HIMA HIMax User guide

SYSTEM

HIMax®

System Manual

HI 801 001 E Rev. 4.01 (1131)

All HIMA products mentioned in this manual are protected by the HIMA trade-mark. Unless noted

otherwise, this also applies to other manufacturers and their respective products referred to herein.

All of the instructions and technical specifications in this manual have been written with great care and

effective quality assurance measures have been implemented to ensure their validity. For questions,

please contact HIMA directly. HIMA appreciates any suggestion on which information should be

included in the manual.

Equipment subject to change without notice. HIMA also reserves the right to modify the written material

without prior notice.

For further information, refer to the CD-ROM and our website http://www.hima.de and

http://www.hima.com.

© Copyright 2011, HIMA Paul Hildebrandt GmbH + Co KG

All rights reserved

Contact

HIMA Address:

HIMA Paul Hildebrandt GmbH + Co KG

P.O. Box 1261

68777 Brühl

Phone: +49 6202 709-0

Fax: +49 6202 709-107

Type of change

Revision

index

Revisions

technical editorial

4.00 Adjusted to HIMax V4/SILworX V4 X X

4.01 Revised: chapter 3.2, 3.5, 5.2, 9.2 X X

HIMax System Table of Contents

HI 801 001 E Rev. 4.01 Page 3 of 122

Table of Contents

1Introduction ............................................................ 7

1.1 Structure and Use of the Document..................................................................... 7

1.2 Target Audience..................................................................................................... 7

1.3 Formatting Conventions ....................................................................................... 8

1.3.1 Safety Notes ............................................................................................................ 8

1.3.2 Operating Tips ......................................................................................................... 9

2Safety.................................................................... 10

2.1 Intended Use ........................................................................................................ 10

2.1.1 Scope..................................................................................................................... 10

2.1.2 Non-Intended Use.................................................................................................. 10

2.1.3 Operating Requirements........................................................................................ 11

2.1.4 Requirements to be met by the operator and the machine and system

manufacturers........................................................................................................ 13

2.2 Residual Risk ....................................................................................................... 13

2.3 Safety Precautions............................................................................................... 14

2.4 Emergency Information....................................................................................... 14

3Product Description .............................................. 15

3.1 Base Plates and Base Plate Types..................................................................... 16

3.1.1 Base Plate Structure.............................................................................................. 17

3.1.2 Ventilation .............................................................................................................. 18

3.1.3 Monitoring the Temperature................................................................................... 18

3.1.4 Power Supply......................................................................................................... 18

3.2 System Bus .......................................................................................................... 19

3.2.1 System Bus with Line Structure ............................................................................. 21

3.2.2 System Bus with Network Structure....................................................................... 21

3.2.3 Extending the System Bus, System bus Latency .................................................. 24

3.3 Modules and Connector Boards......................................................................... 33

3.3.1 Identifying the Module via SRS.............................................................................. 33

3.3.2 Permissible Slot Assignments................................................................................ 34

3.4 Processor module................................................................................................ 35

3.4.1 Operating System .................................................................................................. 35

3.4.2 Behavior in the Event of Faults .............................................................................. 37

3.5 Noise Blanking ..................................................................................................... 37

3.5.1 Impact of Noise Blanking ....................................................................................... 37

3.5.2 Configuring Noise Blanking.................................................................................... 38

3.5.3 Noise Blanking Sequence...................................................................................... 39

3.5.4 Considering the Effective Direction........................................................................ 41

3.6 Alarm and Sequence of Events Recording ....................................................... 42

3.6.1 Alarm and Events................................................................................................... 42

3.6.2 Creating Events ..................................................................................................... 42

3.6.3 Recording Events................................................................................................... 43

3.6.4 Transfer of Events.................................................................................................. 43

Table of Contents HIMax System

HI 801 001 E Rev. 4.01 Page 4 of 122

3.7 Communication ....................................................................................................44

3.8 Communication with the Programming and Debugging Tool..........................44

3.9 Licensing...............................................................................................................45

4Redundancy .......................................................... 46

4.1 Processor Module ................................................................................................ 46

4.1.1 Decreasing Redundancy ........................................................................................ 46

4.1.2 Upgrading Redundancy..........................................................................................46

4.2 I/O Modules ...........................................................................................................46

4.2.1 Module Redundancy .............................................................................................. 46

4.2.2 Channel Redundancy............................................................................................. 47

4.2.3 Connector Boards for Redundant Modules ............................................................47

4.3 System Bus........................................................................................................... 47

