HID Aero X300 User manual

INSTALLATION GUIDE

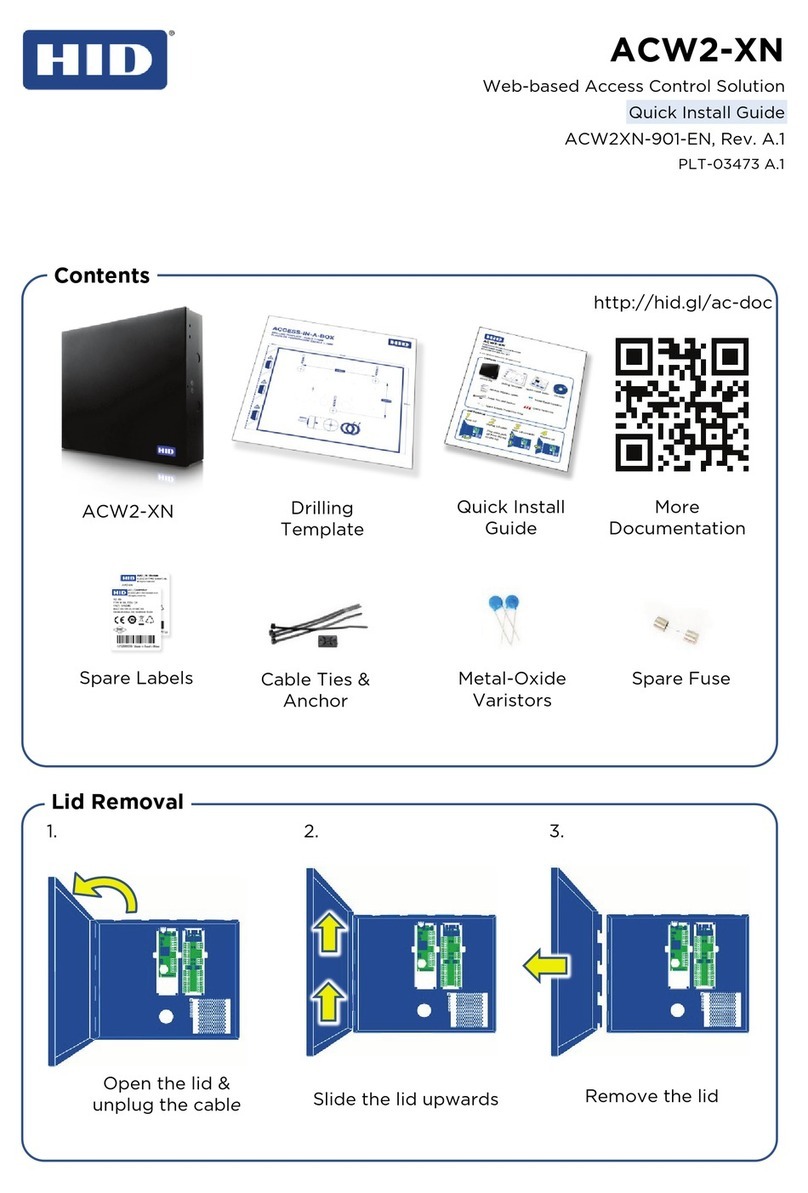

Supplied parts

◾

HID Aero X300 Ouput Control Module (1)

◾

Installation guide (1)

◾

Mounting screws (4) 0.138" × 1" (3.5 mm × 25 mm)

Recommended parts

(not supplied)

◾

Certified DC power supply

◾

Drill with various bits for mounting hardware

◾

For DIN rail mounting: Brackets (2) - Phoenix Contact,

USA 10 Series Rail Adapter, part number 1201578.

