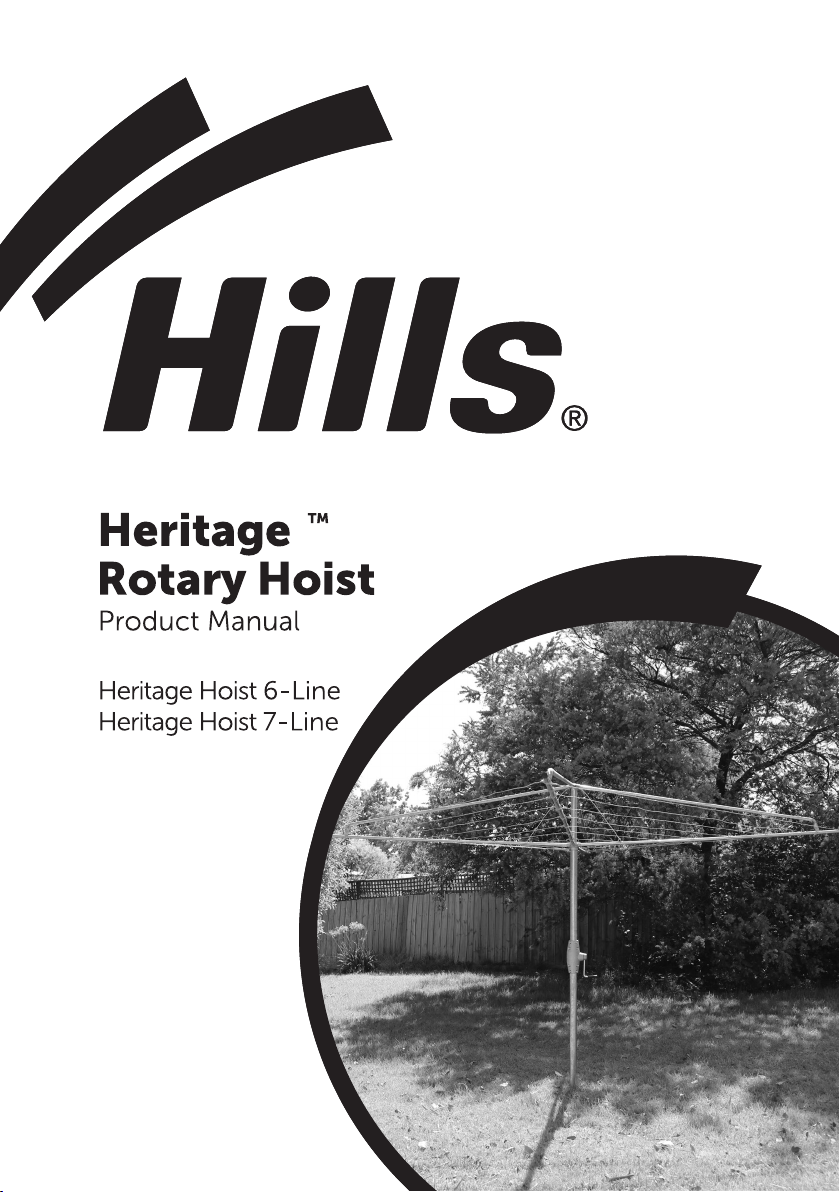

Hills Heritage Hoist 6-Line User manual

Heritage Hoist 6-Line

Heritage Hoist 7-Line

Heritage TM

Rotary Hoist

Product Manual

2Introduction

Congratulations

Congratulations on the purchase of your Hills

Heritage Hoist, which will bring you many years

It is important that you read thisProduct Manual

thoroughly before installation and use.In this

wayyou will benefit from all the design features

and enjoy safe use of the product.

Thank you for choosing Hills.

Warning

• Do not allow children or petsto swing on

theHoist or items of laundry.

• Do not use for any purpose other than

to hang and drywashing.

• Do not use your Hoist if parts are worn

or damaged.

• Patents and registered designs applyto

this product.

HoistPack contents

ID Part name Qty.

796 Main Standard 1

795 Secondary Standard 1

793 Arm 4

794 Tube stay 4

789Rod stay 4

788 Galvanised clothesline wire coil 1

Accessorypack 1

Accessory Pack contents

ID Part name Qty.

