HIOS BLF-2000 User manual

Brushless Screwdrivers for automated assembly machines

●Screwdriver

BLF-2000

BLF-5000

BLF-7000

BLF-7000X

BLF-7025X

●

Screwdriver + Suction (Vacuum) Attachment

BLFQ Series

BLFR Series (For deeply recessed screws)

Operation Manual

(As of November 2016)

Utilizing 100% post-consumer

recycled paper pulp

16A Operation Manual No. ET-A049

1-16-5 Akiyama, Matsudo City, Chiba Pref., Japan 270-2223

Phone: 81-47-392-2001 FAX: 81-47-392-7773

- 2 -

Contents

■ Introduction ........................................................................................................................................... 3

■ Features ................................................................................................................................................... 3

■ Cautions after introducing the screwdriver and the power supply .................................. 4

■ Cautions when installing the screwdriver ................................................................................. 4, 5

■ Cautions when using a universal joint ........................................................................................ 5

■ Precautions ............................................................................................................................................ 6

■ About device adjustment ................................................................................................................ 7, 8

Bit Attachment

About torque adjustment

■ Names of main components of the screwdrivers .................................................................. 9

About ange

Combination table between the screwdrivers for automatic operation

and the power supplies for them

■ Specications of the screwdrivers ................................................................................................ 10, 11

Output torque guide (HI)

■ Exterior dimensions and details of the screwdrivers ............................................................ 11, 12

Figure of installation dimensions

■ Suction (Vacuum) Attachment BLFQ series .............................................................................. 13

BLFQ accessories list

Mouthpiece

Adjustment of mouthpiece

Bits

■ Suction (Vacuum) Attachment BLFR series .............................................................................. 14-19

BLFR accessories list

Identication of the BLFR Mouthpiece Order Code

Types of spring loaded mouthpiece (attachable to BLFR-5000 and BLFR-7000 series)

Adaptive screw size indications

■ Exterior dimensions of the suction attachments ................................................................... 20, 21

■ Vacuum Pump VP-3 ............................................................................................................................ 22

●Abbreviations of product names

Product names are abbreviated as follows for convenience in this document, except for the

cover page:

・Brushless Screwdrivers for automated assembly machines:

screwdriver

・Power supply dedicated for Brushless Screwdriver for automated assembly machines:

power

supply

・BLF-7000, BLF-7000X and BLF-7025X models:

BLF-7000 series

- 3 -

■ Introduction

Thank you for purchasing the BLF series, BLFQ series or BLFR series of the brushless

screwdrivers for automatic operation.

Before using, please make sure to read this instruction manual well and use the tools

properly.

Please keep this manual in a safe place after reading.

NOTE

The screwdrivers have warranted its ability within controlled torque range.

However, please consider the following situation when installing the tools in customer’s

operation.

* If there is any inclusion (ex. Universal joint) at joint part between screwdriver and bit,

output torque would be badly affected by some conditions (ex. inertia or resistance).

Please select proper model considering torque with a margin.

■ Features

● Our brushless screwdrivers are durable and enable stable screw fastening.

● The durability has been improved by simplifying the control circuits.

● There are two types of the vacuum pick up screwdrivers.

The BLFQ is a standard vacuum pick up screwdriver.

The BLFR is for deeply recessed screws.

BLF-2000 BLF-5000 BLF-7000 series

BLT-AY-61 BLT-AY-71

- 4 -

■ Cautions after introducing the screwdriver and the

power supply.

Rotation speed of the screwdriver

● The rotation speed is dierent for forward and reverse rotations. Please refer to the values

on the specication of the screwdriver and the torque guide table only as rough guidelines.

● The rotation speed is measured without load. Please note the rotation speed varies when

the set value is 27 or more.

The controlled torque values are measured with the combination of a HIOS Torque Meter

HP-100 and a Fidaptor*. The values during your work are not always the same as the values

in the table. Please refer to the values in the table only as rough guidelines.

