HESA HE400 Guide

MODEL HE400 MICROWAVE BARRIER

(cod. HE400)

INTRODUCTION

The HE400 is a microwave barrier system for external

protection that requires a simple and fast assembly.

The maximum distance of the beam between a

transmitter and a receiver is 200 meters. The HE400

barrier features four field selectable modulation fre-

quencies to allow the installation of barriers within clo-

se proximity and to reduce the possibility of cross link

modulation or mutual interference.

The HE400 barriers requires a low current absorption

(40mA RX, 38mA TX) thus allowing autonomy for a

long period of time with the use of the internal 12 Vcc

– 2,1Ah battery (in each TX and RX units) in case of

mains power failure. This battery gives an autonomy

of over 36 hours.

Description

Each model HE400 consist of one model HE400T

transmitter and one model HE400R receiver, each sup-

plied with universal mounting bracket for pole mod.

HE401 (diameter mm 70-100).

In order to satisfy more specific installation require-

ments, the following accessories for HE400 are avai-

lable as option:

Part number Model Description

HE402 HE402 Horizontal wall mounting

bracket

HE403 HE403 Pole mounting bracket for

diameter 70-110 mm

HE405 HE405 Transformer for powering

one HE400T or HE400R:

230Vac/19 Vac, 30 VA

HE410 HE410 Outdoor container for

HE405 transformer. For pole

mounting use HE403 bracket

HETS400 TS400 Test instrument for HE400

HE19-12 GP2.1-12 12V 2,1 Ah backup battery

for HE400T and HE400R.

Principles of operation

The transmitter radiates amplitude modulated X-band

energy to the receiver where the received energy is

amplified and processed so that it causes an alarm re-

lay to be energized. When an intruder approaches

the beam, the energy detected by the receiver causes,

if the predetermined level is reached, the relay to be

de-energized and therefore an alarm. Operation of

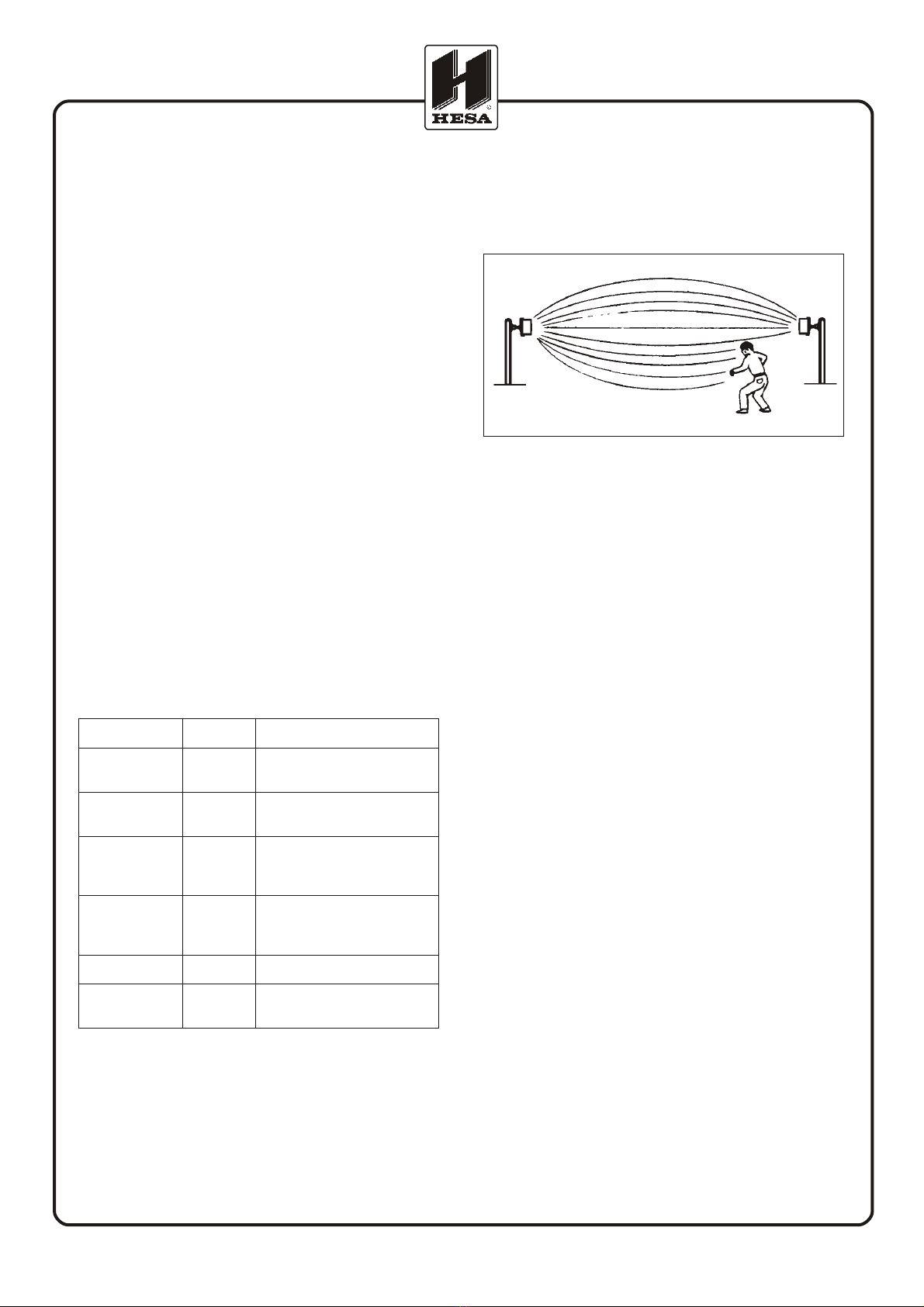

model HE400 is illustrated in Figure 1. A single model

HE400 may cover a distance up to 200m.

