HIOS BL-2000 User manual

BL-2000

BL-3000

BL-5000

BL-5000-15

BL-5000-20

BL-5020

BL-7000

BL-7000HT

BL-7000-20

BL-OPC•BL-ESD•BLQ-CR

BLQ-ESD•BLQ-CR-ESD

Suction•BL-SS

15A

111-6 Akiyama, Matsudo City, Chiba Pref., Japan

TEL: +81 (JAPAN) 47-392-2001

FAX: +81 (JAPAN) 47-392-7773

(anti-static electricity

is standard)

Operation Manual No.: ET-A010

Brushless Driver

BL Series

Operation Manual

(September 2015)

HIOS Inc.

Utilizing 100%post-consumer

recycled paper pulp

- 2 -

Thank you for your purchase of the BL-2000,

BL-3000, BL-5000 or BL-7000 brushless driver.

1. Name of Parts

BL-2000 BL-3000

Joint ring Joint ring

Hanger

Hanger

Switch lever

Rotation direction

switch

Driver cord

Driver cord

Driver cord plug

Driver connector

Rotation

direction switch

Switch

lever

Rotate the protect cover

CCW to take it off and

adjust the torque with

torque adjusting nut.

Torque adjustment

nut protect cover

Joint shaft collar

Torque adjustment nut

Adjusting bolt

(torque adjusting scale)

Bit

- 3 -

2. Accessories

• Bits

• Torque adjusting spring

• There are 2 torque adjusting springs for BL-2000.

In the BL-2000, stronger spring(Black) is installed.

If you want to use weaker spring then replace with

accessory(Yellow) spring.

Select the spring depends on your fastening torque.

• Hex nut L wenches (for BL-5000, BL-7000)

BL-5000 BL-7000

LEVER

PUSH

Joint ring HangerHanger

Torque

adjustment nut

Bit

Bit

Rotation

direction

switch

Rotation

direction

switch

Switch

lever

Switch

lever

Joint shaft collar

Lever/push-to

-start switch

Driver cord plug

Driver cord Driver cord

Driver connector

- 4 -

■ Specications

BL-Series (BL-OPC•BL-ESD•BLQ-CR•BLQ-ESD•BLQ-

CR-ESD•BL-SS)

Lever start type Model BL-2000

BL-2000SS BL-3000

BL-3000SS*

BL-5000

BL-5000SS

BL-5000-15 BL-5000-20

Push-to start type Model

—

Output

torque range

N•m 0.02 - 0.20.2 - 0.55

0.2 - 0.35* 0.2 - 1.2 0.3 - 1.2 0.5 - 1

lbf•in 0.17 - 1.71.7 - 4.8

1.7 - 4.8* 1.7 - 10 2.6 - 10 4.3 - 8.7

(kgf•cm) (0.2 - 2) (2 - 5.5)

(2 - 3.5)* (2 - 12) (3 - 12) (5 - 10)

Torque Switching Stepless Adjustment

Unloaded Rotation

Speed(r.p.m)±10%

HI 990 980 900 1,500 2,200

LOW 650 680 590 1,000 1,500

Screw

size

Machine Screw

1.0 - 2.3 1.7 - 2.3 2.0 - 3.0 2.0 - 3.0 2.0 - 3.0

Tapping screw

1.0 - 2.0 2.0 - 2.3 2.0 - 3.0 2.0 - 2.6 2.0 - 2.6

Weigh (g) 254 320 360 360 360

Bit

type

HIOS Shank H4 H4 H4 H4 H4

HEX Shank —1/4 HEX

H5 & 5 HEX

or 1/4 HEX

H5 & 5 HEX

or 1/4 HEX

H5 & 5 HEX

or 1/4 HEX

Power

Supply

T-45BL ○○○

○ * ○ *

T-70BL ○○○○○

Cord Length (attached cord

table according to the type)

Standard A B B B B

BL-OPC D E E E E

BL-ESD AAAAA

BLQ-CR F H H H H

BLQ-ESD F F F F F

BLQ-CR-ESD F F F F F

BL-SS A B B — —

Lever start type Model BL-5020 BL-7000 BL-7000HT

BL-7000-20

Push-to start type Model

Output

torque range

N•m 0.5 - 2 0.7 - 2.8 0.7 - 3.5 0.5 - 1.5

lbf•in 4.3 - 17.4 6.1 - 24 6.1 - 30 4.3 - 13

(kgf•cm) (5 - 20) (7 - 28) (7 - 35) (5 - 15)

