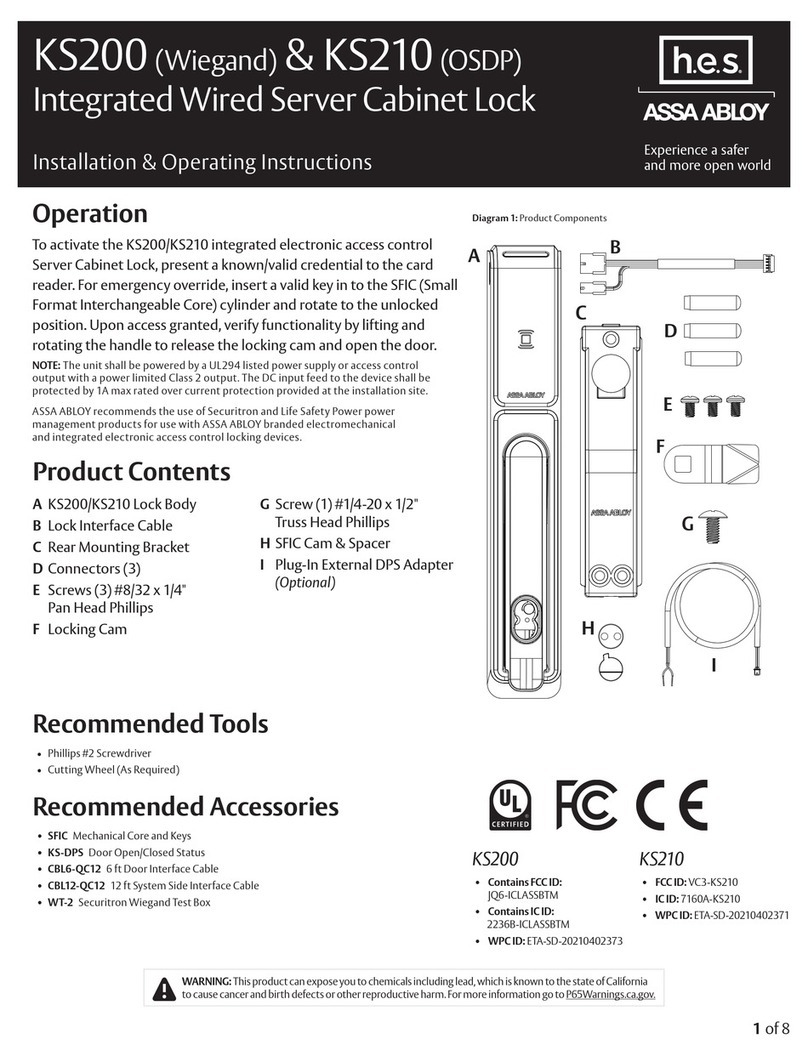

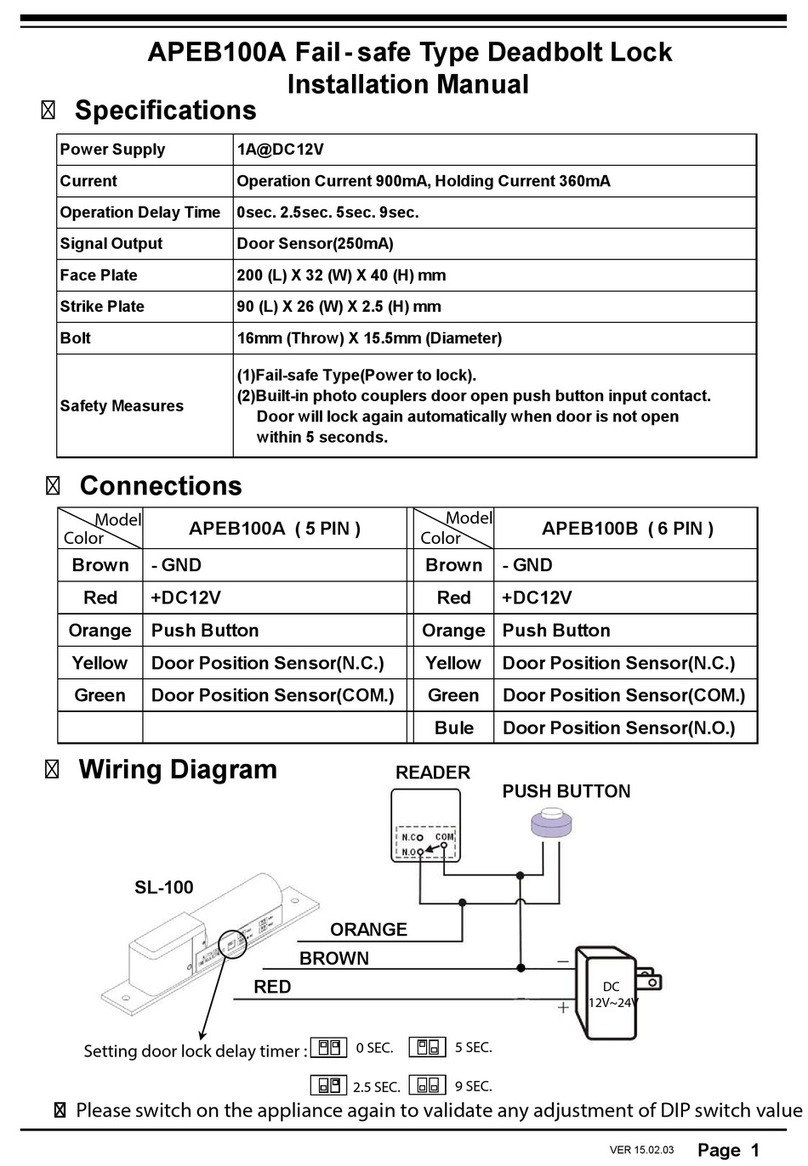

DIAGRAM 3: LATCHBOLT MONITOR

3

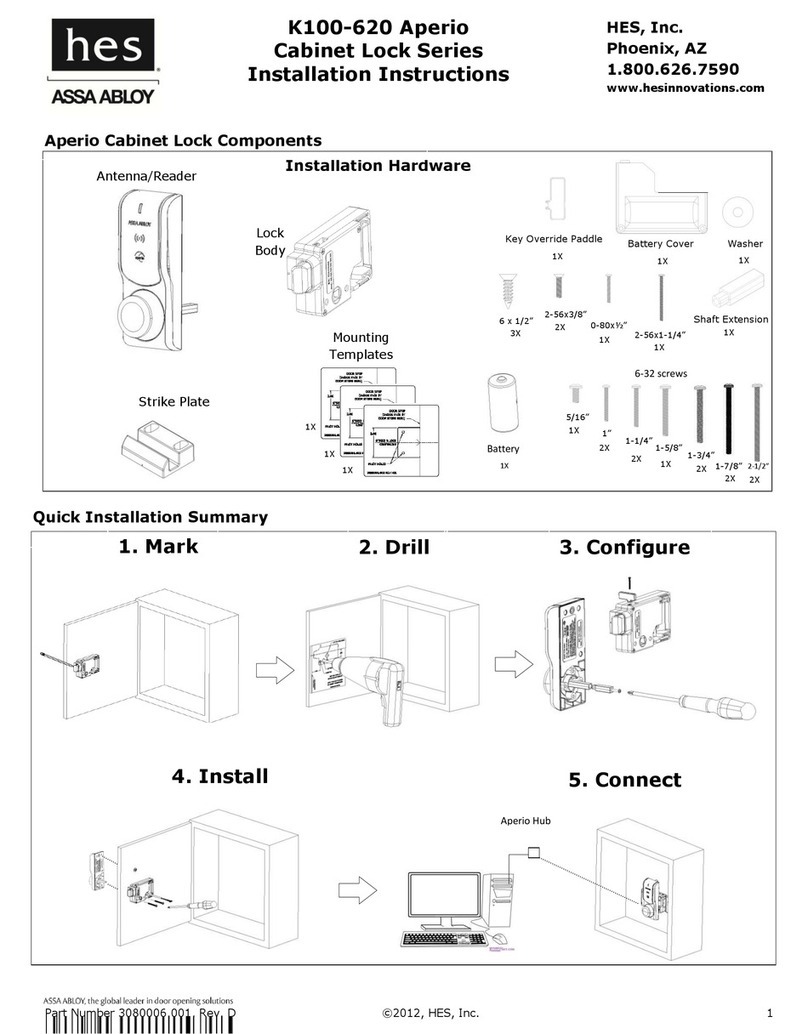

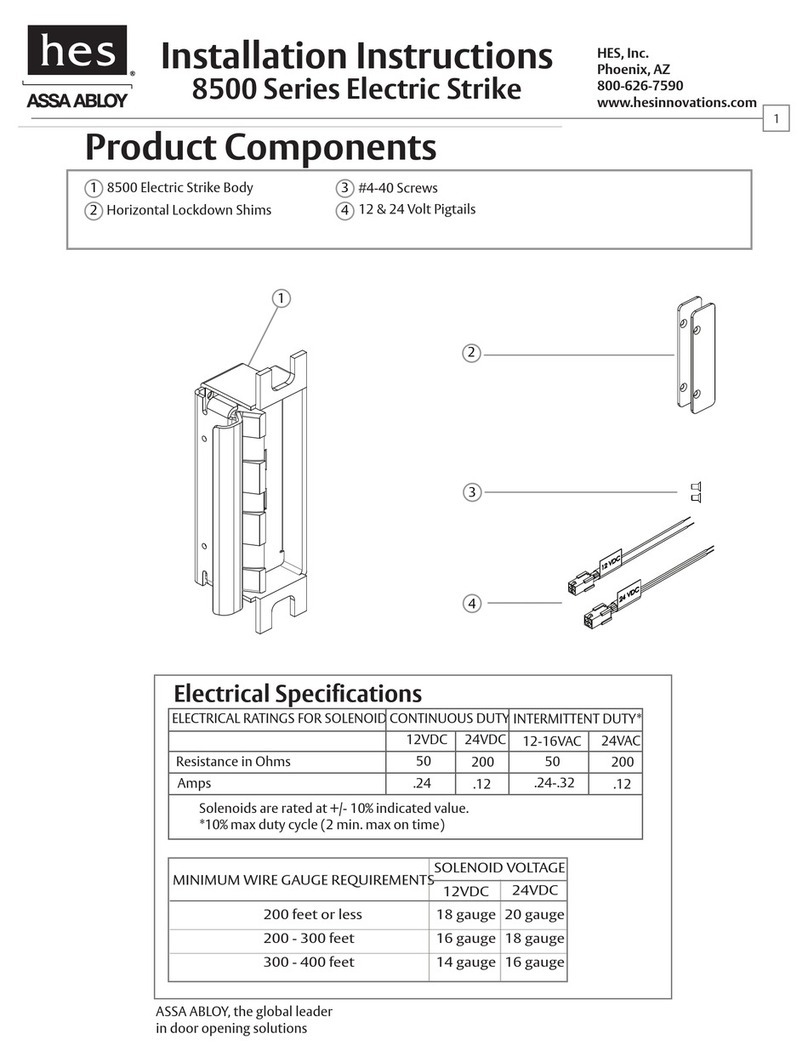

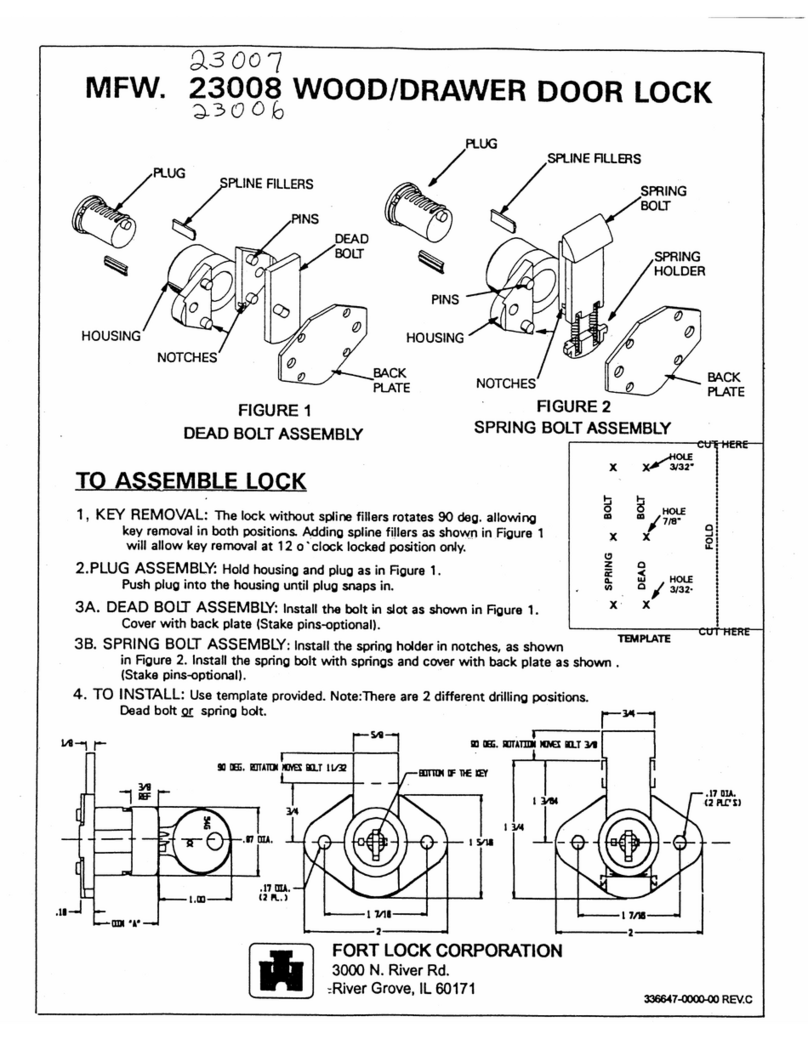

Installation Diagrams

LBM WIRING

White

Orange Normally Open

Green Normally Closed

Common

DIAGRAM 4: STRIKE MONITORDIAGRAM 3: LATCHBOLT MONITOR

Blue Normally Open

Yellow Normally Closed

DIAGRAM 5: CYLINDRICAL LOCKSETS