4.4 Communication ....................................................................................................47

4.4.1 safeethernet ..........................................................................................................47

4.4.2 Standard Protocols................................................................................................. 47

4.5 Power Supply........................................................................................................ 47

5Programming......................................................... 49

5.1 Connecting the Programming System ...............................................................49

5.2 Using Variables in a Project ................................................................................49

5.2.1 Types of Variables..................................................................................................49

5.2.2 Initial Value.............................................................................................................50

5.2.3 System Variables and System Parameters............................................................ 50

5.2.4 Assignment to I/O Channels...................................................................................61

5.2.5 Assignment to Communication Connections..........................................................63

5.2.6 Configuring the Sequence of Events Recording ....................................................63

5.3 Forcing ..................................................................................................................66

5.3.1 Time Limits .............................................................................................................66

5.3.2 Restricting the Use of Forcing ................................................................................ 67

5.3.3 Force Editor............................................................................................................67

5.3.4 Forcing and Scalar Events .....................................................................................67

5.4 Multitasking ..........................................................................................................68

5.4.1 Multitasking Mode ..................................................................................................71

5.5 Loading User Programs....................................................................................... 75

5.5.1 Download ...............................................................................................................75

5.5.2 Reload ....................................................................................................................75

5.6 Loading Operating Systems................................................................................ 78

5.6.1 Load Process ......................................................................................................... 78

5.6.2 Updating and Downgrading Operating Systems .................................................... 79

6User Management .................................................. 80

6.1 User Management for SILworX Projects ............................................................ 80

6.2 User Management for the Controller .................................................................. 80

6.2.1 Default User ...........................................................................................................81

6.2.2 Parameters for User Accounts ...............................................................................82

HIMax System Table of Contents

HI 801 001 E Rev. 4.01 Page 5 of 122

6.2.3 Setting Up User Accounts...................................................................................... 82

7Diagnosis .............................................................. 83

7.1 Light Emitting Diodes.......................................................................................... 83

7.1.1 Definition of Blinking Frequencies.......................................................................... 83

7.1.2 Module Status Indicators ....................................................................................... 84

7.1.3 Redundancy Indicators .......................................................................................... 84

7.1.4 System Bus Indicators ........................................................................................... 85

7.1.5 Rack Connection Indicators................................................................................... 85

7.1.6 Slot Indicators ........................................................................................................ 85

7.1.7 Maintenance Indicators.......................................................................................... 86

7.1.8 Fault Indicators ...................................................................................................... 86

7.1.9 I/O Indicators.......................................................................................................... 87

7.1.10 Fieldbus Indicators................................................................................................. 87

7.1.11 Ethernet Indicators................................................................................................. 88

7.1.12 Ethernet Indicators X-SB Module........................................................................... 88

7.2 Diagnostic History ............................................................................................... 89

7.3 Online Diagnosis.................................................................................................. 89

8Specifications, Dimensioning ................................ 91

9Lifecycle ............................................................... 92

9.1 Installation ............................................................................................................ 92

9.1.1 Mechanical Structure ............................................................................................. 92

9.1.2 Connecting the Field Zone to the I/O Module ........................................................ 92

9.1.3 Earthing.................................................................................................................. 96

9.1.4 Electrical Connections ......................................................................................... 101

9.1.5 Mounting a Connector Board ............................................................................... 103

9.1.6 Considerations about Heat .................................................................................. 104

9.2 Start-Up............................................................................................................... 106

9.2.1 Starting-up the Control Cabinet ........................................................................... 107

9.2.2 Starting-up the PES ............................................................................................. 107

9.2.3 Assigning the Rack ID.......................................................................................... 109

9.2.4 Switching Between Line and Network Structure .................................................. 109

9.3 Maintenance and Repairs.................................................................................. 110

9.3.1 Disturbances........................................................................................................ 111

9.3.2 Connecting the Power Supply after a Service Interruption .................................. 111

9.3.3 Connecting the redundant Power Supply ............................................................ 111

9.3.4 Repair .................................................................................................................. 112

10 HIMax Documentation and Support.......................113

10.1 HIMax Documentation ....................................................................................... 113

10.2 HIMA Service, Training and Hotline ................................................................. 114

Appendix..............................................................115

Application Examples........................................................................................ 115

Glossary.............................................................................................................. 117

Table of Contents HIMax System

HI 801 001 E Rev. 4.01 Page 6 of 122

Index of Figures.................................................................................................. 118

Index of Tables ...................................................................................................119

Index ....................................................................................................................121

HIMax System 1 Introduction

HI 801 001 E Rev. 4.01 Page 7 of 122

1 Introduction

The System Manual describes the configuration and mode of operation of the safety-related

HIMax controller system.

