© HES 20014

Hanchett Entry Systems, Inc. • 2040 West Quail Ave. • Phoenix, AZ 85027 • 800-626-7590 • www.hesinnovations.com • www.electricstrikes.com

FIVE YEAR LIMITED

WARRANTY

ELECTRIC STRIKE TROUBLE SHOOTING GUIDE

If the electric strike does not operate properly after

installation, the following problems may need to be corrected.

Please read carefully before calling for technical service.

Step 1. If the electric strike does not operate properly, open the door

and re-energize the electric strike. If the electric strike operates

properly with the door held open, the lockset may be pre-loading or

binding the keeper of the electric strike.

Solution: The horizontal relationship between the lockset and the

electric strike will have to be adjusted to eliminate the binding between

the bolt of the lock and the electric strike keeper (also See Note 2.)

Step 2. If all mechanical problems have been eliminated without

successful electric strike operation, check the following electrical

problems:

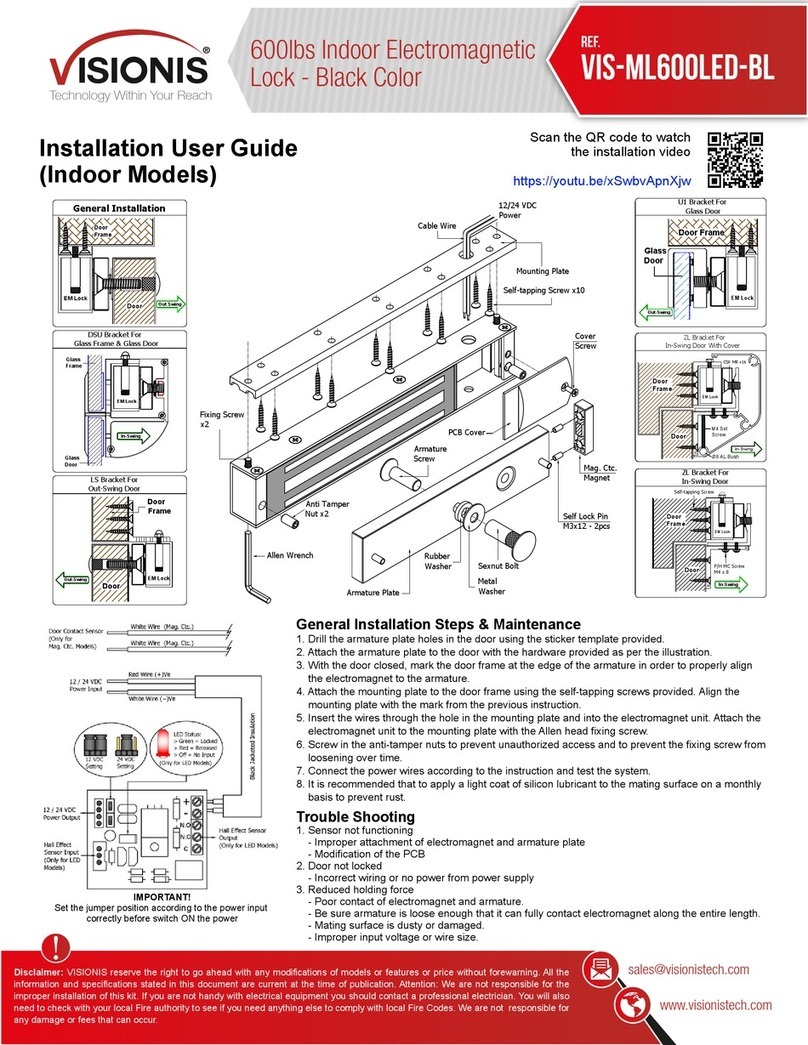

a. Examine the power supply or transformer to verify that the output

voltage is at the listed rating.

b. Verify that the power wires leading to the electric strike are a large

enough gauge to handle the current requirements (see above).

Note: Some voltage may be lost when using smaller gauge wires

over long distances.

c. Using a multimeter: Verify that the input voltage is within the

recommended limits (+-5%).

d. Verify that all peripheral devices such as bridge rectifiers,

SMART-Pacs, buzzers, L.E.D.s etc. are properly connected.

e. Check that the switch, key pad, etc., meets the voltage requirements

for the system.

