Hidral PH-300 User manual

ASSEMBLY INSTRUCTIONS

IM-560en

Vers. 05

22/09/2021

PH-300

VERTICAL LIFTING PLATFORM

ORIGINAL INSTRUCTIONS

ASSEMBLY INSTRUCTIONS

PH-300 VERTICAL LIFTING PLATFORM

IM-560en

Vers. 05

Page 1

Contents

1. Tools and equipment............................................................................................................... Page 2

2. Shaft check............................................................................................................................. Page 3

3. Guide assembly...................................................................................................................... Page 12

4. Assembly of the machine cabinet ........................................................................................... Page 15

5. Hydraulic installation............................................................................................................... Page 16

6. Electrical installation ............................................................................................................... Page 17

6.1. Guide electrical installation........................................................................................ Page 17

6.2. Machine cabinet electric installation.......................................................................... Page 17

7. Vehicle installation .................................................................................................................. Page 18

8. Landing push button panels.................................................................................................... Page 24

9. Upper landing door assembly................................................................................................. Page 26

10. Protective bellows (optional)................................................................................................. Page 35

11. Electrical adjustment............................................................................................................. Page 36

11.1. Adjustment of the circuit breaker ............................................................................. Page 36

11.2. Adjustment of the stop nal limit switches ............................................................... Page 36

11.3. Adjustment of the opening angle of the automatic door........................................... Page 37

12. Hydraulic adjustment ........................................................................................................... Page 38

12.1. Description of the group .......................................................................................... Page 38

12.2. Hydraulic diagram.................................................................................................... Page 38

12.3. Adjustment of the descent speed ............................................................................ Page 39

13. Adjustment of the overload detection system ....................................................................... Page 39

14. Final tests ............................................................................................................................. Page 40