Screws (4) - Self tapping, countersunk,

3.0 mm × 10 mm (or 3.0 mm × 8 mm)

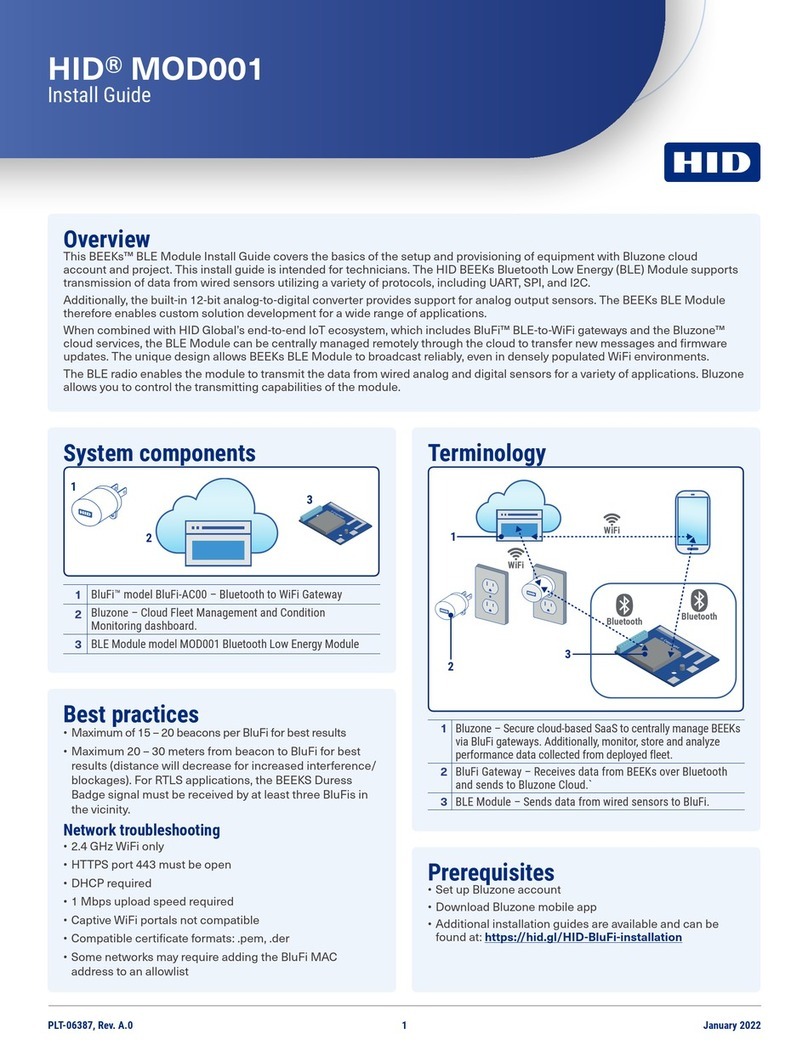

X300 Overview

The X300 has 12 relays, five inputs and one RS-485 port for IO module connection.

POWER, TAMPER, AC FAIL, BATT FAIL

See step 6.

Status LEDs

See page 6

Status LEDs

See page 6

RELAYS 1-12

See step 4.

4.53"

(115 mm)

RELAYS 1-12

See step 4.

INPUTS 1-2

See step 3.

INPUTS 1-2

See step 3.

JUMPERS

See step 2.

5.51

"

(140 mm)

DIP SWITCH

See step 5.

IO MODULE PORT

See step 2.

CABLE REQUIREMENTS (NOT SUPPLIED)

IO Module

One twisted pair, shielded, 24 AWG, 120

impedance, 4,000 ft (1,200 m) maximum

Alarm Inputs

One twisted pair, 30

maximum

Relay Outputs

As required for the load

Power

2-conductor shielded

18 to 16 AWG, 500 ft (150 m)

Output Control Module

PLT-04236, Rev. A.3

HID Aero™ X300 Installation Guide

2

2. Communication wiring

Connect the X300 to the Aero X1100 intelligent

controller using IO Module ports (2-wire RS-485).

Use 1-twisted pair, shielded cable, 120

impedance,

24 AWG, 4,000 ft. (1,219 m) maximum.

Note: Both IN and OUT terminals on the IO MODULE

are the same port and are internally connected.

IO MODULE IN or IO MODULE OUT

Setting the termination jumpers

Install RS-485 termination jumpers on the interface

boards at each end of the communication bus only.