791 Top cap – upper 1

792 Top cap –lower 1

787 Arm staybracket 4

752 Arm end cap 4

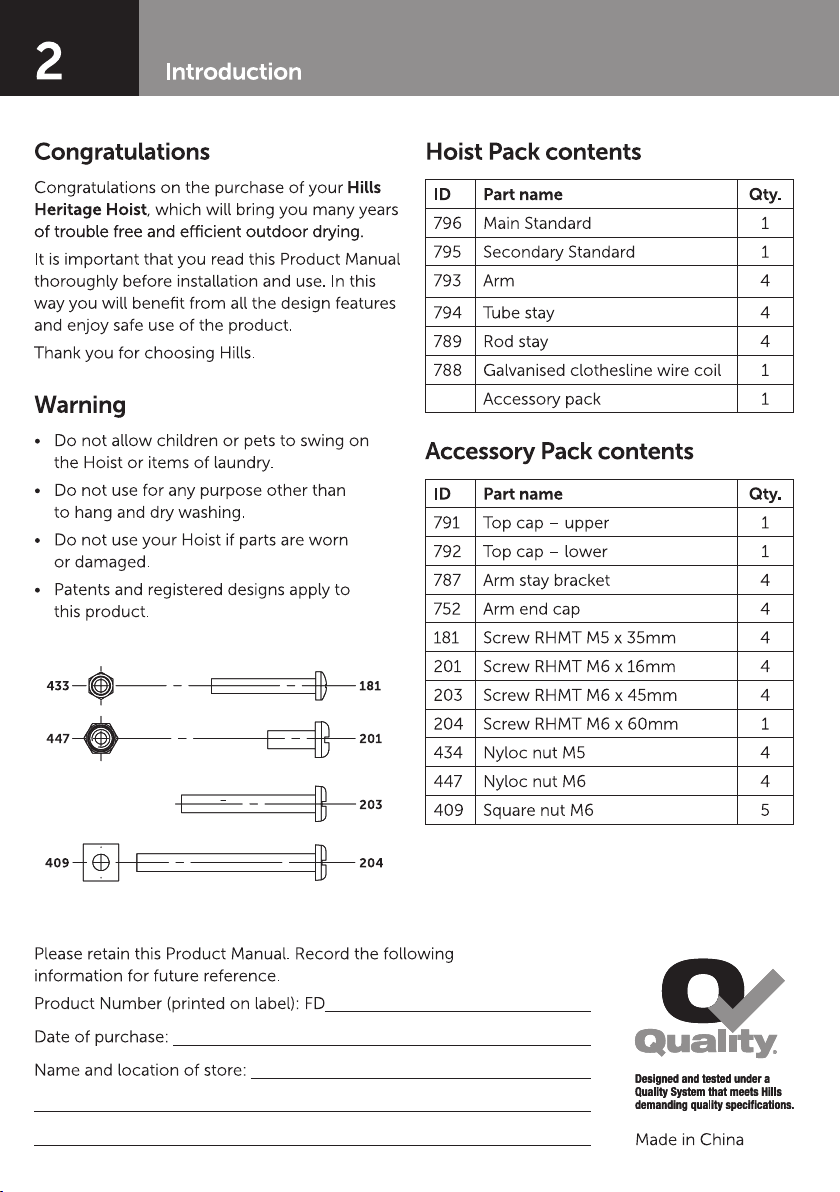

181 Screw RHMTM5x 35mm 4

201 Screw RHMTM6 x16mm 4

203 Screw RHMTM6 x45mm 4

204 Screw RHMTM6 x60mm 1

434 Nyloc nut M5 4

447 Nyloc nut M6 4

409 Square nut M6 5

Please retain this Product Manual. Record the following

information for future reference.

Product Number (printed on label):FD

Date of purchase:

Nameand location of store:

Made in China

433 181

447 201

409 204

203

3

Installation

Select a Suitable Location

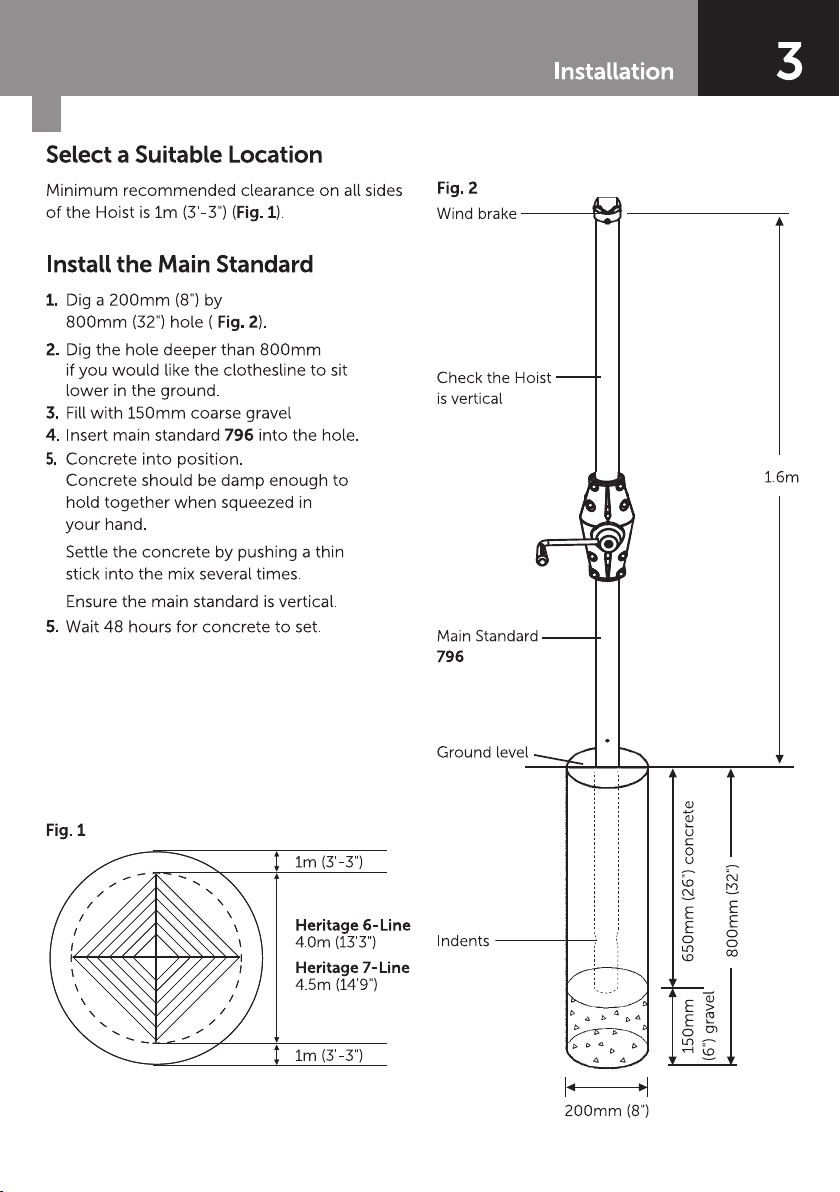

Minimum recommended clearance on all sides

of the Hoist is1m (3'-3") (Fig. 1).

Install the Main Standard

1. Dig a 200mm (8") by

800mm (32") hole (Fig. 2).

2. Dig the hole deeper than 800mm

if you would like the clothesline to sit

lower in the ground.

4. Insert main standard 796into the hole.

5.

Concrete into position.

Concrete should be damp enough to

hold together when squeezed in

your hand.

Settlethe concrete by pushing a thin

stick into the mixseveraltimes.

Ensure the main standard is vertical.

5. Wait 48 hours for concrete to set.

Fig. 2

Wind brake

Check the Hoist

is vertical

Main Standard

796

Indents

200mm (8")

1.6m

800mm (32")

650mm (26") concrete150mm

(6") gravel

Ground level

1m (3'-3")

Heritage 6-Line

4.0m (13'3")

Heritage 7-Line

4.5m (14'9")

1m (3'-3")

Fig. 1

3. Fill with 150mm coarse gravel

4Assembly

Arm andStay Assembly

1. Fit top cap lower assembly 792to secondary

standard assembly 795and fasten securely

with screw 204and nut 409 (Fig. 5).

2. Locate arm staybracket 787 onto the arm

793and align themount holes.

Ensure the bracket is assembled as per Fig 6

(with staples up).

3. Squeeze the arm staybracket 787 together

and fasten securely with screws 181and nuts

434(Fig. 6).

4. Fit tubestays 794to arm staybrackets 787

and fasten securely with screws 201and

nuts 447(Fig. 6).

5. Place the arms intothe cross and assemble

the tube stay intothe top cap assembly 791

and 792with the screw 203.

Note:Do not fit the nut yet.

6. Repeat step 5 for the other three arms.

For Model4 fit nuts 409 to screws 203now.

For Model5 refer tostep 7.

7. For Model 5, hook the inner rod stays 789

into the innermost staples on thearms.

Position other end underneath the top cap

lower assembly 792and onto screw 203.

