HIOS VB Series User manual

Transformerless Screwdriver

100V

VB-1510/VB-1510PS/VB-1510-18/VB-1510PS-18/

VB-1820/VB-1820-PS/VB-3012/VB-3012PS/

VB-3020/VB-3020PS/

VB-4504/VB-4504PS with Shockless Stand

120V

VB-1510/VB-1510PS/VB-1510-18/VB-1510PS-18/

VB-1820/VB-1820PS/VB-3012/VB-3012PS/

VB-4504/VB-4504PS/VB-4504PS with Shockless Stand

220-240V

VB-1510/VB-1510PS/VB-1510-18/VB-1510PS-18/

VB-1820/VB-1820PS/VB-3012/VB-3012PS/

VB-4504/VB-4504PS/VB-4504PS with Shockless Stand

ET-A036 19A

Brushless Screwdriver

VB Series

Operation Manual

(May 2019)

- 2 -

WARNING

When using electric tools, the following basic safety precautions should always

be adhered to in order to reduce the risk of re, electric shock or personal injury:

READ ALL INSTRUCTIONS

1. Keep Work Area Clean.

Cluttered areas and benches can result in injuries.

2. Consider Work Area Environment.

Don’t expose tools to rain. Don’t use tools in damp or wet locations.

Keep work area well lit.

Never use the tool in an area with dangerous objects present. (gasoline,

benzene, thinner, gas glue, etc.)

3. Secure Work.

Use clamps or a vice to hold work piece. It’s safer than using your hand and it

frees up both hands required to operate the tool.

4. Guard Against Electric Shock.

Prevent body contact with grounded surfaces such as pipes, radiators, ranges

and refrigerator enclosures.

5. Keep Away From Children.

Do not allow visitors to use the tool. All visitors should be kept away from work

area.

6. Store Idle Tools.

When not in use, tools should be stored in a dry and high or locked-up place out

of reach of children.

7. Do Not Force The Tool.

The tool will operate better and safer at the rate for which it was designed.

8. Remove Adjusting Keys And Wrenches.

Make a habit of checking to see that keys and adjusting wrenches are removed

from the tool before turning it on.

9. Use The Correct Tool.

Use the tool for the correct work for its rated power and design.

10. Dress Properly.

Do not wear loose clothing or jewelry as they can be caught in moving parts.

Wear protective headwear to contain long hair.

11. Use Safety Glasses.

Also use a face or dust mask if the operation involves dust.

12. Do Not Abuse The Cord.

Never carry the tool by its cord or pull it to disconnect from the power outlet.

Keep the cord away from heat, oil and sharp edges.

13. Do Not Overreach.

Maintain proper footing and balance at all times.

14. Maintain Tools With Care.

Keep tools sharp and clean for better and safer performance.

Follow instructions for lubricating and changing accessories.

To use the tool for an extended period of time safely, perform periodical

inspections on the tool and if damaged, request repairs by authorized service

facility.

Keep hands dry, clean and free from oil and grease.

Inspect extension cords periodically and replace if damaged.

15. Disconnect Tools.

When the tool is not in use, such as attaching and removing the bit, changing

the Carbon Brush, inspection or cleaning, disconnect the tool from the power

outlet.

16. Avoid Unintentional Starting.

Ensure that the switch is o when plugging in.

Do not carry the tool with nger on the switch.

17. Stay Alert.

Always remain vigilant., use common sense, and do not operate the tool when

- 3 -

you are tired.

18. Check Damaged Parts.

Before using the tool further, a damaged protective cover or other parts should

be carefully checked to determine whether the tool will operate correctly and

perform as designed. Check the alignment, binding, damage, and mounting

of any moving parts. Protective covers or other parts that are damaged should

be properly repaired or replaced by an authorized technician or service facility

unless otherwise indicated elsewhere in this instruction manual.

19. Extension Cords For Outdoor Use.

When the tool is used outdoors, use only extension cords marked for outdoor

use.”

