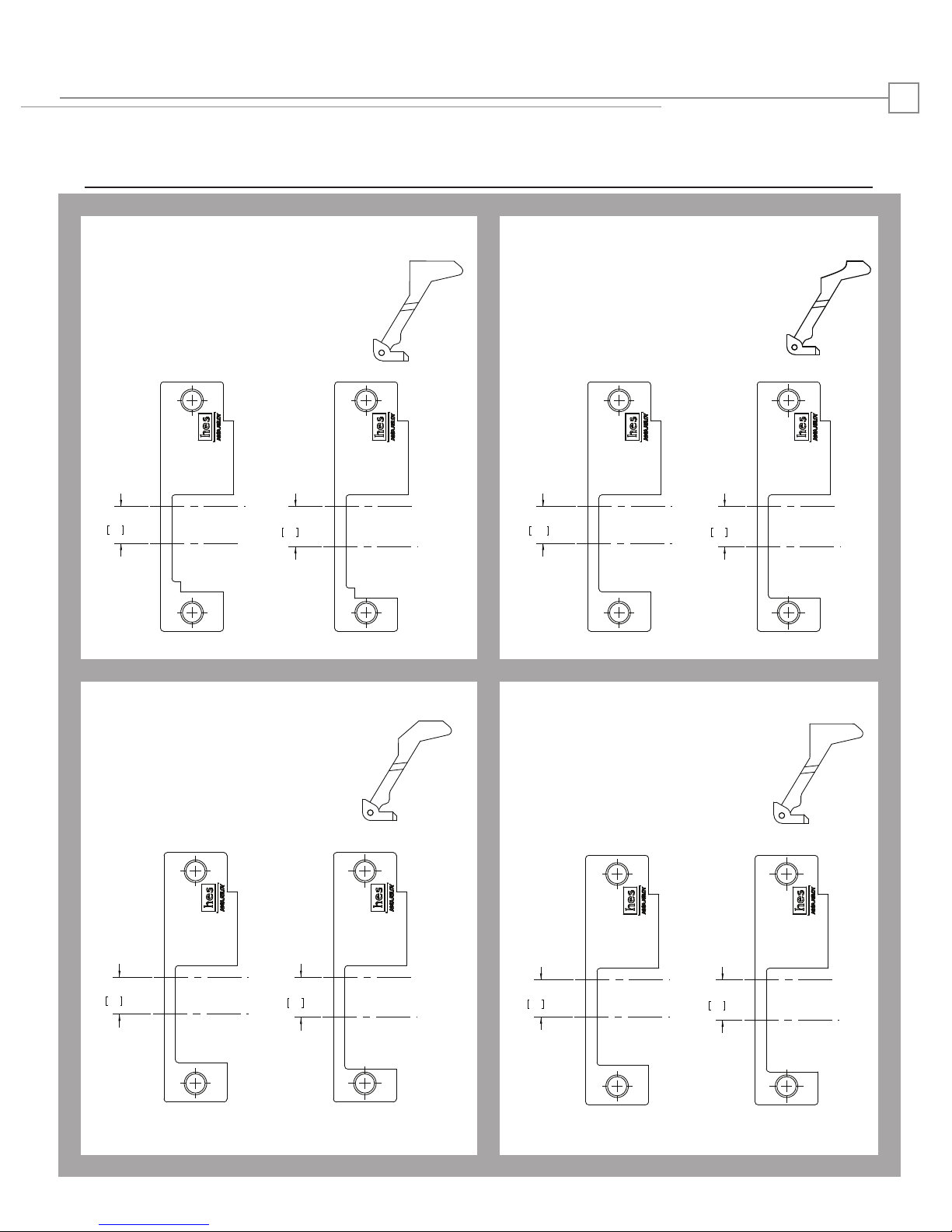

RED

RED/

GREEN

BLACK

VIOLET

RED

BLACK

VIOLET

RED/GREEN

IF CONNECTOR IS MISSING

DIAGRAM 1: 12V to 24V CONVERSION

(+ 12 VDC)

(-NEG)

(+ 24 VDC)

(-NEG)

or

ELECTRIC

STRIKE

ELECTRIC

STRIKE

CONNECT

TOGETHER

CONNECT

TOGETHER

CONNECT

TOGETHER

Evaluate Opening

1. Verify opening is plumb and square and evaluate latch

bolt condition. For important details, see “Troubleshooting

Tips” on page 3.