IM-560en

Vers. 05

Page 2

ASSEMBLY INSTRUCTIONS

VERTICAL LIFTING PLATFORM PH-300

1. Tools and equipment

●Safety goggles

●Gloves

●Safety boots

●Drill with several bore bits for concrete Ø6, Ø10 and Ø16

●Manual resin aplicator HILTI HDM330 for the supplied anchorages

●Spirit level

●Bob plumb

● Complete at spanner or star spanner set

●Torque wrench for 5 Nm

●Star screwdriver

●Slot head screwdriver

●Funnel

●Ruler with a 1.5 m aproximate length

Personal protection

Tools and equipment

ASSEMBLY INSTRUCTIONS

PH-300 VERTICAL LIFTING PLATFORM

IM-560en

Vers. 05

Page 3

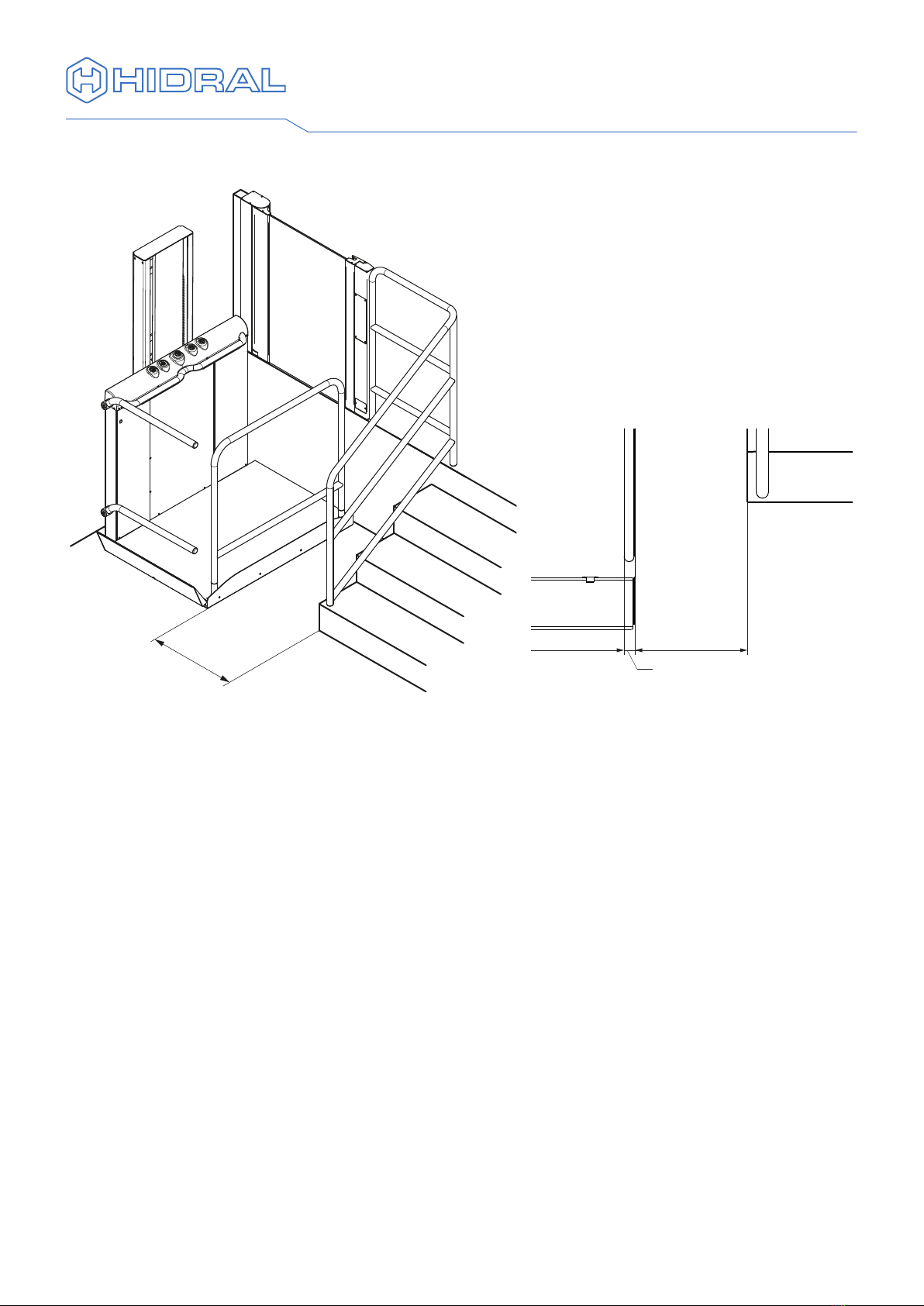

2. Shaft check

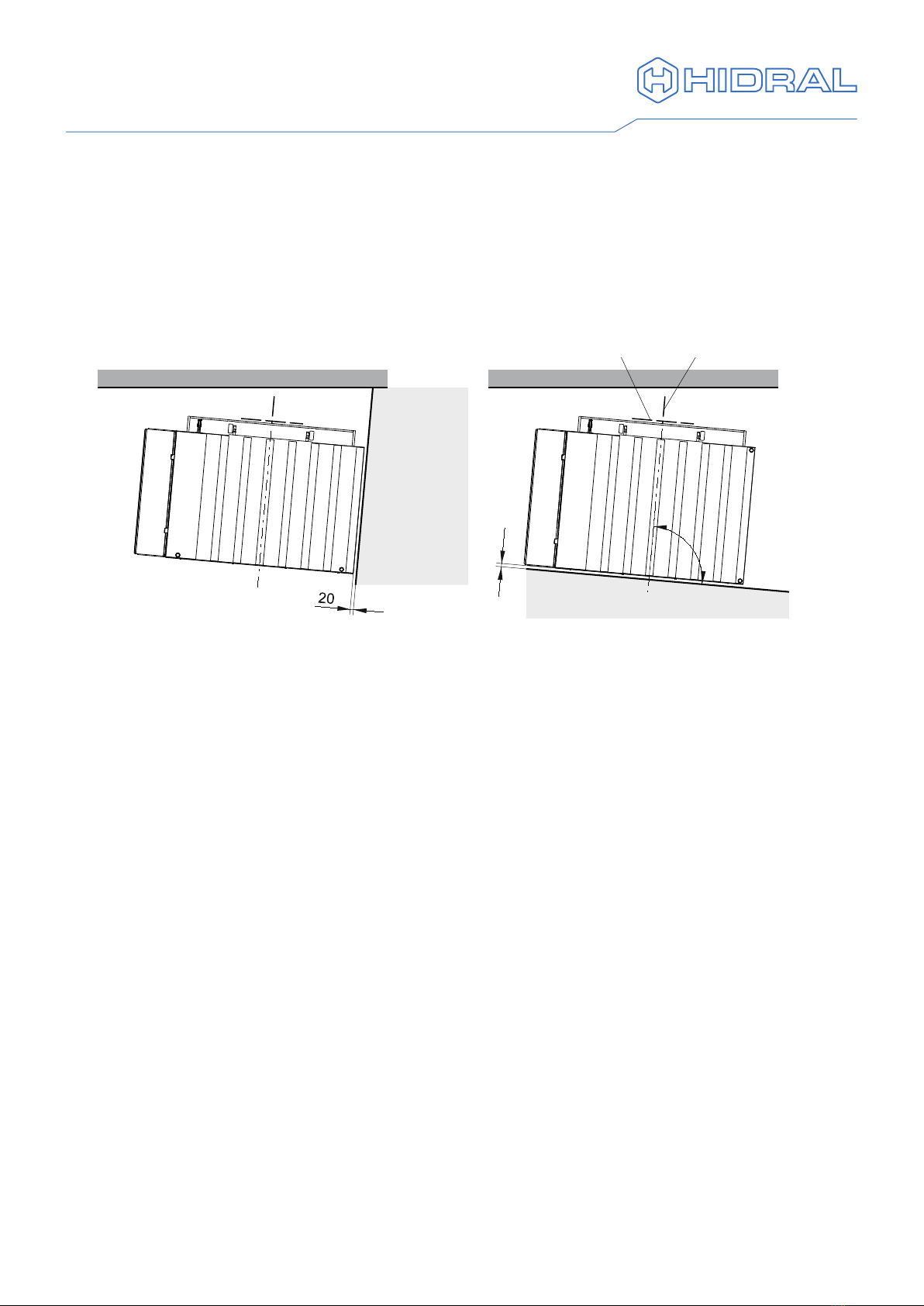

1 Install suitable protections to prevent risks of falling during assembly.

2 Check that the supplied anchorages are appropriate for the type of wall the guide

shall be xed upon. The chemical anchorages are appropriate for walls made of

structural concrete, solid bricks or hollow brick.

3 Verify the characteristics of the wall to which the guide shall be xed. The guide is

designed to be xed to the oor, to the slab of the upper landing level and on the

upper end of the guide. In case a resistant enough support is not available for the

xation on the upper end of the guide the two upper xations may be moved to the

central xation plate to the slab. The reaction forces of the guide assembly on the

oor and xation wall are indicated in the following drawing.

With xation on the upper

end of the guide

Only with xation to the slab

of the upper landing level

2.5 kN

2 kN

2 kN

0.6 kN

2 kN

0.6 kN

2 kN

R 1100

2.5 kN

2 kN

2 kN

20 kN

20 kN

R 1100

20 kN

20 kN

IM-560en

Vers. 05

Page 4

ASSEMBLY INSTRUCTIONS

VERTICAL LIFTING PLATFORM PH-300

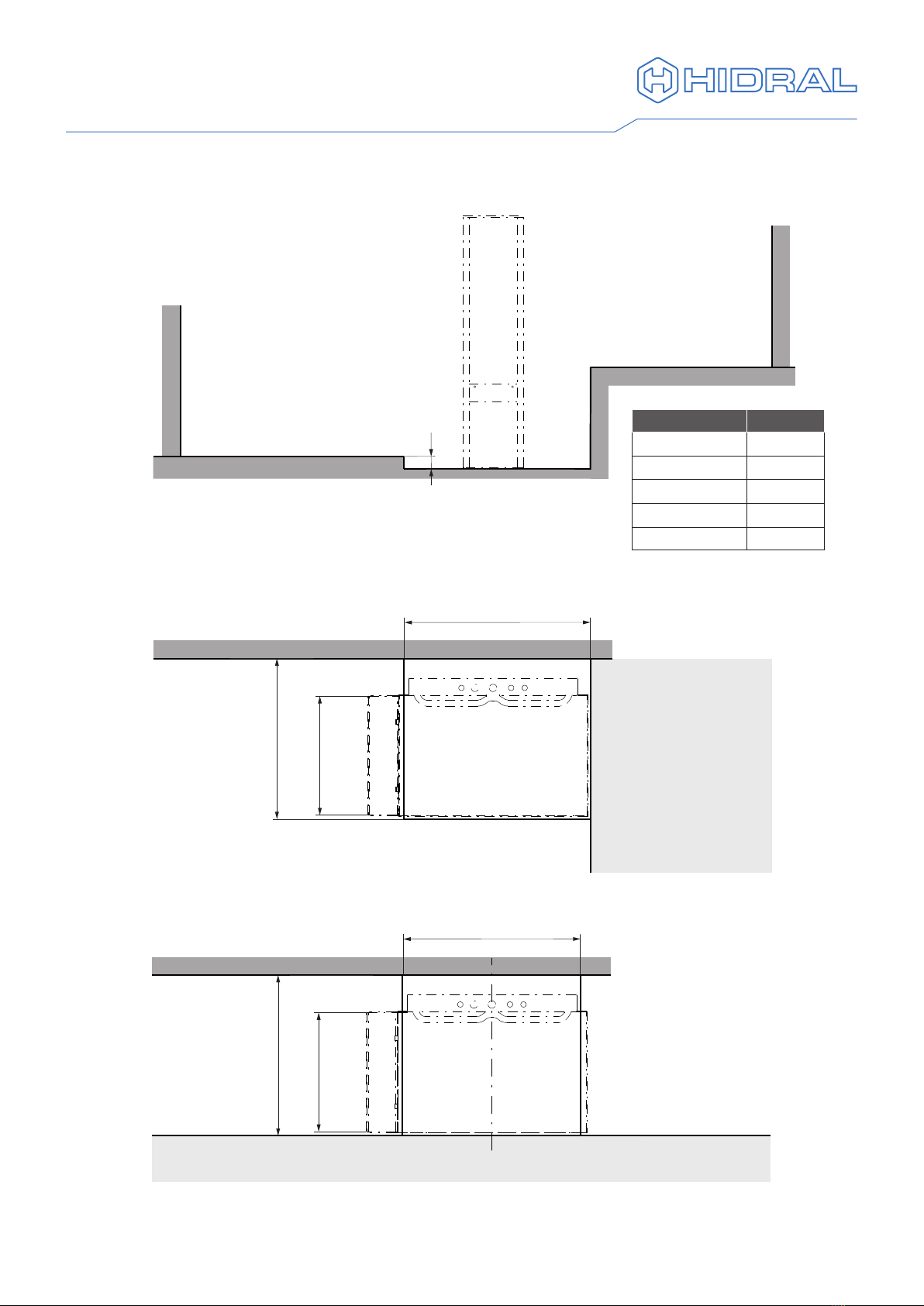

4 Check that the following dimensions are within the specied limits. Should this not

be case, get in touch with our aftersales department.

