Toro OSMAC G3 Satellite User manual

OSMAC®G3 Satellite

Installation Instructions

Introduction

The OSMAC G3 controller is designed for installation on a substantial concrete foundation with embedded conduit

of various diameters to enable power, eld and earth ground wiring to be routed into the cabinet. A mounting bolt

positioner and basic mounting hardware components are included with each controller. Additional materials required to

complete the installation must be obtained separately. A material list can be compiled by reading through the instructions

completely prior to starting the installation.

CAUTION: For your protection and the safety of the product user, comply with all Caution and Warning Statements

within this document. All installation practices must comply with all applicable national and/or local electrical and

construction codes.

Foundation Construction

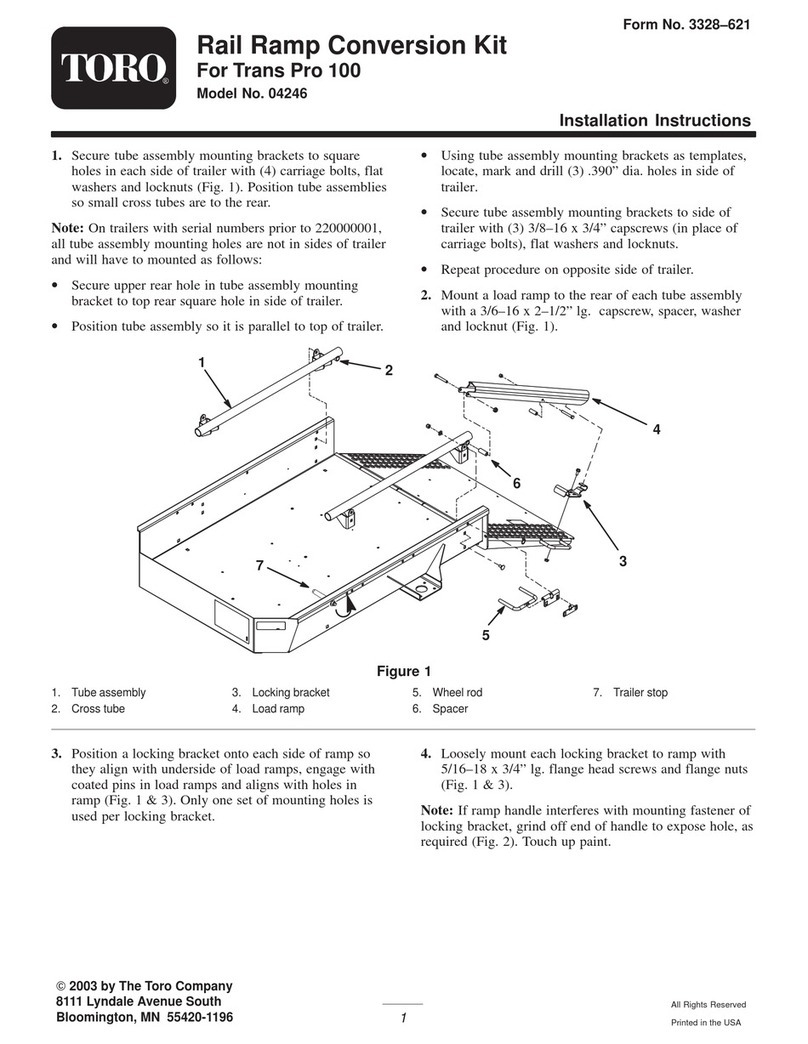

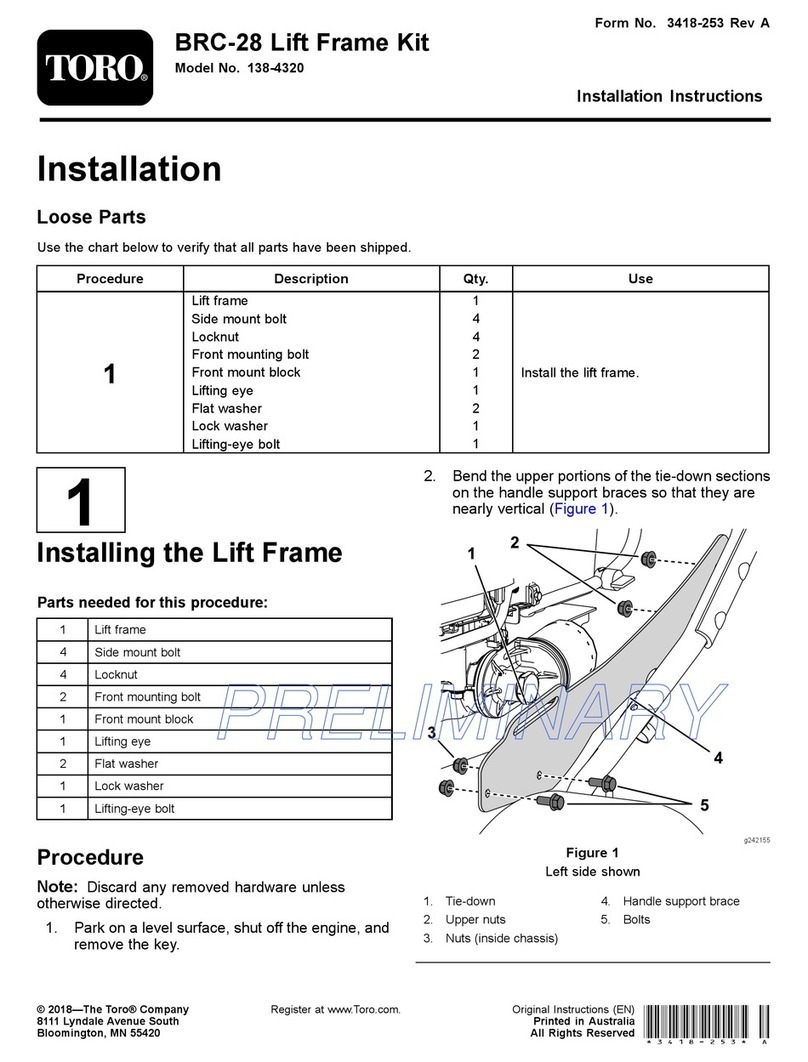

1. Prepare a hole for the foundation Figure 1 Wood Form

See *Note

Concrete

Mounting Bolt w/ Hex Nuts

(Typical 4 Places)

2" (51mm) Max

6" (15.2cm)

Mounting Bolt

Positioner

30"

(76cm)

30"

(76cm)

2"

(51mm)

Taper

Plastic Cabinet Base Area

Metal Cabinet Base Area

Mounting Bolt Positioner

3" (76mm) Conduit - Field

(32 Stations Each)

3/4" (19mm) Conduit

Earth Ground

3/4" (19mm) Conduit

AC Power

and wiring conduit using the

minimum recommended dimensions

shown in Figure 1.

*Note: Refer to local electrical

codes for required depth of buried

wiring.

2. Trench to the foundation site as

required for each wiring run.

3. Position the straight and sweep

elbow conduit sections in the

foundation hole as shown. Tape

the conduit ends to seal out dirt.

Backll soil to form a 6" (15.2cm)

foundation depth. Conduit should

not extend more than 2" (51mm)

above the nished top surface of the

foundation.

4. Prepare the sides of the foundation