The Receiver incorporates an automatic gain control

circuit (AGC) that adequates the signal to the distance

needed to be covered. Furthermore there are phased

locked loop circuits (PLL) to detect the signal radiated

within a specified frequency band.

Another possibility is the possibility to synchronize the

transmitters: in case two or more TX units have to be in-

stalled on two or more parallel levels in the same di-

rection, a connector is available in order to synchro-

nize the start of the signals radiated to the different re-

ceivers.

Alignment and control

In order to perform a good alignment it is necessary

only a standard voltmeter. On both the receiver and

the transmitter it is available the J2 connector (10 PIN

header) for controlling all the signal and the power

supply levels. We suggest the use of the optional

TS400 Test Instrument Interface that has onboard a

connector, 3 LEDs and buzzer and the connection cab-

le for the J2 header. This interface simplifies the con-

nection of the voltmeter to the barrier. You can even

connect a oscilloscope in order to determine the level

of the received signal.

On the Receiver and the Transmitters boards there are

also 5 LEDs that show the status of the alarm relay, the

presence of the power supply, the correct oscillator

operation and the use of the correct channel between

the TX and the RX.

Model HE400 microwave barrier DT01142 - Page 1

Fig. 1 - Detection pattern

DOCUMENTAZIONE TECNICA TECHNICAL DOCUMENTATION

Installation

HESA advises to make an inspection of the site to pro-

tect considering the following elements:

Width pattern of detection area

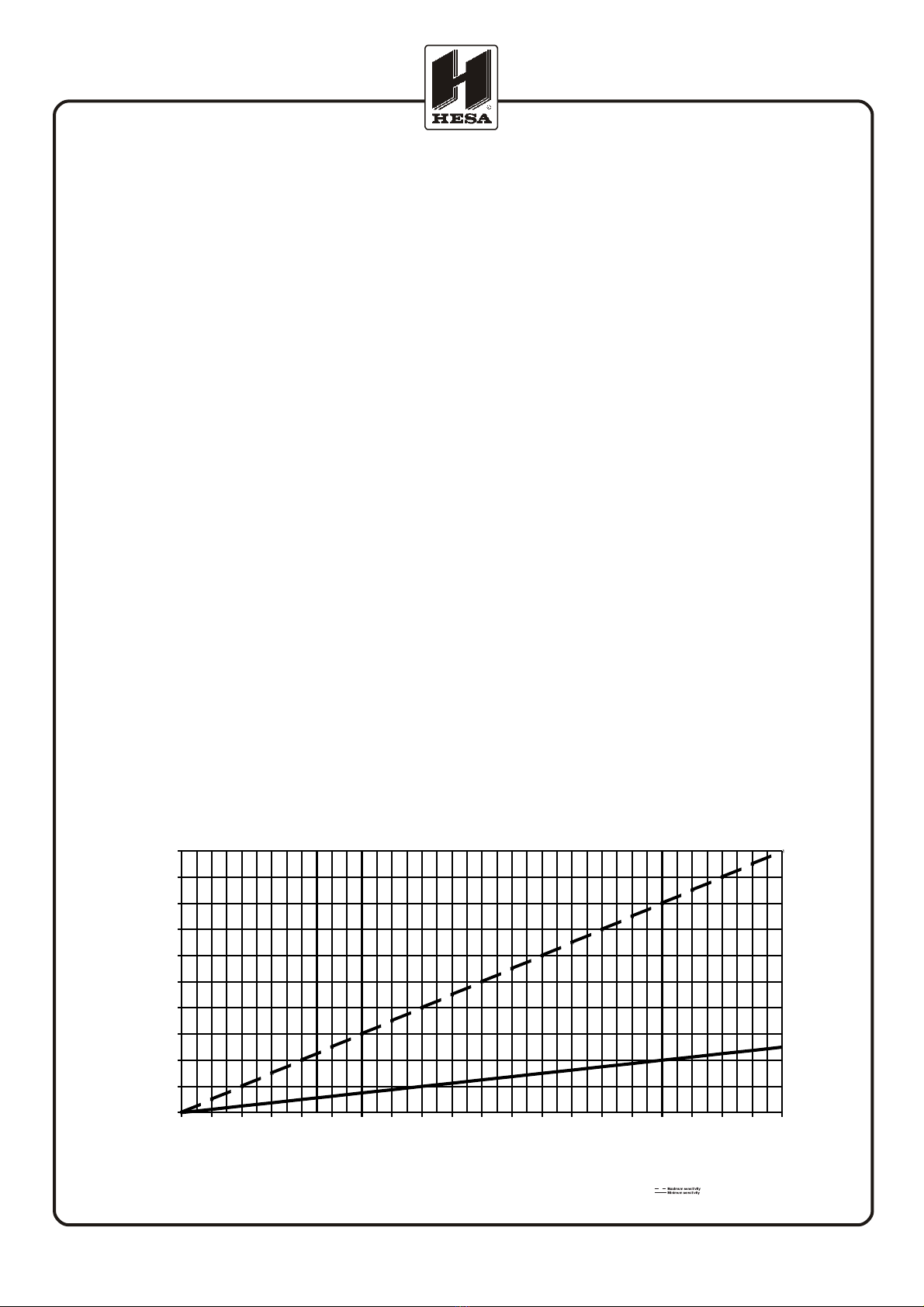

The width of the beam varies depending on the distan-

ce between the receiver and the transmitter and the

sensitivity level used. The following diagram (Figure 2)

allows you to determine the maximum width of the

beam that is at half of the distance of the barrier.

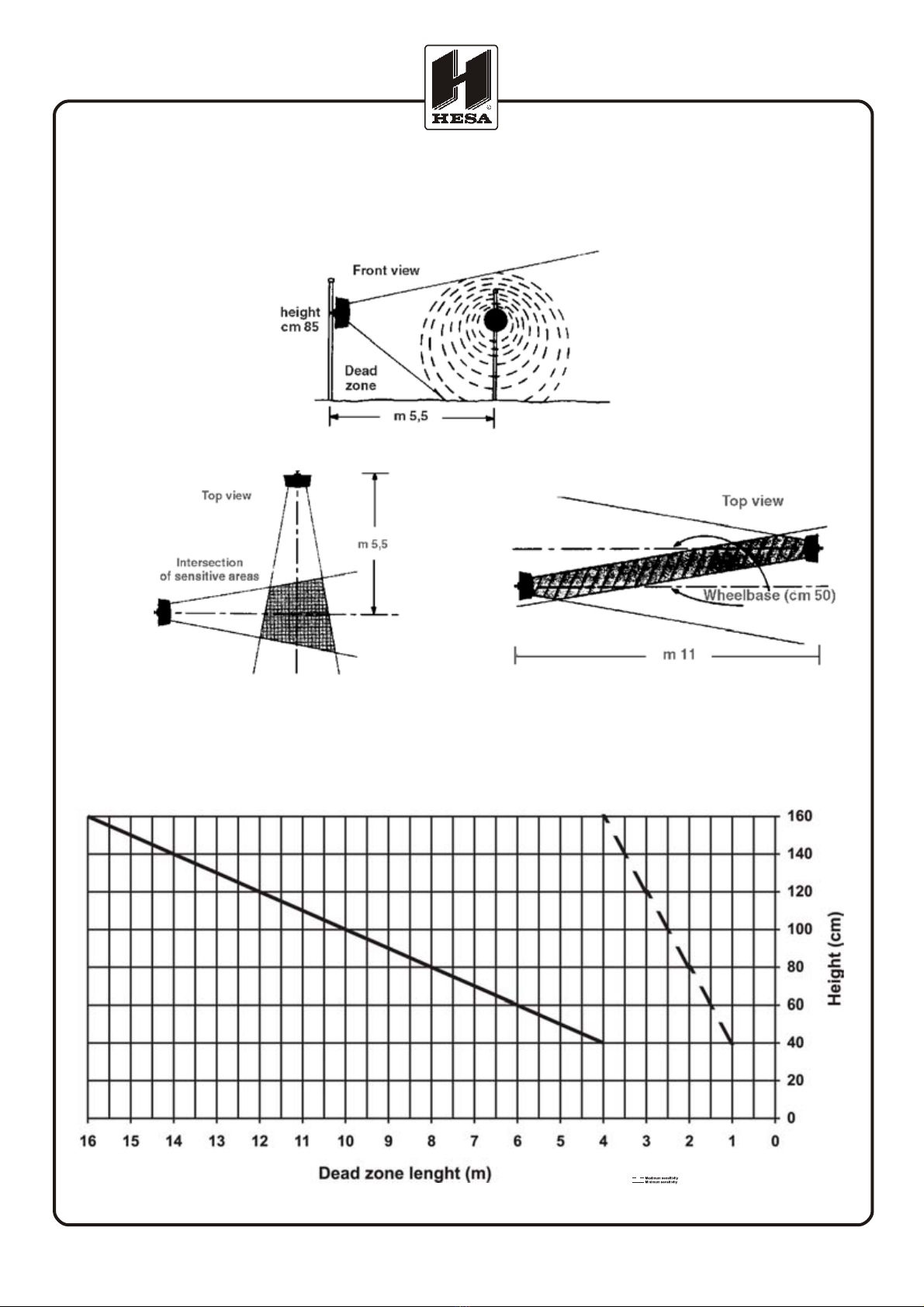

Mounting height

The mounting height from the ground of the barrier de-

pends on the installation requirements but especially

must be determined considering that the increase of

the height increases also the the length of the uncove-

red area that is the area to the ground not covered by

the beam of the barrier. This information is important

also for determining the overlapping of two barriers

that are crossing or that are installed in parallel. Plea-

se note that the uncovered area increases by decrea-

sing the sensitivity (see Figure 4).