- R Platform travel. Permissible deviation of ± 50 mm

- E0 Minimum space for access on lower level: ≥2040

Upper

level

Lower

level

R

E0

- E1 Minimum space on upper level with 180º access: ≥1200

Upper levelLower level

E1

d

- E1 Minimum space on upper level with 90º access: ≥1200

Upper level

Lower level

E1

d

ASSEMBLY INSTRUCTIONS

PH-300 VERTICAL LIFTING PLATFORM

IM-560en

Vers. 05

Page 5

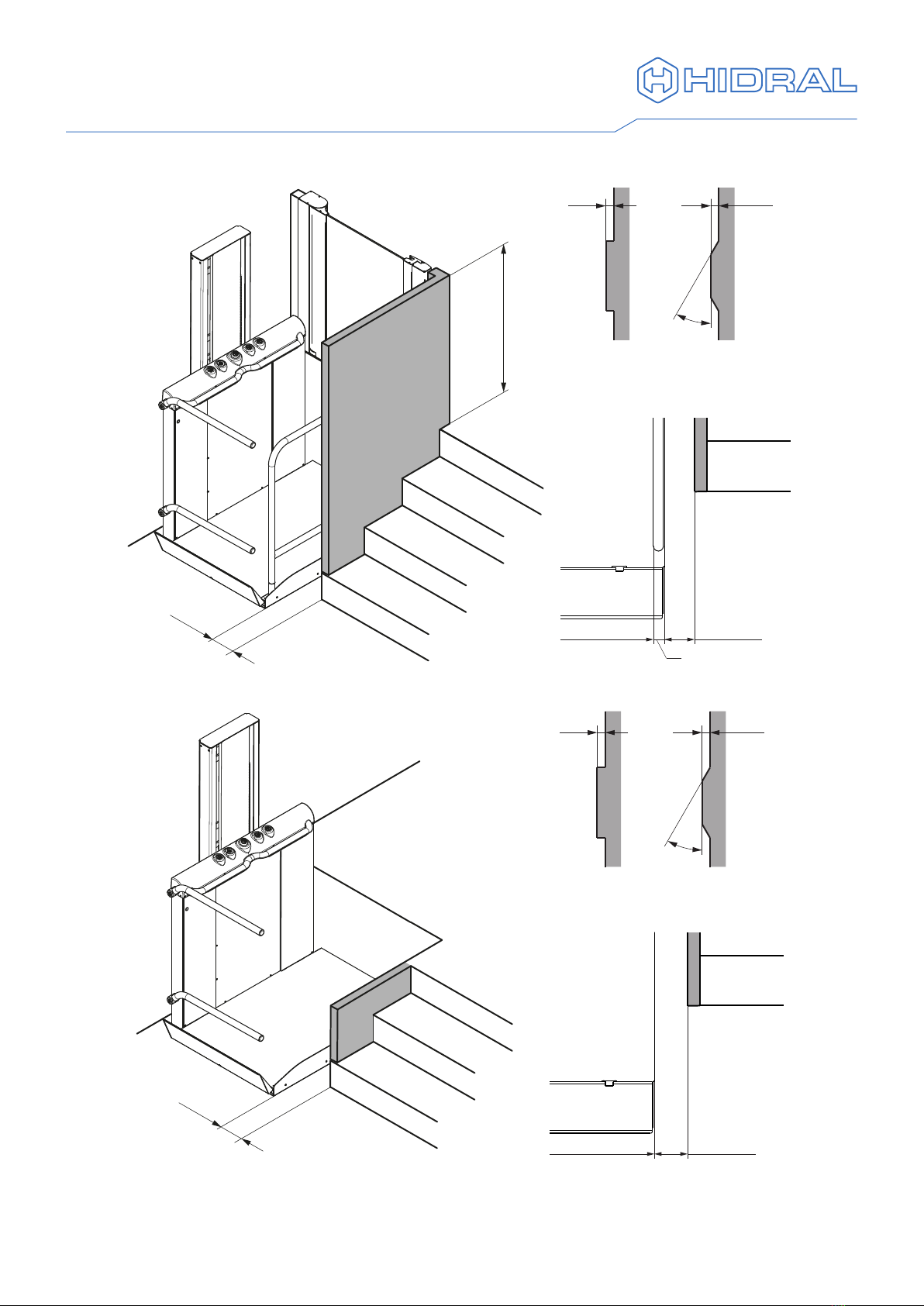

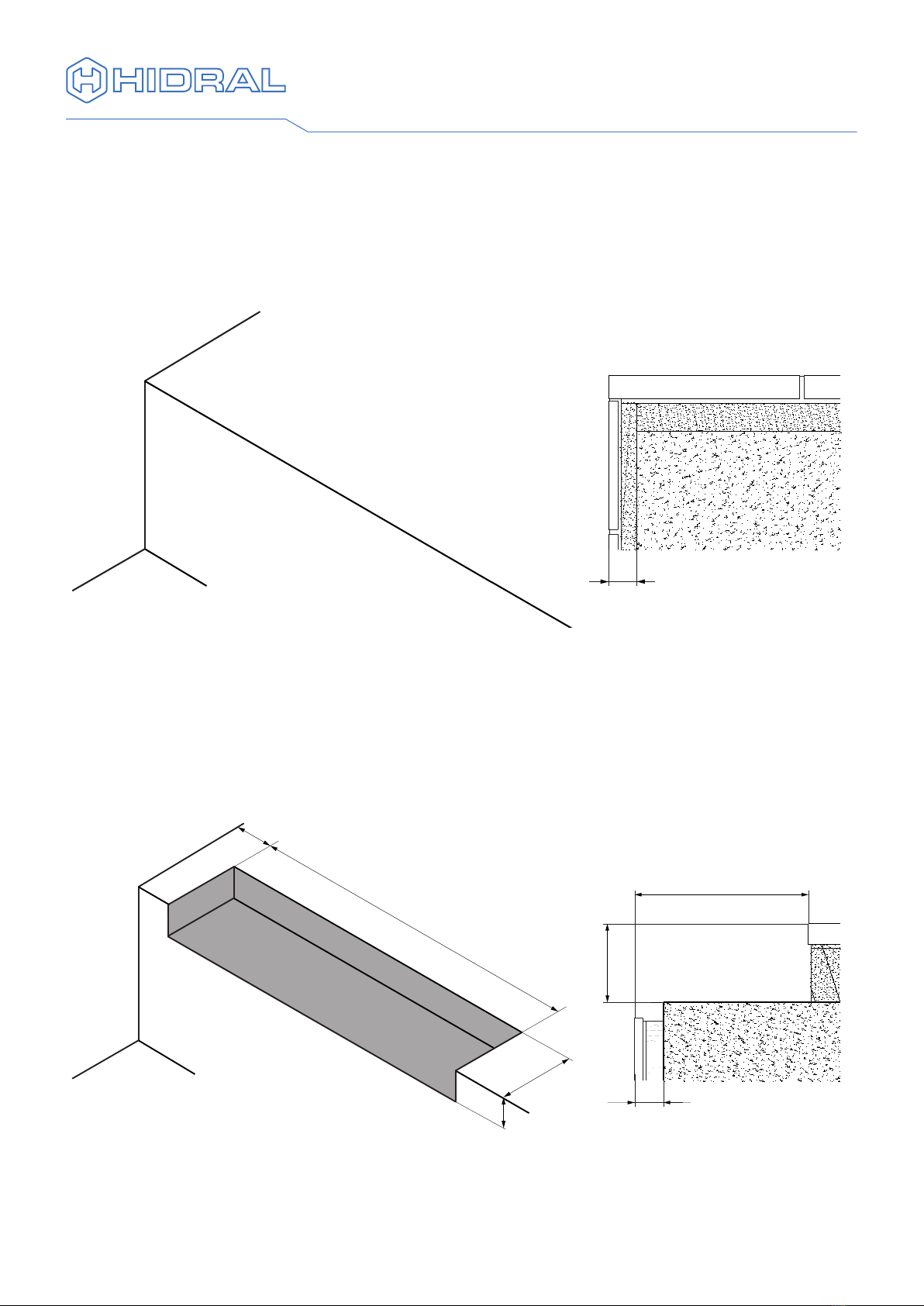

5 Check adjacent surface requirements:

- Upper access side. Vertical, continuous, solid and without projections; throughout

the dimension of the platform

- Guide side. Vertical, continuous, solid and without projections

- Side without access. According to the value of the travel (R) and the distance to the

platform (d):

R≤500 R>500 Surface

- d=20 Vertical, continuous, solid and without projections;

throughout the dimension of the platform

20≤d<120 80≤d<120 Vertical, continuous, solid and without projections

120≤d<400 Vertical, continuous and solid

d≥400 No specic requirements

Vertical, continuous and solid, throughout the dimension of the platform, for R>500 (d=20)

Permitted projection dimensions for

wall without projections

d=20A

1100

d=20

1.5÷5≤1.5

≤15º

IM-560en

Vers. 05

Page 6

ASSEMBLY INSTRUCTIONS

VERTICAL LIFTING PLATFORM PH-300