* For measuring torque with the screwdriver, use a daptor (accessory of HP-100), which

reduces and absorbs the inertia generated at stoppage and has the ability to reproduce

near-screw-fastening conditions to detect the torque when the clutch fires during

rotation of the screwdriver. Also, please use a dedicated torque measuring instrument,

HM Series, which can measure output torque of the screwdriver after it is installed.

■ Cautions when installing the screwdriver

● Note that screw fastening cannot be done with the screwdriver being installed upward.

● About the speed setting for screwdriver descending

If the descending speed of the Z-axis is faster than the screw fastening speed, screw oating

may occur due to overloaded tightening. Set the descending speed of the screwdriver

appropriate for the screw fastening.

● Consider the stiness against Z-axis including the installation board of the screwdriver.

Note 1) Please select Z-axis based on the following formula: Screwdriver weight +

Installation angle weight = Tightening reaction force

Make sure to install the screwdriver with the above condition satisfied. (Please

contact us for details.)

Note 2) Please determine the thickness of the installation board tolerable with stiness and

reaction force.

Guideline for the installation board thickness ・BLF-2000/BLF-5000: 8 mm or more

・BLF-7000 Series: 10 mm or more

● If the screw fastening cycle is short and constant torque is always required when a tapping

screw is fastened, it is necessary to check the required torque level by using an actual

machine. In such case, feel free to contact us.

● If the torque is high, presume that the reactive force against the screwdriver is strong and

the stiness of the installation ange and Z-axis will impact on the screw fastening.

● Even if the above setting conditions are satised, overload may occur. In such case, review

the installation conditions.

● The ange and the main body of the screwdriver are xed with left-handed screws.

- 5 -

● For the load in the direction to the axis of the screwdriver (thrust direction), design using a

damper mechanism.

* Dampers with simple shock absorbers are available from HIOS. Consider using them if appropriate.

Product Name: BLF Damper Unit

Part Number: BLF-DP (*Installation board is not included.)

Thrust Load Specications

Initial load 0mm Approx. 0.12N・m(1.2kg)

Stroke 7mm Approx. 0.6N・m(6kg)

■ Cautions when using a universal joint

● Offset from the center axis causes overload by twisting of the output axis. Incomplete

xation may cause power loss, overload on the screwdriver or twist, and may decrease the

output power of the screwdriver.

As a result, incomplete tightening may occur even if the output torque is a standard value.

● When using a universal joint, make sure that a rotational load is not applied to the bit.

(Note)

When using a universal joint, output torque of the screwdriver and the actual output torque

may be dierent due to inertia. Make sure to measure both torque of the screwdriver and

the actual output torque.

● When a universal joint is installed, make sure not to overload in the direction of the axis of

the screwdriver (thrust direction), and not to damage the workpiece and the screw bottom.

Guidelines for the load limit BLF-2000: 3kg or less

BLF-5000/BLF-7000 Series: 5kg or less

● When a universal joint or xture is installed under screw fastening conditions, implement

test tightening several times.

1. Is it fastened at the set torque?

2. Is the rotating speed of the screwdriver constant?

3. Isn’t the bit wobbling?

4. Is there any abnormal noise...etc? Check these prior to the nal tightening.

● When using a universal joint, make sure the bit turns by hand.

installation

board

Damper

- 6 -

■ Example

■ Precautions

● Please read this instruction manual thoroughly before use to ensure proper operation.

● On any commercial power supply, install a ground-fault interrupt breaker and safety circuit

breaker.

● Connect the power supply to ground and use only the rated voltage.

● Please consider every condition such as power loss and inertia due to the Joint Shaft part,

etc. from the body to the bit of the screwdriver. Make sure to select the screwdriver that well

meets the requirements.

● In case a universal joint or jigs are used, the actual output torque values may be dierent

from the corresponding torque values displayed on the specication table.

● Please conrm that the screwdriver and the power supply are the right combination.

● The overload protection will be activated when the screwdriver is locked or has become

overloaded. If the screwdriver is overloaded repeatedly, the maximum ratings of the power

supply or screwdriver may be exceeded. If the screwdriver becomes overloaded during normal

operation or begins to malfunction due to developing excessive heat, stop the ongoing operation

immediately, turn the main power switch o, remove the power cable, and contact our service

department or HIOS distributor for repairs.