Typically the height should be of 85 cm. The

height is between ground and the middle of the devi-

ce.

For security purposes we advise to overlap the ends of

the barriers in order to eliminate the uncovered areas.

Considering an average sensitivity and a mounting

height of 85 cm, you should overlap for about 5,5 m

in the corners and for about 11 m on the rectilinear

protections. In case there are consecutive barriers, the

distance between the centers should be of about 50

cm (see Figure 3).

Model HE400 microwave barrier DT01142 - Page 2

DOCUMENTAZIONE TECNICA TECHNICAL DOCUMENTATION

0

2

4

6

8

10

12

14

16

18

20

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200

Lun

g

hezza della barriera

(

m

)

Diametro a metà tratta (m)

Fig.2: Diameter of the sensitive zone

Distance between TX and RX (m)

Model HE400 microwave barrier DT01142 - Page 3

DOCUMENTAZIONE TECNICA TECHNICAL DOCUMENTATION

Fig. 4: Installation height of devices

Fig. 3: Attention to dead zones!

Installation of the HE400 barriers

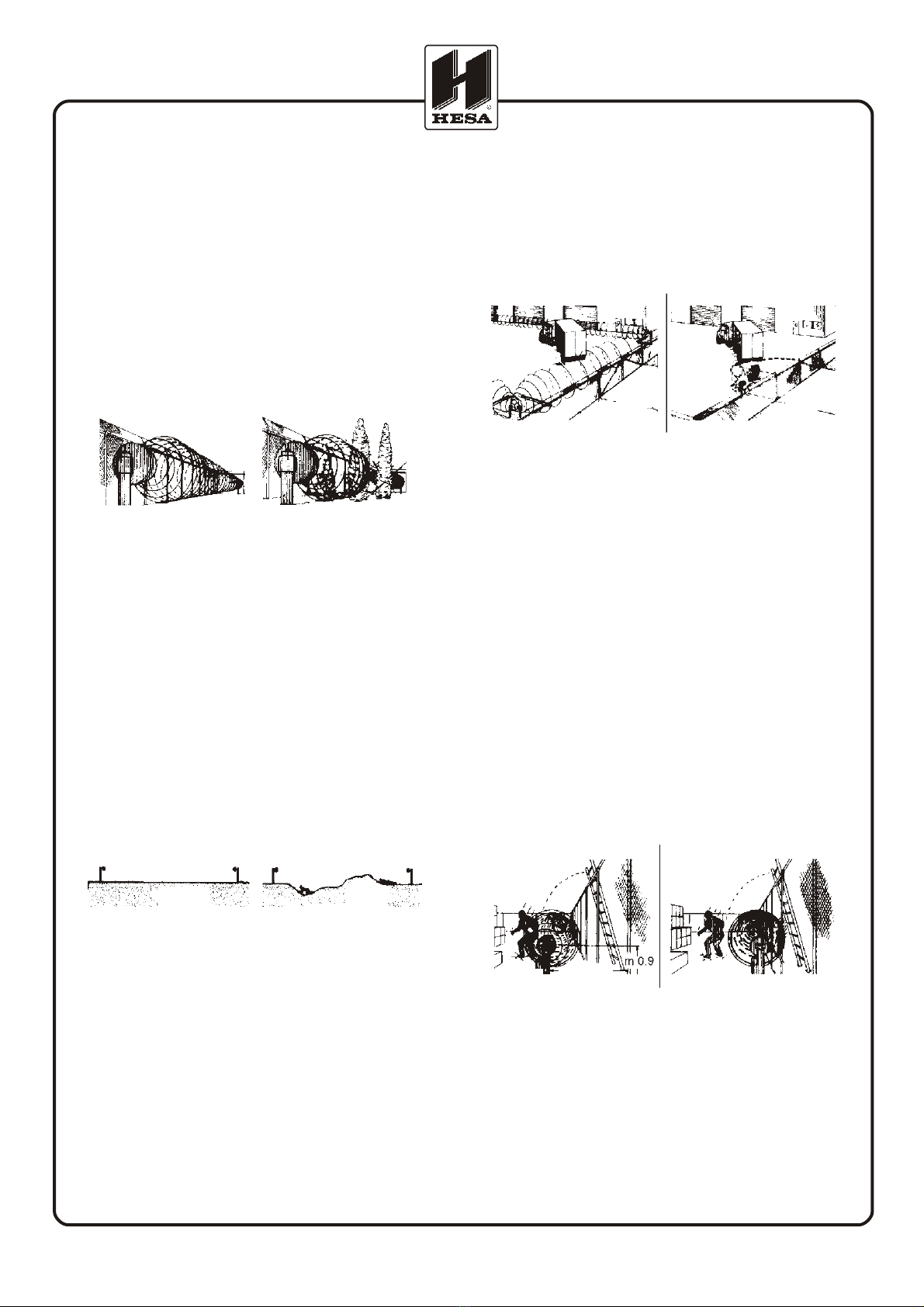

Required area. Model HE400 barrier must be loca-

ted in an area which is free of moving object such as

chain link fences, trees, bushes and large area of wa-

ter (see Fig. 5). Large moving objects within the protec-

tion pattern will be indistinguishable from an intruder

and will cause nuissance alarms. The clear area requi-

red for a model HE400 installation depends upon the

distance to be covered by the link. In each installation

the cleared area must be at least as large as the pro-

tection pattern.