Vertical, continuous and solid, for R>500 (d= 80÷400)

1.5÷5≤1.5

≤15º

d=80÷400A

40

d=80÷400

1100

Permitted projection dimensions

for wall without projections

(for d=80÷120 only)

Vertical, continuous and solid, for R≤ 500 (d= 20÷400)

1.5÷5≤1.5

≤15º

Permitted projection dimensions

for wall without projections

(for d=20÷120 only)

d=20÷400

d=20÷400A

ASSEMBLY INSTRUCTIONS

PH-300 VERTICAL LIFTING PLATFORM

IM-560en

Vers. 05

Page 7

No specific requirements (d≥400)

d≥400A

40 (for R>500 only)

d≥400

IM-560en

Vers. 05

Page 8

ASSEMBLY INSTRUCTIONS

VERTICAL LIFTING PLATFORM PH-300

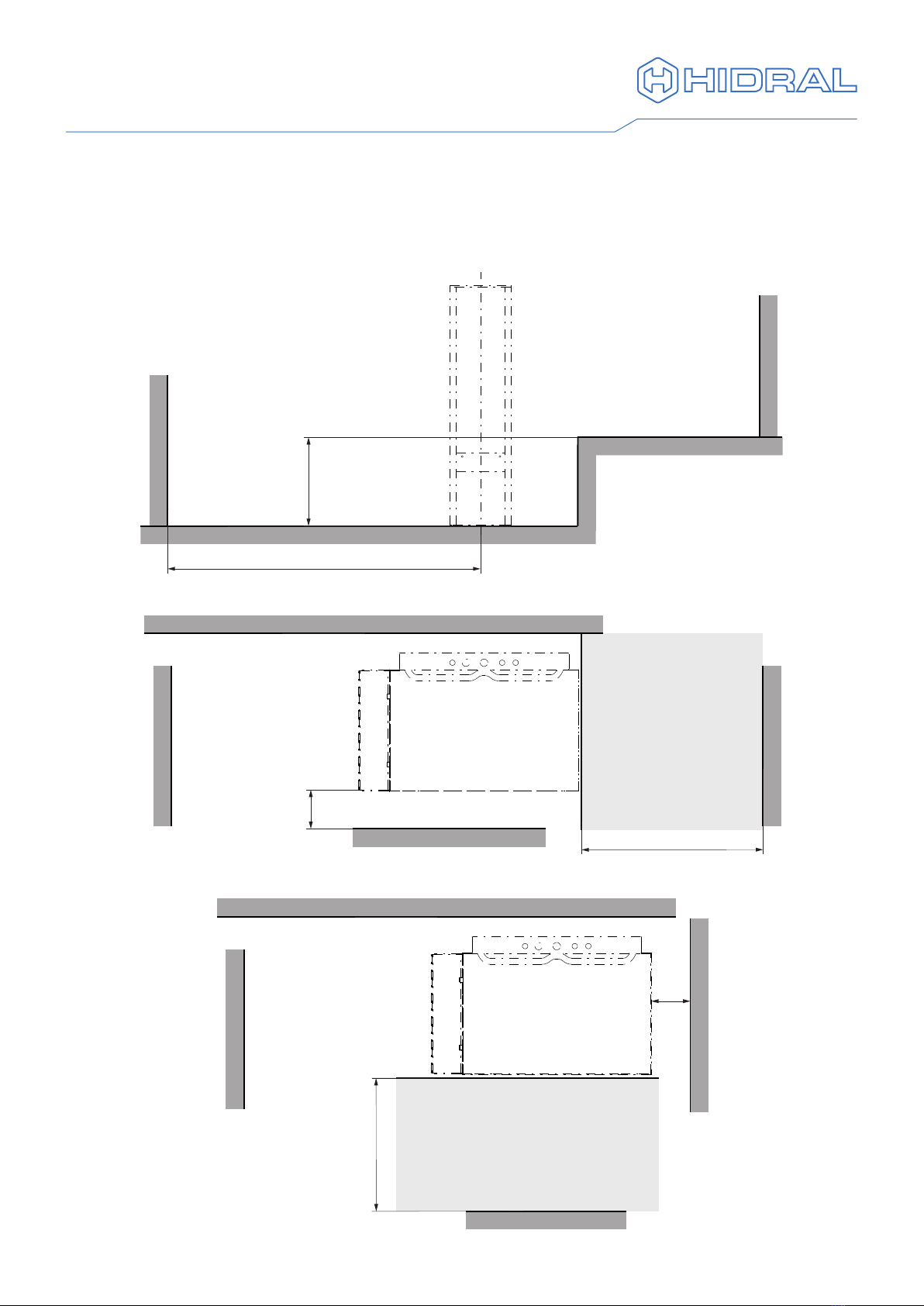

6 For the lower protection option, check that the pit dimensions are correct.

- F Pit depth

R (mm) F (mm)

≤ 400 ≥30

400< ≤ 700 ≥45

700< ≤1000 ≥60

1000< ≤1300 ≥75

1300< ≤1500 ≥90

Upper

level

Lower

level

F

- Pit dimensions for 180º access: (A+255) x 1220

Upper levelLower level

1220

A+255

A

- Pit dimensions for 90º access: (A+255) x 1150

Upper level

Lower level

1150

A+255

A

ASSEMBLY INSTRUCTIONS

PH-300 VERTICAL LIFTING PLATFORM

IM-560en

Vers. 05

Page 9

7 Check that the existing construction meets the necessary requirements for the

assembly of the upper-level doors, according to alternative Ⓐfor the option of

direct attachment to ooring or Ⓑfor the option of attachment by means of a built-

in plate.