HIMax can be used for various control tasks within the process and factory automation

industry.

1.1 Structure and Use of the Document

This System Manual is composed of the following chapters:

Safety Information on how to safely use the HIMax system

Product Description Structure of the HIMax systems

Communication Brief description of the communication between the HIMax and

other systems. For more information, refer to the Communication

Manual HI 801 101 E.

Redundancy Options for increasing availability

Programming Important instructions on how to create a user program

User Management User management for accessing to the HIMax controllers

Diagnosis Summary of the diagnostic options

Specifications, Dimen-

sioning

Data related to the entire system. Data concerning the individual

components are specified in the corresponding manual

Lifecycle Phases of one HIMax system lifecycle

Installation

Start-up

Service and maintenance

HIMax Documentation

and Support

Overview of the documentation and on how to get access to the

support

Appendix Configuration examples for the HIMax systems

Glossary

Index of tables and index of figures

Index

1.2 Target Audience

This document addresses system planners, configuration engineers, programmers of

automation devices and personnel authorized to implement, operate and maintain the

devices and systems. Specialized knowledge of safety-related automation systems is

required.

All staff members (planning, installation, commissioning) must be informed about the risks

and potential consequences resulting from the manipulation of a safety-related automation

system.

Planners and configuration engineers must have additional knowledge about the selection

and use of electrical and electronic safety systems within automated systems, e.g., to

prevent improper connections or faulty programming.

The operator is responsible for qualifying the operating and maintenance personnel and

providing them with appropriate safety instructions.

Only staff members with knowledge of industrial process measurement and control,

electrical engineering, electronics and the implementation of PES and ESD protective

measures may modify or extend the system wiring.

1 Introduction HIMax System

HI 801 001 E Rev. 4.01 Page 8 of 122

1.3 Formatting Conventions

To ensure improved readability and comprehensibility, the following fonts are used in this

document:

Bold: To highlight important parts

Names of buttons, menu functions and tabs that can be clicked and

used in SILworX.

Italics: System parameter and variables

Courier Literal user inputs

RUN Operating state are designated by capitals

Chapter 1.2.3 Cross references are hyperlinks even though they are not particu-

larly marked. When the cursor hovers over a hyperlink, it changes its

shape. Click the hyperlink to jump to the corresponding position.

Safety notes and operating tips are particularly marked.

1.3.1 Safety Notes

The safety notes are represented as described below.

These notes must absolutely be observed to reduce the risk to a minimum. The content is

structured as follows:

Signal word: danger, warning, caution, notice

Type and source of danger

Consequences arising from the danger

Danger prevention

The signal words have the following meanings:

Danger indicates hazardous situation which, if not avoided, will result in death or serious

injury.

Warning indicates hazardous situation which, if not avoided, could result in death or se-

rious injury.

Warning indicates hazardous situation which, if not avoided, could result in minor or

modest injury.

Notice indicates a hazardous situation which, if not avoided, could result in property

damage.

NOTICE

Type and source of damage!

Damage prevention

SIGNAL WORD

Type and source of danger!

Consequences arising from the danger

Danger prevention

HIMax System 1 Introduction

HI 801 001 E Rev. 4.01 Page 9 of 122

1.3.2 Operating Tips

Additional information is structured as presented in the following example:

iThe text corresponding to the additional information is located here.

Useful tips and tricks appear as follows:

TIP The tip text is located here.

2 Safety HIMax System

HI 801 001 E Rev. 4.01 Page 10 of 122

2 Safety

All safety information, notes and instructions specified in this document must be strictly

observed. The product may only be used if all guidelines and safety instructions are

adhered to.

This product is operated with SELV or PELV. No imminent danger results from the product

itself. The use in Ex-Zone is permitted if additional measures are taken.

2.1 Intended Use

This chapter describes the conditions for using HIMax systems.

2.1.1 Scope

The safety-related HIMax controllers are certified for use in process controllers, protective

systems, burner systems and machine controllers.

All HIMax input and output modules (I/O modules) can be operated with an individual

processor module or with several redundant processor modules.