hole with wood forms.

5. Prepare the mounting bolt positioner

with the 5/16" x 4-1/2" bolts and

nuts (provided) as shown in Figure 1.

The threads should extend 2"

(51mm) from the top surface of the

bolt positioner.

6. Pour concrete into the formed

foundation hole. Press the mounting

bolt positioner into the concrete

until it is ush and level with the

foundation surface and aligned with

the conduit.

7. Finish the concrete with a level at

area for the pedestal base (13" x

13" [33cm x 33cm] for the metal

cabinet or 16" x 16" [41cm x 41cm]

for the plastic cabinet). To prevent

pooling at the base of the pedestal,

add a slight taper away from the

cabinet base contact area. Allow the

concrete to suciently harden before

continuing.

8. Remove the hex nuts from the

mounting bolts. Place the pedestal

on the pad ensuring all bolts pass

though the holes provided. Install a

at washer and a hex nut on each bolt and tighten securely.

Earth Ground Installation

Important! Toro surge protection devices require an acceptable earth ground to dissipate excess energy. An earth

ground is required in all cases, and a measured resistance of 10 ohms or less is recommended. If it is impractical to

achieve a measured resistance of 10 ohms, the installation of ground rods, ground plates, and ground enhancement

material per the grounding material manufacturer’s instructions is recommended. It is further recommended that all earth

grounds and surge protection devices be checked yearly and after each lightning event. Toro advises against the use of a

bonding/shielding wire in conjunction with Toro irrigation control systems. Grounding materials or equipment that are not

specied in these instructions should not be connected to the Toro control products, Toro communication/power wiring

or the grounding for the communication/power wiring. All electrical equipment grounds must meet local electrical codes.