CAUTIONS IN OPERATION

1. This Screw Driver is integral unit consisting of Screw Driver parts and cord

parts.

If there are any problems, do not disassemble the tool.

Stop operations and have the tool repaired immediately.

2. Never lubricate the tool with aerosol oil or similar lubricants. Doing so may

result in expensive repairs.

3. Do not drop, hit or abuse the tool. Doing so may cause problems such as

cracks or damage.

4. Never use chemicals to wipe the body cover.

5. Use only under the correct voltage (220-240V).

Never use with the higher voltages.

6. Do not pull the AC cord when unplugging from the power outlet.

Doing so may cause the wire to become severed.

7. To avoid dragging the AC cord on oor, use the Spring Balancer to hang the

AC cord.

8. For safety use, do not set the torque adjusting nut higher than 10 on the

torque adjusting scale.

9. Use the tool intermittently: (ex: 0.5sec.on/4.5sec.o)

10. Do not tighten more than 720 tapping screws in an hour.

11. This tool is not for tightening wood screws.

12. Never change the forward ←→ reverse direction immediately while the motor

is running.

13. If the tool is not being used, set the start switch and Forward/o/Reverse

switch to“OFF” position and unplug the AC cord plug.

GROUNDING INSTRUCTIONS

The tool should be grounded while in use to protect the operator from electric

shock.

The tool is equipped with a three-conductor cord and two-prong grounding-

type plug to t the proper grounding-type receptacle.

The green (or green and yellow) conductor in the cord is the grounding wire.

SAVE THESE INSTRUCTIONS

We thank you for your purchase of HIOS Electric Screw Driver.

SUMMARY

The VB Brushless Driver uses a high-performance brushless motor for

maintenance free and reliable screw fastening operations. A clean working

environment can be achieved as the driver does not output any harmful carbon

particles.

There is little heat generated from the motor, meaning there are very few

heat-related problems when using the driver for extended periods of time.

The brushless motor is the optimum choice when considering the working

environment and work quality.

The VB Brushless Driver case is made of anti-static plastic to prevent the

generation of static electricity.

