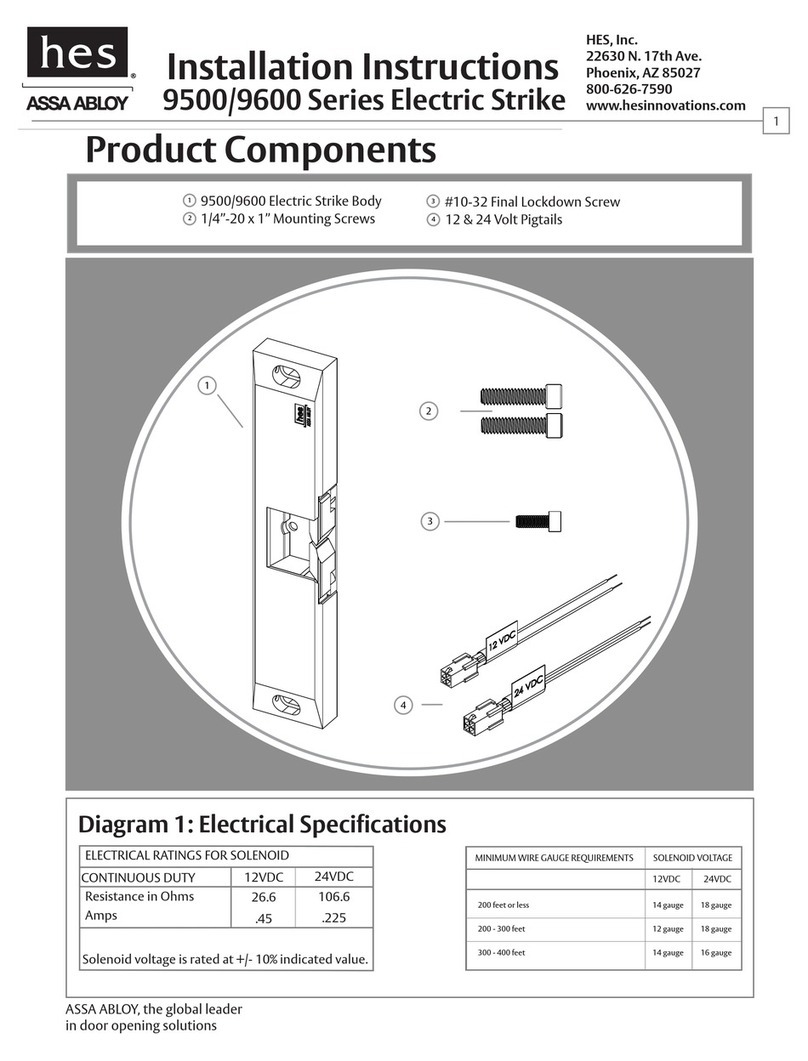

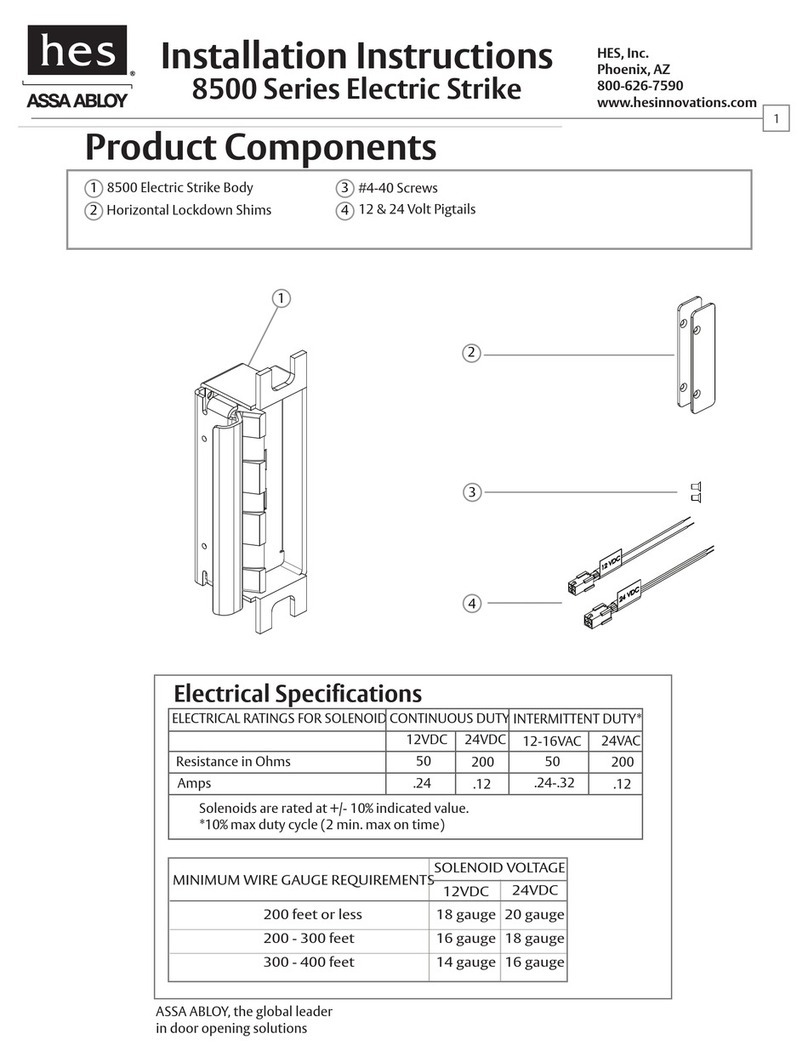

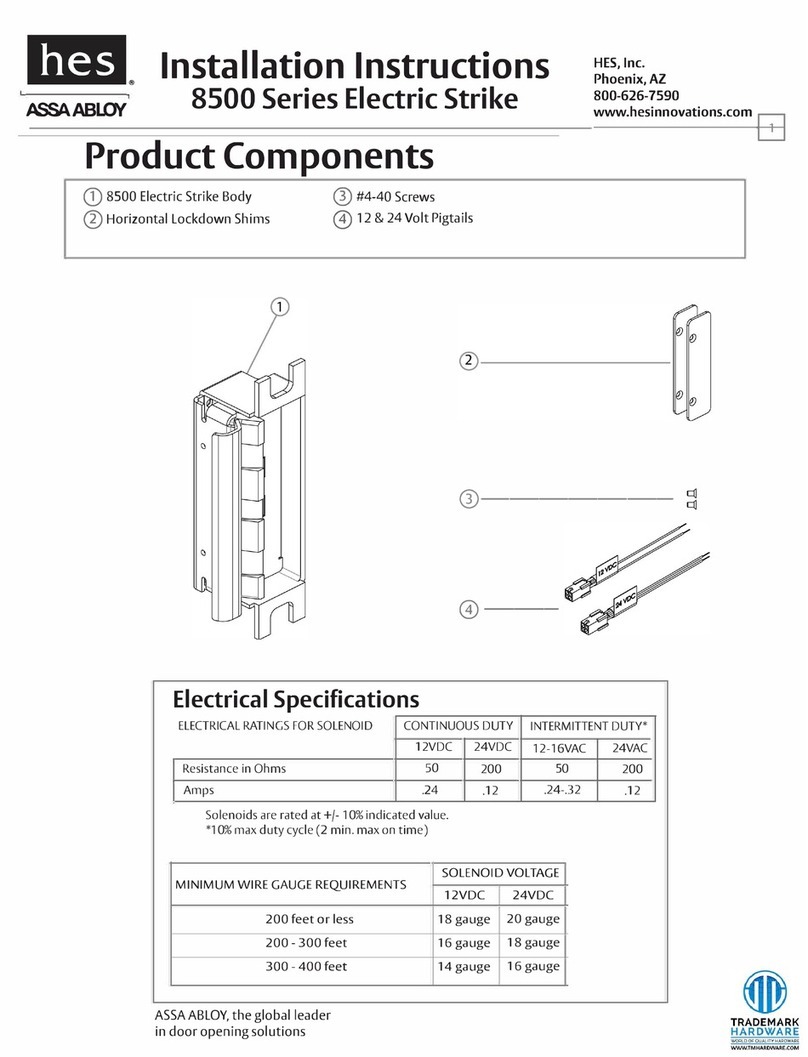

ELECTRICAL RATINGS Continuous Duty

FOR SOLENOID

24 VDC (+ 10%) 12 VDC (+ 10%)

Resistance in Ohms 100 25

Watts Seated 6 6

Amps Seated .24 .48

-

CAUTION! Before connecting any device at the installation site, verify input voltage and current using a

multimeter. Many power supplies and transformers operate at higher levels than listed. Any input voltage

exceeding 10% of the solenoid rating may cause severe damage to the unit and will void the warranty.

For any questions regarding this information, call our Technical Service Line at 1-800-626-7590

Solenoids are rated at +/- 10% indicated value

FIVE YEAR LIMITED WARRANTY

• U.L. and U.L.C. listed for

fire door accessory, category

10C (file #843X), for use with 3

hour “A” labeled doors (fail

secure only)

• U.L. listed for burglary

resistance, category 1034

(file #51WK)

• ANSI A250.13-2003

Windstorm Resistant

U.L. Tested

Standard UL 1034 listed for:

• 1500 lbs. static strength rating

• 70 foot-lbs dynamic strength

rating

• 250,000 cycles endurance rating

Note: At the request of HES this

model was tested and verified by

UL for the following voluntary

(not required) ratings:

• 3,000 lbs static strength rating

• 2,000,000 cycles of operation

Wiring diagram for 12/24 volts

12 VOLT DC 24 VOLT DC

FIG. A FIG. B NOTE: The 1006 is supplied as a 12 volt

DC unit. For 24 volts DC, see

figure B.

INSTRUCTIONS:

1. Cut the violet and black wires.

2. Splice the violet and black wires

together that are coming out of the

strike. Connect the violet and black

wires together with connector.

3. Individually cap the remaining

two wires coming out of the pigtail.

4. The unit is now 24VDC.

(Wiring methods and materials shall be in

accordance with the National Electric

Code, ANSI/NFPA 70, 1996. This unit

must be powered from a UL listed limited

energy power source.)

©HES 2005

3

4036006.001 rev B

-

Optional LBM/LBSM Wiring Information

(LBM/LBSM ordered separately)

MINIMUM WIRE GAUGE Solenoid Voltage

REQUIREMENTS

24 VDC 12 VDC

200 feet or less 18 gauge 18 gauge

200 - 300 feet 18 gauge 16 gauge

300 - 400 feet 16 gauge 14 gauge