Ⓐ Direct attachment to ooring

- Maximum wall plastering or covering thickness of 35 mm.

≤35

ⒷAttachment by means of a built-in plate

- Gap at the edge of the upper-level measuring at least 210 mm in width and

clearance plus 320 mm in length, centred with the position of the door.

- Structural concrete surface to attach the plate at a maximum distance from

oor level of 100 mm.

- Maximum wall plastering or covering thickness of 35 mm.

PL+320

210

75

≤100

≤100

210

≤35

IM-560en

Vers. 05

Page 10

ASSEMBLY INSTRUCTIONS

VERTICAL LIFTING PLATFORM PH-300

8 For the built-in push button panel option, check that the channels made begin

and end approximately as indicated for alternative Ⓐwith a cabinet on the lower

landing or Ⓑwith a cabinet on the upper landing.

ⒶCabinet on lower landing

910 for PL=800

1010 for PL=900

850÷1050

55

55

130

2050

30

Electrical inlet

600

850÷1050

55

55

130

750

1900

For upper

landing door

Without upper

landing door

ASSEMBLY INSTRUCTIONS

PH-300 VERTICAL LIFTING PLATFORM

IM-560en

Vers. 05

Page 11

ⒷCabinet on upper landing

600

180

910 for PL=800

1010 for PL=900

850÷1050

55

55

130

2050

30

850÷1050

55

55

130

750

For upper

landing door

Without upper

landing door

600

IM-560en

Vers. 05

Page 12

ASSEMBLY INSTRUCTIONS

VERTICAL LIFTING PLATFORM PH-300

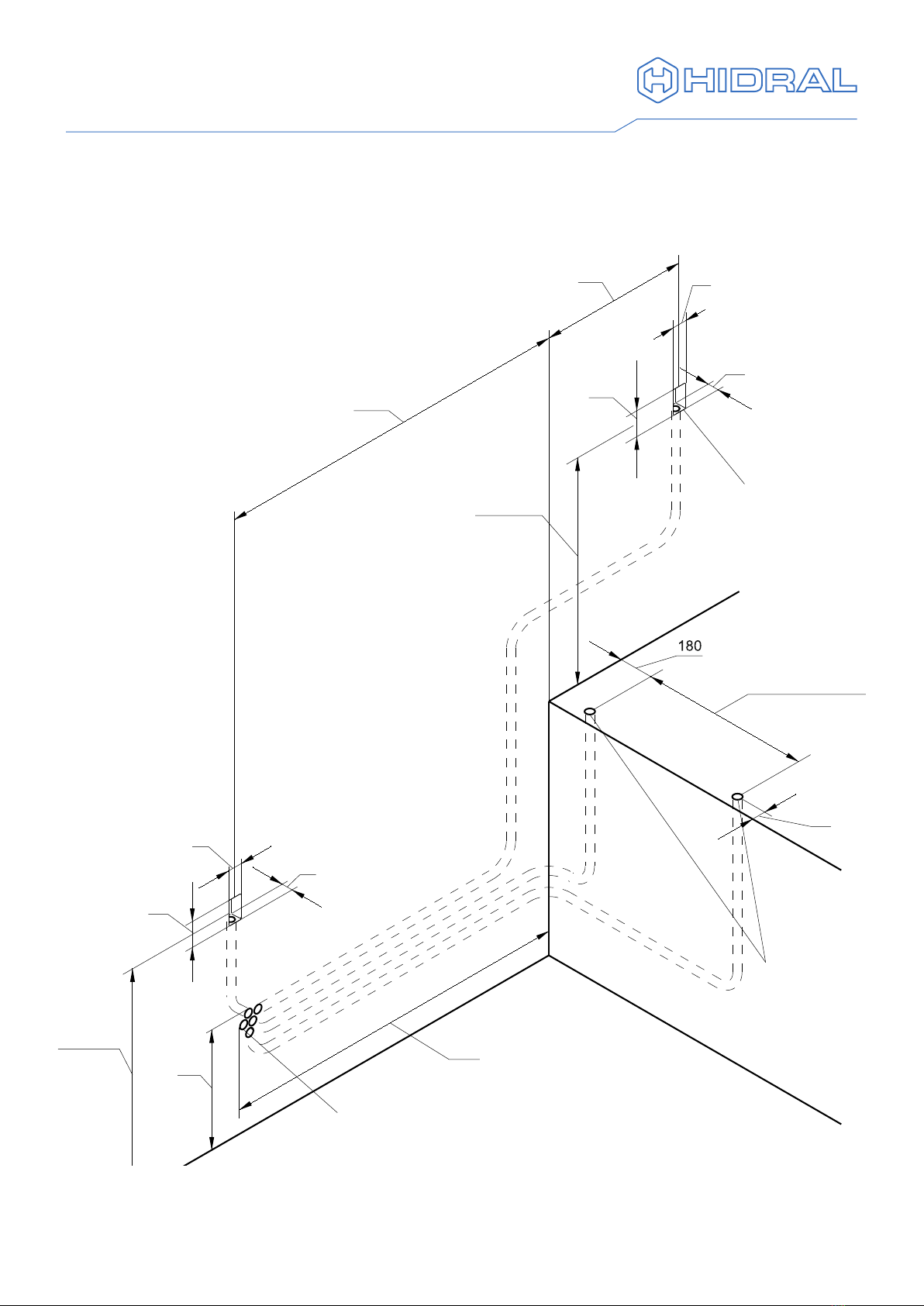

3. Guide assembly

1 Draw the guides axis on the ground. This must be perfectly parallel to the surface

of the upper access side, in the case of a 180º access, or at right angles to the

surface of the upper access side, in the case of a 90º access. To secure this

position, use the oor as a template, placing it on the ground 20 mm from the upper

access side and parallel to it. Draw a line on the ground, along the guide side,

using the oor as a reference and mark the centre of the oor. Remove the oor

from the ground.

20

90°

Guide axis markingLine paralell to the guide

2 Remove the front cover of the guide from the guide assembly.

3 Position the guide assembly on the wall and on the mark of the guide axis drawn

on the ground. Ensure that the guide and the line drawn in the previous section are

parallel.