Prepare Strike

2. The electric strike ships in fail secure mode. If you need

to convert the unit to fail safe, see Diagram 2 on page 5.

Please note that operation in fail safe mode removes the

fire rating of the electric strike.

Prepare Frame

3. Remove dustbox and prepare door jamb per the

template detail on page 6. Be sure to allow enough room

behind the electric strike in the cut out to avoid pinching

the wires.

Install Deadlatch Platform

4. Select correct option. Determine platform position

appropriate for the lockset (see Diagram 4 on page 5).

5. Insert deadlatch platform into the keeper slot as shown

in Diagram 5 on page 5, ensuring that the screw holes in

the deadlatch platform foot and outer casing are aligned.

It may be necessary to slightly retract the keeper in order

to properly seat the deadlatch platform fastening foot.

6. Fasten the deadlatch platform to the electric strike using

the #4-40 screw provided.

Install Strike in Frame

7. Select and electrically connect the appropriate 12 or 24

Volt pigtail to match system power as illustrated in

Diagram 1 below. For 12V AC/DC or 16V AC, the pigtail

marked “12 VDC” should be used. For 24V AC/DC, the

pigtail marked “24 VDC” should be used. If no connector

is present, configure the wires as shown in Diagram 1.

8. If using Latchbolt Monitor (LBM) or Latchbolt Strike

Monitor (LBSM), see Diagram 3 on page 5.

9. Connect the 12 or 24 Volt pigtail to the electric strike.

10. Insert electric strike in jamb cutout and install the

appropriate faceplate using the #12-24 screws provided.

Partially tighten screws and close the door.

11. Verify lockset’s deadlatch is positioned on top of the

deadlatch platform, and does not touch the faceplate. See

troubleshooting tips for more information.

Set Horizontal Adjustment

12. Open the door and pull the electric strike flush with

the inside face of the frame (in the direction of the

opening), and tighten screws.

13. Close the door. If excessive movement (door play) or

preload exists when latched, remove strike from the jamb

cutout, and add one or two of the horizontal lockdown

shims to the front face of the electric strike (See Diagram

6 on page 6). Ensure the horizontal lockdown shim is

making contact with the inside face of the frame. Check

again and add or remove additional shims until proper

horizontal adjustment is achieved.

Important Trouble Shooting Tips

NOTE! The 8500 electric strike requires that the opening be plumb and square to ensure proper catch

and release of the latchbolt.

EVALUATING LATCH BOLT CONDITION

ACCOMMODATING DOOR SAG

DOOR FACE

APPLY FORCE IN

THIS DIRECTION

TO LATCH BOLT

APPLY LUBRICANT TO THIS SURFACE

Figure 2: Lubricate latch bolt as required

If latch bolt does not

clear faceplate, remove

material as shown

and install SD faceplate

Figure 3: Door Sag Adjustment

Door sag and latchbolt wear are two common conditions that

may prevent an electric strike from working properly. Here are

some quick tips to ensure the HES 8500 performs at its best:

Poorly constructed, worn or damaged latchbolts may not

interact properly with the ramp of an electric strike. To check

the condition of your latchbolt, lightly depress the tip of the

latchbolt at a 45 degree angle to the door face -- (see Figure 1).

The latchbolt should be easily pushed into the door. If

abnormal resistance is encountered, apply a lubricant to the

inside of the latchbolt opening with the latchbolt depressed.

(See Figure 2) Check manufacturer for proper maintenance

and approved lubricants. If this does not correct the friction,

additional maintenance on the latchbolt may be required.