Terrain. Since operation of the link requires trasmis-

sion of energy from Trasmitter to Receiver, it is impor-

tant to maintain a clear line of sight between the units.

Therefore, the ground must be flat across the protected

area. Any bumps, hills or ditches in the area will

shadow the beam and may provide crawl space for

an intruder. Bumps or hills must be leveled, and

dithches filled so that the area is flat to within 15 cm.

The protected area can be any stable, reasonably

smooth material such as concrete, asphalt, tilled earth,

or gravel. If there is grass or vegetation in the pro-

tected area, it must be kept cut to a maximum of 8 cm

in height. All the bushes or branches must be cut in or-

der to have a free area as large as the clear area.

Physical protection. Install the trasmitter and re-

ceiver in locations which provide protection from acci-

dental damage as well as from tampering. Simple de-

vices such as bumper posts or parking guards may be

used to protect equipment from damage from vehicles

(see Figure 7).

Best security. Choose the location that will provide

best security, yet be free from nuisance alarms. Al-

ways locate model HE400 inside a fence or inside a

controlled access area to prevent unwanted alarms

due to random foot traffic, vehicles, or large animals.

Typically, units should be mounted between 0.75 and

1.0m above ground level and far enough inside fence

to provide a clear area of protection (see Figure 8).

For maximum security it is necessary to overlap the

ends of links so that the dead spot below and imme-

diately in front of the adjoining link is protected. This

type of location gives maximum possible security. A

11m overlap is recommended at intermediate points,

and a 5.5m overlap is recommended at corners. If site

demands shorter overlap, increased sensitivity will re-

duce dead zone, but will also widen beam. The offset

of overlapping links in line should be approximately

50cm; this distance should be measured from center

of each unit.

Connection of the device to the AC

supply

The apparatus work with AC supply at a maximum vol-

tage of 19Vac. The connection between the receiver

or transmitter and the transformer should be the shor-

test possible (less than 4 m) with a wire not less than

1.5mm2. The wires which connect the transformer to

the 220 VDC must have a section of 2.5mm2. In case

Model HE400 microwave barrier DT01142 - Page 4

DOCUMENTAZIONE TECNICA TECHNICAL DOCUMENTATION

Fig. 5: Attention to trees!

YES NO

Fig. 6: Installation on flat grounds only

YES NO

Fig. 7: Avoid interferences with moving objects

YES NO

Fig. 8: Distance from the fence

YES NO

the AC source is low voltage (19Vac), insulation tran-

sformers should be used, 20V: 20V of at least 80VA.

The length of the connection and the possibility that

each device can use a maximum current of 1A must be

considered in the connection to the 19Vac power sup-

ply; in any case the section of the wires must not be

less than 1.5mm2.

Note: The cable which carries the barrier supply from

the transformers to the battery heads must be shielded

and the shield must be connected to the ground.

Connection of the backup battery

Inside each transmitter and receiver unit there is a spa-

ce for installing a rechargeable battery of 12V 2,1

Ah. The battery is charged by the supplier inside each

head and it is connected to it by red and black wires

with supplied with clips wired to the wire terminal. This

battery, when there is no mains supply, allows an auto-

nomy of over 36 hours to the device (when fully char-

ged). If a greater autonomy is necessary, a larger

power supply should be installed very closed to each

device. The connection of these power supply units

should be done at the terminals of the device marked

with the symbols of - and + 13,8 VDC. The sizing of

these groups should done considering that the DC cur-

rent drawn by each single receiver or transmitter unit

is 70mA approx., including the current drawn by the

backup battery.

The following information describe the wiring and the

alignment of the barrier. Please read carefully the in-

formation about the connector J2.

HE400T Transmitter

MS1: terminal block of TX printed board

VAC0/VAC1: power supply, connect the 19 VAC

output of the trasformer.

PT0/PT1: tamper circuit output N.C., for protection

against unauthorized openings, movements or tampe-

ring. In normal conditions there is a NC circuit (0 ohm)

voltage free. The opening of the contact is determined

by a movement of the TX unit (by AMP1) or after a re-

moval of the head cover (change of state of the switch

connected to J3).

SYNC: With JP1 closed (default) in this block there is

the signal for synchronizing other TX units when two or

more TX devices are working near as in the case of a

two levels protection.

-TX Master: close JP1 and make a connection

between the terminal SYNC of the TX Master to the ter-

minal SYNC of the TX Slaves.

-TX Slave: open JP1 and make connection the termi-

nal SYNC of TX Slave to the terminal SYNC of TX

Master.

Important!:

- do not make any connection to the terminal SYNC if

the synchronization feature is not used.

- Use max three TX Slave with each TX Master, total

length 60m max. (total) of wire connection (capacitan-

ce not higher than 150 pF/m).

- The TX Slave units, when synchronized, use the same

frequency of the TX Master.