4 Plumb the guide rail in both directions and adjust with the supports if necessary.

ASSEMBLY INSTRUCTIONS

PH-300 VERTICAL LIFTING PLATFORM

IM-560en

Vers. 05

Page 13

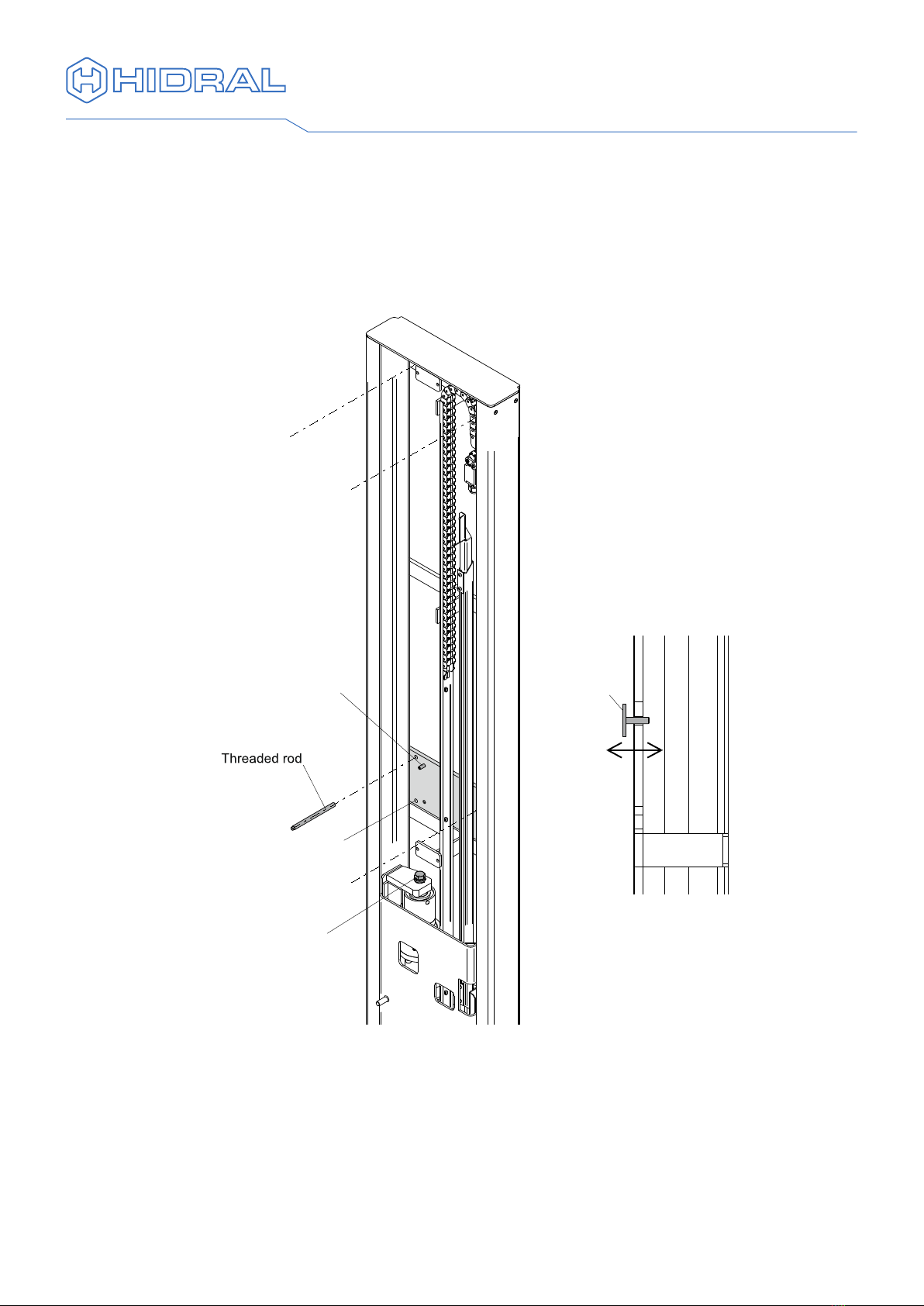

5 Using the guide as a template, make two Ø10 holes on the upper end of the guide

and another two on the upper section of the central plate. Once the rst hole is

drilled, insert a threaded rod to avoid the guide from deviating while the remaining

holes are made. In case an appropriate support for the upper part of the guide is

not available (see point 3 in section "2. Shaft check"), substitute the upper xation

anchorages for two additional xations in the lower holes of the central plate. In

case this plate is difcult to access, remove the bolt that xes the cylinder to the car

and move the car upwards; x the car securely in order to avoid accidents.

Adjustment

supports Adjustment

supports

Lower holes of the

fixation plate

Joint bolt between the

cylinder and the car

IM-560en

Vers. 05

Page 14

ASSEMBLY INSTRUCTIONS

VERTICAL LIFTING PLATFORM PH-300

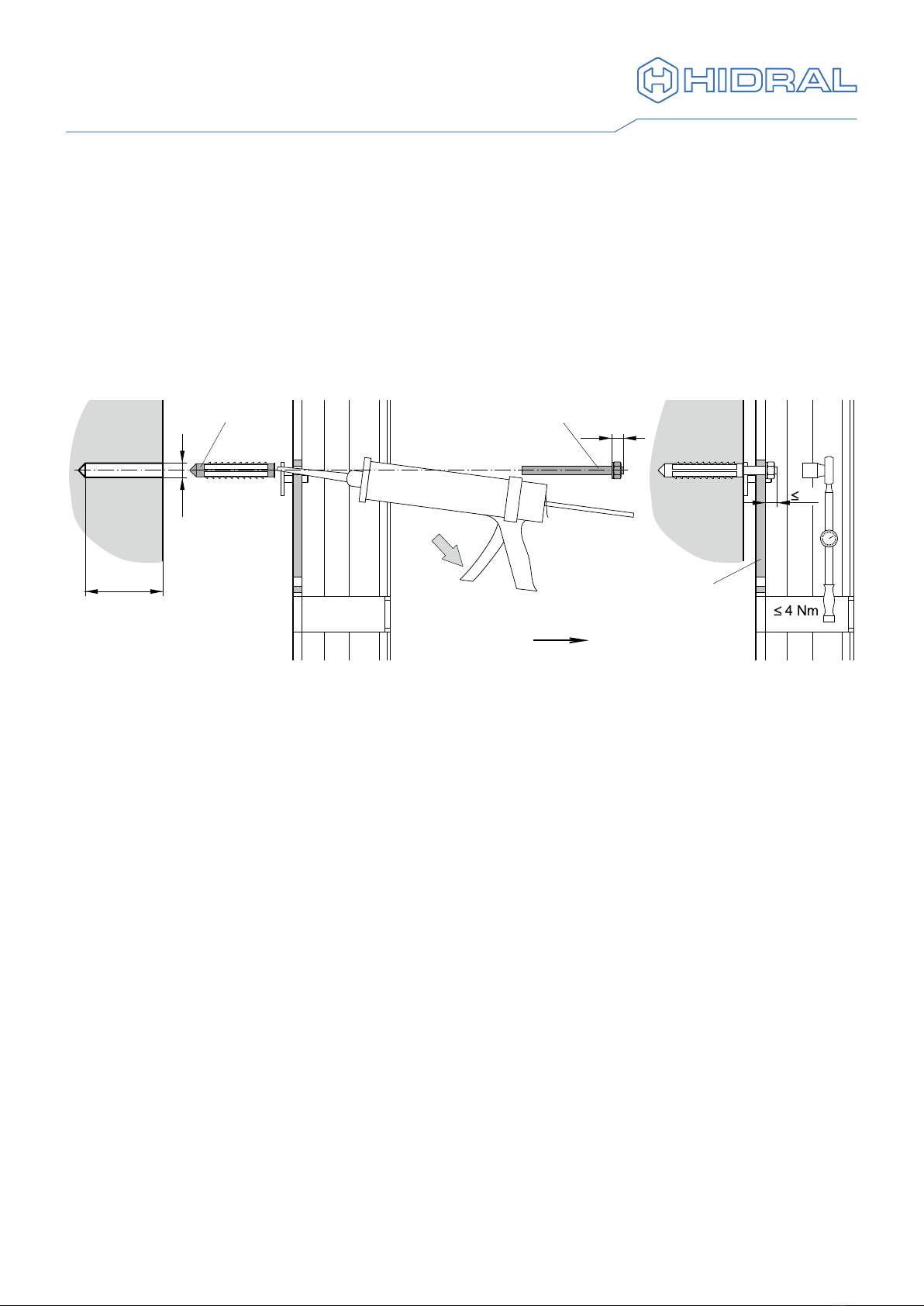

6 Separate the guide from the wall and redrill to Ø16 for a depth of 100 mm.

7 Insert the sheaves; previously, blow the holes.

8 Place the guide again in place.

9 Fill the holes starting from the bottom and making way towards the outside, with

5 strokes of the applicator. Immediately insert the threaded rods together with the

corresponding nuts and washers, to prevent the resin from hardening. The rod

shall be inserted fully and in such a way that it does not protrude more than 20 mm

from the crossbeams, to avoid interferences.