Fit nuts 409 and tighten.

8. Fit end caps 752to the end of each arm.

Secondary Standard Assembly

1. Remove the wind brake and plastic ring

ring from thetop of theMain Standard

assemblyby loosening the securing screw.

2. Insert secondary standard 795into top of

main standard.

3. Rotate secondary standard 795until worm

hook slidesthrough theslot in stabiliser plug

(Fig 3).

4. Drop the wind brake and plastic ring on the

top of the secondary standard. Slide them

back down to their original position and

screw into place.

Fig. 3

Note: Main Standard tube

shown in dotted line for

illustration purposes.

IMPORTANT:

5

5

Cross

796

752

794

793

203

791

792

204409

Cross

409

789

795

794

794

409

Assembly

794

787 201

Staple

447 793

434

181

787

795

Assembly

Fig. 4

Fig. 5 Fig. 6

6Assembly

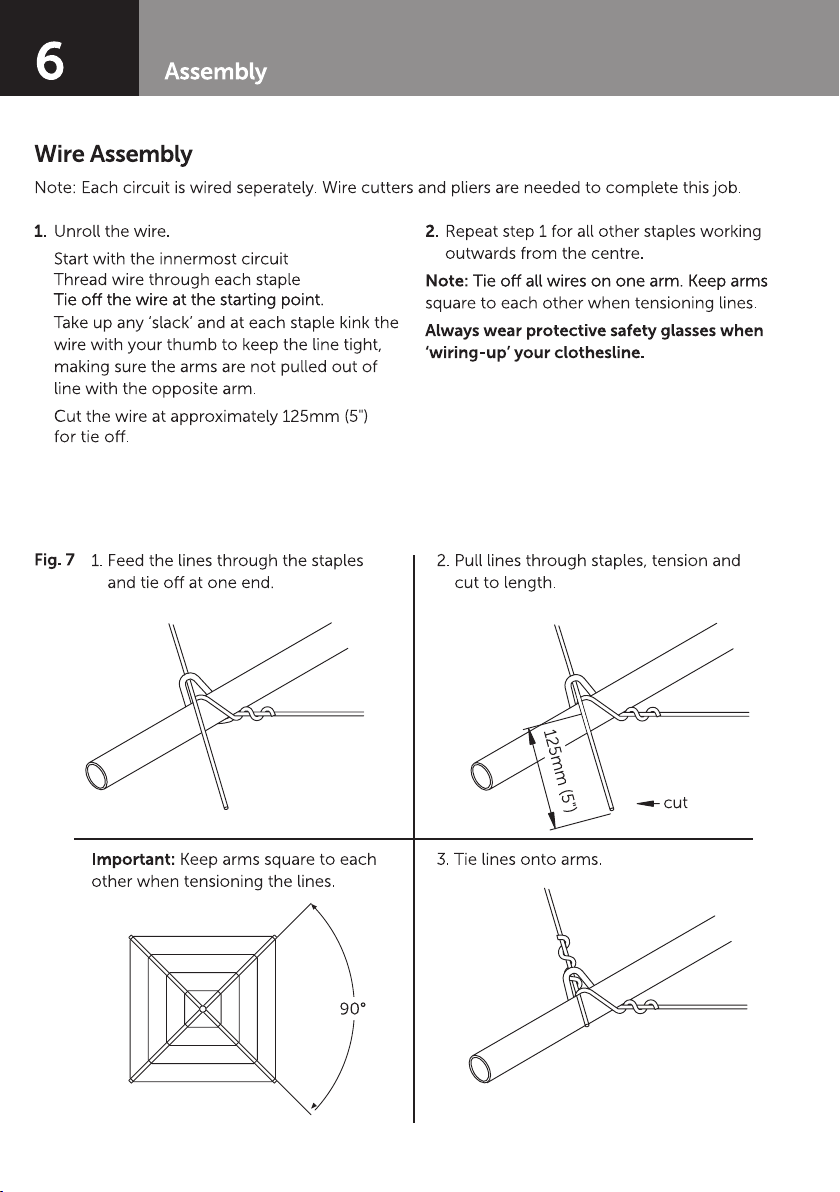

Wire Assembly

1. Unroll thewire.

Start with the innermost circuit

Thread wire through each staple

Take up any ‘slack’ and at each staple kink the

wire with your thumb to keep the line tight,

making sure the armsare not pulled out of

line with the opposite arm.

Cut the wire at approximately 125mm (5")

for tie o.

