SECTION 5 Modes of Operation

7 8

Modes of Operation SECTION 5

Modes of Operation

Regular

This option encompasses any of the following types

of discs: CD-ROMs, Music CDs, Data CDs, DVDs, HD-

DVDs, Computer Discs, Game Discs, Books on Disc, all

recordable CDs and DVDs, Double Sided Discs, Blu-Ray,

Wii U, and PS3.

Note: On this mode of operation, Blu-Ray and PS3

discs may only be cleaned. To “Repair” these types of

discs, run them on the Deep Mode.

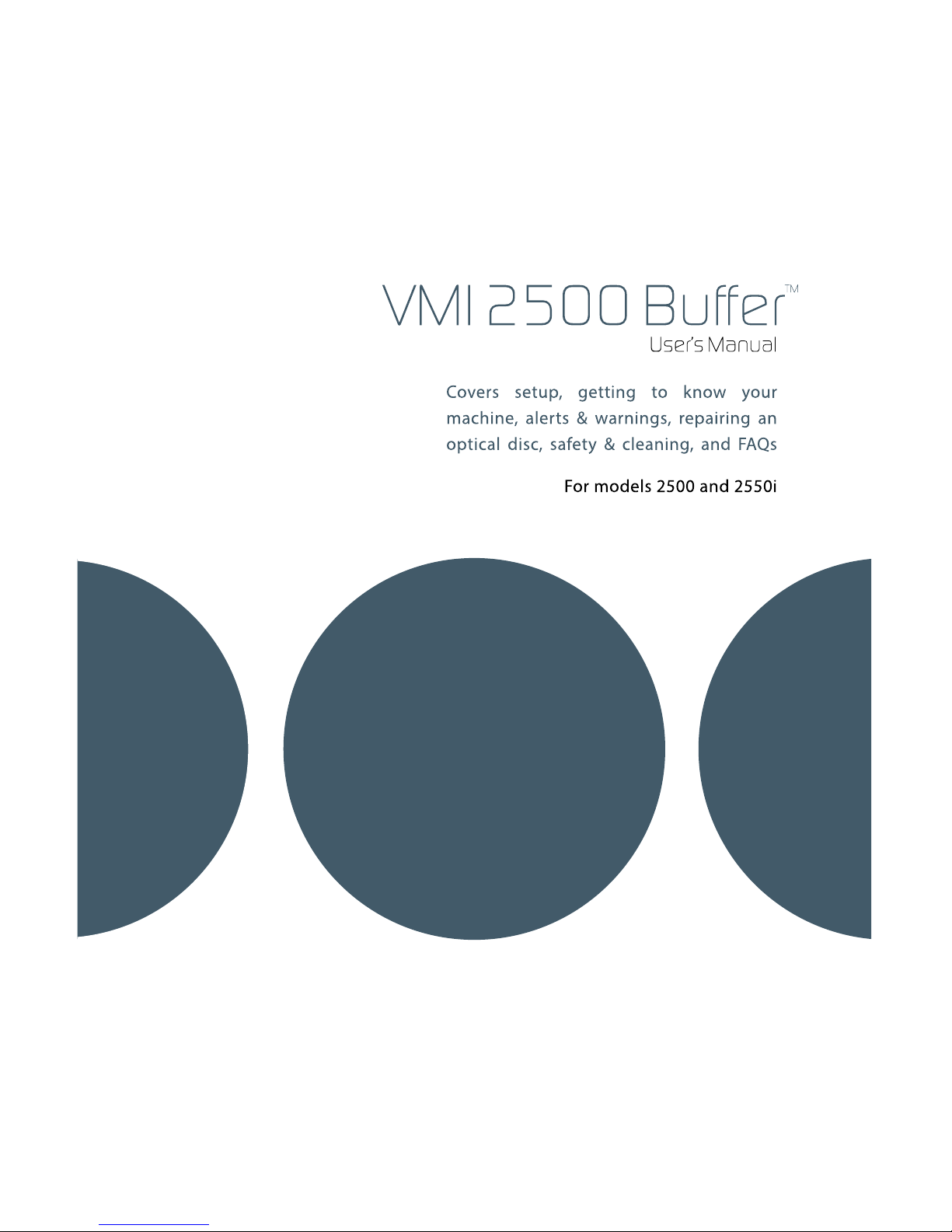

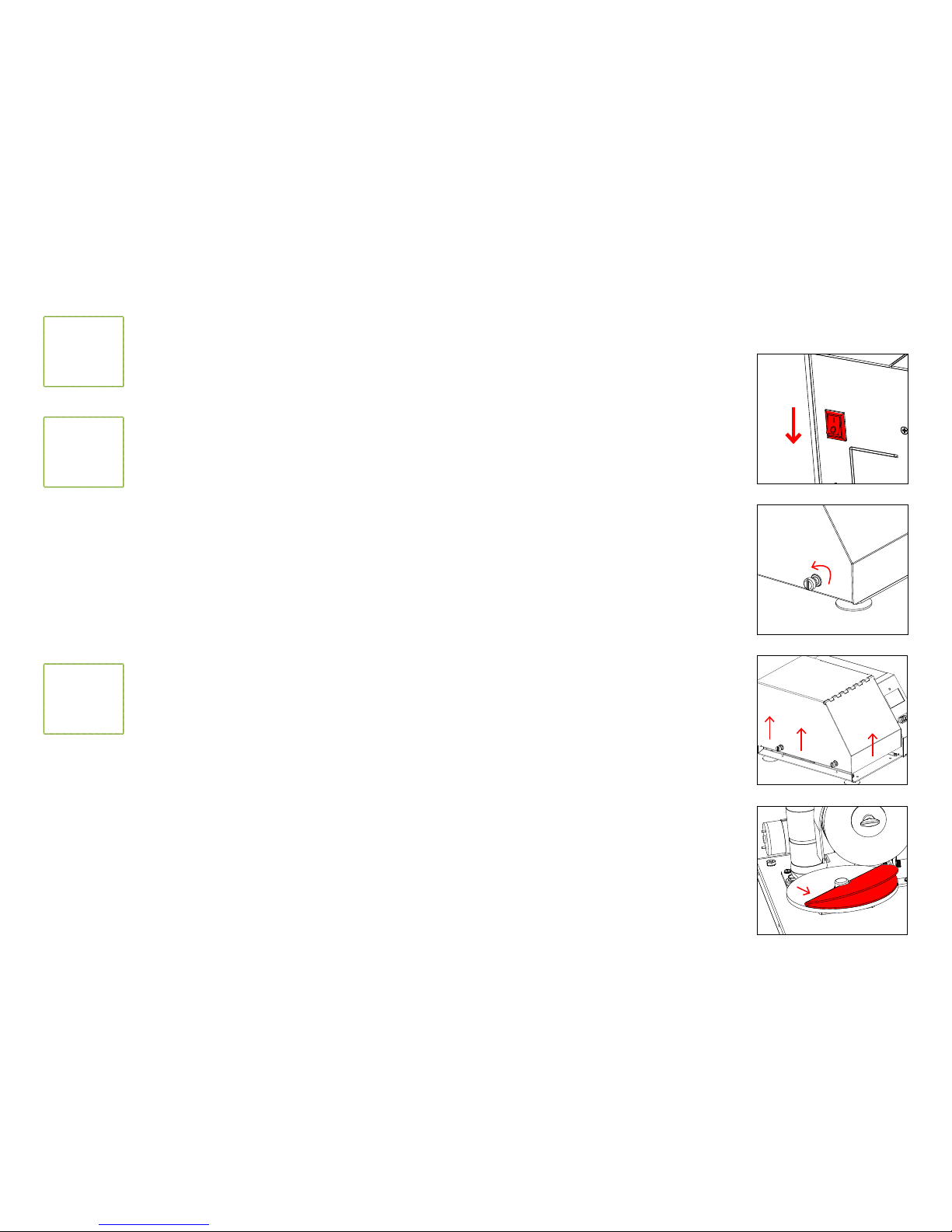

The VMI 2500 is preset to run on the“Regular” mode, as indicated by the Green

LED light illuminated on the Start Button. The Cycle Mode is displayed on the

LCD Screen in the “Main” Menu, on the bottom section. If the line reads: “Cycle

REG”, then your unit is ready for a regular repair mode. This mode is set to run

for 30 seconds.

Deep

This option encompasses any of the following types

of discs: CD-ROMs, Music CDs, Data CDs, DVDs, HD-

DVDs, Computer Discs, Game Discs, Books on Disc,

all recordable CDs and DVDs, Double Sided Discs,

Blu-Ray, Wii U, and PS3.

