INSTALLATION

The Luminous S170 must be installed in accordance with

the following instructions:

NOTES

The Luminous S170 must only be installed in fittings that

meet the requirements of the Design Criteria section.

Refer to the Design Criteria section for other important re-

quirements regarding piping design and sealing of the

clearance space around the Sprinkler Casing.

Do not install any bulb type sprinkler if the bulb is

cracked or there is a loss of liquid from the bulb. With the

sprinkler held horizontally, a small air bubble should be

present. The diameter of the air bubble is approximately

1/16 inch (1,6 mm) for the 135°F/57°C rating to 1/8 inch

(3,2 mm) for the 360°F/182°C rating.

A leak tight 1 inch NPT sprinkler joint should be obtained

withatorqueof20to30ft.lbs.(26,8to40,2Nm).Higher

levels of torque may distort the sprinkler inlet with conse-

quent leakage or impairment of the sprinkler.

Do not attempt to compensate for insufficient adjustment

in an Escutcheon Plate by under- or over-tightening the

Sprinkler. Readjust the position of the sprinkler fitting to

suit.

1. The sprinkler must be installed only in the pendent posi-

tion and with the deflector parallel to the mounting sur-

face.

2. With pipe thread sealant applied to the pipe threads,

hand tighten the sprinkler into the sprinkler fitting.

3. Wrench tighten the sprinkler by wrenching on the Cas-

ing with a pipe wrench whenever the casing is readily ac-

cessible. Otherwise, use a W-Type 7 Sprinkler Wrench

(Ref. Figure 3). The wrench recess of the W-Type 7 is to

be applied to the sprinkler wrench flats (Ref. Figure 1).

4. After a suspended ceiling has been installed or the finish

coat has been applied to a fixed ceiling (as applicable),

slide on the outer piece of the Escutcheon until it comes in

contact with the ceiling. Do not lift the ceiling panel out of

its normal position.

In the case of the outer piece of the Deep Ceiling Es-

cutcheon, hold the outer piece in contact with the mount-

ing surface (ceiling), and then rotate the inner piece ap-

proximately 1/4 turn with respect to the outer piece, to

hold the Deep Escutcheon firmly together.

CARE AND MAINTENANCE

The Luminous S170 must be maintained and serviced in

accordance with the following instructions:

NOTES

Absence of the outer piece of an escutcheon, which is

used to cover a clearance hole, may delay the time to

sprinkler operation in a fire situation.

Before closing a fire protection system main control valve

for maintenance work on the fire protection system which

it controls, permission to shut down the affected fire pro-

tection systems must be obtained from the proper authori-

ties and all personnel who may be affected by this action

must be notified.

It is recommended that the piping connected to Dry Sprin-

klers be periodically checked to assure that proper pitch

and drainage is in accordance with the minimum require-

ments of the National Fire Protection Association if the

piping is subject to freezing temperatures.

A Vent Hole is provided in the Bulb Seat (Ref. Figure 2)

to indicate if the Dry Sprinkler is remaining dry. Evidence

of leakage from the Vent Hole is an indication that there

may be weepage past the O-ring seal and, therefore, it is

an indication that the sprinkler needs to be removed for

determining the cause of leakage (e.g. an improper instal-

lation or an ice plug). The fire protection system control

valve must be closed and the system drained before re-

moving the sprinkler.

Sprinklers which are found to be leaking or exhibiting vis-

ible signs of corrosion must be replaced.

Automatic sprinklers must never be shipped or stored

where their temperatures will exceed 100°F/38°C and

they must never be painted, plated, coated or otherwise

altered after leaving the factory. Modified sprinklers must

be replaced. Sprinklers that have been exposed to corro-

sive products of combustion, but have not operated,

should be replaced if they cannot be completely cleaned

by wiping the sprinkler with a cloth or by brushing it with a

soft bristle brush.

Care must be exercised to avoid damage to the sprinklers

— before, during, and after installation. Sprinklers dam-

aged by dropping, striking, wrench twist/slippage, or the

like, must be replaced. Also, replace any sprinkler that

has a cracked bulb or that has lost liquid from its bulb.

(ref. Installation Section Note).

The owner is responsible for the inspection, testing, and

maintenance of their fire protection system and devices in

compliance with this document, as well as with the appli-

cable standards of the National Fire Protection Associa-

tion (e.g., NFPA 25), in addition to the standards of any

other authorities having jurisdiction. The installing contrac-

tor or sprinkler manufacturer should be contacted relative

to any questions.

It is recommended that automatic sprinkler systems be in-

spected, tested, and maintained by a qualified Inspection

Service.

STAR SPRINKLER

Page 4 1-6.2.11

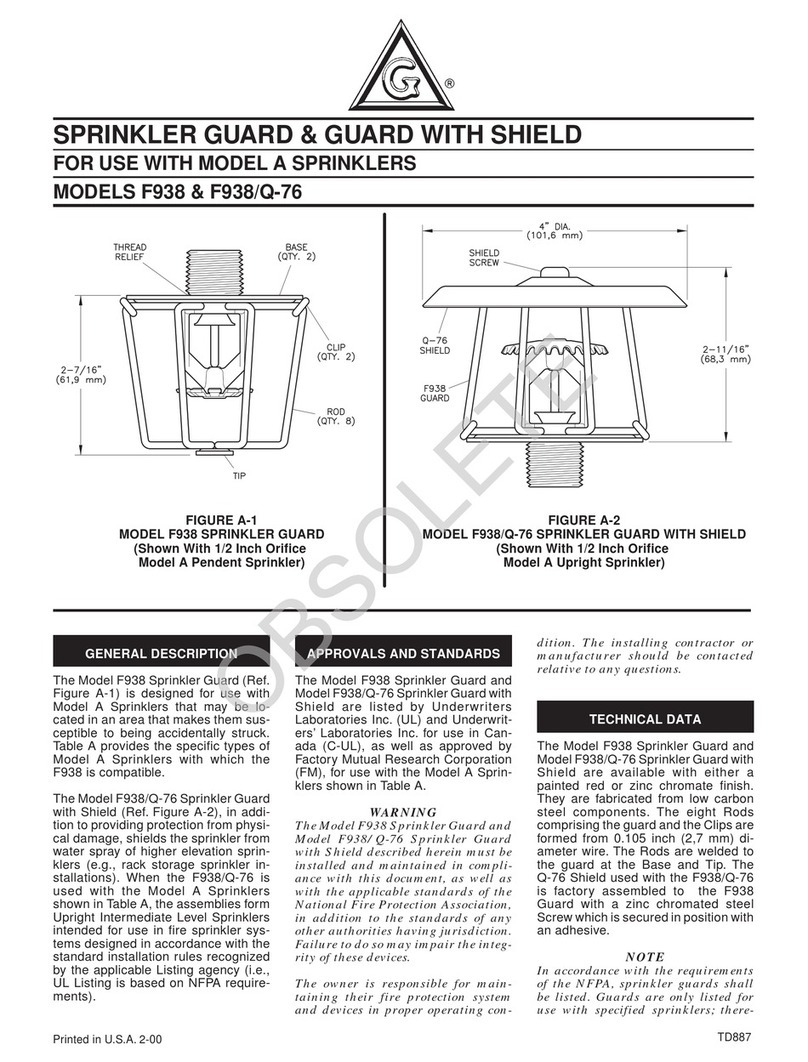

FIGURE 3

W-TYPE 7

(#2349) SPRINKLER

WRENCH

RECESS

WREN

H

ENSURE ENGAGEMENT WITH

PUSH WRENCH IN TO

SPRINKLER WREN

HIN

AREA