Hi-Force JAS Series User manual

INSTRUCTION MANUAL: Aluminium Jacks

Model Series: JAS, JAH

Hi-Force Limited –Prospect Way –Daventry –Northants NN11 8PL –United Kingdom

Tel: +44(0) 1327 301000: Fax: +44(0) 1327 706555: Website: www.hi-force.com

All Hi-Force JAS and JAH series jacks are supplied

from the factory pre-filled with oil, and are ready for

use.

1.0 Inspection of the product upon receipt:

On receipt of the product, visually inspect the item

for any evidence of shipping damage. Please note

shipping damage is not covered by warranty. If

shipping damage is found notify the carrier

immediately and refrain from putting the product

into service. The carrier is responsible for repair and

replacement costs resulting from damage in transit

shipment.

2.0 Safety Precautions:

Read and follow all the instructions and safety

warnings carefully prior to use of the equipment.

Failure to do so could result in equipment damage

or failure of the equipment or personal injury. Hi-

Force will not be held responsible for any damage to

the equipment or personal injury resulting from

unsafe use of the product, lack of maintenance or

incorrect operation. If in doubt on the correct usage

of any Hi-Force equipment, contact your nearest Hi-

Force office or distributor. If the operator has not

been trained on high pressure hydraulic equipment

and its safe use consult your local Hi-Force sales

office who can offer you training courses for

operators.

All operators should ensure that all necessary

personal protective equipment as specified by their

employer is worn when operating any hydraulic

equipment. Safety shoes, safety glasses/ visor and

protective gloves should be worn at all times. All

relevant risk assessments should be completed prior

to use of the equipment.

Description:

This equipment is provided for the purpose of lifting

or lowering loads, or exerting a force, under the

control of a trained operator.

The equipment is supplied completely assembled

and ready for use. No service adjustments are

necessary or possible during operation.

An internal safety relief valve (factory set) is fitted

which limits the load that may be lifted to the

equipment rated load + 10% maximum.

Keep hydraulic Jacks away from flames and

direct heat.

Hydraulic Jacks must only be serviced by a

qualified technician.

To protect your warranty, only use Hi-Force’s

hydraulic oil.

Immediately replace any worn or damaged parts

using genuine Hi-Force parts only.

Model Series: JAS103, JAS105

Hi-Force JAS Jacks are despatched from the factory

pre-filled with oil, and are ready for use. They can be

used, if installed correctly, in any position, for

example sideways, upside down etc.

Hi-Force JAS Jacks are supplied in two model

options:-

JAS103 10tonne Capacity 75mm stroke.

JAS105 10tonne Capacity 125mm stroke.

There are two safety devices fitted as follows:

Pressure Relief Valve to prevent

overloading.

Steel stop ring to limit maximum stroke.

3.0 Operation.

TO LIFT OR PUSH LOAD

Using the Operating Lever Assembly turn Release

Valve Screw clockwise to close.

Put the Operating Lever into the Handle Socket and

operate pump. The piston will rise and lift the load.

When the piston reaches full stroke the stop ring

prevents the piston from rising further.

TO LOWER LOAD

Using the Operating Lever turn the Release Valve

Screw anti-clockwise to open. Opening the Release

Valve SLOWLY will control rate of lowering. Do NOT

overload Jack during lowering. The JAS jacks are

fitted with a return spring, so the piston will retract

even under no load.

INSTRUCTION MANUAL: Aluminium Jacks

Model Series: JAS, JAH

Hi-Force Limited –Prospect Way –Daventry –Northants NN11 8PL –United Kingdom

Tel: +44(0) 1327 301000: Fax: +44(0) 1327 706555: Website: www.hi-force.com

CARE AND STORAGE

Wipe the piston clean before lowering. When the

Hydraulic Jack is not in use store upright with the

piston retracted in a clean environment.

SAFETY WARNINGS!

ALWAYS raise the piston to the load.

DO NOTdrop loads onto the Jack.

ALWAYS support the base of the Jack when

in use.