Procedure

115V

WARNING

HIGH

VOLTAGE

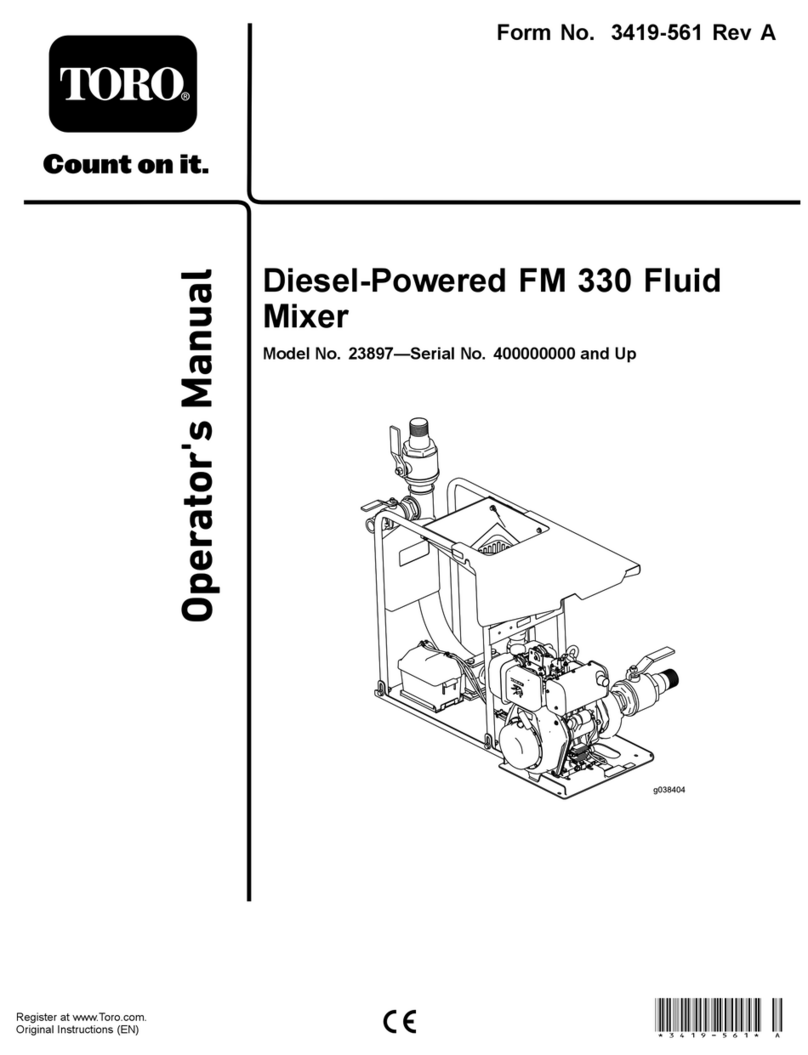

Figure 2

Chassis

Ground Lug

850-00

Valve Cover

Copper-Clad

Ground Rod

#6 (6mm2) Solid

Copper Ground Wire

12' (3.7m) Maximum

1. Drive a 5/8" (16mm) by 8' (2.5m) copper-

clad steel rod into well-moistened soil not

more than 12' (3.7m) from the satellite. The

top of the ground rod should be slightly

below grade level.

2. Using a 5/8" (16mm) clamp or “Cad weld”

fastener, attach a length of #6 (6mm2) solid

copper wire near the top of the ground

rod. Avoiding sharp bends, route the wire

through the foundation into the controller

cabinet. Secure the wire to the large copper

ground lug provided on the power supply

chassis. See Figure 2.

Note: Make sure the soil surrounding

the ground rod(s) remains well moistened

at all times. The addition of some form of

irrigation may be required if the satellite is

installed in a non-irrigated location.

3. Measure the ground resistance per the

instructions provided with the ground test

instrument. If the resistance exceeds the

acceptable limit, additional ground rod(s)

can be installed at a distance equal to twice

the buried depth of the rst rod; i.e., 16'

(4.9m).

Note: A Toro Valve Cover, P/N 850-00, works well for covering the ground rod and providing access to the ground

wire connection(s).

Input Power Installation

CAUTION: When installing multiple controllers, polarity of the Line and Neutral connections must be properly

maintained throughout the irrigation system. Reversed polarity may cause damaging potentials to exist at one or more

controller locations. An equipment ground wire from the power source must also be connected to the satellite power

supply terminal block.

WARNING

AC POWER WIRING MUST BE INSTALLED AND CONNECTED BY QUALIFIED PERSONNEL ONLY.

ALL ELECTRICAL COMPONENTS AND INSTALLATION PROCEDURES MUST COMPLY WITH ALL

APPLICABLE LOCAL AND NATIONAL ELECTRICAL CODES. SOME CODES MAY REQUIRE A MEANS OF

DISCONNECTION FROM THE AC POWER SOURCE, INSTALLED IN THE FIXED WIRING, HAVING A CONTACT

SEPARATION OF AT LEAST 0.120” (3MM) IN THE LINE AND NEUTRAL POLES.

ENSURE THE AC POWER SOURCE IS OFF PRIOR TO CONNECTING TO THE CONTROLLER.