Torque Switching Stepless Adjustment

Unloaded Rotation

Speed (r.p.m)±10%

HI 750 960 700 2,200

LOW 500 630 500 1,500

Screw

size

Machine Screw

2.0 - 4.0 2.6 - 5.0 2.6 - 4.0 2.6 - 4.0

Tapping screw

2.0 - 3.0 2.6 - 4.0 2.6 - 4.0 2.6 - 4.0

Weigh (g) 360 640 640 640

Bit

type

HIOS Shank

H5 & 5 HEX H5 & 5 HEX H5 & 5 HEX H5 & 5 HEX

HEX Shank 1/4 HEX 1/4 HEX 1/4 HEX 1/4 HEX

Power

Supply

T-45BL

○ *

———

T-70BL

○ *

○○○

Cord Length (attached cord

table according to the type)

Standard B C C C

BL-OPC E E E E

BL-ESD AAAA

BLQ-CR H I I I

BLQ-ESD F F F F

BLQ-CR-ESD F F F F

BL-SS ————

(Note) Use only 2(HI) power outlet with the * models.

These models may not perform properly on 1(LOW) power outlet.

● Output torque range and rotational speed in the above specications

is for Model BL-2000, BL-3000 driver, using the T-30BL power pack or

driver Models BL-5000 and BL-7000, using the T-70BL power pack.

- 5 -

●Referenceofattachedcordfordrivers

Type AttachedCord Type AttachedCord

A 2m Cord ESD Type (5P) F 2m Cord ESD Type (5P) & Iinclude

ESD Vinyl tube

B 1.5m Cord Type (5P) G 2m Cord ESD Type (5P) & Iinclude

Vinyl tube

C 2m Cord Type (5P) H 1.5m Cord Type (5P) & Iinclude

Vinyl tube

D 2m Cord ESD Type (6P) I 2m Cord Type (5P) & Iinclude Vinyl

tube

E 2m Cord Type (6P)

* The applicable cord especially for OPC is 6PIN type. (*Regular cord is

5PIN type) Combination type screw driver (ex. ESD+OPC) is attached

applicable type cord (2m).

●ExternalDimensions

172

∅26

207

Max.∅38 Min.∅26

(WD cut shape)

BL-5000

BL-2000

∅32.5

192

BL-3000

239

Max.∅40 Min.∅36

(WD cut shape)

BL-7000

■ PowerSupplies

The Brushless Driver must be operated together with a Power

Pack.

Powering the Brushless Driver with the Hios T-30BL and the

T-70BL Power Pack will insure operation of the driver at its

full capacity.

●BLdriverandPowerPackcombinations

PowerPackModel Max.numberofdrivers

BL-2000 BL-3000 BL-5000 BL-7000

Power Pack for

Brushless Driver

T-45BL 1 1 ○

T-70BL 1 1 1 1

■ CautionstoObserveWhenUsing

1. In push-to-start mode, the driver will begin turning in

response to only a slight pressure. Take care that it is

under complete control when in push-to-start mode.

2. The driver can be damaged by accidental falls or impacts.

3. Take care to avoid exposing the driver to oil based

- 6 -

substances.

4. The driver does not require lubrication and should not be

lubricated.

■ Pre-operatingPreparations

1. Check that the proper Power Pack is being used with the

driver.

2. Connect the Power Pack to plug AC100 to 240 V .

3. Turn the power switch on, check to see that the power

switch light of the Power Pack goes on, then switch the

power off. If the light didn't go on, replace the fuse with the

spare provided with the pack, referring to the Power Pack

specications.

4. If you want to use as "Push start", follow the instructions

"5" below.

5. To operate in Push-to-start Mode.

BL-3000

Use tweezers to switch lever start/

push start.

BL-5000

Rotate 1the hex head screw to

detach 2the switch lever and

set the start switch to the "PUSH"

position.

Use it without attaching the hex

head screw and the switch lever.