When implementing safety-related communications between various devices, ensure that

the overall response time does not exceed the fault tolerance time. All calculations must be

performed in accordance with the rules specified in Safety Manual HI 800 003 E.

Only connect devices with safe electrical isolation to the communications interfaces.

Application in accordance with the 'De-Energize to Trip Principle'

The automation devices have been designed in accordance with the 'de-energize to trip'

principle.

A system that operates in accordance with the 'de-energize to trip principle' does not

require any power to perform its safety function.

Thus, if a fault occurs, the input and output signals adopt a de-energized, safe state.

Application in accordance with the 'Energize to Trip Principle'

The HIMax controllers can be used in applications that operate in accordance with the

'energize to trip' principle.

A system operating in accordance with the 'energize to trip' principle requires power (such

as electrical or pneumatic power) to perform its safety function.

When designing the controller system, the requirements specified in the application

standards must be taken into account. For instance, line diagnosis for the inputs and

outputs may be required

Use in Fire Alarm Systems

All HIMax systems with analog inputs are tested and certified for used in fire alarm systems

in accordance with DIN EN 54-2 and NFPA 72. To contain the hazard, these systems must

be able to adopt an active state on demand.

The operating requirements must be observed!

2.1.2 Non-Intended Use

The transfer of safety-relevant data through public networks like the Internet is not

permitted unless additional security measures such as VPN tunnel or firewall have been

implemented to increase security.

With fieldbus interfaces, no safety-related communication can be ensured.

The use under environmental conditions other than those specified in the following section

is not permitted.

HIMax System 2 Safety

HI 801 001 E Rev. 4.01 Page 11 of 122

2.1.3 Operating Requirements

The devices have been developed to meet the following standards for EMC, climatic and

environmental requirements:

Standard Content

IEC/EN 61131-2 Programmable controllers, Part 2

Equipment requirements and tests

IEC/EN 61000-6-2 EMC

Generic standards, Parts 6-2

Immunity for industrial environments

IEC/EN 61000-6-4 Electromagnetic Compatibility (EMC)

Generic emission standard, industrial environments

Table 1: Standards for EMC, Climatic and Environmental Requirements

When using the safety-related HIMax control systems, the following general requirements

must be met:

Requirement type Requirement content

Protection class Protection class II in accordance with IEC/EN 61131-2

Pollution Pollution degree II in accordance with IEC/EN 61131-2

Altitude < 2000 m

Housing Standard: IP20/IP00

If required by the relevant application standards (e.g., EN 60204),

the device must be installed in an enclosure of the specified protec-

tion class (e.g., IP54).

Table 2: General requirements

Climatic Requirements

The following table lists the key tests and thresholds for climatic requirements:

IEC/EN 61131-2 Climatic tests

Operating temperature: 0...+60 °C

(test limits: -10...+70 °C)

Storage temperature: -40...+85 °C

Dry heat and cold resistance tests:

+70 °C / -25 °C, 96 h, power supply not connected

Temperature change, resistance and immunity test:

-25 °C / +70 °C und 0 °C / +55 °C,

power supply not connected

Cyclic damp-heat withstand tests:

+25 °C / +55 °C, 95 % relative humidity,

power supply not connected

Table 3: Climatic Requirements

Mechanical Requirements

The following table lists the key tests and thresholds for mechanical requirements:

IEC/EN 61131-2 Mechanical tests

Vibration immunity test:

5...9 Hz / 3.5 mm amplitude

9...150 Hz, 1 g, EUT in operation, 10 cycles per axis

Shock immunity test:

15 g, 11 ms, EUT in operation, 3 shocks per axis and direction (18

shocks)

Table 4: Mechanical Tests

2 Safety HIMax System

HI 801 001 E Rev. 4.01 Page 12 of 122

EMC Requirements

Higher interference levels are required for safety-related systems. HIMax systems meet

these requirements in accordance with IEC 62061 and IEC 61326-3-1.

See column 'Criterion FS' (Functional Safety).