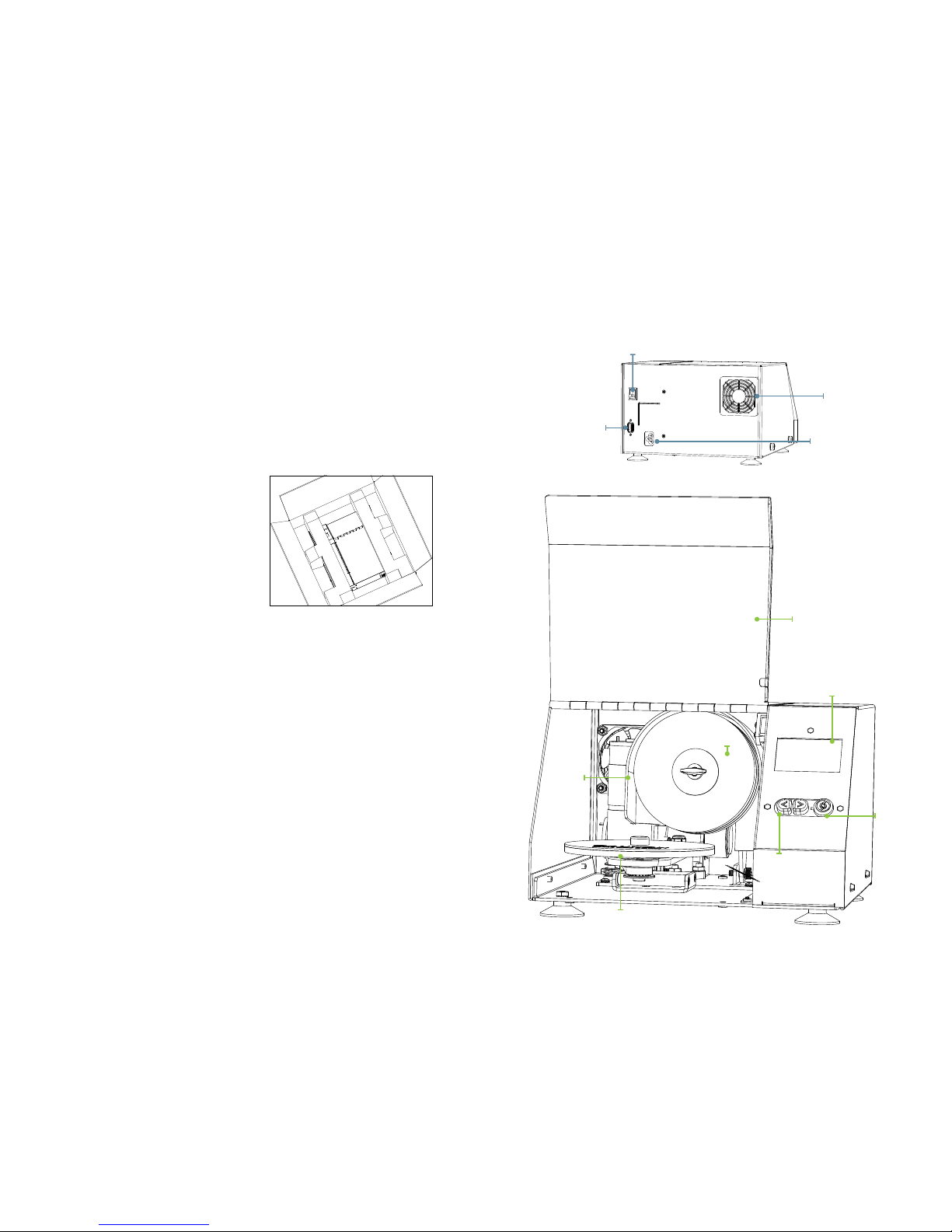

The VMI 2500 is preset to run on the “Regular” mode.

To switch the machine over to the “Deep” mode of

operation, press either one of the Scroll Buttons until Cycle Deep appears on

display. Once the machine is set to the “Deep” mode, this will be indicated by a

Blue LED light illuminated on the Start Button. Located on the LCD Screen in the

“Main”Menu, on the bottom section, this is where the Cycle Mode is displayed.