BL-7000

Rotate the hex head screw to detach

the switch lever (Fig-1) and reattach

the switch lever upsidedown. (Fig-2)

To convert the starting mechanism from lever-start to push-to-start,

remove the hex head screw and switch lever, turn the switch lever

upside-down and use the hex head screw to re-fasten the switch

lever.

6. Connect the driver power cord to the Power Pack. (Both

ends of this cord have the same type of connector. Be sure

that the interlocking guide ts together properly and tighten

the joint ring.)

Hex head

screw

Switch lever

LEVER

PUSH

Hex head

screw

Switch lever

1

2

Fig-2Fig-1

- 7 -

■ OperatingProcedure

1. Attach a bit to the driver. (See "Attaching a Bit" below)

• If using model BL-3000, remove the torque adjustment nut

cover before attaching a bit.

2. Set the driver to clockwise or counter-clockwise rotation as

desired, then push the switch lever to check that the driver

turns in the correct direction. After checking, be sure the

switch is left on the clockwise setting.

Caution: Always turn the power off before reversing the

rotationdirectionsetting.

3. Make the desired torque adjustment setting. (See "Torque

Adjustment" below.)

4. Begin fastening by tting the end of the bit to the head of a

screw to be tightened and pulling the switch lever.

• In push-to-start mode, the driver automatically goes on

when pressure is applied to the bit end.

5. The clutch will immediately stop rotation when the preset

torque level is reached. At this point, raise the driver from

the screw and release the switch lever. Repeat this cycle

for each tightening operation.

• In push-to-start mode, do not raise the driver from the

screw head until rotation has stopped.

6. Set rotation direction to counterclockwise to loosen a

screw. Very tightly fastened screws can be loosened by

repeatedly applying the driver to the screw to obtain short

bursts of rotation force.

■AttachingaBit

Besuretoeitherturnthepower

switch off or disconnect the power

cordbeforeattemptingtochange

bits.Failuretodosocouldbe

especiallydangerousifthedriveris

set to push-to-start mode. In either

case,unexpectedstartupofthe

drivercouldresultininjury.

If using model BL-3000, BL-5000 or BL-

7000, raise the joint shaft collar at the

bottom of the tool, then insert the bit.

• As for BL-2000, press the Joint-shaft

collar towards inside of the screwdriver

and insert the bit.

• If using model BL-3000, push the joint

shaft collar into the tool to attach the bit.

Then pull on it to be sure it is properly

attached.

Caution

Joint shaft

collar

- 8 -

■ TorqueAdjustment

Torque is controlled by the tension on a spring inside the

torque adjustment nut. If set the nut tighter, the output torque

is higher.

• The adjustment torque scale does not give the actual

output torque. Please regard the output torque graph as

an approximate guide.

■ TorqueAdjustmentProcedure

1. If you have a predetermined torque value, set that value

on the scale using the torque adjustment nut.

• The BL-2000 Electric Screwdriver have ‘Double nut

system’ (Nut xing ring and Torque adjusting nut) to avoid

loosening from shock or vibration to the Screwdriver.

● BL-2000

• At rst, keep the Nut xing ring

to t the scale at which, if you

want to adjust.

• Then turn the Torque adjusting

nut toward the Nut xing ring.

• Lastly, to avoid the loosening of

the ‘Torque adjusting nut fasten

strongly the Nut fixing ring by

holding the ‘Torque adjusting

nut’.

●BL-3000

If using model BL-3000, make

the setting by pushing the nut

collar upwards, removing the

torque adjustment nut

and turning it so the

point over the nut aligns

with the groove.

●BL-5000, BL-7000

If using model BL-5000 or 7000,

set the torque adjustment nut

using the hex wrench that is

provided.

Torque scale

BL-2000

Torque

adjustment nut

Nut securing ring

BL-3000

Torque

adjustment nut

Nut securing

ring

Torque

adjustment

scale

5 mm hex nut L wrench

- 9 -

2. Turn the driver on and tighten a screw to check that the

driver stops at a satisfactory level of tightness.

3. Readjust the torque setting, tighter or looser, as necessary.

Repeat the procedure until you arrive at the desired torque

setting.

It is recommended that a Hios torque meter be used to

measure torque. Use the HP series for measurement of the

driver's torque setting and the HDP series or the HDM series

to measure loosening or tightening torque of screws.

