3. Before using this product, read the

operator's manual completely and

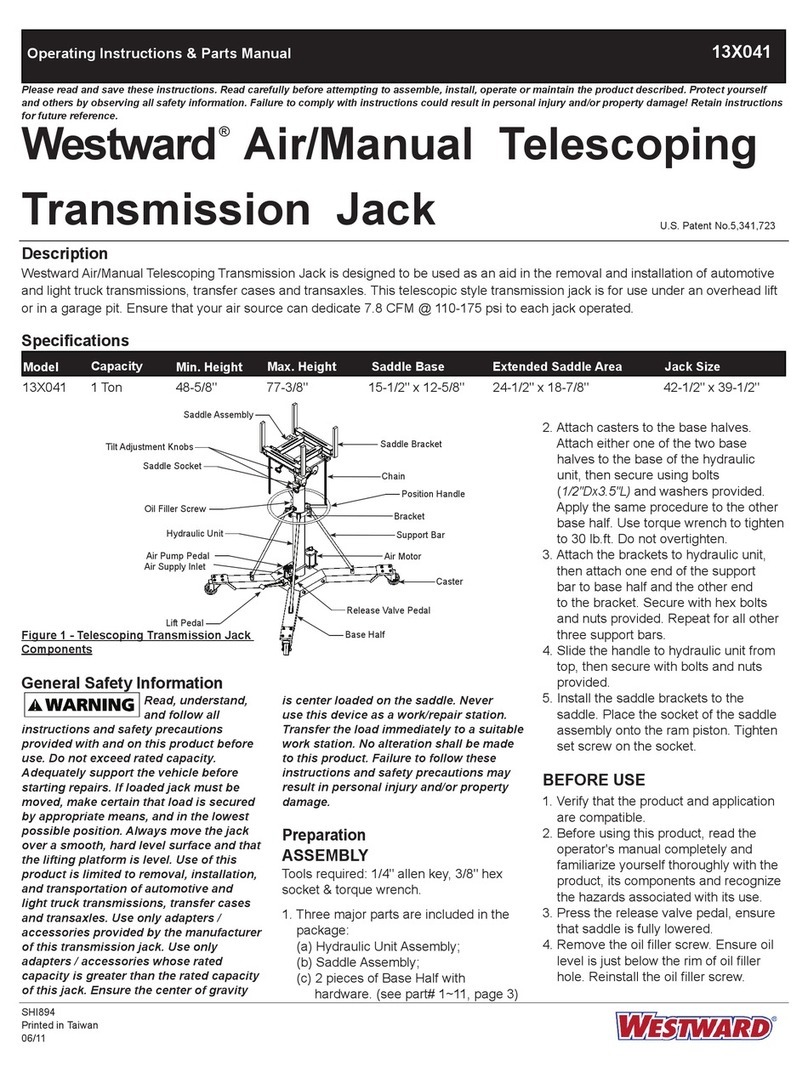

familiarize yourself thoroughly with

the product and its components, and

recognize the hazards associated with

its use.

4. Verify that the product and application

are compatible.

PREPARATION (cont)

5. To familiarize yourself with basic

operation, locate and turn the release

valve (pump handle):

a. Clockwise until rm resistance is felt to

further turning. This is the ‘CLOSED’

release valve position used to raise

the saddle.

b. Counter-clockwise, but no more than

1/2 turn from the closed position. This

is the ‘OPEN’ release valve position

used to lower the saddle.

6. With saddle fully lowered and release

valve closed, pump the handle. If lift

arm responds immediately, jack is

ready for use. If jack does not respond,

follow Bleeding/Venting Trapped Air

instruction below. Check oil level. Proper

oil level will vary from just covering

the ram cylinder to 3/16” above it as

seen from the oil ller hole. Reinstall

oil plug.

7. Ensure that jack rolls freely. Raise and

lower the unloaded saddle throughout

the entire lifting range before putting into

service to ensure the pump operates

smoothly. Replace worn or damaged

parts and assemblies with authorized

replacement parts only.

Bleeding/Venting Trapped Air

With the release valve in the OPEN position

(step 5b. above) and with saddle fully

lowered, locate and remove the oil ller

plug. Pump handle 6 to 8 full strokes. This

will help release pressurized air which may

be trapped within the reservoir. Reinstall the

oil ller plug and check operation.

OPERATION

Lifting

1. Place vehicle transmission in park,

with emergency brake on and wheels

securely chocked to prevent

inadvertent movement.

2. Close release valve by turning handle

clockwise firmly. Position jack saddle

under lift point.

3. Verify lift point. To lift, pump handle

until load reaches desired height.

4. Transfer the load immediately to

appropriately rated jack stands.

Lowering

1. Raise load high enough to clear jack

stands, then carefully remove the jack

stands.

2. To lower saddle, slowly turn handle

counter-clockwise, but no more than ½

turn. If load fails to lower, carefully

transfer the load to another lifting

device and jack stands. Carefully

remove affected jack and then stands.

Carefully remove primary jack, again

turning the release valve, slowly, no

more than 1/2 turn.

MAINTENANCE

NOTICE: Use premium quality hydraulic

Westward®Hydraulic Quick Lifting

Service Jack SUV

2

Westward Operating Instructions and Parts Manual 1VW32 and 1AVR1

!WARNING

jack oil. Do not use hydraulic brake fluid,

alcohol, glycerine, detergent motor oil or

dirty oil. Improper fluid can cause serious

internal damage to the jack rendering it

inoperative.

Adding Oil

1. With saddle fully lowered and pump

piston fully depressed, set jack in its

level position. Locate and remove vent

screw.

2. Fill until approximately 3/16" above the

inner cylinder as seen from the filler

hole. Re-install vent screw.

Changing Oil

For best performance and longest life,

replace the complete fluid supply at least

once per year.

1. With saddle fully lowered and pump

piston fully depressed, remove vent

screw.

2. Lay the jack on its side and drain the

fluid into a suitable container.

NOTICE: Dispose of hydraulic fluid in

accordance with local environmental

regulations.

3. Fill with good quality jack oil. Reinstall

vent screw.

4. Follow Bleeding/Venting Trapped Air

procedure.

Lubrication

1. A coating of light lubricating oil to pivot

points, axles and hinges will help to

prevent rust and assure that wheels,

casters and pump assemblies move

freely.

2. Periodically check the pump piston and

ram for signs of rust or corrosion.

Clean as needed and wipe with an oily

cloth.

NOTICE: Never use sandpaper or

abrasive material on piston and ram

surfaces.

3. When not in use, store the jack with

pump piston and ram fully retracted.

!WARNING

Manufactured for Grainger International, Inc.,

Lake Forest, IL 60045 U.S.A.