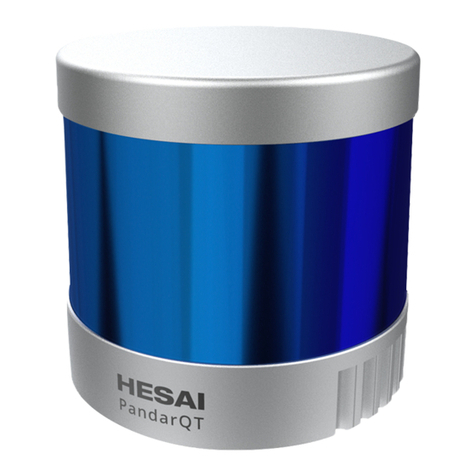

◼

Safety Precautions

In all circumstances, if you suspect that the device malfunctions or is damaged, stop using it immediately to avoid potential hazards and injuries. Contact an

authorized Hesai Technology service provider for more information on device disposal.

Handling

This device contains metal, glass, plastic, as well as sensitive electronic components. Improper handling such as dropping, burning, piercing, and squeezing

may cause damage to the device.

In case of dropping the device, STOP using the device immediately and contact Hesai technical support.

Enclosure

This device contains high-speed rotating parts. To avoid potential injuries, DO NOT operate the device if the enclosure is loose or damaged.

To ensure optimal performance, do not touch the device’s enclosure with bare hands. If the enclosure is already stained, please refer to the Sensor

Maintenance chapter in user manuals for the cleaning method.

Eye Safety

Although the device meets Class 1 eye safety standards, DO NOT look into the transmitting laser through a magnifying device (microscope, eye loupe,

magnifying glass, etc.).

For maximum self-protection, avoid looking directly at the device when it is in operation.

Repair

DO NOT open and repair the device without direct guidance from Hesai Technology. Disassembling the device may cause degraded performance, failure in

water resistance, or potential injuries to the operator.

Power Supply

Use only the cables and power adapters provided by Hesai Technology. Only the power adapters that meet the device’s power requirements and

applicable safety standards can be used. Using damaged cables, adapters or supplying power in a humid environment can result in fire, electric shock,

personal injuries, product damage, or property loss.