NEVER go under load when only the Jack

supports it.

DO NOT attempt to lift a load greater than

the capacity of the Jack.

Provide solid and flat foundation for the

jack to operate from.

Make sure that there is sufficient spare

lifting capacity and stroke when selecting

Jack/s for any application.

Check the Jack load rating before use.

Avoid off-centre loading.

Before using any hydraulic equipment, read the

operating instructions carefully and check that they

are fully understood.

Model Series JAH –20tonne to 60tonne Capacity.

JAH1230C

JAH620SR JAH660

Hi-Force JAH range of lightweight Aluminium jacks

offer a wide variety of capacities and lift height

options. Available as either plain ram lifting jacks,

with or without ‘failsafe’ mechanical lock ring, or

optional low height claw lifting design. All models

are constructed of lightweight Aluminium with all

critical functioning parts from high quality steel.

This manual covers the following model variants of

Jack:-

JAH620,JAH1220,JAH630,JAH1230,JAH660,JAH1260

Jacks with plain piston only

JAH620C,JAH1220C,JAH630C, JAH1230C,JAH660C,

JAH1260C

Jacks with plain piston and lifting claw

attachment

JAH620SR,JAH1220SR,JAH630SR,JAH1230SR,

JAH660SR, JAH1260SR

Jacks with Failsafe locking ring.

Please read the following instructions carefully

before operating the product and keep them in a

safe place for future reference.

It is the responsibility of the purchaser to ensure that

operators are properly trained in the safe use of this

equipment and have access to HI-Force Operating

and Safety Instructions.

No modification and/or additions may be made to

this equipment without the written permission of the

manufacturer.

It is expected that the product is used by

competent technical personnel who have been

properly trained to use hydraulic lifting equipment

Description:

This equipment is provided for the purpose of lifting

or lowering loads, or exerting a force, under the

control of a trained operator.

The equipment is supplied completely assembled

and ready for use. No service adjustments are

necessary or possible during operation.

An internal safety relief valve (factory set) is fitted

which limits the load that may be lifted to the

equipment rated load + 10% maximum.

Before Each Use

Ensure that the jack is in good condition.

Check the external surfaces for absence

of mechanical damage and/or oil leaks. If

either is present do not use the equipment

and have it serviced.

Ensure that the external surfaces are dirt

free.

Check the oil level

GENERAL OPERATING INSTRUCTIONS

Place the jack on a firm level foundation

fully supporting the jack base, and if

INSTRUCTION MANUAL: Aluminium Jacks

Model Series: JAS, JAH

Hi-Force Limited –Prospect Way –Daventry –Northants NN11 8PL –United Kingdom

Tel: +44(0) 1327 301000: Fax: +44(0) 1327 706555: Website: www.hi-force.com

necessary place suitable material between

the load point and jack ram to avoid

damaging the structure to be lifted.

Use the jack by operating the lever in a

steady controlled movement at a

maximum of 30 strokes per minute.

Remove the operating lever when not in

use.

The ram should only be extended

hydraulically; it should never be pulled out

by hand or used to carry the jack.

SAFETY.

READ THIS MANUAL BEFORE OPERATING THE JACK.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS

COULD RESULT IN SERIOUS BODILY INJURY.

Do Not position the jack by using the

operating lever in the release valve. If the

jack is to be placed some distance under

the load, use the operating lever in the

operating lever/quadrant socket to position

the jack.

Do not attempt to exceed the rated load

on the head or toe of the jack.

The maximum working load and the travel

of the hydraulic jack is marked on the

equipment,

In operation, never drop loads onto the

jack. Always raise the head/toe to the

load.

Always ensure the full base area of the jack

is supported when in use.

Always ensure that loads are applied

centrally to the ram, or to the full extent of

the claw.

DO NOT allow any persons to work under

the load, when it is only supported by

hydraulic jacks.

Always clean the ram and retract it after

use.

Always remove the jack operating handle

when not in use.

Do not use if there is evidence of oil

leakage.