Most doors experience some sagging over time. To check for

door sag, look at the location of the lock’s deadlatch in relation

to the 8500’s deadlatch platform. The deadlatch should rest fully

on the deadlatch platform. If the deadlatch contacts the faceplate

or the edge of the 8500’s body, the latchbolt may not be fully

released when the strike is activated causing the door not to be

released.

To correct this condition, remove the 8500 and cut material

from the bottom edge of the frame opening and possibly the

mounting tabs (Note: make sure to sure to retain the mounting

hole). This allows the 8500 to be shifted down slightly in the frame.

Reinstall the 8500, using the SD faceplate instead of the standard

faceplate.

If this does not correct the issue, additional maintenance on the

door may be necessary.

Lubrication of the 8500 electric strike is not necessary.

Figure 1: Apply force to latch bolt

3

STRIKE LUBRICATION

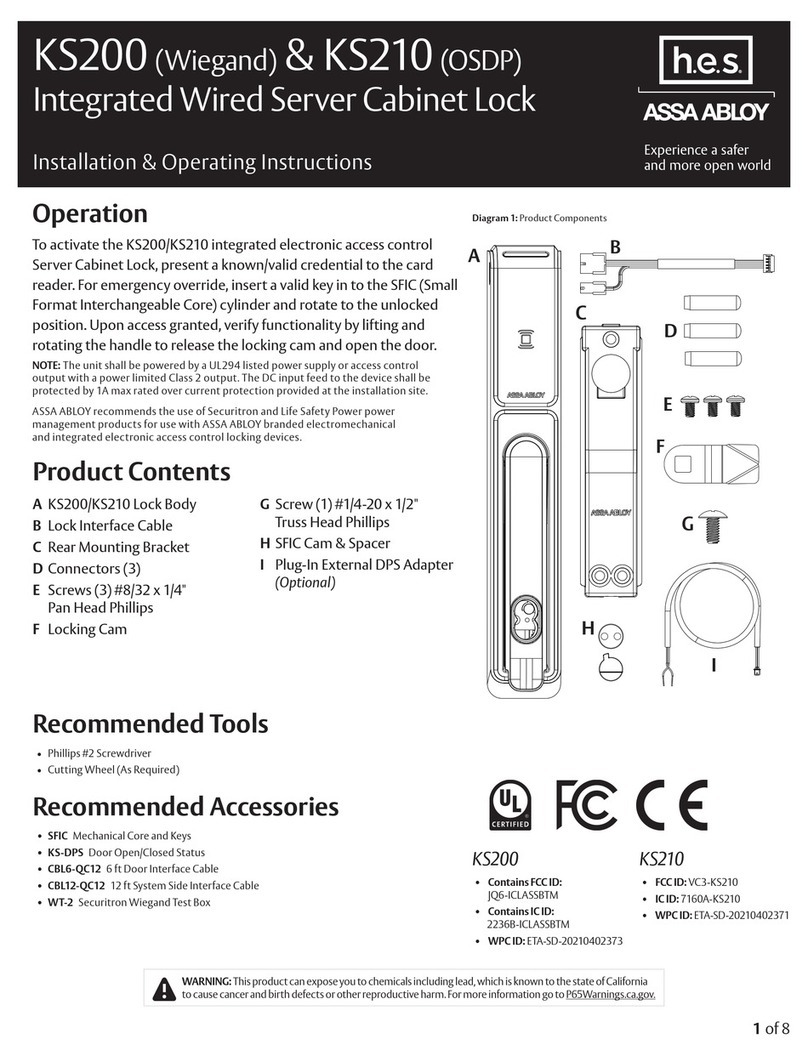

8500 Options

851M

Compatible with mortise locksets:

Sargent (8100, 8200, 9200)

852K

Compatible with mortise lockset:

Corbin Russwin (ML 2000)

852L

Compatible with mortise lockset:

Schlage

852M

Compatible with mortise locksets:

Yale (8700* & 8800), Accurate,

Falcon, Kaba Ilco/Unican

4

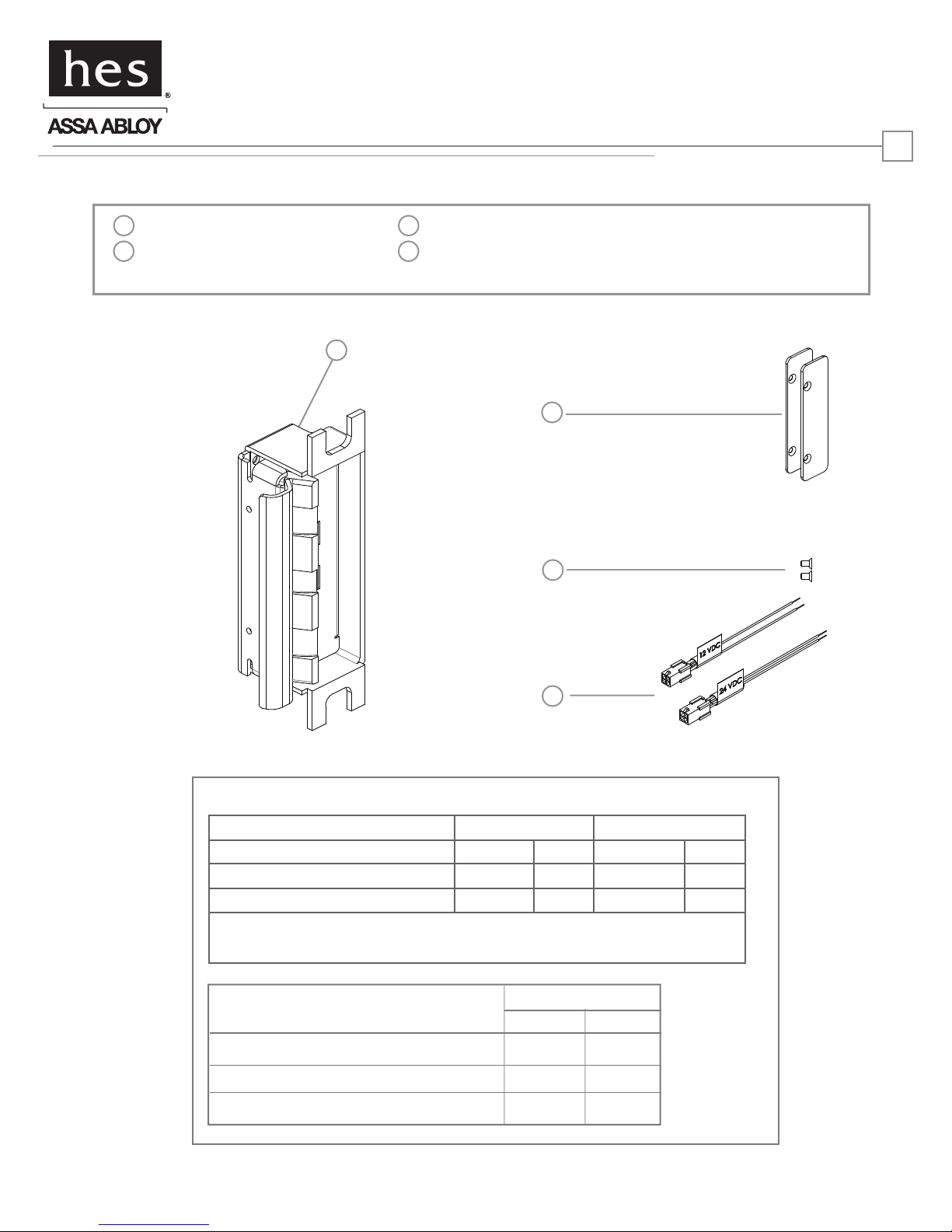

!= centerline of faceplate

2nd line = centerline of faceplate opening

23/32"

18.2

C

L

25/32"

19.8

C

L

25/32"

19.8

C

L

23/32"

18.2

C

L

25/32"

19.8

C

L

23/32"

18.2

C

L

25/32"

19.8

C

L

23/32"

18.2

C

L

* Manufactured after 2005.