2. Repeat step 1 for all other staples working

outwards from the centre.

Note:

square to each other when tensioning lines.

Always wear protective safety glasses when

‘wiring-up’ your clothesline.

Fig. 71. Feed the lines through the staples

Important:Keep arms square toeach

other when tensioning the lines.

2. Pull linesthrough staples, tension and

cut to length.

3. Tie linesontoarms.

125mm (5")

cut

90°

Note: Each circuit is wired seperately. Wire cutters and pliers are needed to complete this job.

7

Assembly

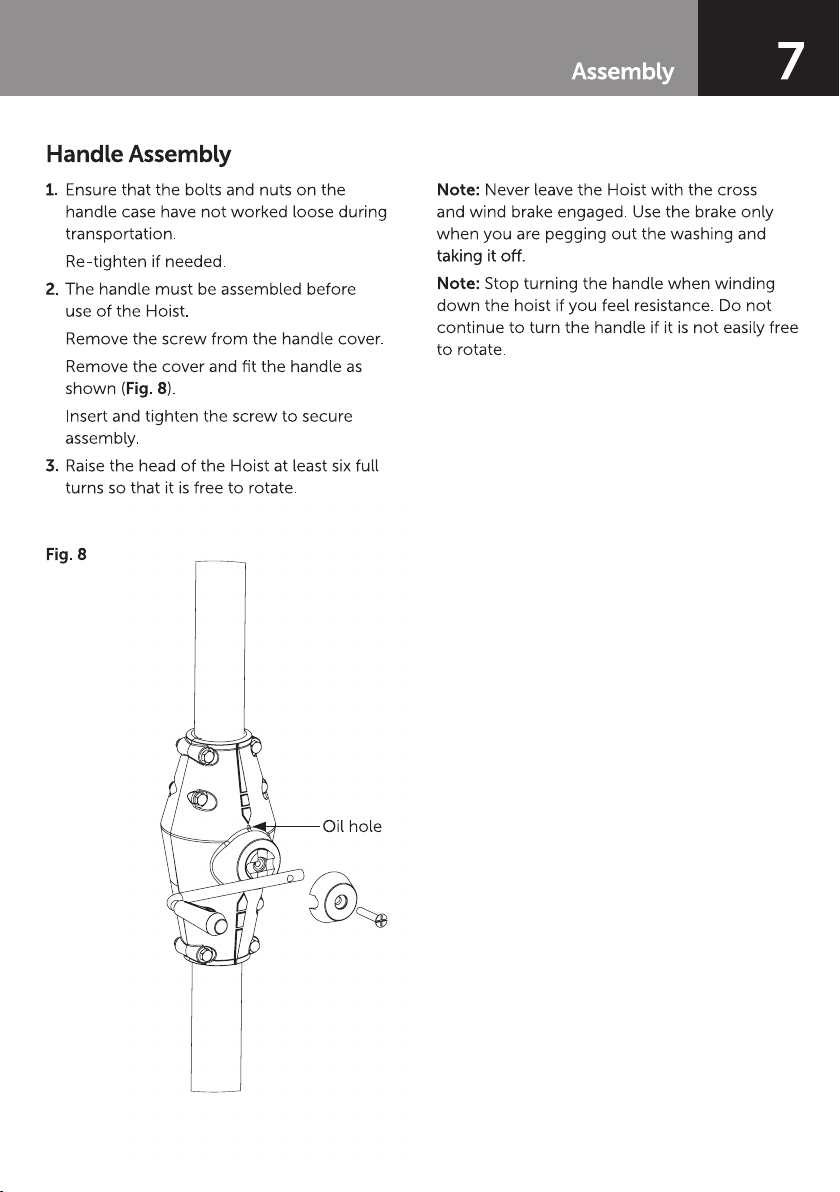

Handle Assembly

1. Ensure that thebolts and nuts on the

handlecase have not worked loose during

transportation.

Re-tighten if needed.

2. Thehandle must beassembled before

use of the Hoist.

Remove the screw from the handle cover.

Remove thecover and fit the handle as

shown (Fig. 8).

Insert and tighten the screw to secure

assembly.

3. Raise the head of the Hoist at least six full

turns so that it is free to rotate.

Note:Never leave the Hoist with the cross

and wind brake engaged.Use the brake only

when youare pegging out the washing and

Note:Stop turning the handle when winding

down the hoist if you feel resistance. Do not

continue toturn the handle if it isnot easily free

to rotate.