Test standards Interference immunity tests Criterion

FS

IEC/EN 61000-4-2 ESD test: 6 kV contact, 8 kV air discharge 6 kV, 8 kV

IEC/EN 61000-4-3 RFI test (10 V/m): 80 MHz...2 GHz, 80 % AM

RFI test (3 V/m): 2 GHz...3 GHz, 80 % AM

RFI test (20 V/m): 80 MHz...1 GHz, 80 % AM

-

-

20 V/m

IEC/EN 61000-4-4 Burst test

Power lines: 2 kV and 4 kV

Signal lines: 2 kV

4 kV

2 kV

IEC/EN 61000-4-12 Damped oscillatory wave test

2.5 kV L-,L+ / PE

1 kV L+ / L -

-

-

IEC/EN 61000-4-6 High frequency, asymmetrical

10 V, 150 kHz...80 MHz, 80 % AM

20 V, ISM frequencies, 80 % AM

10 V

-

IEC/EN 61000-4-3 900 MHz pulses -

IEC/EN 61000-4-5 Surge:

Power lines: 2 kV CM, 1 kV DM

Signal lines: 2 kV CM, 1 kV DM at AC I/O

2 kV / 1 kV

2 kV

Table 5: Interference Immunity Tests

IEC/EN 61000-6-4 Noise emission tests

EN 55011

Class A

Emission test:

radiated, conducted

Table 6: Noise Emission Tests

HIMax System 2 Safety

HI 801 001 E Rev. 4.01 Page 13 of 122

Power Supply

The following table lists the key tests and thresholds for the device's power supply:

IEC/EN 61131-2 Review of the DC supply characteristics

Alternatively, the power supply must comply with the following stan-

dards:

IEC/EN 61131-2 or

SELV (Safety Extra Low Voltage) or

PELV (Protective Extra Low Voltage)

HIMax devices must be fuse protected as specified in this manual

Voltage range test:

24 VDC, -20 %...+25 % (19.2 V...30.0 V)

Momentary external current interruption immunity test:

DC, PS 2: 10 ms

Reversal of DC power supply polarity test:

Refer to corresponding chapter of the system manual or data sheet of

power supply.

Backup duration withstand test:

Test B, 1000 h

Table 7: Review of the DC Supply Characteristics

ESD Protective Measures

Only personnel with knowledge of ESD protective measures may modify or extend the

system or replace a module.

NOTE

Electrostatic discharge can damage the electronic components within the control-

lers!

When performing the work, make sure that the workspace is free of static, and

wear an ESD wrist strap.

If not used, ensure that the module is protected from electrostatic discharge, e.g.,

by storing it in its packaging.

Only personnel with knowledge of ESD protective measures may modify or extend

the system wiring.

2.1.4 Requirements to be met by the operator and the machine and system

manufacturers

The operator and the machine and system manufacturers are responsible for ensuring that

HIMax systems are safely operated in automated systems and plants.

The machine and system manufacturers must validate that the HIMax systems are correctly

programmed.

2.2 Residual Risk

No imminent danger results from a HIMax system itself.

Residual risk may result from:

Faults in the engineering

Faults in the user program

Faults in the wiring

2 Safety HIMax System

HI 801 001 E Rev. 4.01 Page 14 of 122

2.3 Safety Precautions

Observe all local safety requirements and use the protective equipment required on site.

2.4 Emergency Information

A HIMax controller is a part of the safety equipment of a system. If the controller fails, the

system adopts the safe state.

In case of emergency, no action that may prevent the HIMax systems from operating safely

is permitted.

HIMax System 3 Product Description

HI 801 001 E Rev. 4.01 Page 15 of 122

3 Product Description

HIMax is a safety-related control system and is intended for continuous operation and

maximum availability.

HIMax is a modular system. Functions such as processing, input and output, and

communication are distributed on plug-in modules. These modules must be inserted in one

or multiple base plates. A controller specific to the concrete application can be created by

selecting appropriate modules.

Ethernet cables are used to interconnect the base plates.

The controller can be easily adapted to future extensions of the process to be controlled,

e.g., by adding modules or base plates containing modules.