This mode is set to run for 1 minute.

Cleaner

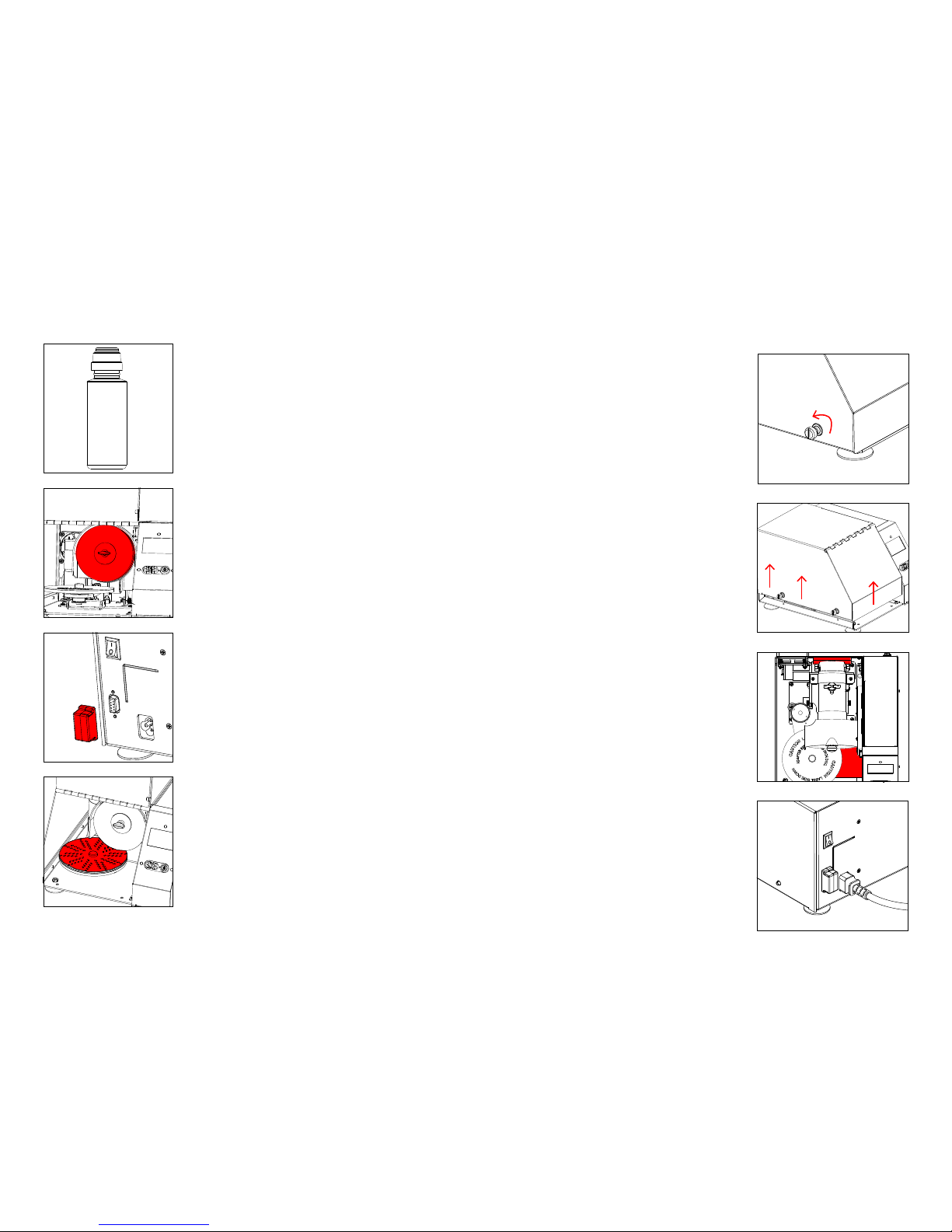

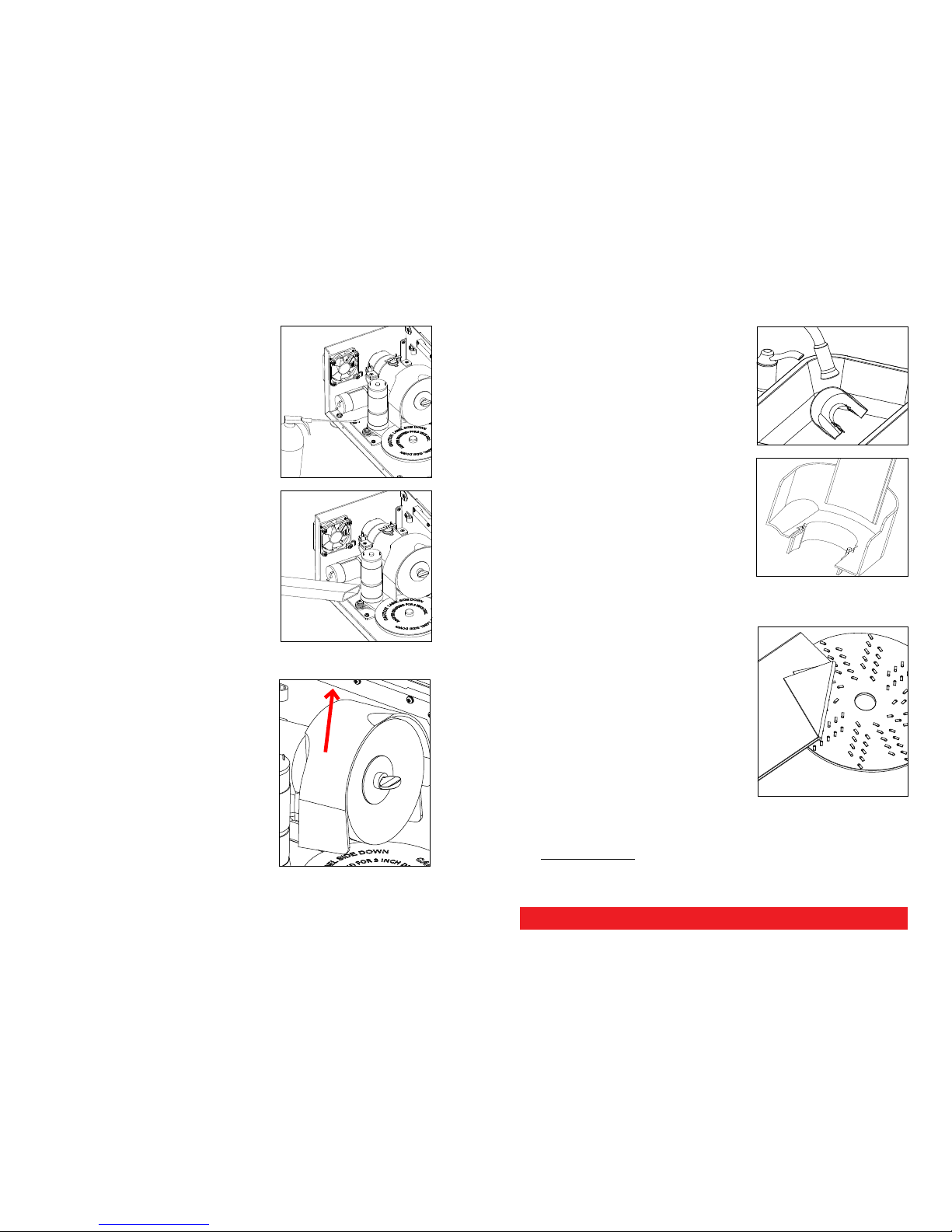

Over time, the Bung Wheel will become encased

with dried solution and plastic particles. Bung

Wheels left in this condition will eect the

repair quality of the discs and in some extreme

circumstances may cause damage to the discs

themselves. For this reason the VMI 2500 has been

designed to notify the Operator to clean the Bung

STAT READY

COUNT 499

CYCLE REG

STAT READY

COUNT 499

CYCLE DEEP

STAT READY

COUNT 499

CYCLE CLNR

Wheel. After about 20 minutes of machine operation, the Main Menu will

display the message: “Cycle CLNR”, on the bottom section of the Cycle Mode

line. The Start Button will also ash an illuminated Red LED light. At this point

load the Cleaner Disc onto the rubber platter.

Note: Make sure the Cleaner Disc is loaded Label Side Down! Close the front

cover and press the Start Button. Upon completion, the machine will reset back

to the preset “Regular” mode and the Operator can now continue using the

machine.