Note 1: A quick way to determine if an electric strike is defective is to

install it in a site where another electric strike has been installed and

working properly. Another way is to use an alternative power source to

test the electric strike (i.e. a DC battery pack.)

Note 2: If the voltage is slightly too low to operate the electric strike, a

35 volt, 220 micro-farad capacitor may be installed across the bridge

rectifier (positive to positive, negative to negative) to provide an initial

boost of power to the unit. This is also helpful to overcome slight pre-

loading conditions (as in step 1.)

FOR ANY QUESTIONS REGARDING THIS INFORMATION, CALL

OUR TECHNICAL SERVICE LINE AT 1-800-626-7590

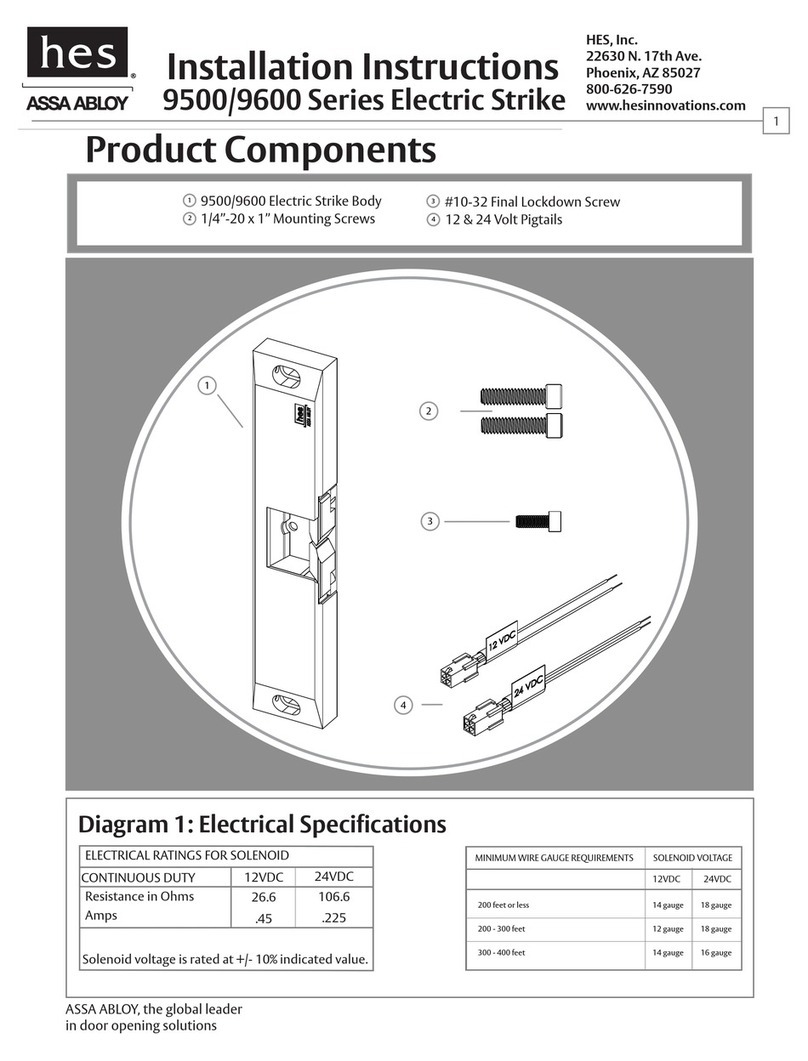

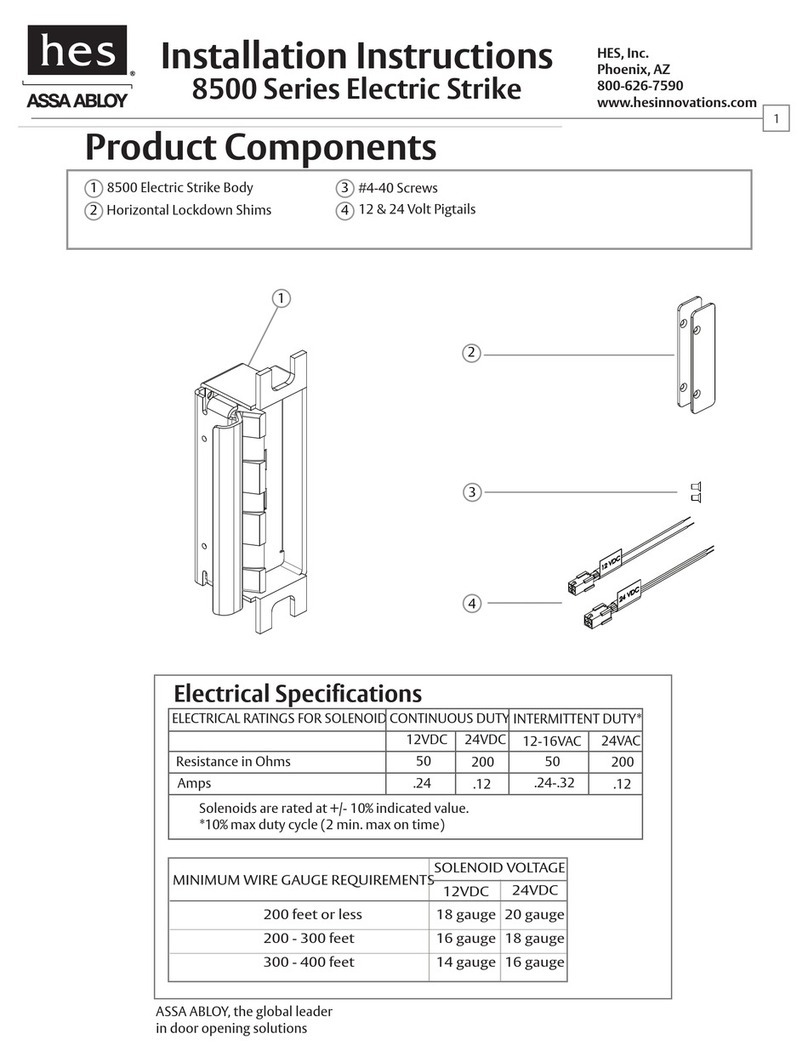

ELECTRICAL RATINGS Continuous Duty

FOR SOLENOID 24 VDC 12 VDC

Resistance in Ohms 106.6 26.6

Amps Seated .225 .45

C

CAU

AUT

TI

IO

ON!

N! Before connecting any device at

the installation site, verify input voltage and

current using a multimeter. Many power

supplies and transformers operate at higher

levels than listed. Any input voltage exceeding

5% of the solenoid rating may cause severe

damage to the unit and will void the warranty.