Failure to do so will compromise the proper operation

of the communication channel.

To other

devices

on the bus

To other

devices

on the bus

RS-485

termination jumper

JUMPER

DESCRIPTION

IN

Install only on the first and last unit on the

communication bus.

OUT

Install only if not the first or last unit on the

communication bus.

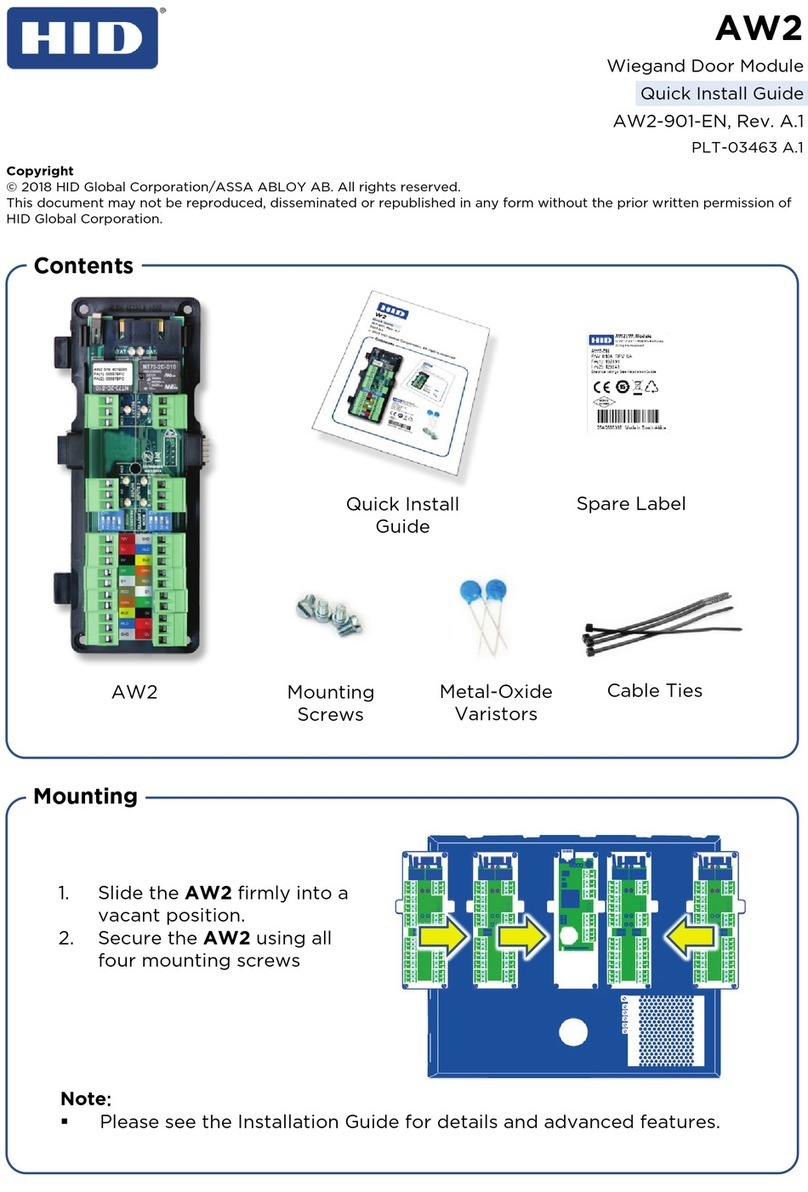

1. Mounting the X300

ATTENTION

Observe precautions for handling

ELECTROSTATIC SENSITIVE DEVICES

◾

Always mount the controllers and interface panels

in a secure area.

◾

Mount using the supplied screws 0.138" × 1"

(3.5 mm × 25 mm).

◾

Alternatively mount on a DIN rail using compatible

DIN rail mounting brackets and screws.

See Recommended parts.

Note: The side terminal connectors must be

removed to fit the mounting brackets.

HID Aero™ X300 Installation Guide

3.

Input circuit wiring

Inputs are typically used for the following:

◾

To monitor door position.

◾

Request to exit.