10 Wait for an hour without touching the threaded rods until the resin hardens

denitely. Tighten the nuts with a maximum torque of 4 Nm.

20

Rod, washer and nut

x5

> 1h

17

Crossbeam

100

Ø16

Sheave

ASSEMBLY INSTRUCTIONS

PH-300 VERTICAL LIFTING PLATFORM

IM-560en

Vers. 05

Page 15

4. Assembly of the machine cabinet

Access to the cabinet shall be suitable lighted and shall not be blocked in any way.

It shall be installed in a dry environment, and may not be installed outdoors.

The cabinet is foreseen for installation in a position adjacent to the guide assembly,

either on the lower level or on the upper level. Plastic channels are supplied to install

the hydraulic piping and electric connection cables so that these may be hidden,

taken the foreseen position into account. If the cabinet is installed in a different

position not adjacent to the guide, the hydraulic piping and the electric connection

cables shall be installed in appropriate conduits or channels (not supplied).

A working area of 550x700x2000 mm in front of the cabinet shall be guaranteed.

The machine cabinet shall be installed protected from high temperatures and

radiations to ensure that the temperature inside is between +5ºC and +40ºC.

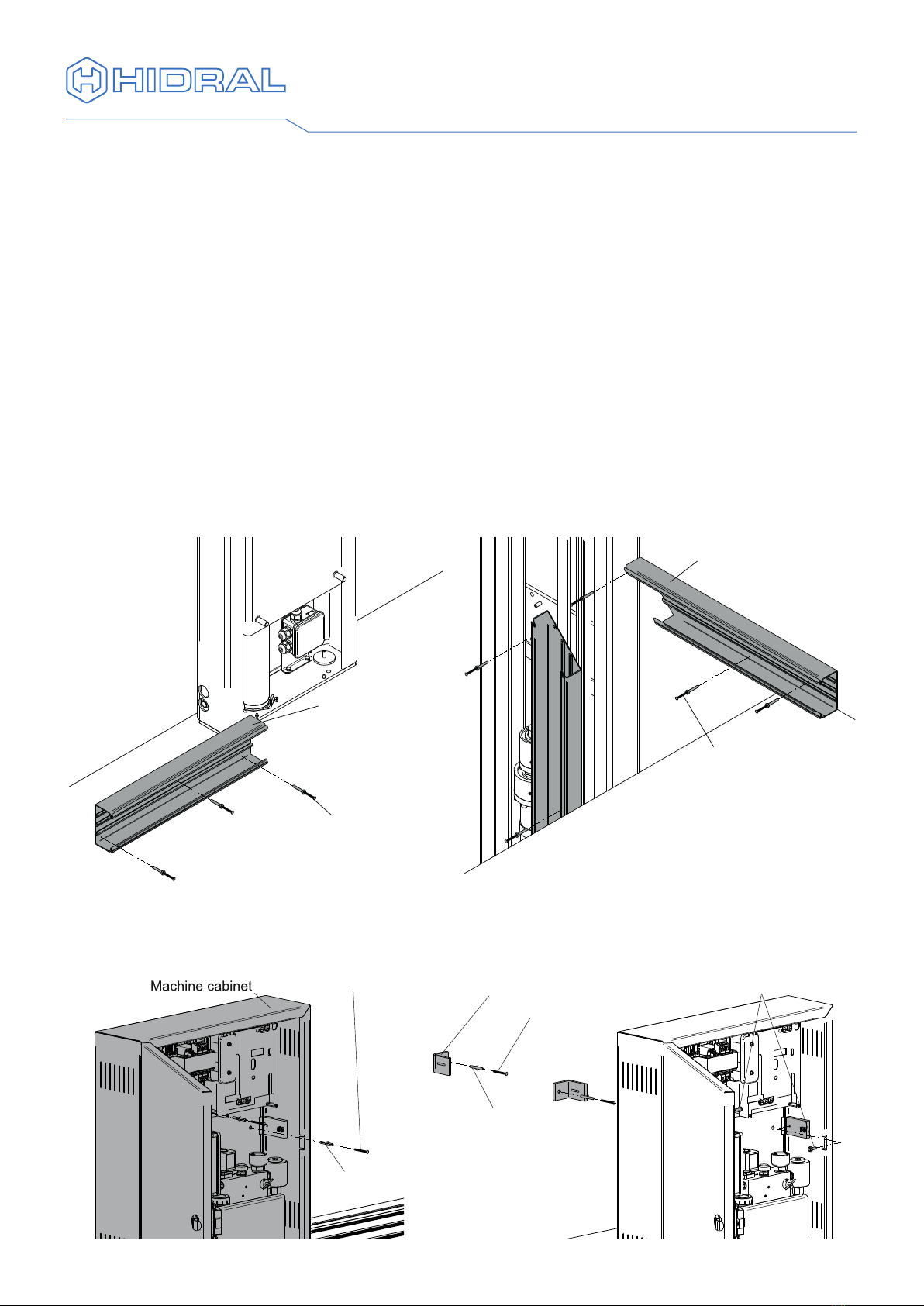

1 Attach the supplied conduit to hide the hydraulic and electrical connections

between the guide rail and the machine cabinet at the upper or lower end of the

guide rail, according to alternative Ⓐwith a cabinet on the lower landing or Ⓑwith

a cabinet on the upper landing. Use the supplied anchors.

60x110 conduit

Anchor for

Ø6 conduit

Ⓑ

Ⓐ

60x110 conduit

Anchor for

Ø6 conduit

2 Place the machine cabinet adjacent to the conduit and x it denitely to the wall.

Two additional xation brackets are supplied for the xation that allow the cabinet

to be installed slightly separated from the wall.

Fixation brackets Bolt M5x12

Screw ST 5.5x45

Plug Ø8

Screw ST 5.5x45

Plug Ø8

Location of the cabinet

IM-560en

Vers. 05

Page 16

ASSEMBLY INSTRUCTIONS

VERTICAL LIFTING PLATFORM PH-300

5. Hydraulic installation

1 Insert the bent end of the exible pipe through the lower opening in the machine

cabinet and the straight end of the pipe through the lower hole in the guide rail.

2 Screw the bent end of the pipe to the shut off valve and screw the straight end of

the pipe to the oil inlet of the cylinder. Reject the protection plugs.

Flexible pipe

Bent end

3 Fill the hydraulic power unit with the supplied oil.

Funnel

ASSEMBLY INSTRUCTIONS

PH-300 VERTICAL LIFTING PLATFORM

IM-560en

Vers. 05

Page 17

6. Electrical installation

6.1. Guide electrical installation

1 Plug in the guide rail connection cable to the control board in the machine

cabinet and bring the cable through the channel towards the guide rail. Open the

connection box in the guide rail assembly and plug in the connectors in this end.

