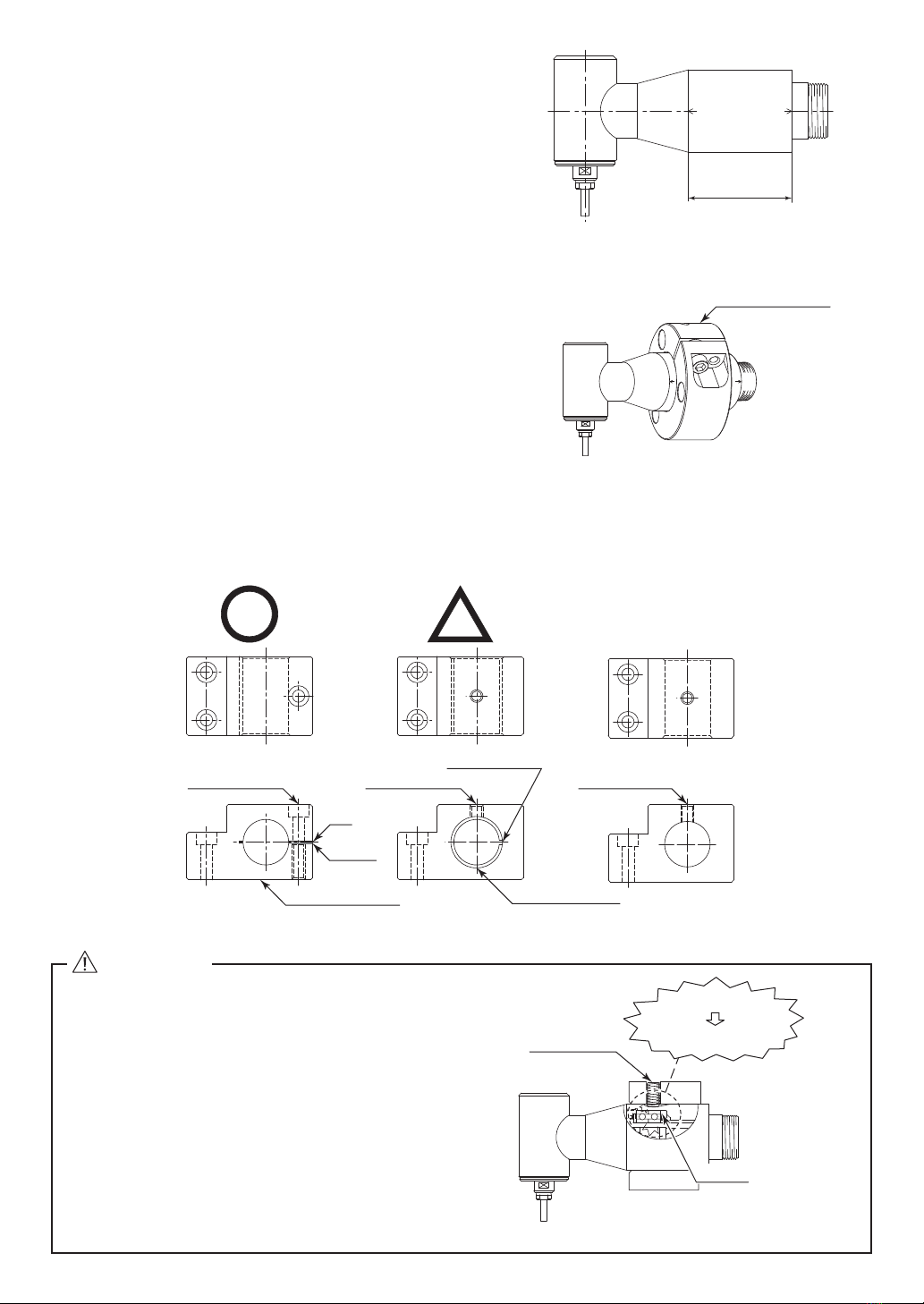

CAUTION

・How to confirm the correct tightening or clamping of the Spindles in the holder : In case of use

a brushless motor.

Measure the current value of the CONTROLLER's power cord by the clamp meter.

Fasten the holder so that the increase in the no-load current value (during rotation at the

maximum rotation speed) with the Spindle fastened is 10mA (for type 200V / 230V) or less,

compared to the no-load current value (during rotation at the maximum rotation speed)

without fastening the Spindle. Do not over-tighten the Fastening Bolt. It may damage Spindle's

precision and shorten the life of the bearings.

・The final responsibility for ensuring holder's safety for use in a given application is left to the

designer of the equipment in which NAKANISHI's Spindle is installed.

NAKANISHI offers Spindles with a wide variety of capabilities and specifications.

Please carefully check the Spindle's specifications against the requirements of your equipment

and verify suitability and safety of the Holder prior to initial use.

6

③How to fabricate the Split Type Holder

(1) Rough bore the inside diameter of the Split

Type Holder.

(2) Cut a slit. (Ex. Slit 2mm) wide

(3) Tighten the Screw for Removal and Force

Open the Slit Area.

(4) Insert a spacer (Ex. thickness = 2mm) into

the Slit Area.

(5) Loosen the Screw for Removal, and tighten

the fastening bolt with the specified torque.

(6) Finish the Split Type Holder so that the

inside diameter of the Split Type Holder is

ȭ30 with its tolerance range from

-

0.01mm

to

-

0.015mm, and its roundness and

cylindricity of less than 5μm.

(7) When inserting the Spindle loosen the

Fastening Bolt and twist the Screw for

Removal, and widen the Slit Area.

Front View

Fastening Bolt

Slit

Side View

Fastening Bolt

Screw for Removal

Spacer

Fastening Bolt

Spacer

Screw for Removal

Spacer

Fig. 11

Steps

12 3 4

Air Pressure (MPa) For Air Motor

0.1 0.2 0.3 0.4

Rotation Speed (min-1) (rpm)

For Brushless Motor

5,000 10,000 15,000 20,000

Rotation Time (min)

15 10 10 15

Items to Check

No Abnormal

Noises.

The Spindle housing temperature during

the break-in process should not exceed

20 degrees C (36 degrees F) above

ambient temperature. Should the Spindle

exceed this limit, rest the Spindle for at

least 20 minutes and re-start the break

in procedure from the beginning. If the

housing temperature rises again and

exceeds 20 degrees C (36 degrees F)

above ambient temperature, check the

Spindle and motor for proper installation.

The Spindle

housing

temperature

during the break-

in process should

not exceed

20 degrees C

(36 degrees F)

above ambient

temperature.

Table 1.

8. BREAK-IN PROCEDURE

During transportation, storage or installation, the grease inside the bearings will settle. If the Spindle is suddenly run at

high-speed, the grease will be ejected from the bearings, causing excessive heat that will cause bearing damage. After

installation, repair, initial operation, or long periods of non operation, please follow the break-in procedure detailed in Table 1.