Never extend the ram by any means other

than pumping the jack.

Inspect and clean the jack after every use,

but if subjected to abnormal or shock

loading inspect for damage immediately.

CHECKING THE OIL LEVEL.

The jacks are normally supplied filled and ready for

use. However before using the jack for the first time,

the oil level should be checked. The oil used should

be a high quality hydraulic oil of HVI ISO46 viscosity,

e.g. Hi-force HFO32.

Remove the dipstick (See figure 1) and check the

oil level. The maximum level is marked on the

dipstick. The level should be within 5mm of this

mark. The dipstick should be screwed fully into

position to determine this level.

OPERATION OF JACK. See Figure 1.

Note: The permissible working load and stroke

of the Jack are marked on the side.

The JAH series Jacks (1) have an in-built hydraulic

pump which is worked by means of an operating

lever (2), under the control of the operator. The

piston (3) is raised on each downwards stroke of the

lever. For lifting, the lever is placed fully into the

operating quadrant (4). Three positions are

provided to enable the user to choose the best

ergonomic position. For lowering, the piston the

lever is removed from the quadrant and placed

into the release screw (5). Turning this anticlockwise

will allow the piston to descend. The amount this is

rotated will control the speed of decent. Only open

a very small amount (approx. 5°) at first. Rotate

clockwise, hand tight after use, to ready the jack for

the next operation.

JACKS WITH LOCKING COLLARS (TYPE SR)

All models can be supplied with threaded

pistons and locking collars to mechanically support

the load without relying on the hydraulic circuit.

When the load is at the required position, rotate the

locking collar clockwise until it rest hand-tight on

the top of the jack body.

To undo –operate the jack so that the hydraulic

circuit just takes the load of the locking collar.

Rotate the collar anticlockwise until it reaches the

top of the piston.