Contact HES Customer Support for more information

5

Installation Diagrams

LBSM WIRING

Brown

Blue Normally Open

Yellow Normally Closed

Common

LBM WIRING

White

Orange Normally Open

Green Normally Closed

Common

White

Orange

Green

DIAGRAM 3: FAIL SAFE TO FAIL SECURE

a

b

c

Loosen screws, but do not

remove them

Move screws to the Fail Safe

position as shown

Tighten screws

Remove fire screw

(Located under label)

Fail Safe

DIAGRAM 3: LBM & LBSMDIAGRAM 2: Fail Safe Conversion

DIAGRAM 4: Deadlatch Platform Position

Position 2

Strike shown in LH/RHR position

DIAGRAM 5: Deadlatch Platform Installation

Position 1

(RH/LHR)

Position 1

(LH/RHR)

Brown

Blue

Yellow

Platform Position 1

Platform

Style

Lockset

Sargent 8100, 8200,

9200

Yale 8800

Accurate

Falcon

Kaba Ilco/Unican M

Yale 8700 *

Schlage L9000

M

L

Platform Position 2

Platform

Style

Lockset

LH/RHR handed position shown

K

Corbin Russwin

ML 2000

Fire Screw

d

* Manufactured after 2005. Contact HES Customer Support for more information

6

Frame Preparation* Inches [mm]

© 2011 HES, Inc.

3070006.001 rev B

1-1/4” [32]

1/8” [3]

4-7/8” [124]

4-1/8” [105]

3-3/8” [86]

*Note: The 8500 electric strike will require removal of dust boxes of less than 1-3/8” in depth.

Remove additional material as needed to provide clearance for electric strike and wires.