■ IfRepairsareRequested

Check the items listed in the table below, and if a malfunction

is found, contact your store of purchase of our company.

Always include your warranty card when sending in the driver

for repairs.

Symptoms Cause and Treatment

The driver motor

sometimes fails to operate

• Is the cord severed?

Stop any work and request repairs.

The driver is weak and

cannot tighten screws

sufciently

• Is the torque setting at the correct position?

Refer to the output torque guidance

- 10 -

■ ApproximateGuidanceofOutput

Torque(duringHIinput)

Scale ring setting

Scale ring setting Scale ring setting

Scale ring setting Scale ring setting

Black

(installed)

BL-3000

White

BL-3000SS*

White

Yellow

(attached)

N•m

0.25

0.2

0.15

1.5

1.0

0.5

0.1

0.05

0.03

N•m

N•m N•m

0.8

0.5

0.6

0.7

0.4

0.3

0.2

0.1

0.02

12345678

12345678

12345678

BL-5000

BL-5000-SS

BL-5000-15

BL-5000-20

2.0

1.5

1.0

0.5

12345678

BL-5020

3.0

1.0

0.7

0.5

1.5

2.0

2.5

N•m

1 2345678910

Scale ring setting

1 2345678910

BL-7000

BL-7000-20

BL-5000

BL-5000-SS

BL-5000-15

BL-5000-20

BL-7000

BL-7000-20

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.7

N•m

BL-7000HT

BL-2000

BL-2000SS

BL-3000

BL-3000SS*

- 11 -

- 12 -

This manual suits for next models

3

Table of contents

Other HIOS Power Screwdriver manuals

HIOS

HIOS BLF-2000 User manual

HIOS

HIOS CL-9000NL User manual

HIOS

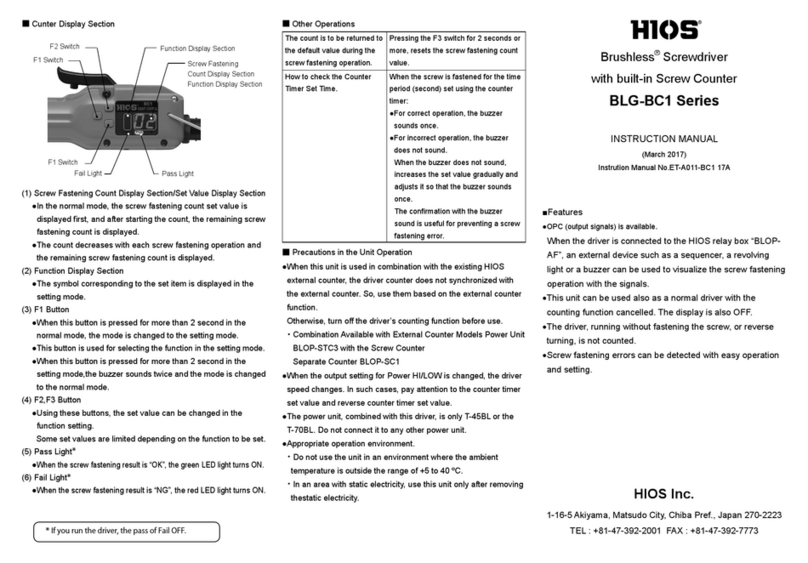

HIOS BLG-BC1 Series User manual

HIOS

HIOS VZH-1820 User manual

HIOS

HIOS JUKUREN BLG-BC2 series User manual

HIOS

HIOS JUKUREN BLG-BC2 series User manual

HIOS

HIOS DCD-40L User manual

HIOS

HIOS BLG Series User manual

HIOS

HIOS CL-9000 User manual

HIOS

HIOS CL-2000 Installation manual

Popular Power Screwdriver manuals by other brands

Würth

Würth ASS 14-1/4" Translation of the original operating instructions

EINHELL

EINHELL TE-CD 18/2 Li Original operating instructions

DeWalt

DeWalt DCF620 Original instructions

Lux Tools

Lux Tools A-BS-20-D instruction manual

Erbauer

Erbauer ECDT18-Li-2 Original instructions

Conrad

Conrad 2524385 operating instructions