Fig. 8

Oil hole

8

Hills Handy Hints

• Commencehanging the washing on the

inside line starting with the smallest garments

and work your way outwards.

• The wind brake assists in the pegging and

unpegging of clothes on a windydayby

restricting the free rotation of the Hoist.It can

be engaged by winding the Hoist fullydown.

• To save excess walking, rotate the Hoist

by pulling onearm and thewind brake will

position in the next bay for loading.

• After hanging out your washing it is

recommended that the handle be wound up

at least sixfull turns to disengage the wind

brake.

• For faster drying elevate the Hoist fully to

collect any breeze. The rotating action of

the Hoist gives natural spin drying of your

washing.

Care and Maintenance

It is a good idea to occasionally inspect all

componentsand check for wear and tear or

damage. If there is anydamage, parts should be

replaced with originalHills spares or the Hoist

repaired before using again.

The Hoist should be periodically wiped clean

with a damp cloth and mild detergent.

1. To lubricate the worm gear and handle

assemblyperform the following:

a. Apply a few drops of oil through the oil

hole in the gear case abovethe handle

shaft (Fig. 8). Use any light gradeoil or

Lanonlin based lubricant.

Note:Should theHoist squeak when rotating,

wind theHoist up and apply (rub) a small

amount of bar soap on theelevated section of

the secondary standard 795(Fig.4).

Handy Hints

9

10-Year Warranty*

*In addition to other rights and remedies that

may be available under any applicable law,

Cyclone ToolsPty Ltd warrants to the purchaser

of the product (customer) that this Clothesline

will be free from defects in workmanship and

materials for 10 yearsand the Galvanised Wire

for 1 year from the date of purchase of the

product. If a defect in material or workmanship

becomes evident during that period, Cyclone

Tools Pty Ltd will, at its option, either:

• replace the product; or

• refund tothe customer the purchase price

paid by the customer for the product.

In the event of such a defect, the product

should be returned to the place of purchase

of the product bythecustomer, together

with proof of purchase, for replacement or

refund. Any handling and transportation (and

other expenses incurred in claiming under this

warranty) are not covered by this warrantyand

will be borne by the customer, not Cyclone

Tools Pty Ltd.

The obligation of Cyclone ToolsPty Ltd under

this warranty is limited to the circumstances set

out above and is subject to:

• theproduct not having been altered,

tampered with or otherwisedealt with byany

person in a manner other than as intended in

respect of the relevant product;and

• theproduct not having been used or applied

in a manner that is contrary to customary

usage or application of the relevant product

or contraryto anystated instructionsor

specification of Cyclone ToolsPty Ltd (or its

related bodiescorporate).

For products purchased in Australia:

Our goods come with guaranteesthat cannot

be excluded under the Australian Consumer

Law. You are entitled toa replacement or

refund for a major failure and compensation

for anyother reasonably foreseeableloss or

damage. You are also entitled to have the goods

repaired or replaced if thegoods fail tobe of

acceptable quality and the failure does not

amount to a major failure.

For products purchased in New Zealand:

Our goods come with guaranteesthat cannot

be excluded under the Consumer Guarantees

Act. Cyclone Tools Pty Ltd will comply with

our obligations to you under the Consumer

Guarantees Act.

Cyclone Tools Pty Ltd

ABN 89169 427 061

Level 1, 660Doncaster Road,

Doncaster Vic3108

Phone:1300 300564

Email: hhl.enquiries@amesau.com

Warranty

10 Contacts

Hills Contacts

We are committed to providing you with

complete customer satisfaction.If youhave any

questions or commentsabout our productsor

servicesplease contact your nearest Customer

Service Centre during their local business hours:

Australia

1300 300 564

New Zealand

0800 021 027

Email

hhl.enquiries@amesau.com

Hills Websites

hillshome.com.au

Hills Home Living

hillshome.com.au/need-help/

Hills Consumer Advice

11

Notes

12

Cyclone Tools Pty Ltd.

A.B.N. 89 169 427 061

Issue May2017

HD10842c

This manual suits for next models

1

Table of contents

Popular Irrigation System manuals by other brands

Viking

Viking VK506 Technical bulletin

Autopot

Autopot 36Pot system Set-up guidelines

Tyco Fire Product

Tyco Fire Product CENTRAL CC1 instruction manual

Tyco Fire Product

Tyco Fire Product CENTRAL BV-QR instruction manual

Philips

Philips sonicare AirFloss Ultra user manual

Tyco Fire Product

Tyco Fire Product SIN S3230 manual