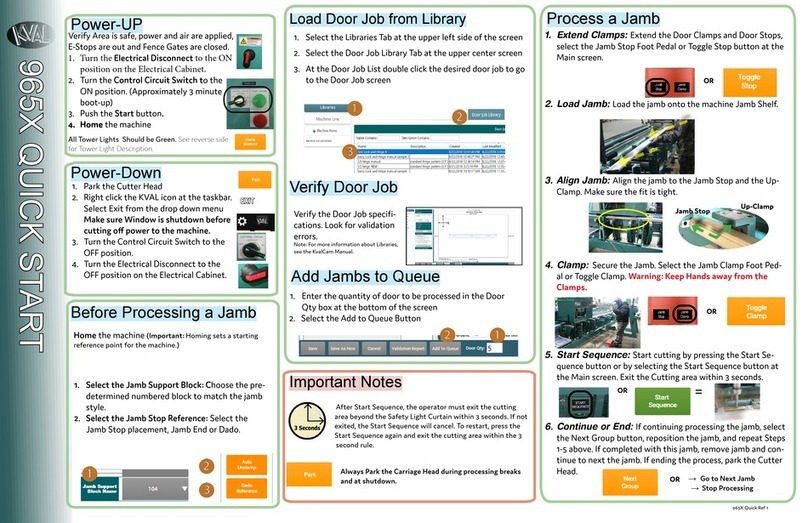

Figure 1 shows the structure of the HIMax system. The figure shows the base plates, both

system busses, the system bus modules, the processor modules and the Connector

Boards of the modules.

To increase availability, HIMax is intended for redundant operation. For more information,

refer to Chapter 3.9.

The system can also be used as mono, non-redundant system. For more information, refer

to Chapter 3.3.2, Variant 1, and Appendix.

In either case, safety-related operation up to SIL 3 is ensured.

3 Product Description HIMax System

HI 801 001 E Rev. 4.01 Page 16 of 122

Figure 1: System Overview

A HIMax system is composed of at least one rack, i.e., rack 0. It has rack ID (e.g., 0) und

contains at least one processor module. All additional racks are extension racks. Among

these, rack 1 may contain one or two processor modules. The remaining racks must

contain no processor modules.

Rack 0 can be extended with up to 15 extension racks. Cables are used to interconnect the

two system busses A and B on all the racks.

3.1 Base Plates and Base Plate Types

HIMax base plates differ in the number of slots.

Each base plate composing a HIMax controller can have 10, 15 or 18 slots.

HIMax System 3 Product Description

HI 801 001 E Rev. 4.01 Page 17 of 122

Base plate types:

With 10 slots: X-BASE PLATE 10 01

for mounting on a flat base, e.g., a mounting plate.

With 15 slots: X-BASE PLATE 15 01

for mounting on a backplane

With 15 slots: X-BASE PLATE 15 02

for 19'' mounting

With 18 slots: X-BASE PLATE 18 01

for mounting on a backplane

A total of one module and one connector board can be plugged in to each slot.

System cables are used to interconnect the base plates.

3.1.1 Base Plate Structure

Hook-in rail with slot number

Backplane Bus

Connector for 24 VDC module power

supply, here slot number 9

Connector for connecting the system

bus to a module, here slot number 9

Guiding Rail for Connector Boards

Backplane with wall flanges or 19’’

mounting flanges

Mounting Rail

Cable Shield Rail

Strain Relief for Supply Line

Clamp Terminal Block

Suppressors for High Voltage Transients

Connector Boards for System Bus Mod-

ules

Figure 2: Base Plate Structure

Both left slots, slot 1 and slot 2, are reserved for system bus modules. The remaining slots

can be used for other modules, but observe the restrictions for positioning processor

modules, see Chapter 3.3.2.

3 Product Description HIMax System

HI 801 001 E Rev. 4.01 Page 18 of 122

Each module has a connector board to which external devices such as sensors, actuators

and other controllers are connected. Both connector boards for the system bus modules

are included within the scope of delivery.

The clamp terminal blocks of the base plate are used to connect the power supply. Two

redundant 24 VDC power supply units can be connected.

3.1.2 Ventilation

A suitable fan rack located above the base plate ensures the ventilation.

The air flows from the fan rack downwards through the modules and through the

connection space located in front of the connector boards. To ensure proper ventilation,

insert blank modules in all the unused slots of the base plate!

NOTE

Controller damage due to overheating!

Overheating can destroy electronic components!

Only operate HIMax systems if ventilation is ensured!

A fan rack with suitable dimensions is available for each base plate type. Depending on the

width, the fan racks are equipped with 2, 3 or 4 fans. For more information, refer to the

X-FAN Manual (HI 801 033 E).

Additional dissipation of the generated hot air must be ensured, see Chapter 9.1.6.

3.1.3 Monitoring the Temperature

The modules monitor their own temperature. Use the SILworX programming tool to display

the temperature level and evaluate it for programming reactions.

Details of configuring the temperature monitoring in chapter 9.1.6 .

3.1.4 Power Supply

The HIMax system requires a power supply of 24 VDC.