- Connect together GND terminals of TX Master and TX

Slaves.

JP1: jumper setting for TX Master or Slave. See SYNC

description, connector MS1.

AMP1: movement sensor device. See PT0/PT1 de-

scription, connector MS1.

J3: microswitch connector against unauthorized ope-

nings of the cover of the head. See PT0/PT1 descrip-

tion, connector MS1.

D22: green LED, monitors the 19Vac power supply

presence. Without the power supply and with the bac-

kup battery installed, the LED is turned off but the devi-

ce continues to work normally.

D21: red LED, TX monitors the oscillator. With the

oscillator working correctly the LED is turned off. In

case of an oscillator trouble, the LED is turned on. It is

Model HE400 microwave barrier DT01142 - Page 5

Fig. 9: Transmitter unit circuit board

DOCUMENTAZIONE TECNICA TECHNICAL DOCUMENTATION

turned on also with JP1 open (TX Slave) and without

SYNC signal from the Master TX.

SW1: select one of the four modulation frequencies

for the TX unit; the same feature is found on the RX

heads.

Set TX and RX jumpers at the same positon for proper

function.

J1: TX Antenna assembly connection

J2: TX measure connector.

Pin 1: reference voltage (13,8 VDC)

Pin 2: reference GND

Pin 3-8: not used

Pin 9: TX oscillator reference voltage:

-0 V trouble on oscillator

-9 V normal working

Pin 10: internal reference voltage (9 VDC)

Note:

The voltage on pins 1-2 is also applied to MS2 con-

nector for recharging the backup battery.

It is possible to connect a LED to pin 9 (positive) and

pin 2 (ground) with low current absorbtion (typical

2mA) to monitor the oscillator; in any case, since it is a

CMOS device output, the max current output is 5mA.

MS2: connector for the backup battery; connect the

12V 2.1A rechargeable battery following the polarity

indications marked on the printed circuit; the F1 fuse

(1A) is in series with the positive of the battery.

The battery is automatically charged by the supplier

inside each head. This battery gives the TX an auto-

nomy of over 36 hours in case of mains failure.

F1: Battery protection fuse. See MS2 description.

U2: TO-220 voltage regulator, provides voltage refe-

rence (13,8 VDC). TO-220 metal case is insulated

from the metal case.

General note

The TX electronic board are available with the optio-

nal TEST function and Stand-By mode: see silk-screen

circuit on MS1.

If these functions are active:

TEST: Apply a GND signal (take pin “-“ from MS2) to

activate the test function; the test will be positive if the

correspondent RX will generate an intrusion alarm.

The D20 red LED turns on when the test is active.

STBY: Apply a GND signal (take pin “-“ from MS2) to

activate Stand-by mode of the TX; this inhibits MW si-

gnal emission of TX. Do not modify the JP2 jumper set-

ting (factory default) on the solder side of the PCB.

HE400R Receiver

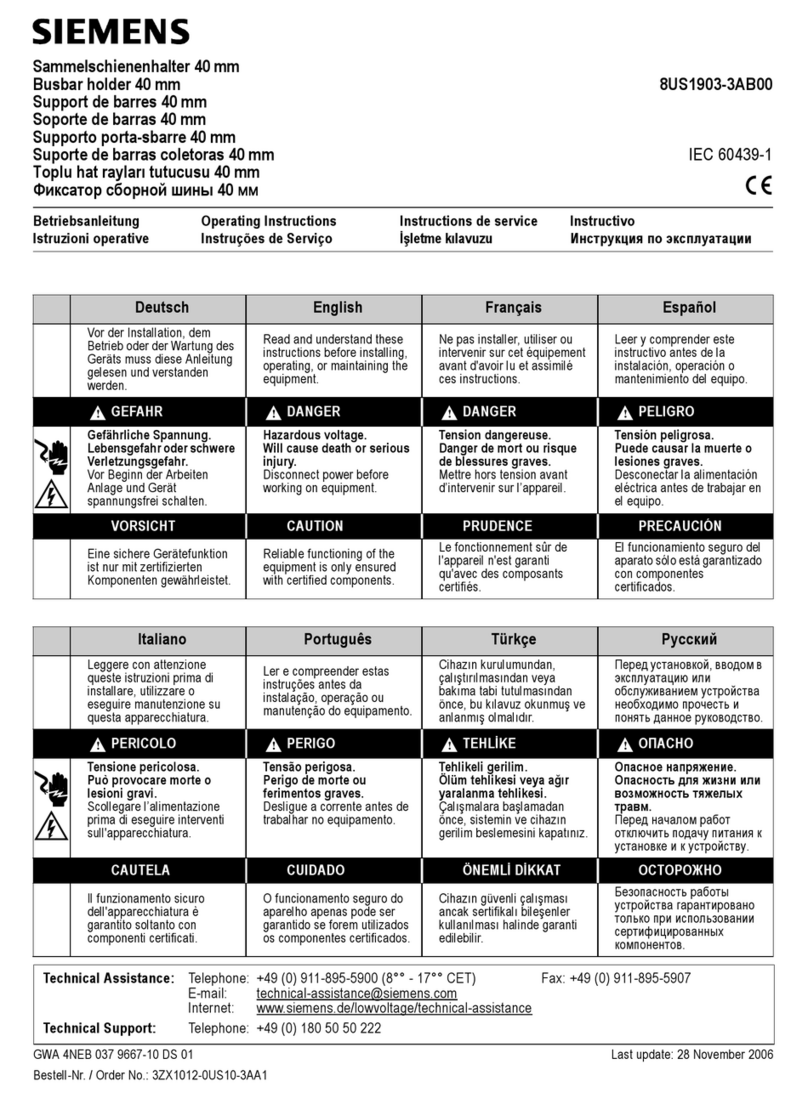

MS1: terminal block of RX printed board

VAC0/VAC1: power supply, connect the 19 VAC

output of the trasformer.