DIAGRAM 6: Horizontal Lockdown Shim Installation

Remove Dust Box

1 Shim = 1/16” [1.6]

2 Shims = 1/8” [3.2]

Table of contents

Other HES Lock manuals

Popular Lock manuals by other brands

Honeywell

Honeywell IDENT-KEY Mounting and Connection Instructions

COMPX

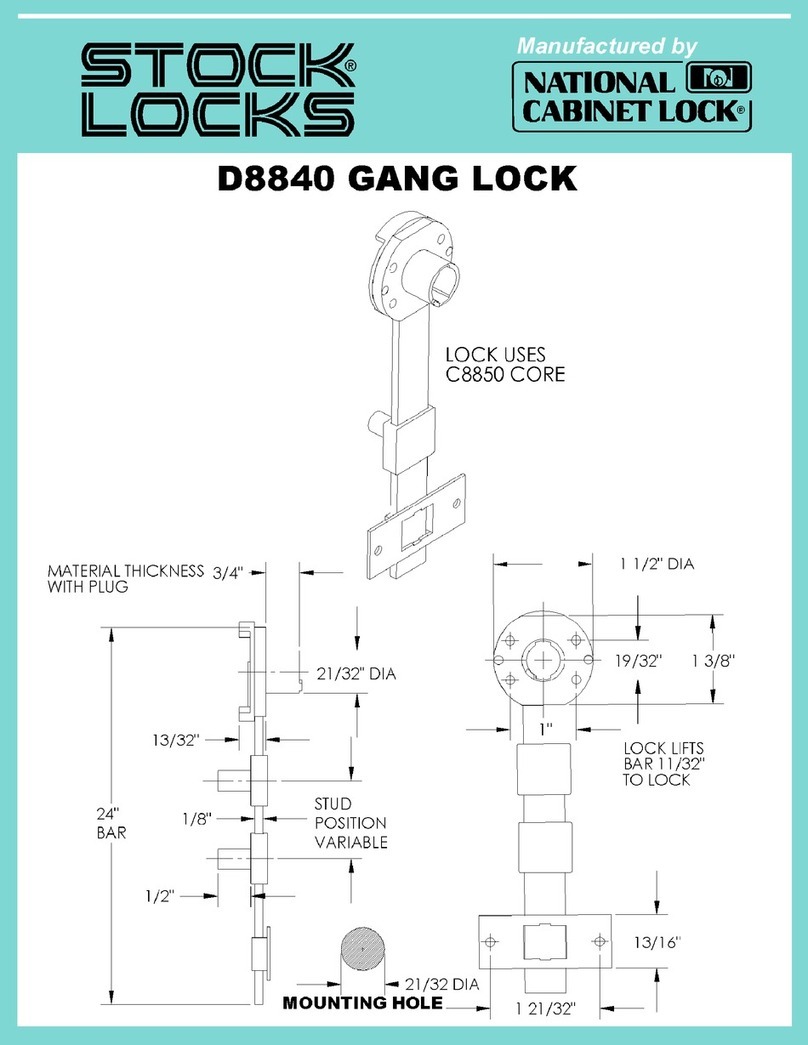

COMPX National D8840 instruction sheet

SICK

SICK i15 Lock operating instructions

Visionis

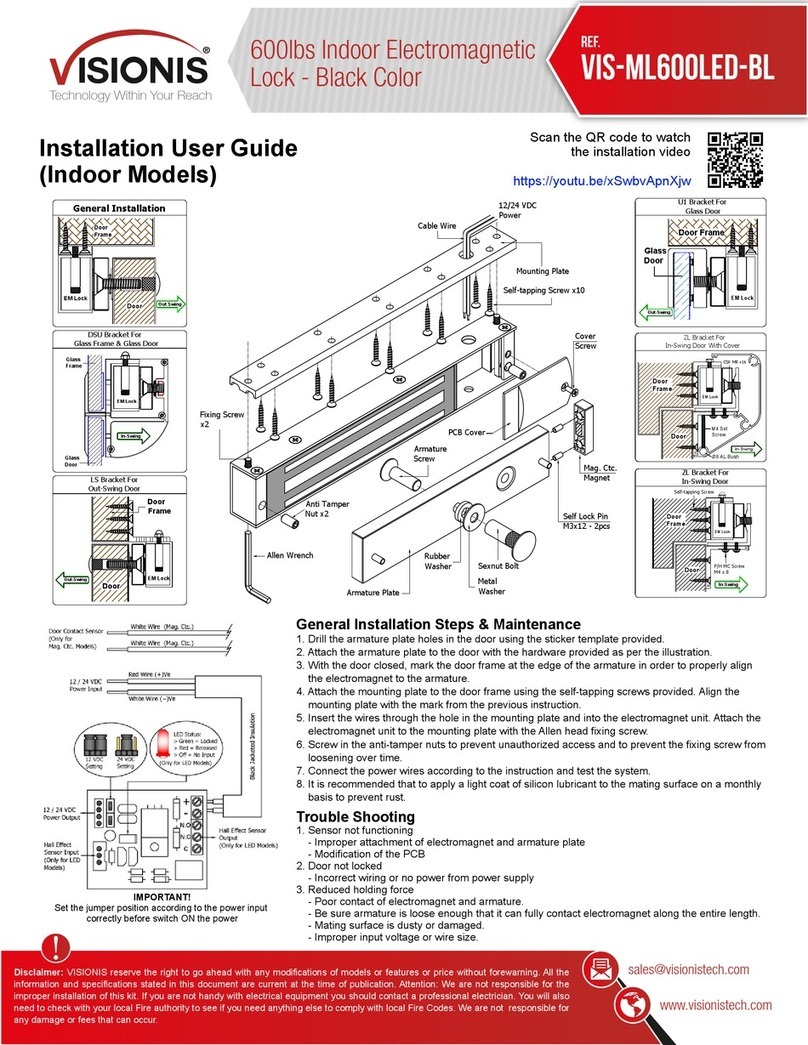

Visionis VIS-ML600LED-BL Installation & user guide

Tecnosicurezza

Tecnosicurezza Pulse Pro T6630/GRP installation instructions

WALDIS

WALDIS PRIMOR 1000 operating instructions