- 4 -

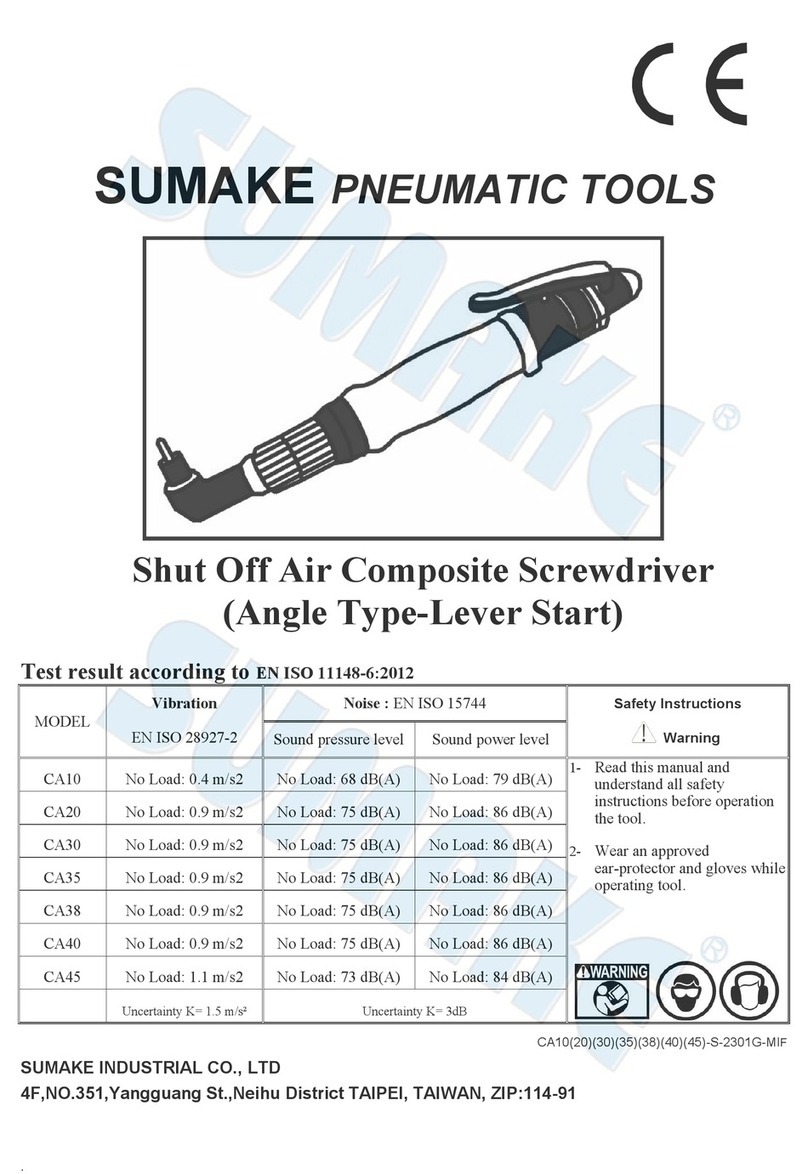

ACplug

Forward/Reverse

Switch

Bit

ProtectiveCover

Torque

adjusting

scale

torqueadjusting

nut

Jointshaftcollar

ACDriverCord

Hanger

TheProtectiveCover

canberemovedfrom

thefrontringbytwisting

itright.

Switch

Lever

Lever Start Type

VB-1510

Push to Start Type

VB-1510PS

Parts Name

- 5 -

ACplug

Forward/

Reverse

Switch

Bit

Softgrip

(rubber)

Torque

adjusting

scale torque

adjusting

nut

Jointshaftcollar

ProtectiveCover

ACDriverCord

Hanger

TheProtectiveCover

canberemovedfrom

thefrontringby

twistingitright.

FrontRing

Switch

Lever

Lever Start Type

VB-1820

VB-3012

VB-3020

VB-4504

Push to Start Type

VB-1820PS

VB-3012PS

VB-3020PS

VB-4504PS

- 6 -

Specications

*1 Lever Start Model

*2 Push-to-Start Model

*3 The value of power consumption is an approximative estimate.

AC Input Power 100V

Model VB-1510

VB-1510PS

VB-1510-18

VB-1510PS-18

VB-1820

VB-1820PS

VB-3012

VB-3012PS

VB-3020

VB-3020PS

VB-4504PS

(with sockless stand)

Power Consumption(W)*

3

20W 40W

Output

Torque

Range

N•m 0.25-1.5 0.2-1 0.4-1.8 0.5-3 1-3 1-4.5

lbf•in 2.2-13 2.2-8.7 3.5-16 4.3-26 8.7-26 8.7-26

Torque Switching Stepless Adjustment

Unloaded Rotation

Speed (r.p.m) ±10%970 1,800 2,000 1,200 2,000 400

Screw Size

(mm)

Machine

Screw 2.0-4.0 2.6-4.0 3.0-5.0

Tapping

Screw 2.0-3.0 2.6-3.0 3.0-4.0

Dimensions

(mm)

Grip ∅33

∅39*1

∅45

(Noncircular shape)

Max.∅41, Min.∅39 (Noncircular shape)*2

Length 255 263*1

286

286*2

Weight (g) 526 750 1,430

Bit Drive

HIOS H4 H5 and 5HEX -

HEX - H5 and 5HEX

- 1/4HEX 1/4HEX 1/4HEX

AC Screwdriver Cord length

3m

- 7 -

AC Input Power 120V

Model VB-1510

VB-1510PS

VB-1510-18

VB-1510PS-18

VB-1820

VB-1820PS

VB-3012

VB-3012PS

VB-4504

VB-4504PS

VB-4504PS

(with sockless stand)