PT0/PT1: tamper circuit output N.C., for protection

against unauthorized openings, movements or tampe-

ring. In normal conditions there is a NC circuit (0 ohm)

voltage free. The opening of the contact is determined

by a movement of the RX unit (by AMP1) or after a re-

moval of the head cover (change of state of the switch

connected to J3).

ALL0/ALL1: Alarm circuit output NC. In normal con-

ditios the circuit is closed (35 ohm voltage free) while

on the opposite it will be open (R=8). The output is

connected to a photo coupler device and therefore the

maximum current load must be lower than 100mA.

AMP1: movement sensor device. See PT0/PT1 de-

scription, connector MS1.

J3: microswitch connector again unauthorized ope-

nings of the cover of the head. See PT0/PT1 descrip-

tion, connector MS1.

D9: green LED, monitors the 19Vac power supply pre-

sence. Without the power supply and with the backup

battery installed, the LED is turned off but the device

continues to work normally.

D8: green LED, monitors the RX link to the TX signal.

D7: red LED. The LED turns on when an alarm is de-

tected.

SW1: select one of the four modulation frequencies

for the RX unit; the same feature is found on the TX

heads.

Set TX and RX jumpers at the same positon for proper

function.

J1: RX Antenna assembly connection

J2: RX measure connector.

Pin 1: reference voltage (13,8 VDC)

Pin 2: reference GND

Pin 3: 200mV signal. By connecting an oscilloscope

(AC), it is possible to determine the quality of the si-

gnal received; after the normalization period it must

stabilize to 200mVpp ±5%.

Pin 4: not used

Pin 5: threshold value. It indicates the threshold value

set on the RX, selectable by PT5 trimmer.

This value is inversely proportional to the detection

sensitivity and the value must be in the range 0.4-9 V

measured with a digital voltmeter.

Pin 6: RX alarm output reference voltage:

-0 V: not in alarm

-9 V: in alarm

Pin 7: internal reference voltage (5 VDC)

Pin 8: AGC signal: barrier alignment voltage referen-

ce, inversely proportional to the quality of the barrier

alignment.

For the best alignment, the signal must be included

in the range 2,5-6,5 VDC.

Pin 9/10: not used.

Model HE400 microwave barrier DT01142 - Page 6

DOCUMENTAZIONE TECNICA TECHNICAL DOCUMENTATION

Notes on the above listed signals

- The voltage present on pins 1-2 is also used on the

MS2 connector for recharging the backup battery.

- The signal on pin 3 must be monitored in those parti-

cular critical installations where it can happen to have

a strong signal reflection. In normal installation condi-

tions, it is sufficient to align the units using a digital

voltmeter connected to pin 8 (AGC) and pin 2 (GND).

- It is possible to connect a LED with low current con-

sumption (2 mA) directly to pin 6 in order to monitor

the alarm output. Connect to this pin loads lower than

5mA.

- The AGC signal on pin 8 must be measured with a di-

gital voltmeter. Wait at least for 10 seconds between

each alignment test in order to consider valid the mea-

sure.

PT4: Trimmer for adjusting the RX speed detection:

turn clockwise to lower this parameter and on the op-

posite for increasing it (see on the printed circuit for re-

ference signals).

PT5: Trimmer for adjusting the RX sensitivity: turn

clockwise to lower this parameter and on the opposite

for increasing it (see on the printed circuit for referen-

ce signals).

MS2: connector for the backup battery; connect the

12V 2.1A rechargeable battery following the polarity

indications marked on the printed circuit; the F1 fuse

(1A) is in series with the positive of the battery.

The battery is automatically charged by the supplier

inside each head. This battery gives the RX an auto-

nomy of over 36 hours in case of mains failure.

F1: Battery protection fuse. See MS2 description.

U2: TO-220 voltage regulator, provides voltage refe-

rence (13,8 VDC). TO-220 metal case is insulated

from the metal case.