2 Fix the cable to the guide using a cord to the upper section of the travelling cord

support.

Control board

Guide connection

cable

Fixation

6.2. Machine cabinet electric installation

1 Using an allen key, remove the knob in the main switch and the embellisher to gain

access to the protection outer casing and connect the supply of the machine to the

electric board.

Embelisher

Protection

IP switch

IM-560en

Vers. 05

Page 18

ASSEMBLY INSTRUCTIONS

VERTICAL LIFTING PLATFORM PH-300

7. Vehicle installation

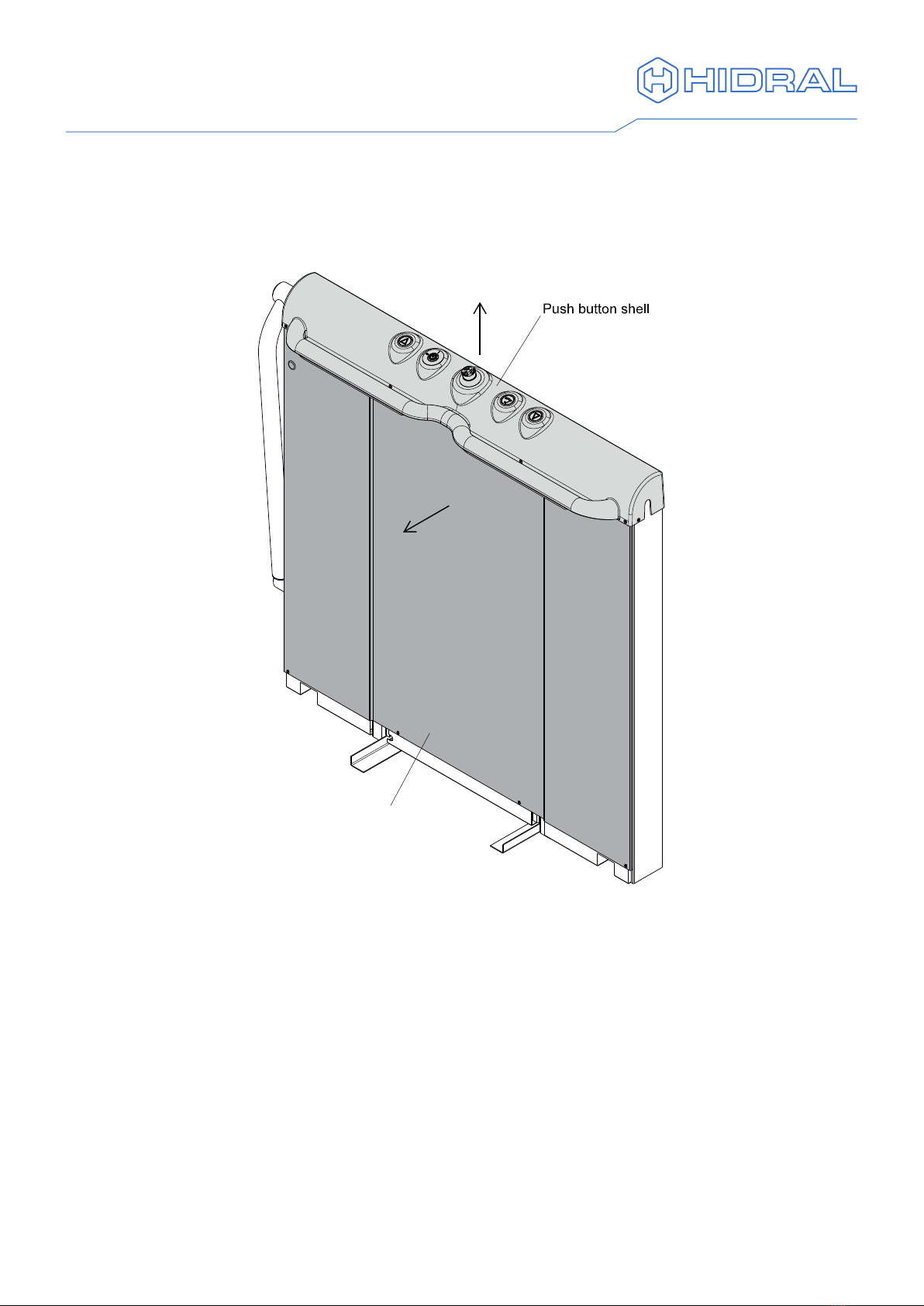

1 Remove the xation bolts for the push button shell, unplug the connector and

remove the shell.

2 Remove the lower bolts in the front vehicle cover and remove it.

Cover

3 Position the vertical structure next to the cart enough to insert the cables from the

guide rail and position the cable support plate.

4 Bring the vertical structure towards the guide and insert the rods in the cart in the

vertical structure, until they are in contact with the holes. Fix the vertical structure

with the four M12 biaseled ring nuts.

5 Fix the cable support plate to the vertical structure with four M4 nuts.

Table of contents

Popular Lifting System manuals by other brands

TOOL WAREHOUSE

TOOL WAREHOUSE HMWT-1000 quick start guide

BraunAbility

BraunAbility 02 Series Service manual

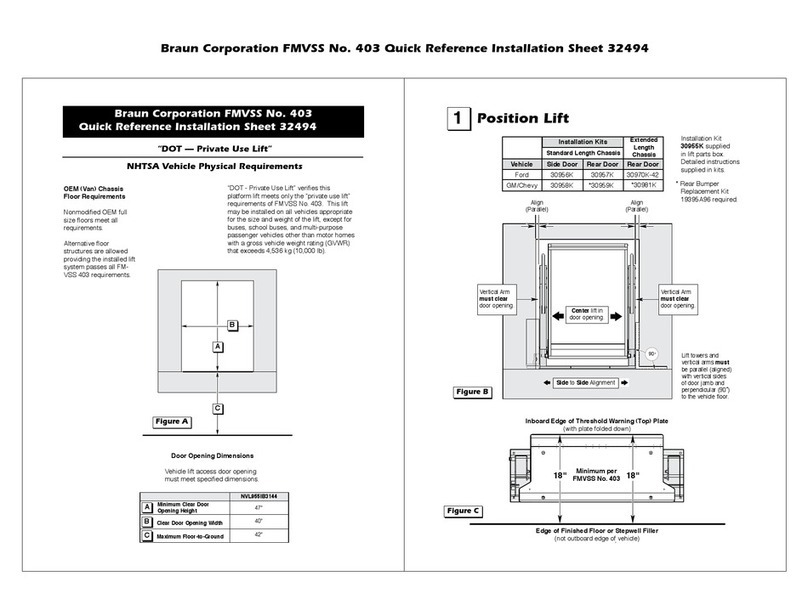

Braun

Braun FMVSS No. 403 Quick reference installation sheet

morse

morse 520-115 Operator's manual

Aqua Creek Products

Aqua Creek Products REVOLUTION F-702RLNA manual

Altrex

Altrex MiTower Assembly guide

Aqua Creek Products

Aqua Creek Products Scout Excel F-SCTXL manual

Tractel Group

Tractel Group pakrol 1 Operating and maintenance instructions

HAMACO

HAMACO ML-150-45V-D12 user manual

CASCOS

CASCOS TV2000H user guide

Harbor Freight Tools

Harbor Freight Tools PITTSBURGH 56617 Owner's manual & safety instructions

SINOLIFT

SINOLIFT ETM Series operating manual