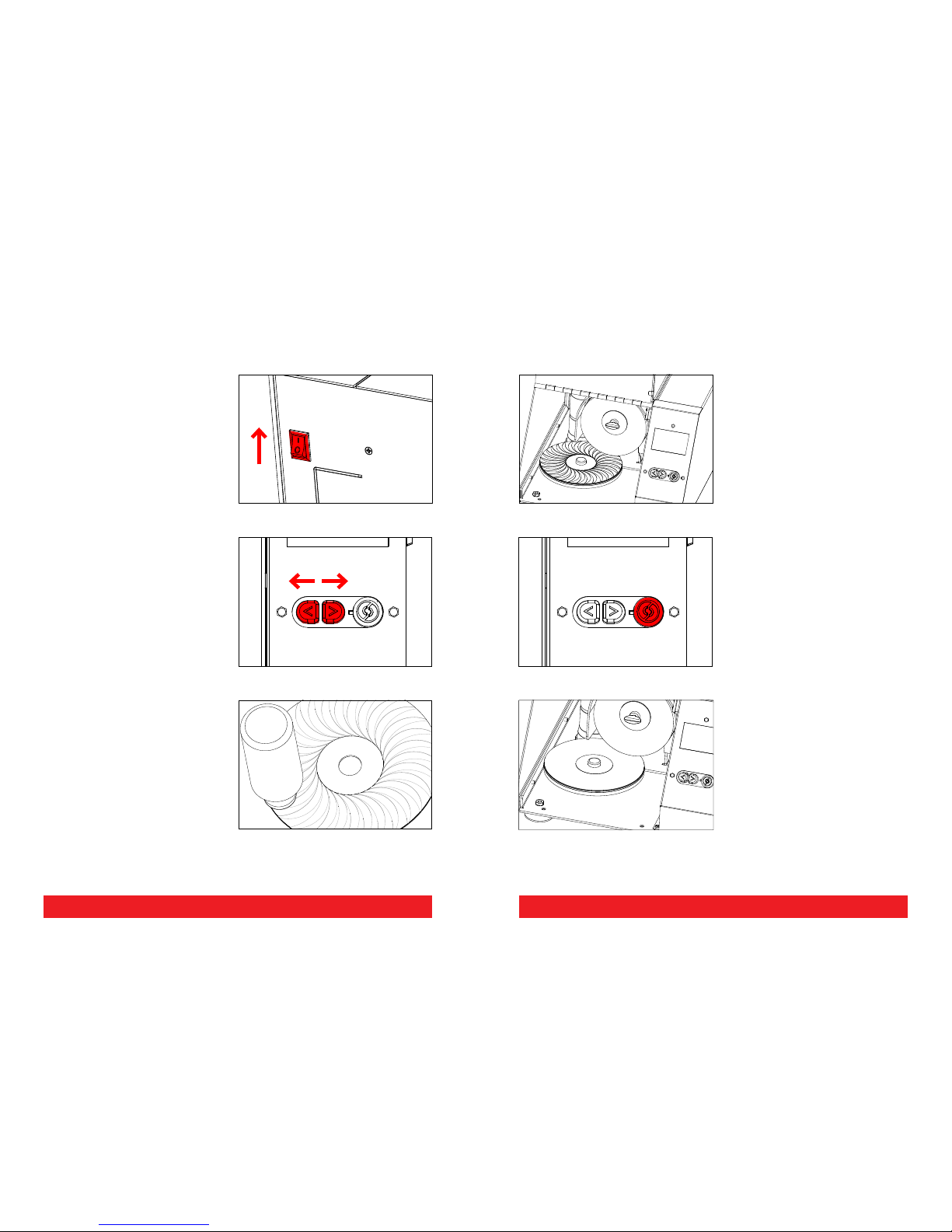

At certain times, the Operator may choose to run the “Cleaner” mode before

the machine instructs the Operator to do so. In order to activate this mode of

operation, press either one of the Scroll Buttons until cycle CLNR appers on

display. Once the machine is set to the “Cleaner” mode, this will be indicated

by a ashing Blue LED light illuminated on the Start Button. The Cycle Mode

displayed on the bottom section of the Main Menu will read: “Cycle CLNR”.

Proceed to insert the Cleaner Disc, close the front cover, and press the Start

Button.