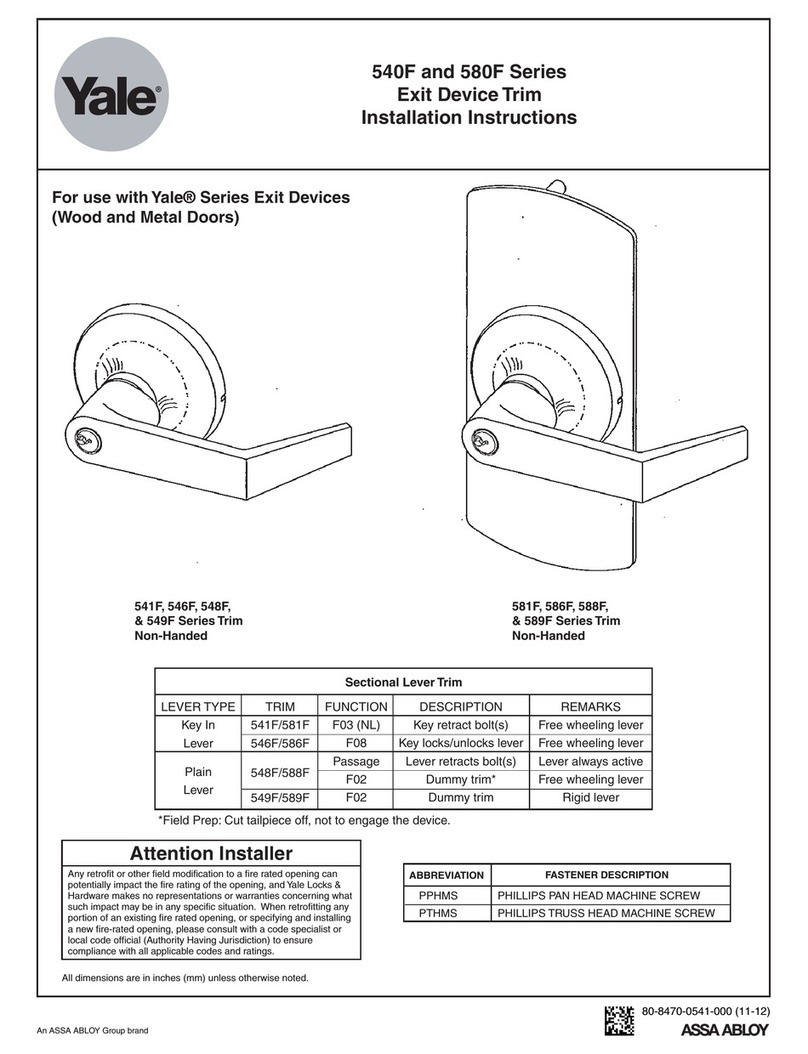

MINIMUM WIRE GAUGE Solenoid Voltage

REQUIREMENTS

24 VDC 12 VDC

200 feet or less 18 gage 14 gage

200 - 300 feet 18 gage 12 gage

300 - 400 feet 16 gage 12 gage

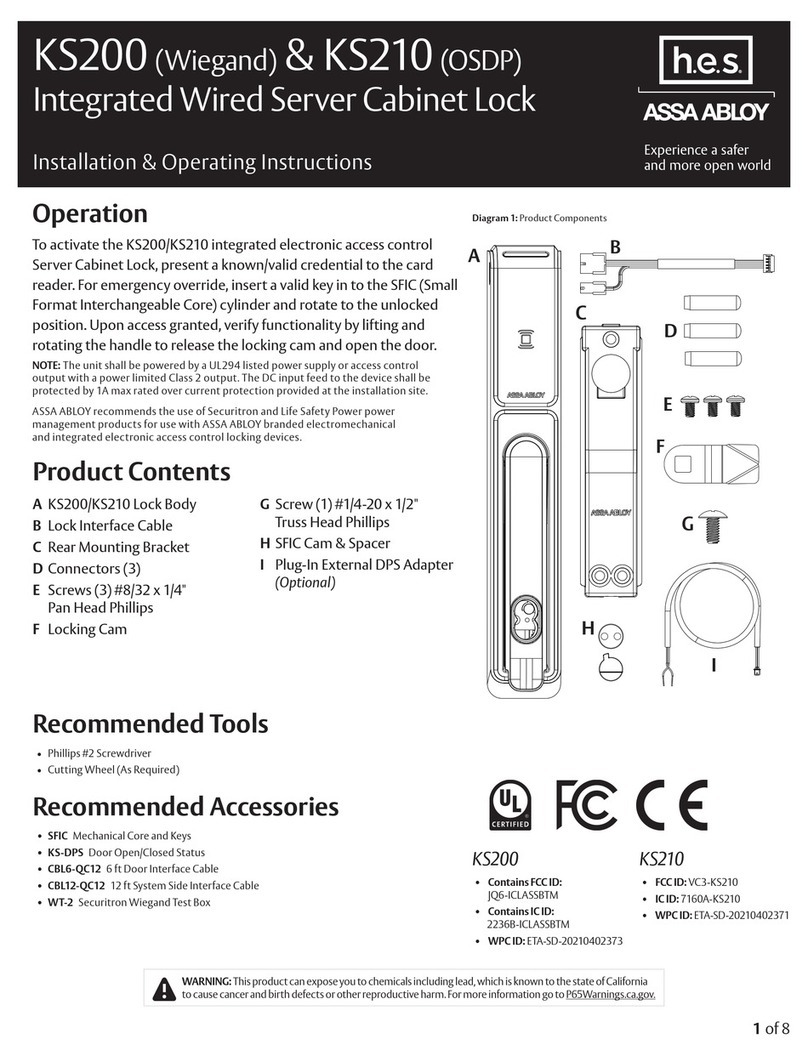

12 Volts

Figure A

White

Blue Yellow

Orange

RIB

AFigure B

24 Volts

RIB

White Yellow

Blue

Blue

Orange

Orange

Part #LHA9600/004

WIRING DIAGRAM FOR 12/24 VOLTS

Caution: To prevent damage to the unit, cap all wires.

Note: 9600 is supplied as a 12 volt unit. For 24 volts see figure B.

9600 LATCHBOLT MONITOR:

WIRING COLOR CODE:

White –Common

Yellow –N.O.

Orange –N.C.

Note:

Horizontal Lock

Down Screws x2