HIKOKI G 10SF5 User manual

Other HIKOKI Grinder manuals

HIKOKI

HIKOKI G 23SCY2 User manual

HIKOKI

HIKOKI G 10ST User manual

HIKOKI

HIKOKI G1810DF User manual

HIKOKI

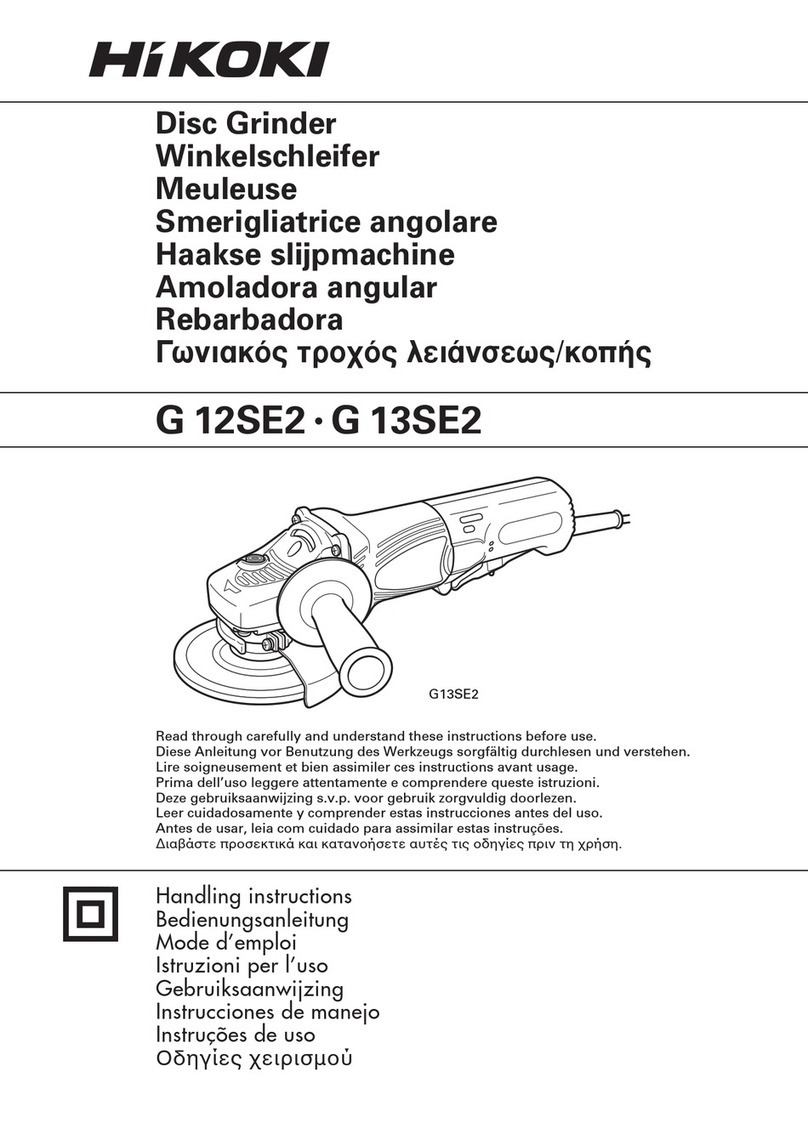

HIKOKI G 13SE2 User manual

HIKOKI

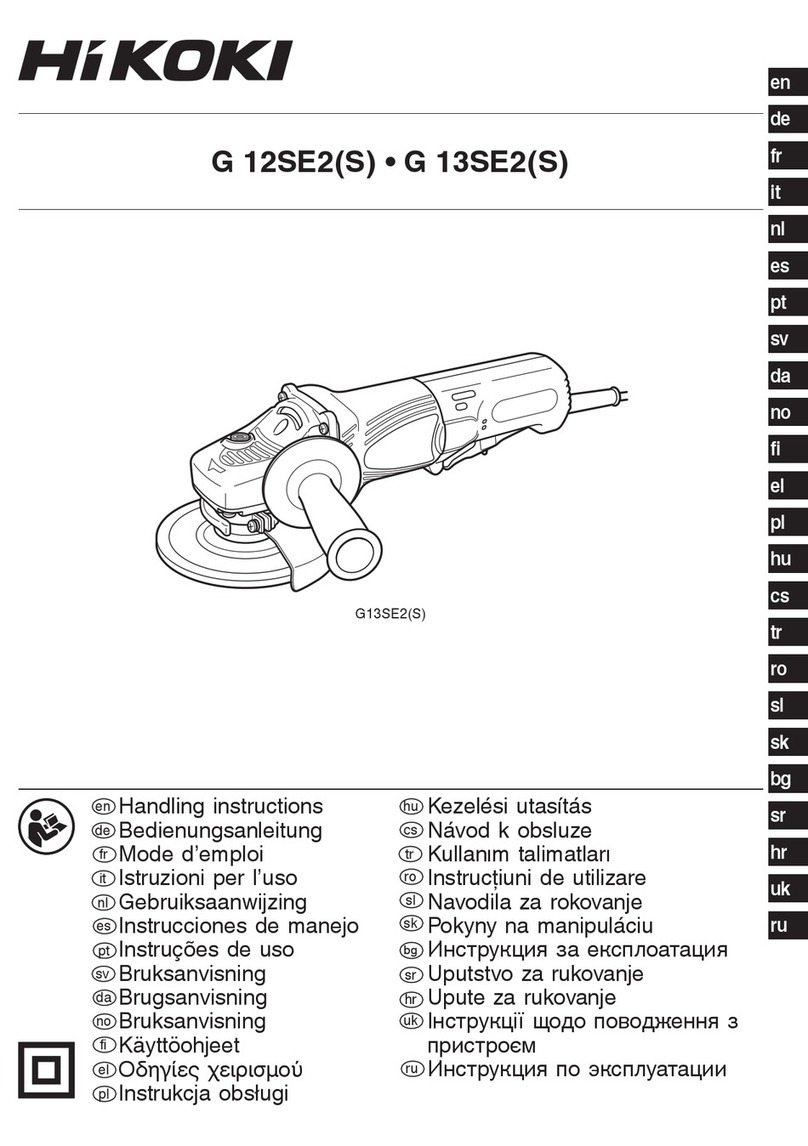

HIKOKI G 12SE2 S User manual

HIKOKI

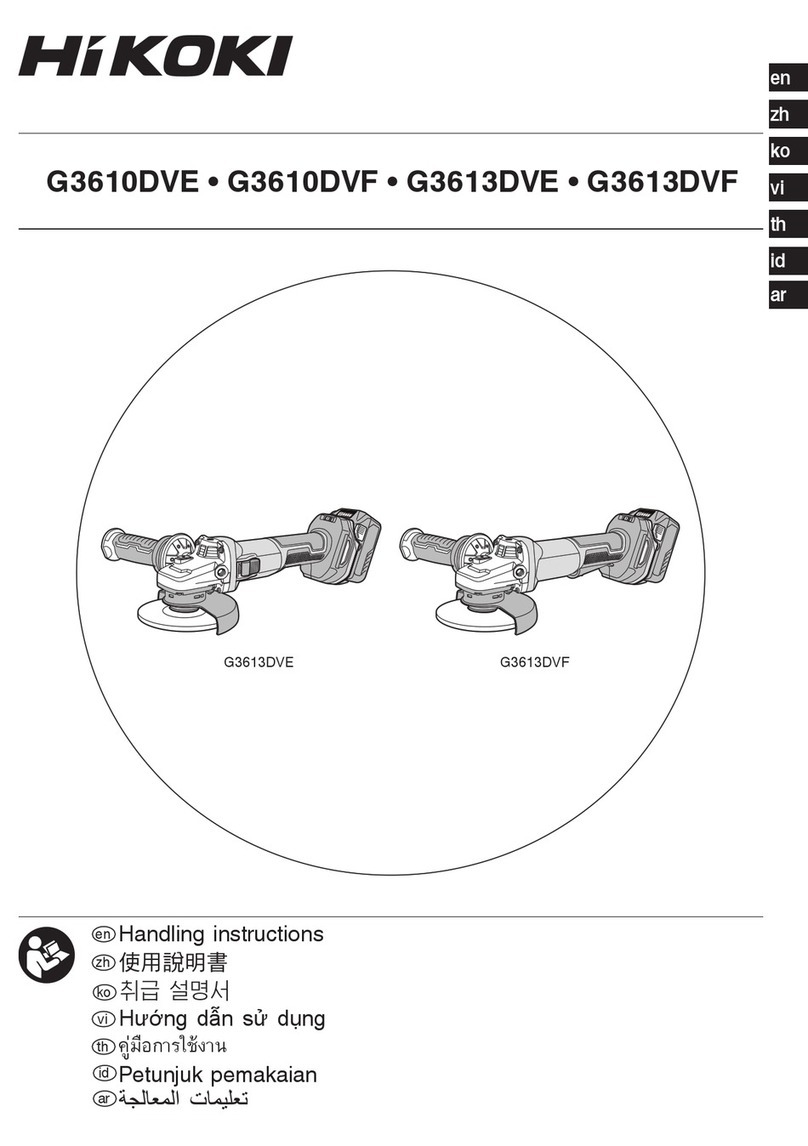

HIKOKI G3610DVF User manual

HIKOKI

HIKOKI G 12STA(S) User manual

HIKOKI

HIKOKI PDA-125M User manual

HIKOKI

HIKOKI GP 2S2 User manual

HIKOKI

HIKOKI G13SP User manual

HIKOKI

HIKOKI G 23UDY2 User manual

HIKOKI

HIKOKI GP18DA User manual

HIKOKI

HIKOKI G 18SE3 User manual

HIKOKI

HIKOKI G 3612DVE User manual

HIKOKI

HIKOKI G 12STA User manual

HIKOKI

HIKOKI G 12SA3 User manual

HIKOKI

HIKOKI G 18BYE User manual

HIKOKI

HIKOKI G 23BYE User manual

HIKOKI

HIKOKI G 1812DA User manual

HIKOKI

HIKOKI GP18DA User manual