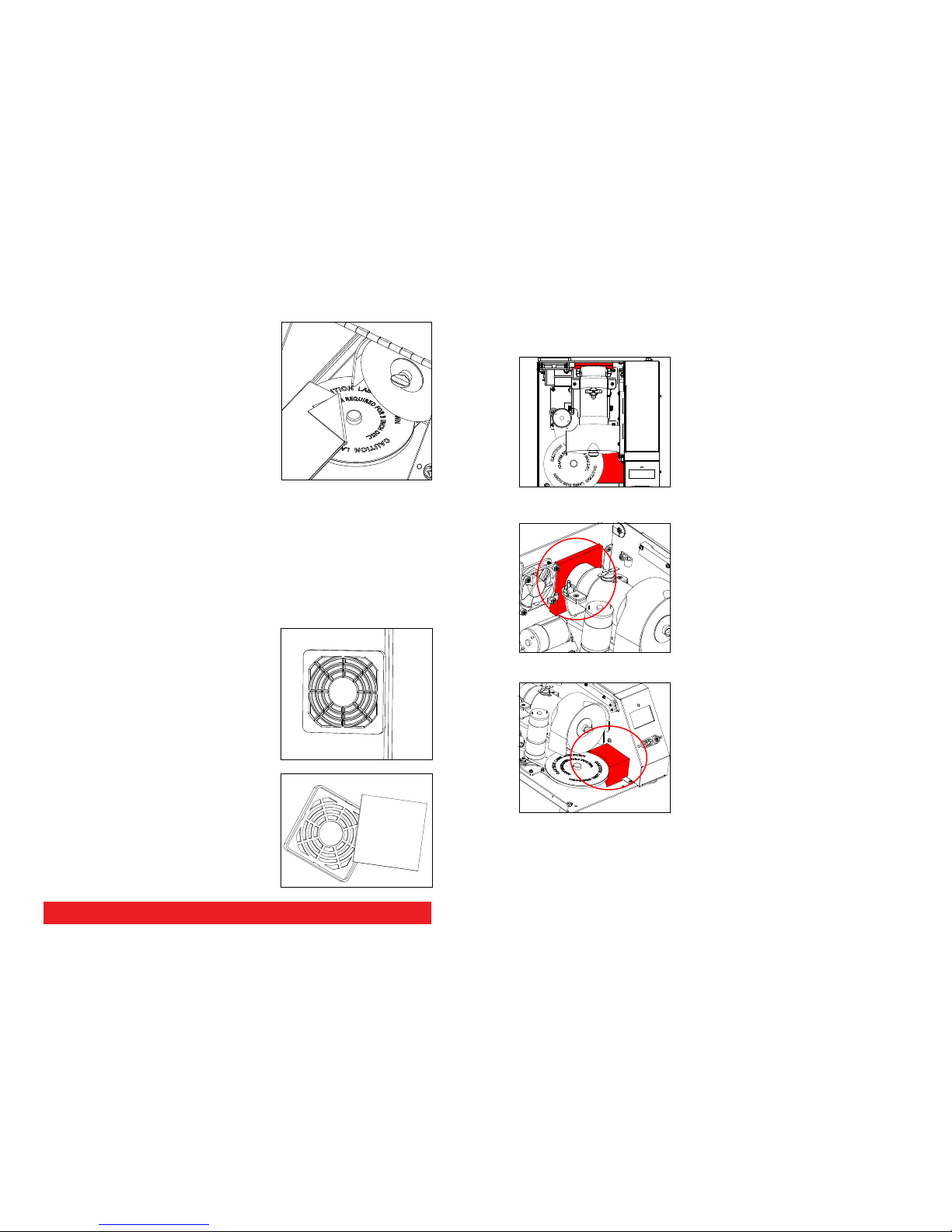

Emergency Stop

At anytime during the cycle you can stop a cycle prematurely, by pressing any

button on the User Interface or by lifting open the front cover. Once the button

is pressed or the front cover is lifted open, the cycle will stop and the Main Menu

will display an error message: “Emergency Stop Wait”. An illuminated ashing

Red LED light on the Start Button will also appear. Once the machine has

realigned itself (Note: The Front Cover must be closed in order for the machine

to realign itself), the machine will reset back to the last mode of operation that

was selected. The Operator may now continue using the machine.