LBSM WIRING

Brown

Blue Normally Open

Yellow Normally Closed

Common

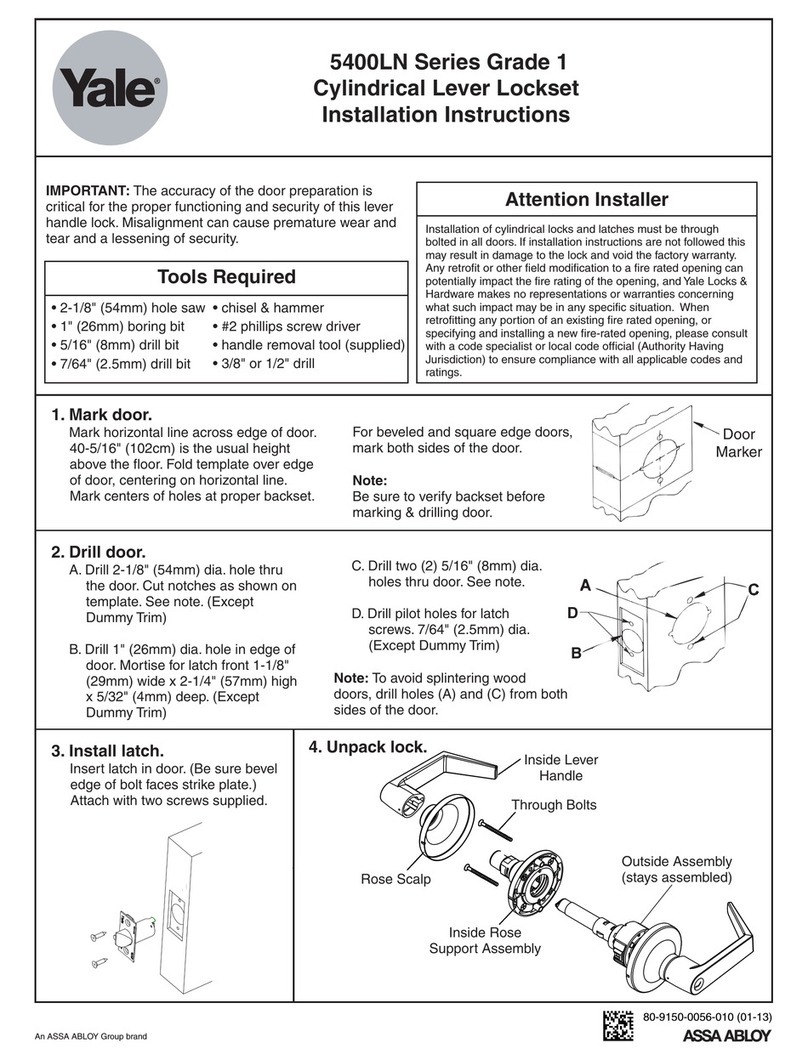

DIAGRAM 5: FAIL SAFE CONVERSION

Convert Mode

Figure 1: FAIL SECURE OPERATION

The 9500/9600 series Electric Strike is

pre-set for FAIL SECURE OPERATION as

shown in Figure 1.

1. To convert to Fail Safe Operation, loosen

the 4-40 screws located on the rear of the

strike as shown in Figure 2, but do not

remove them.

2. Move the screws to the Fail Safe Operation

position as pictured (away from the center

of the strike) in Figure 2. There are screws

on both the left and right side of strike. Both

pairs of screws must be repositioned to

convert the strike to Fail Safe Operation.

3. Tighten both sets of 4-40 screws after they

have been moved to the Fail Safe Operation

position.

4. For 9500 series strikes, remove the “Listed

Fire Rated Hardware” label if the strike is

used in the fail safe operation. Using the

9500 in Fail Safe operation negates the fire

rating.

Verify

Verify that both keepers are in Fail Safe

Operation. Both keepers should be

unlocked without power, but lock when

power is applied.

If one or both keepers is still in the Fail

Secure Operation, verify that the 4-40

screws have been moved all the way into the

countersunk hole as illustrated in Figure 2.

Figure 2: FAIL SAFE OPERATION*

White

Orange

Green

Brown

Blue

Yellow