been damaged, to smooth it back over

areas where bare metal is exposed.

NOTES

Only retouching of the wax coating ap-

plied to the wrench flats and frame

arms is permitted, and the retouching

is to be performed only at the time of

the initial sprinkler installation.

The steel rod should be heated only to

the point at which it can begin to melt

the wax, and appropriate precautions

need to be taken, when handling the

heated rod, in order to prevent the

installer from being burned.

If attempts to retouch the wax coating

with complete coverage are unsuc-

cessful, additional wax can be ordered

in the form of a wax stick (the end of

which is color coded). Only the correct

color coded wax is to be used, and

retouching of wrench flats and frame

arms is only permitted at the time of

initial sprinkler installation. With the

steel rod heated as previously de-

scribed, touch the rod to the area re-

quiring additional wax with the rod an-

gled downward, and then touch the

wax stick to the rod approximately

one-half inch away from the area re-

quiring retouching. The wax will melt

and run down onto the sprinkler.

Care and

Maintenance

TheSeriesTY-LSprinklersmustbe

maintained and serviced in accord-

ance with the following instructions:

NOTES

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down the

affected fire protection system must be

obtained from the proper authorities

and all personnel who may be affected

by this action must be notified.

Absence of an escutcheon, which is

used to cover a clearance hole, may

delay the time to sprinkler operation in

a fire situation.

Sprinklers that are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never be

painted, plated, coated or otherwise

altered after leaving the factory. Modi-

fied or over-heated sprinklers must be

replaced.

Care must be exercised to avoid dam-

age to the sprinklers - before, during,

and after installation. Sprinklers dam-

aged by dropping, striking, wrench

twist/slippage, or the like, must be re-

placed.

Frequent visual inspections are rec-

ommended to be initially performed for

corrosion resistant coated sprinklers,

after the installation has been com-

pleted, to verify the integrity of the cor-

rosion resistant coating. Thereafter,

annual inspections per NFPA 25

should suffice; however, instead of in-

specting from the floor level, a random

sampling of close-up visual inspec-

tions should be made, so as to better

determine the exact sprinkler condi-

tion and the long term integrity of the

corrosion resistant coating, as it may

be affected by the corrosive conditions

present.

The owner is responsible for the in-

spection, testing, and maintenance of

their fire protection system and de-

vices in compliance with this docu-

ment, as well as with the applicable

standards of the National Fire Protec-

tion Association (e.g., NFPA 25), in

addition to the standards of any other

authorities having jurisdiction. The in-

stalling contractor or sprinkler manu-

facturer should be contacted relative to

any questions.

It is recommended that automatic

sprinkler systems be inspected,

tested, and maintained by a qualified

Inspection Service in accordance with

local requirements and/or national

codes.

Limited

Warranty

Products manufactured by Tyco Fire

Products are warranted solely to the

original Buyer for ten (10) years

against defects in material and work-

manship when paid for and properly

installed and maintained under normal

use and service. This warranty will ex-

pire ten (10) years from date of ship-

ment by Tyco Fire Products. No war-

ranty is given for products or

components manufactured by compa-

nies not affiliated by ownership with

Tyco Fire Products or for products and

components which have been subject

to misuse, improper installation, corro-

sion, or which have not been installed,

maintained, modified or repaired in ac-

cordance with applicable Standards of

the National Fire Protection Associa-

tion, and/or the standards of any other

Authorities Having Jurisdiction. Mate-

rials found by Tyco Fire Products to be

defective shall be either repaired or

replaced, at Tyco Fire Products’ sole

option. Tyco Fire Products neither as-

sumes, nor authorizes any person to

assume for it, any other obligation in

connection with the sale of products or

parts of products. Tyco Fire Products

shall not be responsible for sprinkler

system design errors or inaccurate or

TFP120 Page 3 of 4

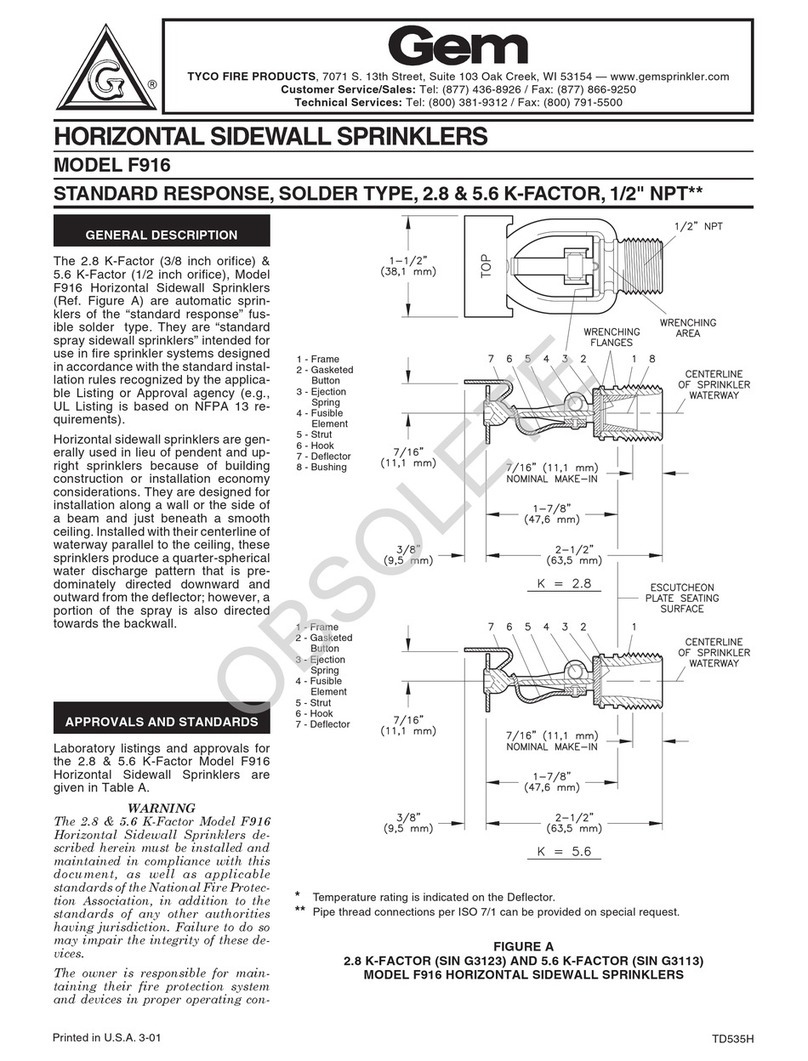

TYPE TEMP.

RATING

FRAME

COLOR

CODE

NATURAL

BRASS

CHROME

PLATED

SPRINKLER FINISH

NOTES:

1. Listed by Underwriters Laboratories, Inc. (UL) for Light or Ordinary Hazard Occupancies.

2. Listed by Underwriters Laboratories, Inc. for use in Canada (C-UL) for Light or Ordinary Hazard Occupancies.

3. Approved by Factory Mutual Research Corporation (FM) for Light Hazard Occupancies.

N/A: Not Available.

TABLE A

LABORATORY LISTINGS AND APPROVALS

5.6

1/2"

NPT

HORIZONTAL

SIDEWALL

(TY3311)

165°F/74°C Unpainted

212°F/100°C White

280°F/138°C Blue

1, 2, 3

KLEAD

COATED

WAX

COATED

WAX OVER

LEAD COATED

1, 2

N/A