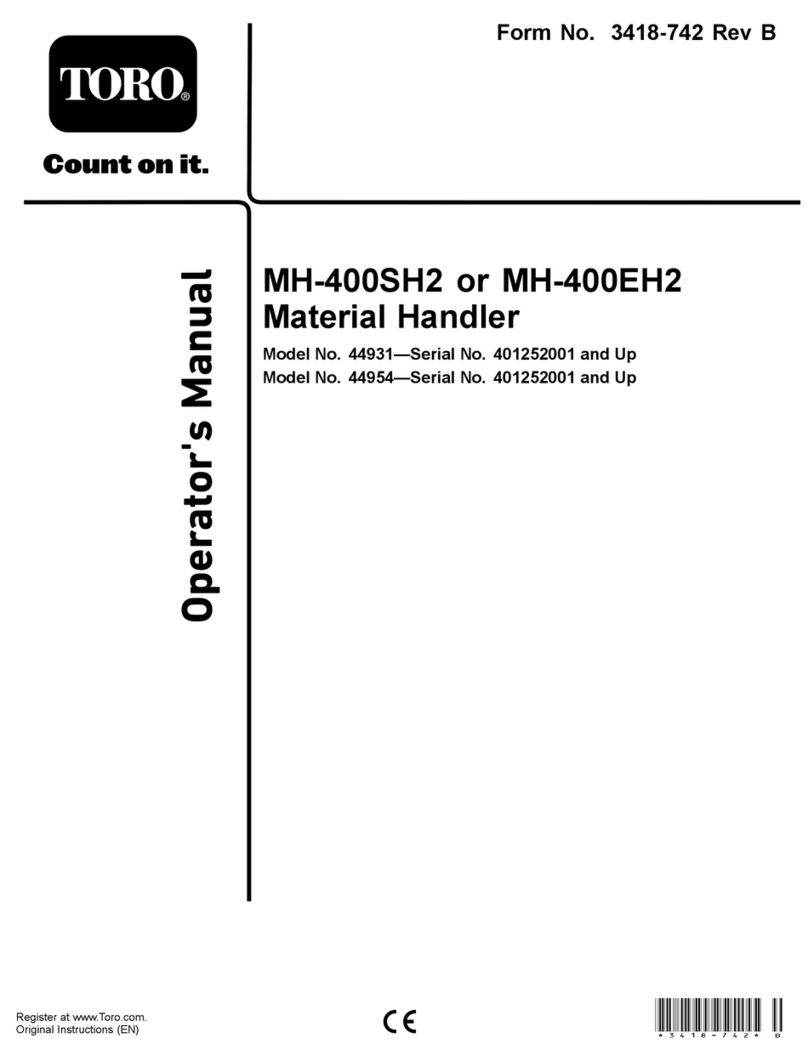

1. Place the controller’s main power switch in the O position. See Figure 3.

2. Position the input voltage select switch to the 115V (for 115-120V service) or 230V (for 230-240V service) as

required.

3. Remove the power wiring access cover located on the back of the power supply assembly. See Figure 4.

Note: The power and equipment ground wires are connected to a terminal block located on the back of the

power supply assembly. The power wire access hole provided will accommodate a 3/4" (19mm) conduit tting. If

conduit is required by code, install a section of exible 3/4" (19mm) electrical conduit from the foundation conduit to

this access hole.

4. Route the appropriate size 3-conductor cable (10 AWG [2.5mm2] maximum) from the power source location to the

power supply terminal block.

Line

Hot (Black)

Hot (Black)

Hot (Brown)

Neutral

Neutral (White)

Hot (Blue or Red)

Neutral (Blue)

Equip. Grnd.

Green

Green/Yellow

Green/Yellow

AC Service Type

115/120 V a.c. 50/60 Hz (Dom.)

230/240 V a.c. 50/60 Hz (3-Phase)

230/240 V a.c. 50/60 Hz (Int)

Table 1

5. Reference Table 1 for the appropriate

type of power connection. Secure the

wires to the terminal block as indicated

in Figure 4.

6. Reinstall the power wiring access

cover.

7. Apply power to the controller.

Note: The satellite incorporates a 24 V a.c. Hot Post feature on each station output module which enables control

valves to be identied through momentary activation. To utilize the Hot Post feature, the satellite power supply must

be switched on. If you do not wish to use the Hot Post feature, leave the controller’s main power switch O until the

installation has been completed. See Figure 6.

115V

WARNING

HIGH

VOLTAGE

Input Voltage

Select Switch

4.0A Circuit Breaker –

Control Functions

3.2A Fuse –

Station Output

On

Off

Main PowerSwitch/

1.5A Circuit Breaker

Figure 3

3/4" (19mm) Conduit

(Optional)

Cover (Side View)

Equipment

Ground

Neutral

Line

Figure 4

Field Wire Installation

CAUTION: The OSMAC G3 controller is capable of operating up to 12 stations simultaneously when operating with

a pump, or 16 stations simultaneously without a pump. To prevent possible controller damage, total output current load

must not exceed 3.2 amps. If more than one valve per station will be connected, calculate the total in-rush current load

which would be imposed in the maximum operating conditions and use this value as a guide during installation and

operation of the controller.

Procedure

1. Attach the control and common wires to each valve and/or valve-in-head solenoid leads using an approved

waterproof splicing method. Route the wires into the controller cabinet through the 3” (76mm) conduit.

2. If an automatic pump start is required, refer to the applicable wiring diagram in Figure 5 (page 4) and install

accordingly.

CAUTION: Do not connect the pump starter directly to the controller’s pump start circuit – damage to the

controller will result.

Note: The pump circuit can also be utilized to control a master valve if required.

Field Wire Installation (continued)

Multiple Controllers

Single Controller

Pressure Switch With

Controller Override

Starter

Power

Source

Starter

Power

Source

Starter

Power

Source

Pump Power

Source

Pressure Switch Pump Power

Source

Pump Power

Source

Relay

24 V a.c.

1A Max.

Relay

24 V a.c.

1A Max.

(Typical)

Relay

24 V a.c.

1A Max.

Pump

Pump

Pump

Pump

Pump

Pump

Pump

Com

Com

Com

Com

Magnetic

Pump

Starter

Magnetic

Pump

Starter

Mag.

Pump

Starter

To Other

Controllers

Figure 5

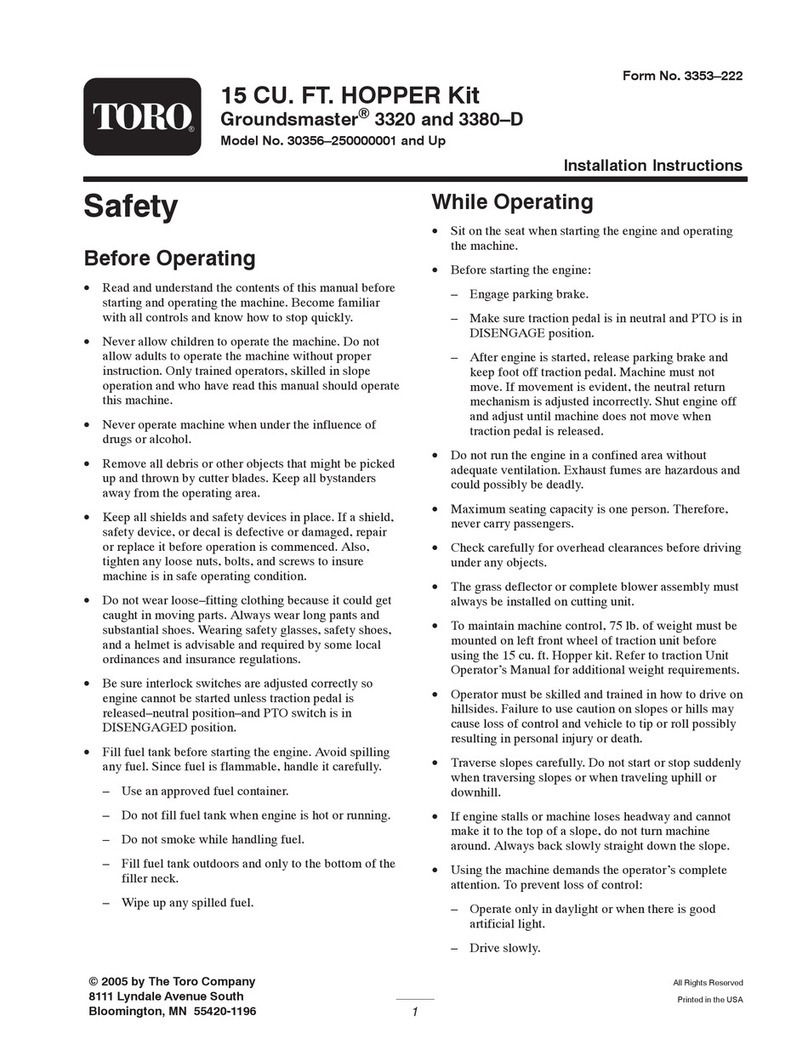

3. Secure the eld common wire(s) and

pump start relay (or master valve) wire to

the appropriate terminals on the Pump/

Com module. See Figure 6.

4. Momentarily touch each valve control wire

to the Hot Post to activate and identify the

corresponding valve(s).

5. Secure the valve control wires to the

station terminals in the preferred order

of operating sequence. Station terminals

are numbered left to right, 1–32 (front)

and 33–64 (back). Each terminal can

accommodate two 14 gage (1.5mm2) solid

copper wires. See Figure 6.

Note: A loop is provided on the plastic

chassis below each output module enabling

a wiring strain relief to be installed when the

optional standard terminal block connector is

used. After connecting the eld wires, install

a nylon cable tie through the loop and around

the wire bundle. Ensure the terminal block

is properly mated with the output module

connector after tightening the cable tie.

See Figure 6.

Note: The 3-position switches

4

24 V a.c.

Hot Post

Field Common

Control Switch

Pump Circuit

LED Indicator

24 V a.c.

Output LED

Indicator

24 V.a.c. Output

LED Indicator

(fuse condition)

24 V a.c. Output

LED Indicators

(one per station)

Field Common

LED Indicator

Field Common

LED Indicator

Pump Relay

Terminal

Field Common

Terminals (3) Station Output

Terminals

Standard

Terminal Block

(optional)

Cable Tie

Strain Relief

3A Fuse

(Station Output)

Station Output

Switches (optional)

1A Fuse

(Pump Circuit)

Pump Output

LED Indicator

Pump Circuit

Control Switch

Figure 6

provided on the pump/com module and the

optional station terminal board enable local

control of the eld common, pump circuit

and station output. The switch positions are

as follows:

ON (up) – Manually activates the circuit. The

pump, eld common or station output will

remain on until the switch is moved to the

AUTO or OFF position.

OFF (center) – Manually opens the circuit.

Operation of the circuit will not occur while

the switch is in this position.

AUTO (down) – Enables the circuit to be

automatically controlled during automatic or

manual (hand-held radio) operation.

CAUTION: To prevent damage to the

station output circuit fuse, do not exceed 3

amp load when manually activating multiple

station outputs.

Selecting the Radio Frequency

The OSMAC G3 controller has 6 pre-programmed user-selectable radio frequencies. The frequencies are programmed

at the factory or by the distributor prior to delivery of the satellite. However if a frequency change is desired, any of the 6

pre-programmed frequency channels can be modied to any desired radio frequency.

Important: The base station transmitter and satellite must be set to the same frequency to enable communication.

What’s Running

Manual Watering

Scheduled Watering

Communication

Diagnostics

Setting

Page Monitor Sig

Page History

Radio Menu

Sat Address: 001

Comm Code: Central

Receive Only Radio

Radio Frequency

Radio Information

Radio Send Command

Promiscuous: No

WMX Enable: Yes

Reset Radio Defaults

Channel: 1

Rx Freq1 462.2125MHz

Tx Freq1 462.2125MHz a

Channel: 1

Rx Freq1 462.2125MHz

Tx Freq1 462.2125MHza

1. While at the Home Screen, press

SELECT

SELECT

to access the controller menu selection.

2. Use the or arrows to select Communication and press

SELECT

SELECT

to access.

3. Use the or arrows to select Radio Menu and press

SELECT

SELECT

to access.

4. Use the or arrows to select Radio Frequency and press

SELECT

SELECT

to access.

5. While the cursor selection is on Channel: 1, press

SELECT

SELECT

to select. Use the or arrows to scroll through the six

pre-programmed frequency channels. Once the correct frequency is selected, press

SELECT

SELECT

to activate.

6. If the desired frequency does not match any of the pre-programmed channels, any of the six channels can be

modied. Follow Step 4 to select the channel you want to modify. Press arrow to access the frequency number.

Use the or arrows to navigate between the frequency digits. Press

SELECT

SELECT

and use the or to modify each

number to the desired radio frequency.

Assigning the Satellite Address Number

Each satellite requires a 3-digit address number to enable communication with the central controller and/or a hand-held

radio. The address numbers range from 1 (001) through 255.

What’s Running

Manual Watering

Scheduled Watering

Communication

Diagnostics

Setting

Page Monitor Sig

Page History

Radio Menu

Sat Address: 001

Comm Code: Central

Receive Only Radio

001

1. While at the Home Screen, press

SELECT

SELECT

to access the controller menu selection.

2. Use the or arrows to select Communication and press

SELECT

SELECT

to access.

3. Use the or arrows to select Sat Address and press

SELECT

SELECT

to access.

4. Use the or arrows to set the desired address for the satellite. Satellite address can be set to 001 through 255.

Satellites that belong to the same irrigation zone and will receive the same radio commands may be set to the same

satellite address.

Setting Time and Date

What’s Running

Manual Watering

Scheduled Watering

Communication

Diagnostics

Settings

Clock Set: 11:15am

Clock Mode: Am/Pm

Date Mode: MMDDYY

Date: 01/01/16 Fri

Sat Address: 001

Max Sim Sta: 05

11

Clock Set: 11:15am

Clock Mode: Am/Pm

Date Mode: MMDDYY

Date: 01/01/16 Fri

Sat Address: 001

Max Sim Sta: 05

01

1. While at the Home Screen, press

SELECT

SELECT

to access the controller menu selection. Press the arrow repeatedly until

Settings is selected and press

SELECT

SELECT

.

2. To set the time, press the arrow until Clock Set is selected and press

SELECT

SELECT

. Use the or arrows to navigate

between Hours and Minutes. Use the or arrows to set the values. Press

SELECT

SELECT

to nalize.

3. To set the date, press the arrow until Date is selected and press

SELECT

SELECT

. Use the or arrows to navigate

between days, months and year. Use the or arrows to set the values. Press

SELECT

SELECT

to nalize.

1

4

Satellite Operations Using a Hand-Held Radio

The following list of satellite operations can be initiated in the eld using a hand-held radio keypad. All operation

commands must begin with the following keypad sequence: * 9 followed by the 3-digit satellite address number. The

command code is then entered, followed by additional digits which represent selected stations and/or run time values.

All station numbers from 1–9 must be entered with a preceding 0; i.e., station 1 is entered as 01.

Example: Conrm communication to the satellite by issuing a manual station start command as follows: Press * 9, the

3-digit satellite address code, command code 7521 and 01 (station 1). An audible click should be heard from the station

relay and the corresponding station output LED should turn on. Visually check for sprinkler operation. To step forward

through the stations, press * 1; to step back through the stations, press * 2. To terminate the test, use command code

7520.

Command Code Operation Description

7510 Turns o individual stations; e.g., 7510 01 02 40 turns o stations 1, 2 and 40.

7511 Turns on individual stations; e.g., 7511 01 02 40 turns on stations 1, 2 and 40.

7512 Syringes individual stations for a predetermined number of 30-second intervals (already dened

in the satellite); e.g., 7512 01 02 turns on stations 1 and 2 for 30-second intervals.

7513 Disables individual stations; e.g., 7513 01 03 disables stations 1 and 3. After this command, on

and o commands will be ignored for stations 1 and 3 until the stations are re-enabled.

(See 7514.)

7514 Enables individual stations; e.g., 7514 01 03 enable stations 1 and 3.

7515 Sequentially syringes a specied station number range; e.g., 7515 10 20 will syringe stations 10

through 20 sequentially.

7516 Sequentially syringes individual stations; e.g., 7516 10 11 will syringe stations 10 and 11.

Multiple syringe groups can also be run. Enter two dashes between stations to designate

separate syringe groups; e.g., 7516 10 11 - - 22 24 26 28 will run two sequential syringes at the

same time on stations 10 and 11 and stations 22, 24, 26 and 28.

7517 Turns on individuals stations for a specied number of hours, minutes and seconds;

e.g., 7517 01 30 00 23 24 25 turns stations 23, 24 and 25 on for 1 hour, 30 minutes and no

seconds.

7518 Turns on individual stations for a specied number of minutes; e.g., 7518 10 23 24 25 turns on

stations 23, 24 and 25 for 10 minutes.

7520 Turns o a sequential station run operation (initiated by command code 7521).

7521 Turns on a sequential station run operation; e.g., 7521 01 turns on station 1. To step forward

through the stations, press * 1; to step back through the stations, press * 2.

7524 Turns on individual stations as switches; i.e., does not simultaneously energize the pump.

Note: Will not turn o the pump if already running. E.g., 7524 25 35 45 turns on stations 25, 35

and 45 without energizing the pump.

7525 Turns on individual stations as switches for a time given in minutes; i.e., does not simultaneously

energize the pump in this command string, the run time is entered rst, followed by the station

numbers; e.g., 7525 25 05 42 turns on stations 5 and 45 for 25 minutes without energizing the

pump.

7526 Turns on individual stations as switches for the time given in hours, minutes and seconds. In this

command string, the run time is entered rst, followed by the station numbers;

e.g., 7526 02 30 45 25 26 27 turns on stations 25, 26 and 27 for 2 hours, 30 minutes and 45

seconds.

7540 Turns o all stations (this satellite only).

7543 Disables all stations in all satellites (rain shutdown). Note: Satellite address code is not used

with 7543 or 7544 command codes. The stations will not respond to any further commands until

enabled.

7544 Enables operation of all stations in all satellites. See Note above.

7546 Sequentially syringes all stations for a set length of time; e.g., 7546 turns on all stations for the

predetermined number of 30 second intervals as dened in the syringe time.

8000 Disables pump start.

8001 Enables pump start to be assigned to a station; e.g., 8001 48 assigns pump start to station 48.

8003 00 Disables operation and turns o all stations in the satellite with sequential shutdown.

8003 01 Enables operation of all stations in the satellite.

8004 Changes the password; e.g., 8004 7531 6108 will change the factory default password (7531) to

6108.

Command Code Operation Description

8006 01 Sets the syringe time in 30-second intervals; e.g., 8006 01 0100 (without a password) or 8006

pppp 01 0100 (with a password) sets the syringe time to 100 intervals (50 minutes). The number

of intervals must be given as four digits with leading zeros but can be no greater than 0255.

8006 03 Enables/disables the password. Use 8007 03 01 to enable password protection or 8007 03 00

to cancel password protection.

8008 Congures stations as switches. Stations can be specied individually and in combination with

a range of stations; e.g., 8008 01 12 50 – 60 congures stations 1, 12 and 50 through 60 as

switches. Note: Only a single dash is used when entering a range of stations.

8009 Congures stations for irrigation. Stations can be specied individually and in combination with

a range of stations; e.g., 8009 01 20 45 – 48 congures stations 1, 20 and 45 through 48 for

irrigation.

8011 Resets to factory defaults.

Installing Additional 8-Station Output Modules

The OSMAC G3 controller can be upgraded to a maximum of 64 station outputs with the addition of 8-station output

modules and optional terminal boards. The station module is supplied with the required mounting hardware and

connector cable.

Note: Each of the eight output module positions has a specic station number assignment. An output module can be

installed in any open position. The controller recognizes the module station order as follows:

(Front, left to right)

Backplate

Ribbon Cable

Latch

Output Distribution

Board

Standard-Station

Output Terminal

Block

Optional Station Output

Terminal Board Assembly

8-Station

Output Module

Machine

Screw*

Machine

Screws*

Self-Tapping

Screws

Self-Tapping

Screw

Figure 7

Module position 1 = Stations 1–8

Module position 2 = Stations 9–16

Module position 3 = Stations 17–24

Module position 4 = Stations 25–32

(Back, left to right)

Module position 1 = Stations 33–40

Module position 2 = Stations 41–48

Module position 3 = Stations 49–56

Module position 4 = Stations 57–64

Installation Procedure (Refer to Figure 7)

1. Switch power supply O.

2. Place the 8-station module onto the backplate,

positioning it between the four guideposts.

Carefully press inward at the top of the module

board to engage the plastic latch.

3. Ground and secure the module to the backplate

assembly using the single machine screw

provided. *Important: The machine screws

connect the output and station modules to the

24V power and ground bus bars and must be

installed in the designated locations as indicated

in Figure 10. Do not attempt to use self-tapping

screws in these locations.

4. Install the ribbon cable to the 8-station module

and output distribution board receptacles as

shown. The ribbon cable connectors are keyed

to insert in only one direction.

5. Insert the optional station output terminal

board assembly connector or standard terminal block to the station module receptacle. Secure the terminal board

assembly to the chassis with three self-tapping screws and two machine screws provided.

6. Connect the valve wiring as described on page 4.

7. Switch power supply On.

Specications

Line Voltage: 115-120 or 230-240 V a.c. 50/60 Hz (switchable), 130 VA

Current Draw (no load): 0.21A @ 115-120 V a.c., 60 Hz or 0.10A @ 230-240 V a.c., 50 Hz

Current Draw (maximum load): 0.91A @ 115-120 V a.c., 60 Hz or 0.45A @ 230-240 V a.c., 50 Hz

Secondary Voltage Output: 24 V a.c., 50/60 Hz, 3.0A (85 VA)

Maximum Load Per Station Output: 0.75A (18 VA)

Maximum Load Per Pump/Master Valve Output: 1A (24 VA)

Operating Temperature: -10°C to +60°C (14°F to 140°F)

Storage Temperature: -30°C to +65°C (-22°F to 149°F)

Hardware Features

Plastic or painted stainless-steel cabinetry

Front, back and top locking covers

Modular station output capacity upgradeable in 8-station increments. (48-station maximum when used in conjunction

with TouchNet; 64-station maximum with SitePro.)

Optional output terminal board congurations in 16-station increments

Optional antenna adapter kit available.

Fuses and Circuit Breakers

Power Supply:

1.5A On/O Switch/Circuit Breaker – Main Power Input

3.2A Fuse – Power Supply (Slow Blow)

4.0A Circuit Breaker – Control Functions

Control Modules:

Pump – 1.0A Fuse (Fast Blow, Automotive Type)

Station Output – 3.0A Fuse (Fast Blow, Automotive Type)

WARNING

IF FUSE REPLACEMENT IS REQUIRED, REPLACE WITH A FUSE OF THE SAME TYPE AND AMPERAGE

RATING. FAILURE TO COMPLY CAN RESULT IN SERIOUS INJURY AND/OR EQUIPMENT DAMAGE DUE

TO FIRE HAZARD.

Electronic Compatibility

Domestic: This equipment generates and uses radio frequency energy and if not installed and used properly, that is,

in strict accordance with the manufacturer’s instructions, may cause interference to radio and television reception. It

has been type tested and found to comply with the limits for a FCC Class B computing device in accordance with the

specications in Subpart J of Part 15 of FCC Rules, which are designed to provide reasonable protection against such

interference in a residential installation. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause interference to radio or television reception, which can be determined by

turning the equipment o and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient the receiving antenna.

• Relocate the irrigation controller with respect to the receiver.

• Move the irrigation controller away from the receiver.

If necessary, the user should consult the dealer or an experienced radio/television technician for additional suggestions.

The user may nd the following booklet prepared by the Federal Communications Commission helpful:

“How to Identify and Resolve Radio-TV Interference Problems.” This booklet is available from the U.S. Government

Printing Oce, Washington, DC 20402. Stock No. 004-000-00345-4.

International: This is a CSPR 22 Class B product.

© 2018 The Toro Company, Irrigation Business • www.toro.com Form Number 373-0889 Rev B

Table of contents

Other Toro Industrial Equipment manuals

Toro

Toro Workman 07224-90001 Instruction Manual

Toro

Toro BRC-28 User manual

Toro

Toro FM 330 User manual

Toro

Toro MH-400SH2 User manual

Toro

Toro 301 High Lift User manual

Toro

Toro Groundsmaster 3320 User manual

Toro

Toro 60216C User manual

Toro

Toro MB TX 2500 User manual

Toro

Toro 22340 User manual

Toro

Toro Ultra Buggy e2500 User manual

Popular Industrial Equipment manuals by other brands

Scheppach

Scheppach UMF1600 Translation of original instruction manual

Titan

Titan 680 Installation, Maintenance, and Parts Manual

EASTERN INSTRUMENTS

EASTERN INSTRUMENTS CentriFlow manual

steute

steute Ex STM 298 3G/D Series Mounting and wiring instructions

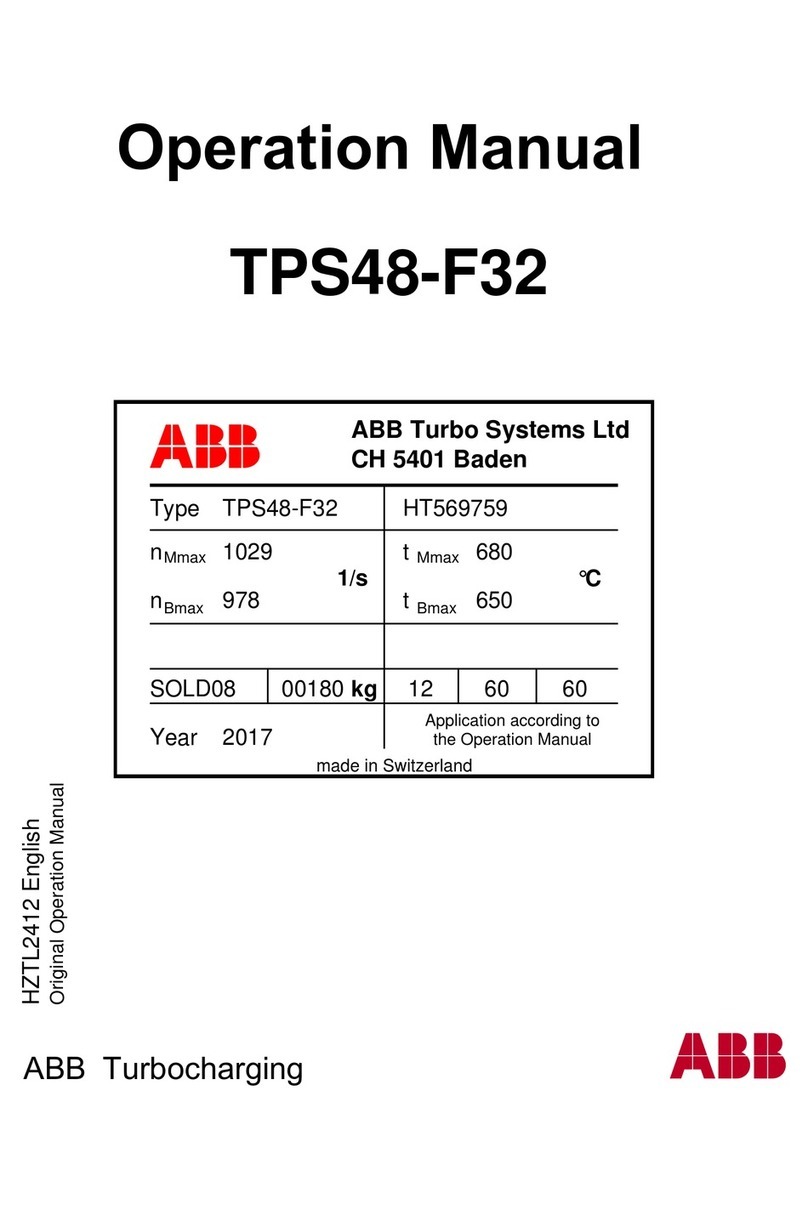

ABB

ABB HT569759 Operation manual

Danfoss

Danfoss VLT Soft Starter MCD 600 installation guide