Model HE400 microwave barrier DT01142 - Page 7

DOCUMENTAZIONE TECNICA TECHNICAL DOCUMENTATION

Fig. 10: Receiver unit circuit board

Model HE400 microwave barrier DT01142 - Page 8

DOCUMENTAZIONE TECNICA TECHNICAL DOCUMENTATION

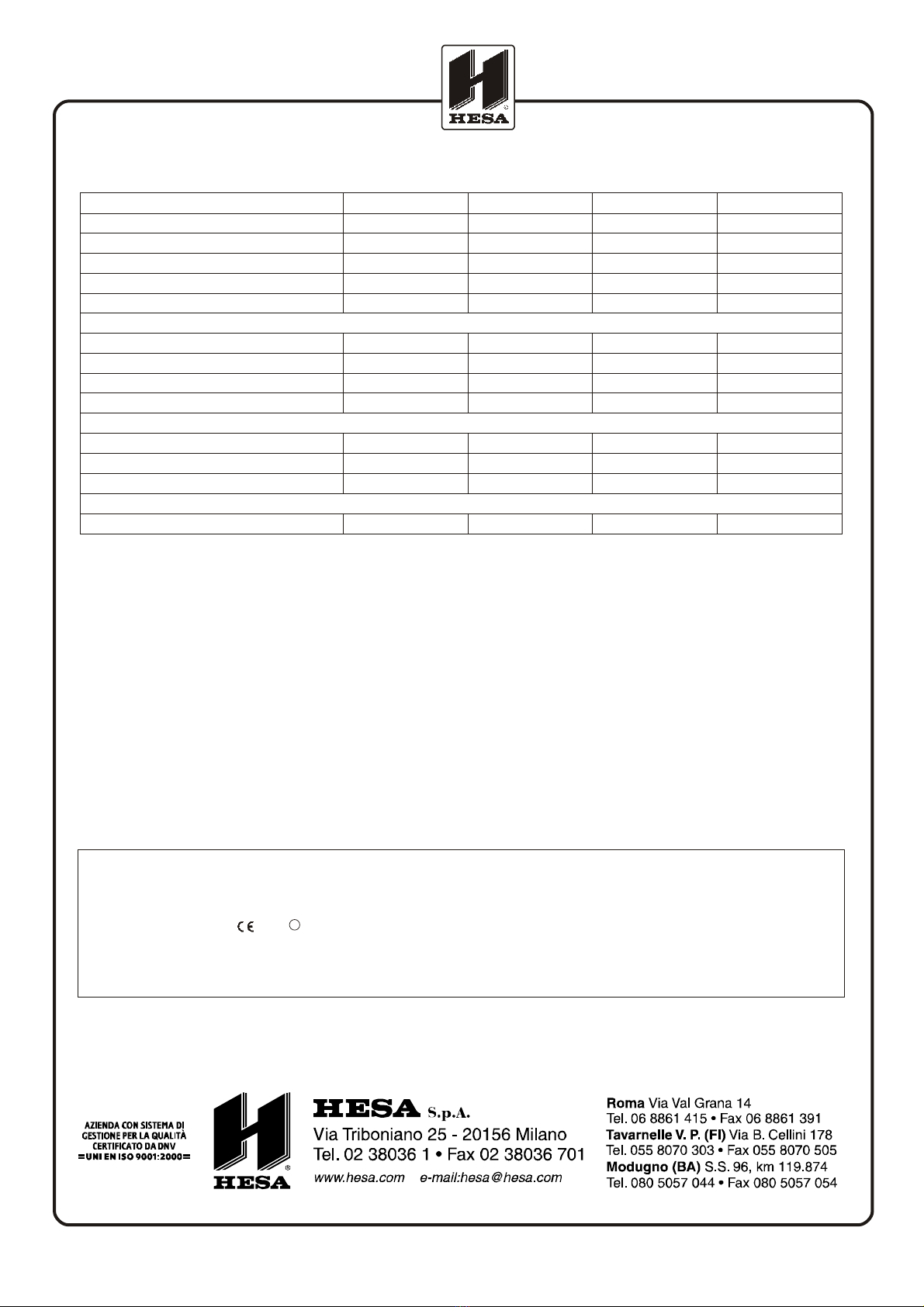

Min. Norm. Max. Note

Working frequency 9.5 GHz 9.9 GHz 9.95 GHz

Maximum power 3 mW

Modulation On/off

Duty-cycle 50/50

Number of channels 4

General internal reference voltage 13.8 VDC

RX current drain in stand-by mode 45 mA

RX current drain in alarm condition 40 mA

TX current drain 38 mA

ALARM OUTPUTS

TX tamper, opening and movement (NC) 30 VA P max

RX tamper, opening and movement (NC) 30 VA P max

RX alarm output (NC) 100 mA I max

CONTROL

RX sensitivity Trimmer

The following statement will be provided with the equipent as required by Article 6.3 of the R&TTE Directive, 199/05/EC:

HE400T is in conformity with all essential requirements of the R&TTE Directive 1999/05/EC. This equipement has been assessed to the following standards:

• Draft ETSI EN 300 440 part 1&2, July 2000

• ETS 300 683: June 1997

• EN 60950: 1992, Incl Amdt 1.4, 11 (+EN 41003/1993)

This product is marked with 0682 wich signifies conformity with Class II product requirements specified in the R&TTE Directive.

Hesa S.p.a. also declare the product HE400, is in conformity with 89/336/EEC and 73/23/EEC directives .

The product. HE400 has been assessed to the following standards:

• ETS 300 683: June 1997

• EN 60950: 1992, Incl Amdt 1.4, 11 (+EN 41003/1993)

!

TECHNICAL SPECIFICATIONS

This manual suits for next models

8

Table of contents

Other HESA Industrial Equipment manuals