◾

Alarm contacts.

Input IN 1 and IN 2 circuits can be configured as

unsupervised or supervised and can use normally open or

normally closed contacts.

For a supervised circuit, add two 1K

, 1% resistors as

close to the sensor as possible.

Custom end of line (EOL) resistances may be configured

via the host software.

Note: The input circuit wiring configurations shown are

supported but may not be typical.

Unsupervised circuit IN 1 or IN 2

Supervised circuit IN 1 or IN 2

1K,1%

1K,1%

4.

Relay circuit wiring

Twelve relays are provided for controlling door lock

mechanisms or alarm signaling.

When controlling the delivery of power to the door

strike, the NO (Normally Open) and C (Common) poles

are typically used.

When momentarily removing power to unlock the door,

as with a mag lock, the NC (Normally Closed) and C

(Common) poles are typically used.

Check with local building codes for proper egress door

installation.

CAUTION

Door lock mechanisms can generate feedback to the

DC Strike

-

+

To DC power source

- +

Fuse

Diode

RELAY 1

to RELAY 12

relay circuit. This can cause damage and premature

failure of the relay, effecting the operation of the X300.

Use a diode to protect the relay. Use a wire of sufficient

gauge to avoid voltage loss.

Diode selection:

◾

Diode current rating: 1x strike current.

◾

Diode breakdown voltage: 4x strike voltage.

◾

For 12 V DC or 24 V DC strike, diode 1N4002

(100V/1A) typical.

HID Aero™ X300 Installation Guide

4

5.

DIP switch configuration

Switches

1

through 5 select the device address. Switches 6 and 7 select the communication baud rate.

Switch 8 is not in use.

1

2

3

4

5

6

7

8

SELECTION

OFF

OFF

OFF

OFF

OFF

Address 0

ON

OFF

OFF

OFF

OFF

Address 1

OFF

ON

OFF

OFF

OFF

Address 2

ON

ON

OFF

OFF

OFF

Address 3

OFF

OFF

ON

OFF

OFF

Address 4

ON

OFF

ON

OFF

OFF

Address 5

OFF

ON

ON

OFF

OFF

Address 6

ON

ON

ON

OFF

OFF

Address 7

OFF

OFF

OFF

ON

OFF

Address 8

ON

OFF

OFF

ON

OFF

Address 9

OFF

ON

OFF

ON

OFF

Address 10

ON

ON

OFF

ON

OFF

Address 11

OFF

OFF

ON

ON

OFF

Address 12

ON

OFF

ON

ON

OFF

Address 13

OFF

ON

ON

ON

OFF

Address 14

ON

ON

ON

ON

OFF

Address 15

OFF

OFF

OFF

OFF

ON

Address 16

ON

OFF

OFF

OFF

ON

Address 17

OFF

ON

OFF

OFF

ON

Address 18

ON

ON

OFF

OFF

ON

Address 19

OFF

OFF

ON

OFF

ON

Address 20

ON

OFF

ON

OFF

ON

Address 21

OFF

ON

ON

OFF

ON

Address 22

ON

ON

ON

OFF

ON

Address 23

OFF

OFF

OFF

ON

ON

Address 24

ON

OFF

OFF

ON

ON

Address 25

OFF

ON

OFF

ON

ON

Address 26

ON

ON

OFF

ON

ON

Address 27

OFF

OFF

ON

ON

ON

Address 28

ON

OFF

ON

ON

ON

Address 29

OFF

ON

ON

ON

ON

Address 30

ON

ON

ON

ON

ON

Address 31

OFF

OFF

115,200 BPS

ON

ON

38,400 BPS

OFF

ON

19,200 BPS

ON

OFF

9,600 BPS

HID Aero™ X300 Installation Guide

6. Input power, cabinet tamper, and UPS fault input wiring

The X300 requires 12-24 V DC power. Connect power

with minimum of 18 AWG wire.

Connect power ground to earth ground in only ONE

LOCATION within the system. Multiple earth ground

connections may cause ground loop problems and is

not advised.

Observe POLARITY on 12-24 V DC input.