The safe electrical isolation of the power supply must be ensured within the 24 V system

supply. Use power supply units of type PELV or SELV only. When used in accordance with

UL regulations, an adjustable power supply unit with a maximum voltage of 150 V and a

maximum performance of 10 kVA is allowed.

The power supply used must have a momentary interruption immunity value of < 10 ms.

HIMA power supply units are appropriately equipped. Before using power supply units from

other manufacturers, ensure their adequate testing.

Two redundant power supply units can be connected.

NOTE

Controller damage due to overvoltage!

Set the power supply unit so that the supply voltage cannot exceed 30 V!

HIMax System 3 Product Description

HI 801 001 E Rev. 4.01 Page 19 of 122

NOTE

Controller damage due to overcurrent!

Protect each base plate pre-fusing it against currents higher than 63 A!

The modules monitor both operating voltages. Use the SILworX programming tool to

display the voltage level and evaluate it for programming reactions.

Estimating the Required Power

Use a rule of thumb to estimate the power required for the power supply.

PTotal = nCPU*35 + nModules*20 + nFans*20 +PExternal

PTotal : Total required power

nCPU: Number of processor modules in use

NModule: Number of modules used without processor modules

nFans: Number of fans in use. Each fan rack contains 2, 3 or 4 fans.

PExternal: Power delivered from the output modules to the connected actuators.

The following reference values are used in this formula:

Power consumption of a HIMax processor module: approx. 35 W

Power consumption of another HIMax module (except for processor module): approx.

20 W

Power consumption of a fan: approx. 20 W

Power consumption of the actuators connected to and supplied by the output modules

The power in watts required for one HIMax system is the result of this rough calculation.

For an exact calculation of the power required, use the power consumption values of the

individual modules as specified in the corresponding manuals. The power consumption

values of the other consumer loads are specified in the corresponding data sheets or

manuals.

3.2 System Bus

The HIMax system operates with two redundant system busses, system bus A and system

bus B.

The system busses run within a base plate. The module is connected with the system

busses by inserting it into the base plate. System busses A and B interconnect the modules

via the system bus modules. The failure of one module does not affect the connections to

remaining modules.

The system bus connection to the modules are electrically isolated from the base plate. An

insulation voltage of at least 1 500 V is ensured between the processor module and each

I/O module.

A system bus module is required to manage a system bus. The system bus module in

slot 1 operates system bus A and the system bus module in slot 2 operates system bus B.

iIf only one system bus module is inserted in the base plate, only one system bus is

available!

If both system bus modules are used to operate the HIMax system, communication runs on

both system busses simultaneously.

If the HIMax system is composed of various base plates, use Ethernet patch cables to

interconnect the system busses on the base plates. These cables must be inserted in the

3 Product Description HIMax System

HI 801 001 E Rev. 4.01 Page 20 of 122

RJ-45 socket located on the connector boards of the system bus modules. System bus A

and system bus B must not be crossed or connected.

It is not allowed to interconnect the system busses of various different HIMax systems!

System bus cable characteristics

Twisted pair Ethernet cables

Cat. 5e or higher for 1 Gbit/s.

RJ-45 connector on both sides.

Industrial standard implementation, e.g., with Harting plugs.

Auto-Crossover allows the use of crossover and straight through cables.

Suitable cables are available from HIMA in standard lengths.

NOTE

System malfunction possible!

The system busses are not normal Ethernet connections. Therefore, the RJ-45 sock-

ets UP and DOWN and DIAG may only be used to connect to HIMax racks.

Do not connect the sockets UP and DOWN and DIAG to local networks or other de-

vices with LAN connection such as the PADT!

Never interconnect or cross system bus A and system bus B!

Operate a system bus in line structure either redundantly or not redundantly for all

racks!

The system bus located between base plates containing CPU modules or responsi-

ble system bus modules must be redundantly connected irrespective of its structure,

network or line.

The system bus can be organized in two different structures:

Line structure

That is the default structure.

Network structure

This structure allows one, if the appropriate network structure exists, to shut down and

replace a base plate during operation, without interrupting the connection to the other

base plates.

Table of contents

Popular Control System manuals by other brands

Teton Grill

Teton Grill Fuel Manager Product installation manual

Hardi

Hardi HC 2500 Series Instruction book

IMV

IMV K2-CE instruction manual

HandyTrac

HandyTrac Key Control System installation & operating manual

HandyTrac

HandyTrac Key Control EASY GUIDE Installation and Operation

DuroZone

DuroZone JTZ-HP manual