Power Consumption(W)*

3

20W 40W

Output

Torque

Range

N•m 0.25-1.5 0.2-1 0.4-1.8 0.5-3 1-4.5

lbf•in 2.2-13 2.2-8.7 3.5-16 4.3-26 8.7-26

Torque Switching Stepless Adjustment

Unloaded Rotation

Speed (r.p.m) ±10%970 1,800 2,000 1,200 400

Screw Size

(mm)

Machine

Screw 2.0-4.0 2.6-4.0 3.0-5.0

Tapping

Screw 2.0-3.0 2.6-3.0 3.0-4.0

Dimensions

(mm)

Grip ∅33

∅39*1

∅45

(Noncircular shape)

Max.∅41, Min.∅39 (Noncircular

shape)*2

Length 255 263*1

286

286*2

Weight (g) 526 750 1,430

Bit Drive

HIOS H4 H5 and 5HEX -

HEX - H5 and 5HEX

- 1/4HEX 1/4HEX 1/4HEX

AC Screwdriver Cord length

3m

- 8 -

AC Input Power 220-240V

Model VB-1510

VB-1510PS

VB-1510-18

VB-1510PS-18

VB-1820

VB-1820PS

VB-3012

VB-3012PS

VB-4504

VB-4504PS

VB-4504PS

(with sockless stand)

Power Consumption(W)*

3

25W 40W 32W

Output

Torque

Range

N•m 0.25-1.5 0.2-1 0.4-1.8 0.5-3 1-4.5

lbf•in 2.2-13 2.2-8.7 3.5-16 4.3-26 8.7-26

Torque Switching Stepless Adjustment

Unloaded Rotation

Speed (r.p.m) ±10%970 1,800 2,000 1,200 400

Screw Size

(mm)

Machine

Screw 2.0-4.0 2.6-4.0 3.0-5.0

Tapping

Screw 2.0-3.0 2.6-3.0 3.0-4.0

Dimensions

(mm)

Grip ∅33

∅39*1

∅45

(Noncircular shape)

Max.∅41, Min.∅39 (Noncircular

shape)*2

Length 255 263*1

286

286*2

Weight (g) 526 750 1,430

Bit Drive

HIOS H4 H5 and 5HEX -

HEX - H5 and 5HEX

- 1/4HEX 1/4HEX 1/4HEX

AC Screwdriver Cord length

3m

- 9 -

Usage Procedure

1. Attach the bit to the driver.

2. Set the fastening torque for the driver unit with torque adjusting nut.

3. Turn the FOR/OFF/REV switch to OFF and connect the

driver power plug to an AC power outlet.

4. Turn the switch to either FOR or REV, start the driver,

and check the direction of rotation.

Caution

When starting the driver, it is extremely dangerous to

pinch the bit end with your ngers or push on the bit end. Never touch the

rotating bit.

5. Operate the clutch until the screw is tightened to the set torque value, then

stop the driver.

6. When loosening a tightened screw, turn the FOR/OFF/REV switch to REV, and

loosen in the reverse direction.

(If the screw does not come loose, tighten the torque adjustment nut to increase

the torque before trying again.)

Torque Adjustment Procedure

1. Remove the torque adjustment protective cover.

2. If the screw fastening torque is already known, set

the torque adjustment nut to the appropriate Level

3. Operate the driver so that the screw is tightened, and

check the tightness of the screw after the driver stops

automatically.

4. If the screw is too loose, slide the torque adjustment

nut upwards to increase the fastening torque. Repeat

this process to determine the appropriate tightness.

CCW

CW

Attaching the Bit

Caution

When attaching the bit, always ensure that the driver FOR/OFF/REV switch is set

to “OFF”, or that the driver power plug has been removed from the AC power

outlet so that there is no power within the driver.

To install the bit, pull the joint shaft collar at the end of the driver upwards and

insert the bit. Check that the bit does not come loose after you have inserted it.

joint shaft collar

Protective Cover

The Protective Cover

can be removed from

the frontring by

twisting it right.

- 10 -

If Repairs are Requested

Check the items listed in the table below, and if a malfunction is found, contact

your store of purchase of our company.

Always include your warranty card when sending in the driver for repairs.

Symptoms Cause and Treatment

The driver motor sometimes

fails to operate

- Is the cord severed?

Stop any work and request repairs.

The driver is weak and cannot

tighten screws suciently

- Is the torque setting at the correct

position?

Refer to the output torque guidance.

- 11 -

Approximate Guidance of Output Torque

(Including PS type)

N•m

N•m

2.0

1.5

1.0

0.5

0.25

12345678

Torque Scale

3.0

1.0

0.5

0.4

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

1.5

2.0

2.5

N•m

N•m

Torque Scale

1 2345678910

Torque Scale

1 2345678910

Black

Black

Black

Silver

(Installed)

Silver + Red

Silver

(Installed)

Silver + Red

2.0

1.5

1.0

0.5

0.25

12345678

Torque Scale

3.0

1.0

0.5

0.4

1.5

2.0

2.5

N•m

Torque Scale

1 2345678910

Silver

VB-1510

VB-1510PS

VB-1510-18

VB-1510PS-18

VB-1820(Silver)

VB-2008(Black)

VB-3012 (Black)

VB-3020(Black)

VB-4504PS

Springcolor

1-35-1 Oshiage, Sumida-ku Tokyo, Japan 131-0045

TEL: 81-3-6661-8821 FAX: 81-3-6661-8828

HIOS Inc.

This manual suits for next models

12

Table of contents

Other HIOS Power Screwdriver manuals

HIOS

HIOS BLF-2000 User manual

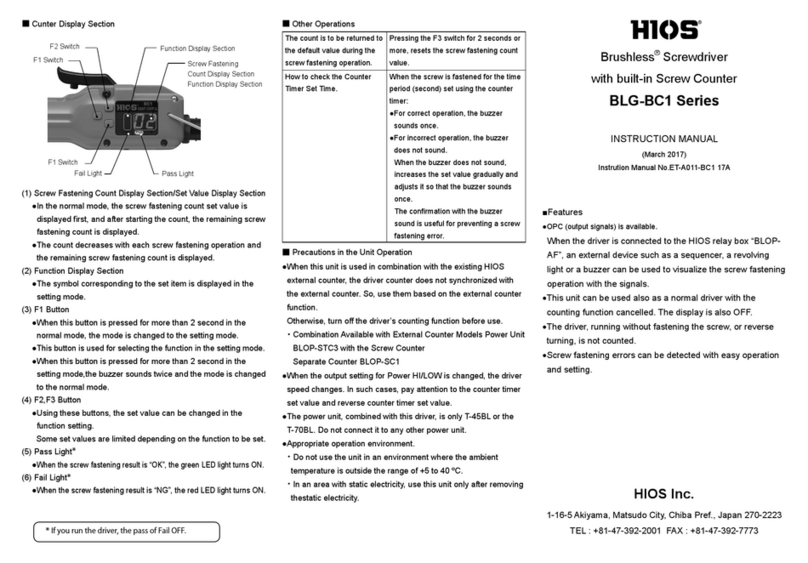

HIOS

HIOS BLG-BC1 Series User manual

HIOS

HIOS DCD-40L User manual

HIOS

HIOS CL-9000 User manual

HIOS

HIOS CL-2000 Installation manual

HIOS

HIOS JUKUREN BLG-BC2 series User manual

HIOS

HIOS JUKUREN BLG-BC2 series User manual

HIOS

HIOS VZH-1820 User manual

HIOS

HIOS BLG Series User manual

HIOS

HIOS BL-2000 User manual

Popular Power Screwdriver manuals by other brands

Bosch

Bosch SG250 Operating/safety instructions

Bosch

Bosch Professional GSR 12 VET Original instructions

Universal Tool

Universal Tool UT8226 Operator instructions

EINHELL Bavaria

EINHELL Bavaria BAS 14,4 operating instructions

niteo

niteo CD0090-22 instruction manual

BASETech

BASETech 1341239 Original operating instructions