Connect the AC FAIL and BATT FAIL inputs to the

corresponding contacts provided on the power supply.

Connect the TAMPER input to a tamper switch on the

enclosure.

TAMPER, AC FAIL, and BATT FAIL connections are

identical to inputs IN 1 to IN 2 and can be configured

as unsupervised or supervised. See step 3. Input

circuit wiring.

HID Aero™ X300 Installation Guide

6

Status LEDs

LED

POWER

ON SELF-TEST

NORMAL OPERATION

ONLINE

ON then OFF

Heartbeat and Online status. Offline = 1 sec rate, 20% ON. Online encrypted comm .1 sec

ON, .1 sec OFF, .1 sec ON, .1 sec OFF, .1 sec ON, .1 sec OFF, .1 sec ON, .3 sec OFF. Waiting

for application download

.1

sec ON,

.1

sec OFF.

COMM

ON then OFF

RS-485 comm status. Indicates communication activity on the SIO communication port.

BATT FAIL

ON then OFF

OFF = Inactive, ON = Active, Flash = Fault.*

AC FAIL

ON then OFF

OFF = Inactive, ON = Active, Flash = Fault.*

TAMPER

ON then OFF

OFF = Inactive, ON = Active, Flash = Fault.*

RELAY 1

OFF

ON = Energized

RELAY 2

OFF

ON = Energized

RELAY 3

OFF

ON = Energized

RELAY 4

OFF

ON = Energized

RELAY 5

OFF

ON = Energized

RELAY 6

OFF

ON = Energized

RELAY 7

OFF

ON = Energized

RELAY 8

OFF

ON = Energized

RELAY 9

OFF

ON = Energized

RELAY 10

OFF

ON = Energized

RELAY 11

OFF

ON = Energized

RELAY 12

OFF

ON = Energized

IN 1

ON then OFF

OFF = Inactive, ON = Active, Flash = Fault.*

IN 2

ON then OFF

OFF = Inactive, ON = Active, Flash = Fault.*

*If this input is defined, every three seconds the LED is pulsed to its opposite state for 0.1 seconds, otherwise,

the LED is OFF.

HID Aero™ X300 Installation Guide

Specifications

HID AERO X300

Input Voltage

12 to 24 V DC ± 10%

Maximum Input Current

500 mA

IO Module

2-wire RS-485, 2,400 to 115,200 bps, asynchronous,

half-duplex, 1 start bit, 8 data bits, and 1 stop bit

Inputs

Five unsupervised/supervised, standard EOL: 1k/1k

, 1%, ¼ watt

(Includes TAMPER, AC FAIL, and BATT FAIL inputs)

UL evaluation for access control use only

Output Relays

Twelve Form-C relays. Contact rating: 2 A @ 30 V DC resistive

ENVIRONMENTAL

Operating Temperature

32 to 158°F (0 to +70°C)

Storage Temperature

-67 to 185°F (-55 to +85°C)

Humidity

5 to 85% RHNC

MECHANICAL

Dimension

6.46" × 5.51" × 1.02" (164 mm × 140 mm × 26 mm)

Weight

342 g

These specifications are subject to change without notice.

Other HID Control Unit manuals

Popular Control Unit manuals by other brands

SMC Networks

SMC Networks SYA3000 Original instructions

Wave2wave

Wave2wave Rome500 Hardware installation manual

KWC

KWC F3SV1001 Installation and operating instructions

Kalatec Automacao

Kalatec Automacao 2DM860H Driver manual

RF-Star

RF-Star CC26X2R manual

Rodix

Rodix FEEDER CUBE FC-40 Plus Series Adjustments and Set Up

HP invent

HP invent ProCurve 8108fl Product End-of-Life Disassembly Instructions

GF

GF 567 instruction manual

Siemens

Siemens CM 1243-5 operating instructions

Watts

Watts LFM127-11 Installation, operation and maintenance

Rockwell Automation

Rockwell Automation Allen-Bradley 1441-DYN25-MBAL user manual

FULTON

FULTON ProtoNode FPC-N54 Startup guide