INSTRUCTION MANUAL: Aluminium Jacks

Model Series: JAS, JAH

Hi-Force Limited –Prospect Way –Daventry –Northants NN11 8PL –United Kingdom

Tel: +44(0) 1327 301000: Fax: +44(0) 1327 706555: Website: www.hi-force.com

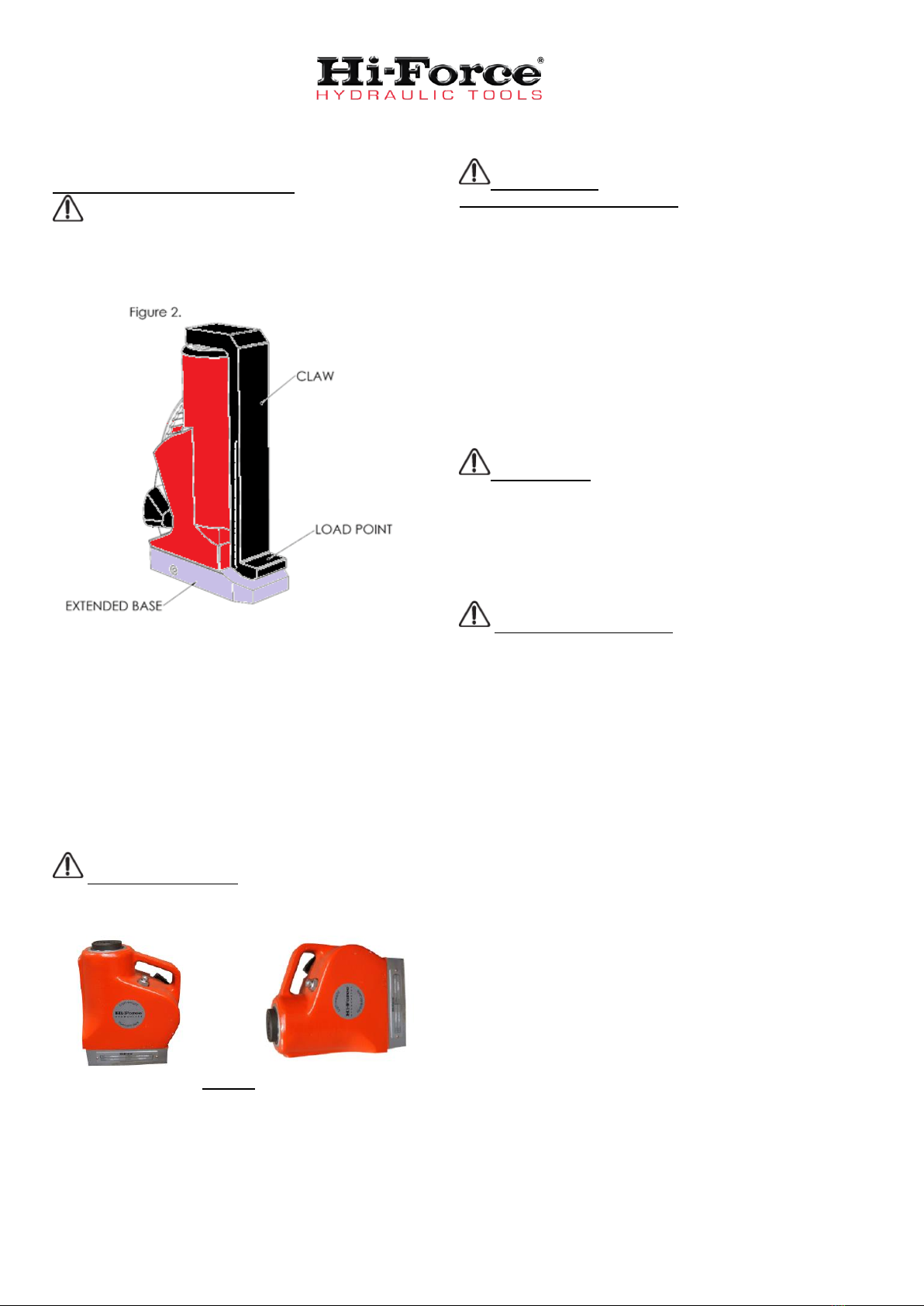

JACKS WITH LIFTING CLAWS (TYPE C)

Claws are supplied as an accessory to

provide a low height lifting point. When fitted, lifting

must always and only be carried out on the toe of

the claw. See Figure 2.

The capacity of the claw is 40% of the capacity of

the jack to which it is fitted. Lifting claws must NOT

be fitted to threaded piston jacks. Lifting claws must

only be used with jacks having extended bases that

extend under the toe of the claw. They must ONLY

be used for vertical movements of loads.

The recess on the underside of the top of the claw

fits around the top of the piston. The heel of the

claw rests against the front face of the jack. Ensure

that the claw is seated properly before use and

that the toe is as far under the load as possible.

OPERATING POSITIONS

The Jack should be used in the two positions shown

below, See Figure 3.

Figure 3

STROKE LIMITER

PISTON STROKE LIMITING DEVICE:

For Operator safety, all JAH jacks are factory-fitted

with a fail-safe positive stop mechanism that

prevents the over-stroking of the piston under

loaded conditions beyond its maximum stated

travel length. If the jack is operated in the over-

stroke mode, oil is by-passed back to the reservoir

to prevent the piston travelling further than its

designed stroke distance.

If pumping of the jack with the operating lever is

continued with the piston in the over-stroke

operation mode, some oil may by-pass the stop

mechanism and appear at the top of the jack. If

this occurs, cease operating the jack and wipe off

any surplus oil.

PLEASE NOTE: That if the over-stroke

mechanism is operated and continuously pumped

with the piston under no load conditions, insufficient

pressure is achieved in the system to engage the

by-pass system of oil to the reservoir, and within a

short number of pumping actions, oil will appear at

the top of the jack.

OPERATING ENVIRONMENT

The jack is intended for use in industrial

environments, in or outdoors between temperatures

of -20 to +50°C. Outside these parameters, consult

Hi-Force Ltd, before use.

This manual suits for next models

21

Other Hi-Force Jack manuals