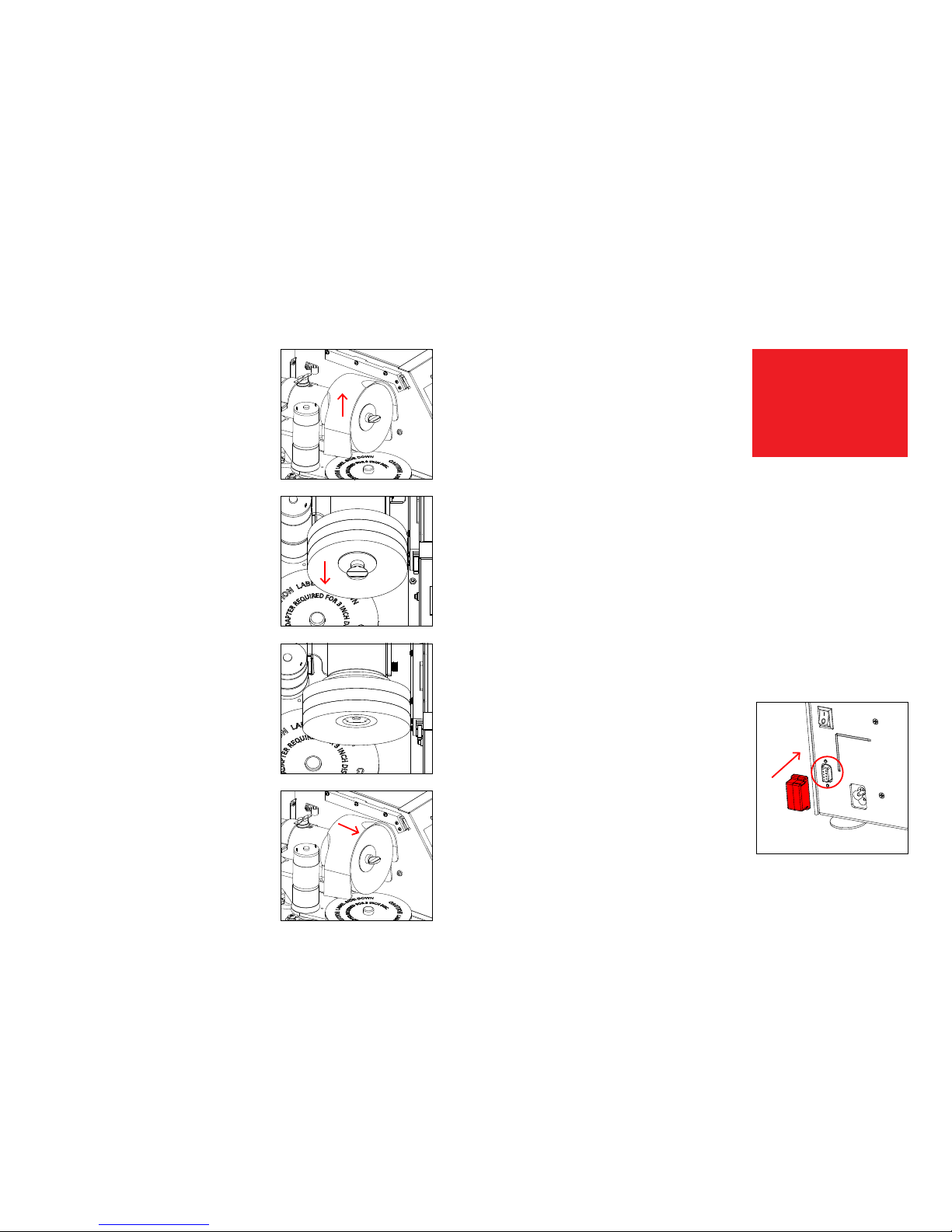

Replace Chip

The consumables (bung wheel and bung solution) have been designed

to be replaced at the same time. The consumables originally provided with

the VMI 2500 and the VMI 2500 Combo Packs are all rated for 500 minutes of

operation. Each conguration is accompanied by a Consumable Counter Chip

which informs the unit that the consumables have been replaced and installed.

The amount of consumable usage time is displayed on the Count line located

on the Main Menu. As the consumables deplete over time, the Count line

display will count down in number according to the minutes left on the chip.

Once the C2 Chip has reached 10%, the main menu will display the following

information: