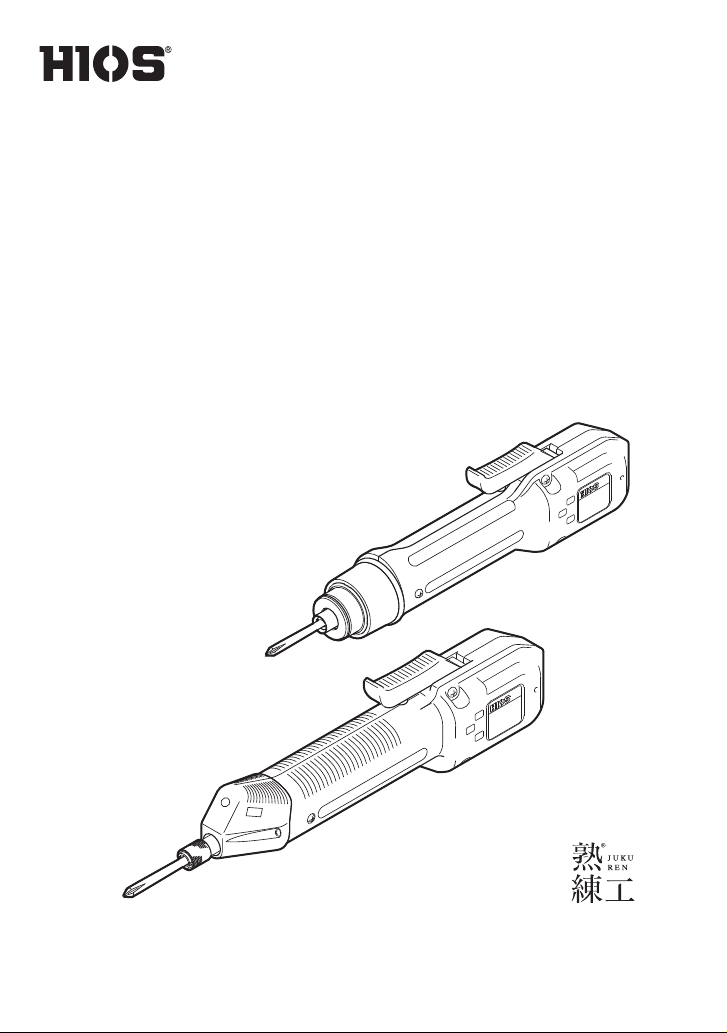

HIOS BLG-7000BC2-GT-S User manual

ET-A011-BC2-GT 21A

Operation Manual

(2021.11)

Built-in screwdriver & Pulse system

BLG-BC2 Series

BLG-4000BC2 / BLG-4000BC2-LT

BLG-5000BC2 / BLG-5000BC2-15 / BLG-5000BC2-18 / BLG-5000BC2-HT

BLG-7000BC2 / BLG-7000BC2-GT (-S/ -HANDLE)

02

03 Important Safety Instructions

05 Checking Supplied Accessories

06 Setting Up the Device

Connecting the Cord

Installing with the Stand (BLG-7000BC2-

GT-S)

Attaching a Bit

Changing the Start Mode (for BLG-5000BC2

Series /BLG-7000BC2 Series)

BLG-5000BC2 Series

BLG-7000BC2 Series

10 Parts and Their Functions

BLG-4000BC2 Series

BLG-5000BC2 Series

BLG-7000BC2

BLG-7000BC2-GT (-S/-HANDLE)

Operation Panel

Stand / Handle

13 Basic Operations

How to Change Rotation Speed

14 Setting the Torque

BLG-4000BC2 Series

Output Torque Guide (HI Input)

How to Change to Smaller Torque

BLG-5000BC2 Series /BLG-7000BC2

Output Torque Guide (HI Input)

BLG-7000BC2-GT

Output Torque Guide (HI Input)

18 Setting the Pass / Fail Criteria

Setting by Direct Teaching

Setting by Manual Procedure

21 Setting Screw Counter

23 Setting Menu List

How to Operate Setup Mode

<Counter>

<Screw Counter>

<Minimum Pulse>

<Maximum Pulse>

<Work Reset Timer>

<Count Timer for Reverse Rotation>

<System>

<Pulse Detection>

<Total Torque-ups (count)>

<Inactive Time of Torque-up>

27 Connecting the Special Cable (Option)

Checking Supplied the Cable Accessories

Connecting to Screwdriver (BLG-4000BC2/

BLG-5000BC2 Series)

Connecting to Screwdriver (BLG-7000BC2)

31 Saving Screw Fastening Data

System Requirements

Screen of Connection

Connecting to Screwdriver

Sending Command

Work Monitor

Screen of Administration

Specications of Communication by Special

Cable

Message Format

Communication Command / List of

Messages

43 Troubleshooting

Common Problems

When the Messages Below Are Displayed

Want to See the Device Version

45 Maintenance

About BLG-7000BC2-GT

46 Specications

BLG-4000BC2 Series

BLG-5000BC2 Series

BLG-7000BC2

BLG-7000BC2-GT

51 Notice

Table of Contents

03

Please read this manual and the power supply unit manual carefully before use to ensure proper operation. In

addition, do not use the product in the way not described in this manual. Please note that we are not

responsible for any problems caused by using the product in a manner that does not conform to the contents

of this manual, using it improperly, or repairing / modifying by a third party except by us or someone specied

by us.

Important Safety Instructions

Installation

◦Do not install the device at the places described

below. Otherwise, it may cause a re or a failure.

・A place of high humidity or with a lot of dust

・A place where it becomes high temperatures

・A place of re

・A place of direct sunshine

・A place containing corrosive gas in the air

・Unstable place

◦Do not use the device where the ambient

temperatures are out of the range of 5 to 40 °C.

Power Supply

◦Be sure to install an earth leakage breaker and a

safety breaker on the commercial power source

before using it.

◦Connect the earth wire to the earth wire terminal

of the outlet. You may have an electric shock

without the earth wire connection in case of an

electric leakage.

◦Avoid the octopus foot wiring and use of an

extension cord. Otherwise, it may cause a re or an

electric shock.

◦Do not connect anything other than specied to

the connection part of this device. Otherwise, it

may cause an electric shock or a failure.

Handling

◦Do not wear clothes with ippers on the cus,

gloves, neckties etc. Otherwise, they may get

caught in the rotating screwdriver and cause an

injury or a failure.

◦Wear suitable clothing and protective eye-wear for

work. Cover long hair with a hat etc. so that you

can work safely.

◦Turn o power when you leave the workplace, or

when you attach / remove a bit / an optional item.

◦If static electricity is charged, you need to

neutralize it before use.

◦Avoid an unstable place or an unreasonable

posture for work. Otherwise, it may cause an

injury.

◦Long-time work or some types of work may cause

strain on your hands, neck, arms or waist, causing

an injury. Avoid long-time work and take a break

regularly.

◦We recommend use of a balancer to prevent the

device from falling and to protect cords / wires.

◦Hold the plug when you attach / remove the

power cord, screwdriver and so on.

◦Protect cords / wires by not giving damages to

them; not remodeling them; not pulling them; not

bending them forcibly; etc. Also, do not place

heavy items on the power cord. Otherwise, it may

cause a re or an electric shock.

◦If you detect an uneven rotation, strange noises,

overheating or activation of a breaker, etc., stop

using the device immediately and have it repaired.

04

However, note that the device may be overheated

depending on the frequency of the workpiece or

screw types. As a countermeasure, prepare spare

screwdrivers of the same model to extend the tact

time and use them alternately, or review the

selection of screwdriver models.

◦Do not overload the device so much that it cannot

clutch. Otherwise, it may cause a failure of the

motor.

◦Do not touch the screwdriver while it is rotating.

Otherwise, it may cause an injury or a failure.

◦Keep your hands and face away from the rotating

section while in use. Otherwise, it may cause an

injury.

◦Remove the bit from the screwdriver when you are

not working.

◦If you cannot attach / remove the bit in the way

described in this document, please make contact

with our service section.

◦Fix the workpiece with jig / clump while in

working.

◦Do not use the switch lever as a hanger. Otherwise,

it may cause an accident or an injury.

◦Do not give a strong impact or excessive force.

Otherwise, it may cause a failure.

◦Do not operate the screwdriver with wet or oiled

hands.

◦Do not operate the FOR / REV switch before the

screwdriver completely stops. Otherwise, it may

cause a failure.

◦Do not disassemble / remodel this device.

Otherwise, it may cause a failure.

◦High torque has a large recoil on the hand or arm.

Hold the driver rmly to avoid being swung

around.

◦

Do not work with the attached anti-reaction stand or

handle removed. It may cause an accident or injury.

Maintenance and Inspections

◦Turn o power and remove the power plug from

the outlet when the device is not in use for a long

time.

◦Remove the accessories from the screwdriver and

store them in the package box when it is not in use

them for a long time.

◦Inspect the device regularly to conrm there are

no damages. If you use it with damages, it may

cause a re or an electric shock.

◦When you clean the device, turn o the power and

remove the power plug from the outlet.

Otherwise, it may cause a re or an electric shock.

◦Use dry cloth to wipe of dust or stains. The dust

may absorb moisture to allow current to ow,

causing a re.

◦Store the device in a place where the appropriate

temperatures and humidity are controlled.

◦Do not store the device in an unstable place or a

place with vibrations. Otherwise, it may cause a

failure.

◦Keep the device out of reach of anyone but people

involved in the workpiece.

◦We recommend genuine HIOS parts for

replacement.

05

Checking Supplied Accessories

Adjustment spring for low torque

(BLG-4000BC2/BLG-4000BC2-LT Only)

HANDLE (BLG-7000BC2-GT-HANDLE)

*Attached to the driver

Stand (BLG-7000BC2-GT-S)

*Slide arm is attached to the driver

Instruction manual

Screwdriver cord: 2 m (6P)

One bit for each socket

Bit Drive

4000BC2-LT 4000BC2 5000BC2

5000BC2-15

5000BC2-18

5000BC2-HT

7000BC2

7000BC2-GT

H4

+#0 (Ø2.0×40mm)

+#0 (Ø2.5×40mm)

+#0 (Ø2.5×40mm)

+#1 (Ø4.0×40mm)

+#1 (Ø4.0×40mm)

+#2 (Ø4.0×40mm)

– –

H5 – –

+#1 (Ø5.0×60mm)

+#2 (Ø5.0×60mm)

+#1 (Ø5.0×60mm)

+#2 (Ø5.0×60mm)

–

1/4 HEX –

+#1 (Ø5.0×50mm)

+#2 (Ø5.0×50mm)

– (Ø5.0×50mm)

+#2 (Ø7.0×100mm)

+#3 (Ø7.0×100mm)

Hexagon L-shaped wrench: 5 mm across ats

(BLG-5000BC2 Series/BLG-7000BC2 Only)

06

Setting Up the Device

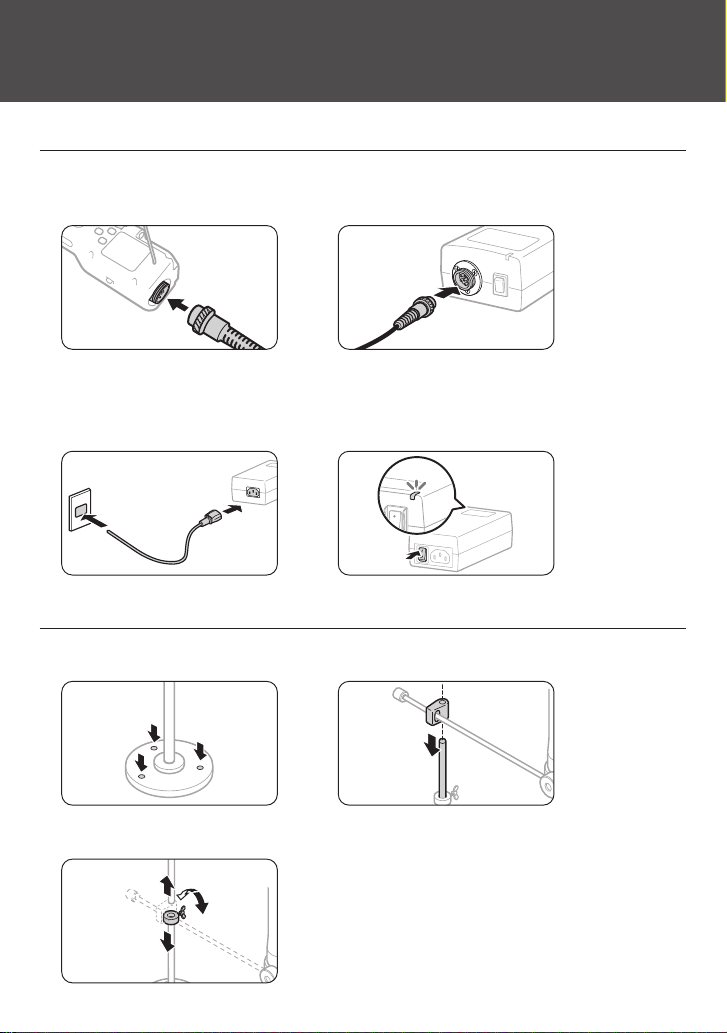

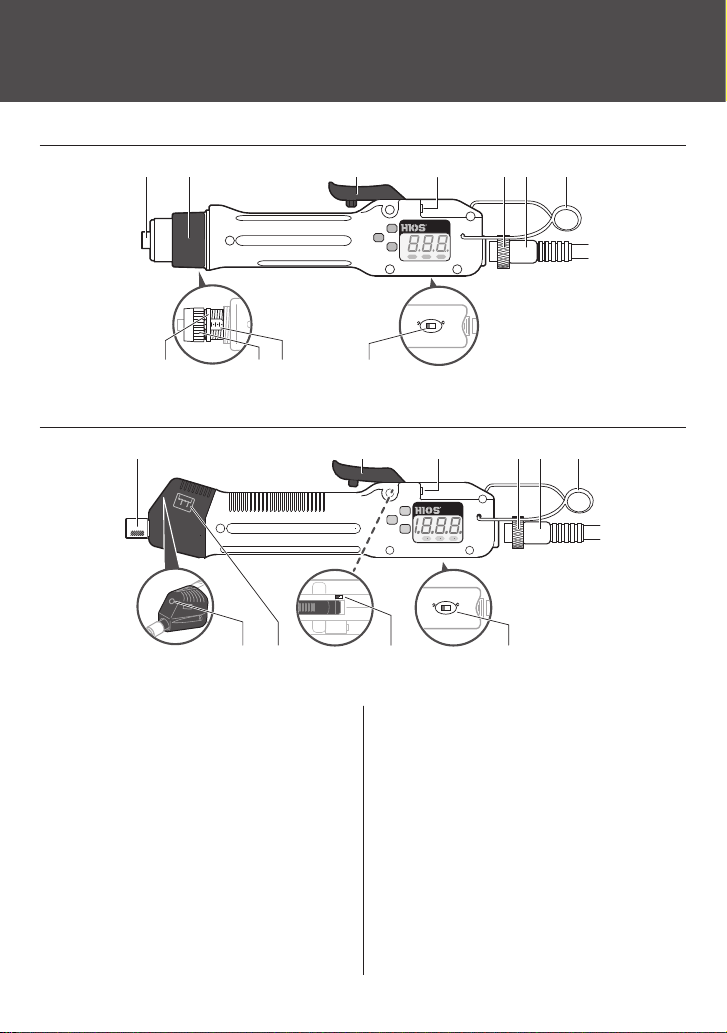

Connecting the Cord

1Connect the screwdriver cord to the power unit and the screwdriver.

◦Use the joint ring for xing to prevent the cord from coming o.

▶

2Connect the power unit cord to the power unit and the outlet and turn

on the switch.

◦The indicator on the power unit turns on.

▶

Installing with the Stand (BLG-7000BC2-GT-S)

1Fix the stand, then put the shockless holder on the pole.

▶

2Adjust the position of the slide arm if needed.

07

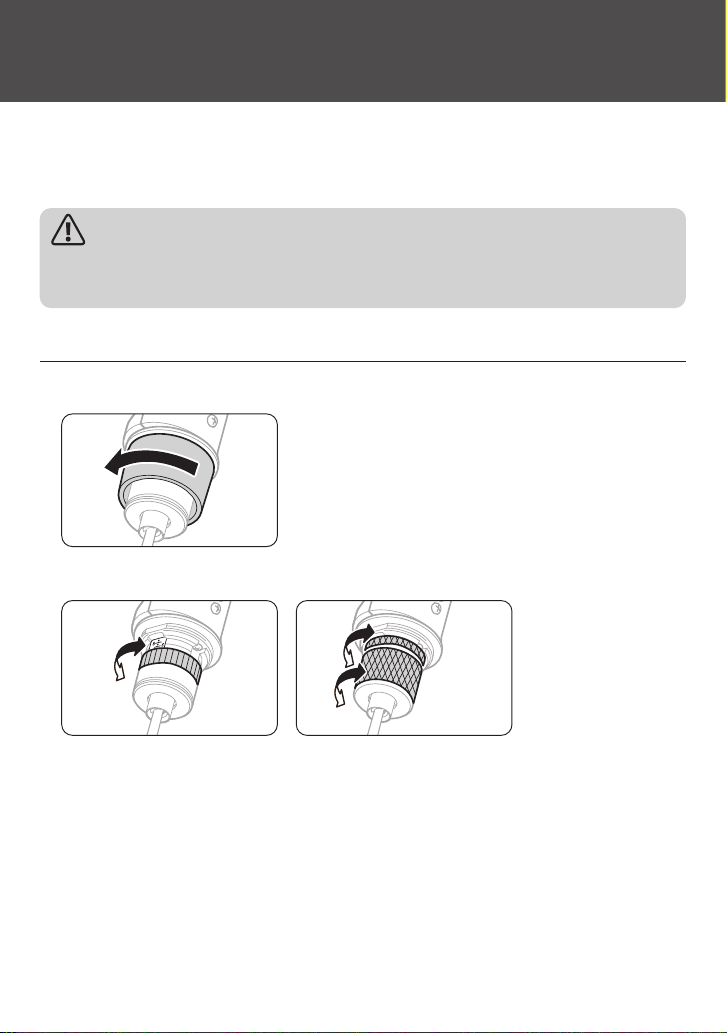

Attaching a Bit

Caution

Do not attach / remove the bit while power is on. Otherwise, it may cause an unexpected

accident.

1Insert the bit into the joint shaft collar.

◦BLG-4000BC2 / BLG-4000BC2-LT: Attach the bit while pushing the joint shaft collar into the

screwdriver.

◦BLG-5000BC2 Series / BLG-7000BC2: Attach the bit while pulling out the joint shaft collar from the

screwdriver.

BLG-4000BC2/BLG-4000BC2-LT

BLG-5000BC2/BLG-7000BC2

2Conrm the bit has been attached rmly by pulling it light.

Precaution for Use of Hexagonal Bit

You cannot use a double head bit with double grooves. Prepare suitable sockets for those bits.

Bit Socket 5HEX (5 mm across ats) 1/4HEX (6.35 mm across ats)

Type 5

14.0

6.35

9.0

08

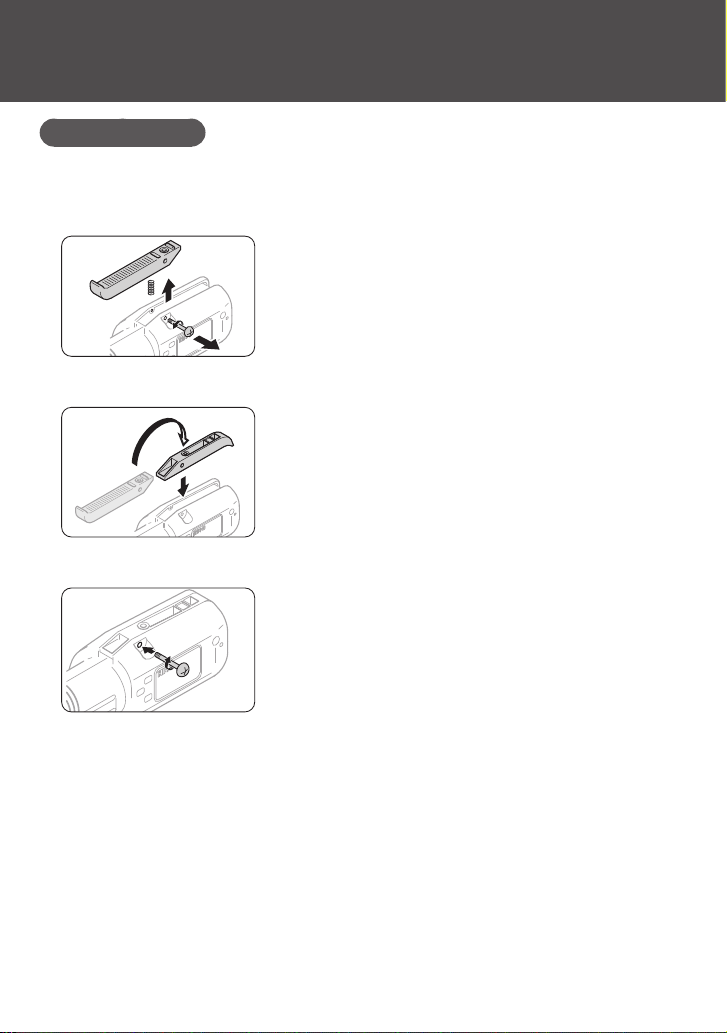

Changing the Start Mode (for BLG-5000BC2 Series /BLG-7000BC2 Series)

You can change the mode to push start for BLG-5000BC2 Series and BLG-7000BC2. In the push

start mode, the screwdriver starts rotation when you press it into an object.

BLG-5000BC2 Series

1Remove the switch lever.

◦Remove the shaft screw.

◦Be careful not to lose the lever spring.

2Change the start mode.

◦Use something pointy such as a pen.

3Re-attach the shaft screw.

Caution

◦Do not give a strong impact to the start mode switch. Otherwise, it may cause a failure.

◦Do not use the screwdriver while the shaft screw is not fixed. Otherwise, it may cause a

failure.

09

BLG-7000BC2 Series

1Remove the switch lever.

◦Remove the shaft screw.

◦Be careful not to lose the lever spring.

2Turn over the switch lever and attach it.

3Re-attach the shaft screw.

10

BLG-4000BC2 Series

REV

0

FOR

BC2

COUNT CONTROL

PASSFail M

8

6

4

2

❶ ❷ ❸ ❹ ❺❻ ❼

❽❾❿⓫

BLG-5000BC2 Series

❶ ❸ ❹ ❺❻ ❼

❽⓬❿ ❾

REV

0

FOR

3

1

57

BC2

COUNT CONTROL

Fail PASS M

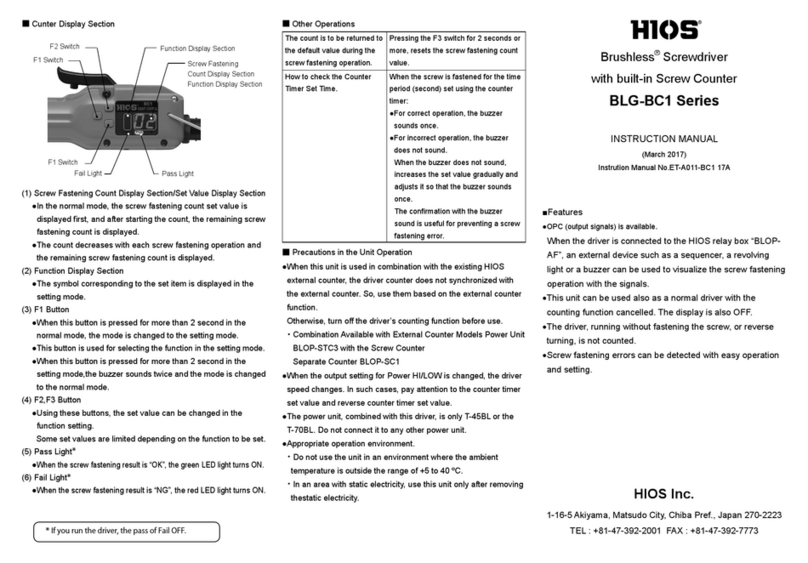

Parts and Their Functions

❶Joint shaft collar

This is to be used to attach the bit or remove it.

❷Protection cover of torque adjustment nut

This can be removed by turning it

counterclockwise.

❸Switch lever

This is used to start the screwdriver.

For 7000BC2, if you attach the lever upside

down, you can use the push start.

❹External I/O port

Send / receive the data via this port with the

special cable (option). You can change the set

values of the screwdriver from an external

device (e.g. PC, PLC, etc.) and send out screw

fastening data.

❺Joint ring

This is to prevent the screwdriver cord from

coming off unexpectedly.

❻Screwdriver cord

This is to connect the screwdriver to the power

unit. The plug on one end is the same as that

on the other end.

❼Hanger

This is used to hang the screwdriver from the

balancer.

11

BLG-7000BC2

BC2

COUNT CONTROL

Fail PASS M

3

1

57

9

REV

0

FOR

❶ ❸

❹

❺❻ ❼

❽❿ ❾

BLG-7000BC2-GT (-S/-HANDLE)

BC2

COUNT CONTROL

Fail PASS M

43

21

R

F

❶ ❸

❹

❺❻ ❼

❽❿❾

❽FOR/REV switch

You can change the rotational direction with

this switch.

◦FOR: Clockwise

◦0: Neutral

◦REV: Counterclockwise

❾Adjustment scale of torque

This is used as a guide for output torque

adjustment. For details, refer to“Setting the

Torque” (P. 14).

❿Torque adjustment nut

This is used for output torque adjustment.

⓫Nut fixing ring (BLG-4000BC2-LT Only)

This prevents the torque adjustment nut from

moving improperly. Fit it closely with the

torque adjustment nut.

⓬Start mode change switch

This is used to change the start mode.

◦L: Lever start

◦P: Push start

For details, refer to “Changing the Start Mode

(for BLG-5000BC2 Series /BLG-7000BC2 Series)”

(P. 08).

12

Operation Panel

PASSFail M

BC2

COUNT CONTROL

❶ ❷ ❸

❹

❺❻❼

Stand / Handle

❿

⓬ ⓫⓭

❾❽

⓯⓮

❶F1 button

This is used to change the mode to setting or

change the setting items.

❷F2 button

This is used to change the mode to direct teaching

or change the digit of the setting.

❸F3 button

This is used to change the setting.

❹Display

This displays the number of pulses, the

operational conditions of the screw counter, error

conditions and etc. In addition, you follow the

instructions on the display during setup.

❺M indicator

This turns on when operations on the button are

inactive. In addition, it blinks in the mode of

temporary fastening (option).

❻PASS indicator

This turns on when the result of fastening a screw

is accepted.

❼Fail indicator

This turns on when the result of fastening a screw

is not accepted.

❽Pole

Adjust the position of the collar.

❾Wing screw

Fix the collar.

❿Slide arm

Absorb the impact of screw fastening.

⓫Collar

Adjust the position of the slide arm.

⓬Stand base

Fix on the work table.

⓭Shockless holder

Attach slide arm to the pole.

⓮Handle fixing bolt

fixing handle to the driver.

⓯Handle

Grip firmly.

13

Basic Operations

1Set the FOR / REV switch to <FOR>.

0

REV

FOR

◦When you change the rotational direction, turn the switch to 0 to stop the screwdriver.

2Start the screwdriver.

◦In the lever mode, pull the switch lever for start.

◦In the push mode, push the screwdriver in the direction of the bit.

◦Grip firmly if it is handle type.

3

1

57

◦When the screwdriver starts, the pulse is counted, and PASS / Fail is indicated by the sound and

the indicator.

PASSFail M

▶

PASSFail

M

◦In case of over 1000 pulses, <–––> is displayed. For details of how to set pass / fail, refer to“Setting

the Pass / Fail Criteria”(P. 18).

◦When a screw is seated, the clutch is activated to stop rotation.

◦If you restart the screwdriver, the PASS / Fail indicator turns o.

How to Change Rotation Speed

When you want to change the rotation speed, use the switch for voltage output setting on the power unit.

◦2: HI (30V)

◦1: LOW (20V)

14

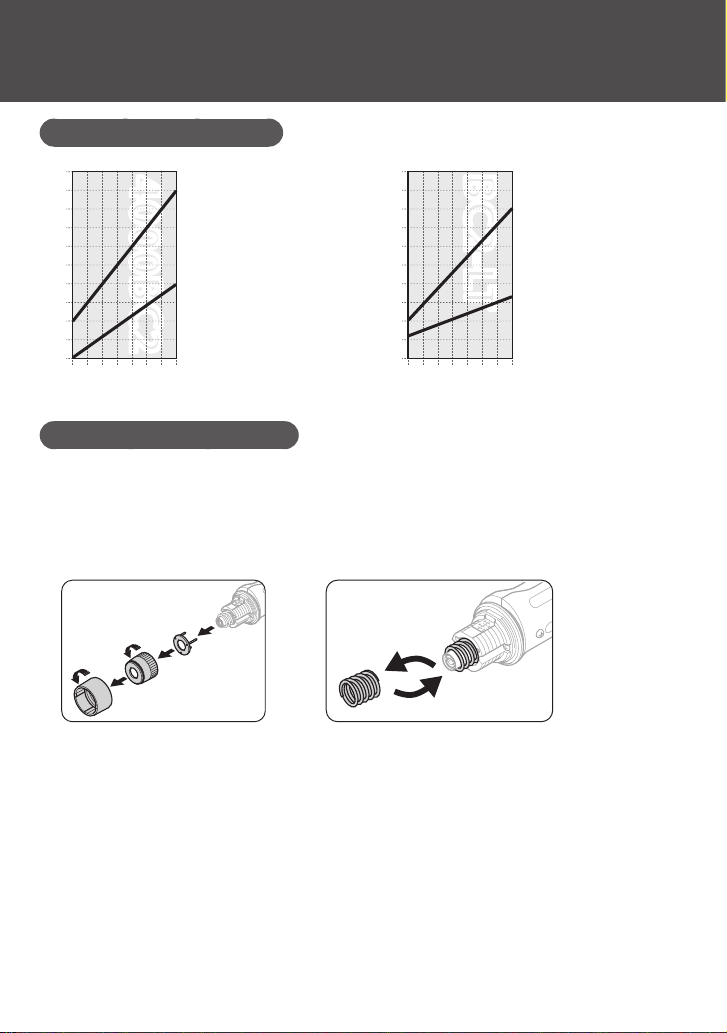

Setting the Torque

The torque can be adjusted by pushing the torque adjustment spring with pressure. If you turn

the torque adjustment nut clockwise, the torque becomes large, and you turn it

counterclockwise, it becomes small.

Caution

“Output Torque Guide”and the torque adjustment scale should be considered as a guide; they

do not guarantee actual torques. Use the torque meter by HIOS to check the torque precisely.

BLG-4000BC2 Series

1Remove the protection cover of the torque adjustment nut.

2Turn the torque adjustment nut to set the fastening torque.

◦Adjust the edge face of the torque adjustment nut to come right above the scale.

◦For BLG-4000BC2-LT, adjust the edge face of the nut xing ring to come right above the scale.

When the nut xing ring’s position is determined, align the torque adjustment nut just to t to the

ring.

3Re-attach the protection cover of torque adjustment nut.

4000BC2-LT4000BC2

15

Output Torque Guide (HI Input)

Spring on the device

Spring in the accessories

4000BC24000BC2

Torque scale

1

0.1

0.3

0.2

0.5

0.4

0.6N·m

2345678

0.05

0.03

0.15

BC2-LTBC2-LT

Torque scale

1

0.10

0.20

N·m

2345678

Spring on the device

Spring in the accessories

How to Change to Smaller Torque

If you use the torque adjustment spring in the accessories, you can change the torque value

smaller. Change the spring depending on the work conditions.

1Remove the torque adjustment nut and the spring holder and replace

the torque adjustment spring.

▶

2Re-attach the torque adjustment nut and the spring holder.

◦Attach the spring holder along the notch.

16

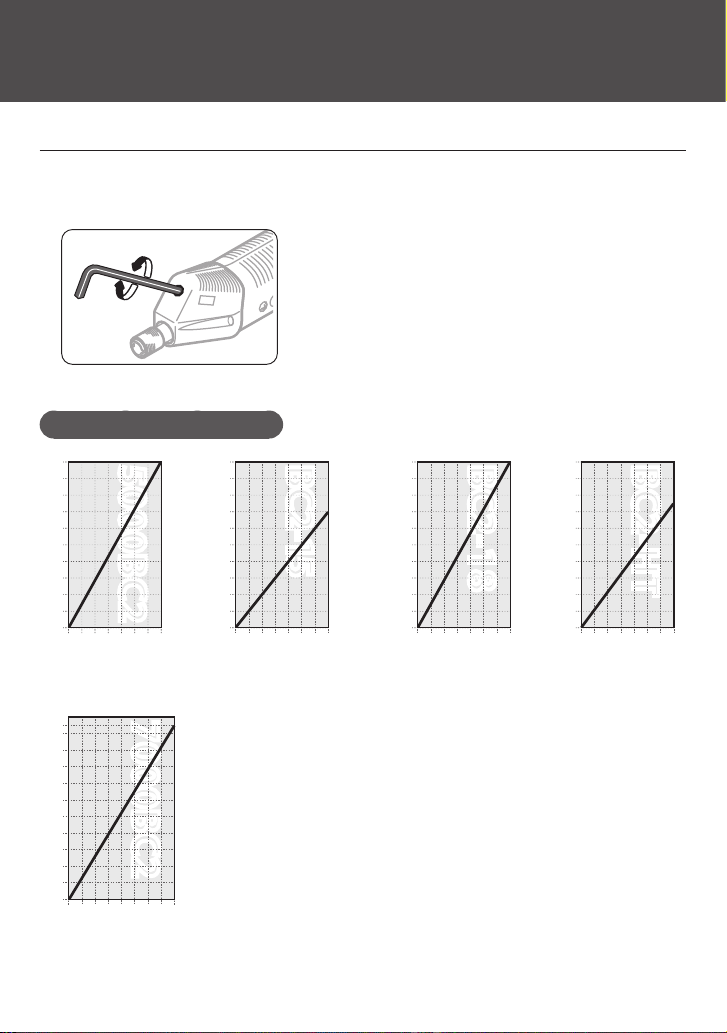

BLG-5000BC2 Series /BLG-7000BC2

1Use the hexagon L-shaped wrench in the accessories to turn the torque

adjustment nut for setting the fastening torque.

◦Adjust the edge face of the torque adjustment nut to align with the scale.

Output Torque Guide (HI Input)

BC2-15BC2-15

BC2-18BC2-18

BC2-HTBC2-HT

5000BC25000BC2

Torque scale

1

0.2

0.6

0.4

1.0

0.8

1.2 N·m N·m N·m N·m

2345678

7000BC27000BC2

Torque scale

0.7

1.5

1.1

2.3

1.9

2.7

2.8

N·m

Torque scale

1

0.5

0.7

1.1

1.3

0.9

1.5

2345678

Torque scale

1

0.5

0.7

0.9

1.1

1.3

1.5

1.7

1.9

2.0

2345678

Torque scale

1

0.3

0.4

0.6

0.8

1.0

2345678

2345678910

17

BLG-7000BC2-GT

1Rotate torque adjusing nut to set torque.

◦Adjust the edge face of the torque adjustment nut to align with the scale.

Output Torque Guide (HI Input)

7000BC2-GT7000BC2-GT

2.0

3.0

3.5

2.5

4.0

4.5

5.0

N·m

21 3 4 5 6 7

Torque scale

18

Setting the Pass / Fail Criteria

This section describes how to set the pass / fail criteria. There are two ways of setting, direct

teaching and manual setting.

Setting by Direct Teaching

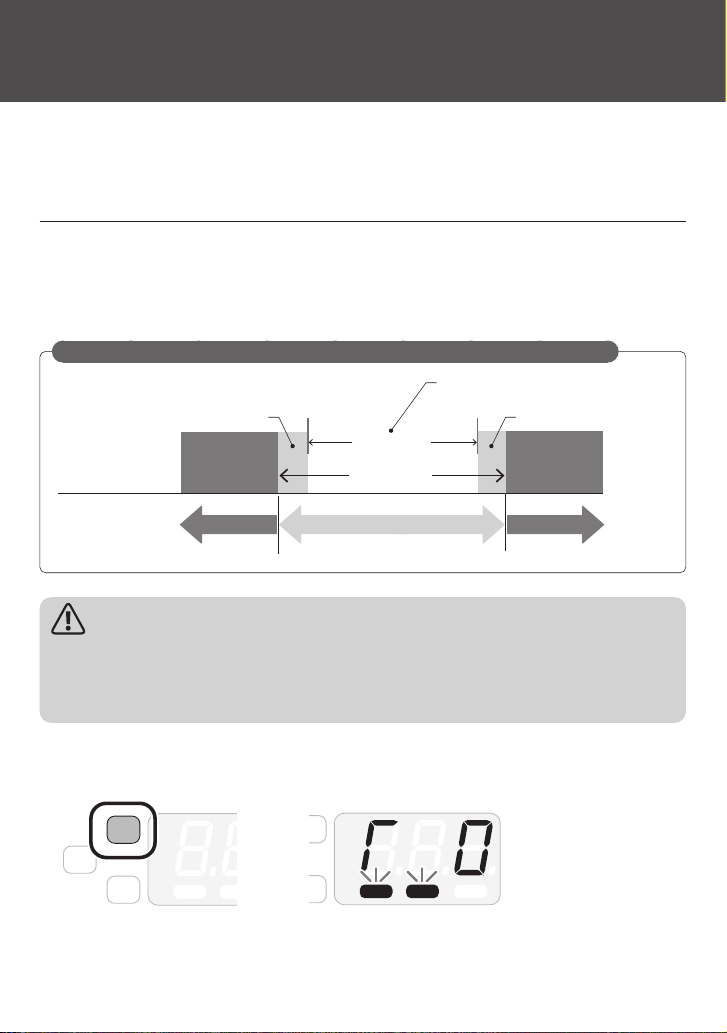

Direct teaching uses real screws and workpieces. It measures the pulses of motor rotation from

when the screwdriver starts turning to when it reaches the torque-up. The maximum and the

minimum measurements of pulses are set as the thresholds for pass / fail. Considering the

measurement errors, you can set allowable ranges on thresholds.

~90 91~131

99~119

132~

Allowable range: -10% Allowable range: +10%

The number of pulses during teaching

FailPASSFail

Pulse

Pass / fail range

Example: Minimum pulse = 100, Maximum pulse = 120, Allowable range = +/-10%

Caution

◦Do not use the conditions (i.e. screws, workpieces, etc.) for teaching different from those of

real operation. Otherwise, it may cause larger errors.

◦Before teaching you need to define the home position by fastening a screw.

1Press and hold the F2 button.

◦The Fail and PASS indicators start blinking.

PASS

Fail

M

▶

PASSFail M

19

2Fasten a screw to a workpiece.

◦The pulse is counted until the screw is seated.

◦Repeat this teaching process at least three times.

▶

PASSFail M

3Press and hold the F3 button to set the allowable range of the

threshold.

PASSFail M

◦Every time you press the F3 button, the allowable range changes.

±0% ▶±5% ▶±10% ▶±15% ▶±20% ▶±0% ▶…

4Press the F1 button to conrm the allowable range.

◦The number of pulses is changed to the one with the tolerance factor calculated on both

thresholds.

PASSFail M

▶

PASSFail M

5Press and hold the F2 button.

PASSFail M

◦The buzzer starts to indicate setting is finished.

◦The number of screws to be fastened is displayed.

20

Setting by Manual Procedure

Input the number of pulses directly to set the criteria.

Caution

If you set the criteria manually, the factor of allowable range has no effect. Then, you need to

set the number of pulses considering the variances of screws and workpieces.

1Press and hold the F1 button.

PASS

Fail

M

▶

PASSFail M

2

Press the F1 button to select <Minimum Pulse> and enter your target number.

PASSFail M

◦If you press the F3 button, the number of the selected digit is changed.

◦

If you press the F2 button, you can move to another digit. The third digit is displayed by scrolling

on the screen.

3

Press the F1 button to select <Maximum Pulse> and enter your target number.

PASSFail M

◦If you press the F3 button, the number of the selected digit is changed.

◦

If you press the F2 button, you can move to another digit. The third digit is displayed by scrolling

on the screen.

4Press and hold the F1 button.

◦The buzzer starts to indicate when the setting is finished.

◦The number of screws to be fastened is displayed.

This manual suits for next models

9

Table of contents

Other HIOS Power Screwdriver manuals

HIOS

HIOS CL-9000NL User manual

HIOS

HIOS JUKUREN BLG-BC2 series User manual

HIOS

HIOS BLF-2000 User manual

HIOS

HIOS DCD-40L User manual

HIOS

HIOS CL-9000 User manual

HIOS

HIOS VB Series User manual

HIOS

HIOS VZH-1820 User manual

HIOS

HIOS BLG-BC1 Series User manual

HIOS

HIOS CL-2000 Installation manual

HIOS

HIOS BLG Series User manual