● When fastening screws on workpieces constructed of plastics susceptible to static electricity

build-up, operation should be done after static electricity has been discharged. If the work

pieces that have not been properly discharged, static electricity may ow up through the

end of the bit, causing malfunctions of the tools.

● Do not disassemble or modify the tools in any way, as doing so may cause malfunctions of the

tools. Such malfunctions are not covered by the HIOS warranty and repairs may be refused.

● The operating environment for the screwdriver should be between 5C and 40C with

relative humidity of 80% or less (there should be no possibility of condensation).

● Do not drop the tools or subject it to mechanical shocks.

●

Always hold the plug when inserting or removing power cables or the driver cords into or from

sockets

.

● Do not drag cords or cables, subject them to oil or to sharp edges, or place them under

heavy objects.

● If the tools will not be used for a long period of time, turn the main power switch OFF and

unplug it from the service outlet.

6

2

Z軸

Y軸

3. When connecting an Angle to the

Z-axis, fix it firmly. If it is loosely

xed, it may cause problems such as

overload.

Guidelines for the installation board

thickness:

・BLF-2000 / BLF-5000: 8 mm or more

・BLF-7000 Series: 10 mm or more

1. For the thickness of

the installation board

of the back board,

appropriate thickness

under the installation

conditions should be

kept when xing.

2. For the thickness of

the installation board,

appropriate thickness

under the installation

conditions should be

kept when xing.

- 7 -

■ About device adjustment

Bit Attachment

1.Bit attachment

· Bit attachment for BLF-2000 (Chart) -1

Push in and hold the Joint Shaft Collar into the

body of the screwdriver to insert the bit.

· Bit attachment for BLF-5000 / BLF-7000 Series

(Chart)-2

Pull up and hold the Joint Shaft Collar from the

body of the screwdriver to insert the bit.

2.Please conrm the attached bit is locked rmly.

BLF-2000 uses the bit of HIOS H4 ( ∅4).

· BLF-5000 and BLF-7000 use the bits of HIOS H5 ( ∅5).

* Please use HIOS genuine bits.

∅4 or ∅5

· The bit drive of BLF-7000X and BLF-7025X is 1/4 HEX. Please purchase the commercial

products.

(Caution) Please purchase the commercial bit with the specied shape.

9.0 mm

6.35mm

(Hex bit types that cannot be used)

● Hex bits with two recesses and double bits cannot be

used with this product.

● BLF-2000

(Chart)-1 Bit attachment

● BLF-5000 / BLF-7000 Series

(Chart)-2 Bit attachment

Push in and hold the Joint

Shaft Collar into the body

of the screwdriver to insert

the bit.

Pull up and hold the joint

shaft collar from the body

of the screwdriver to in-

sert the bit.

- 8 -

About torque adjustment

1. In case the torque value of screw fastening is xed in advance, refer to "Reference tables

of output torques" and turn the Torque Adjustment nut on the screwdriver, using torque

scale numbers (1-8) or (1-9).

(Caution)

Please use the reference tables of output torques as rough guideline to set torque.

2. Please rotate the torque control nut to reach the directly above position of the number.

· Fixation method (BLF-2000 only)

BLF-2000 has a xation mechanism with double lock nuts.

The position set with the Fixing nut is the congured torque setting value.

(Procedure)

2-1. Rotate the Fixing nut to reach the directly above

position of the torque scale number on the

screwdriver.

2-2. Rotate the Torque Adjustment nut to the position

of the Fixing nut. Make sure to tighten the nut

well then. To prevent position error of the Torque

Adjustment nut, tighten the Fixing nut well while

holding the Torque Adjustment nut.

3. Turn on the tools and implement screw fastening. When it stops, check the screw and

optimize the torque value.

* To check the torque of the screwdriver.

・ We recommend our Torque Meter: HM series. Even when you have only limited space,

you can measure the torque of the screwdriver installed to the automated assembly

equipment.

Torque control of BLF-2000

Torque control

scale

Torque

control nut

Fixing nut

1

- 9 -

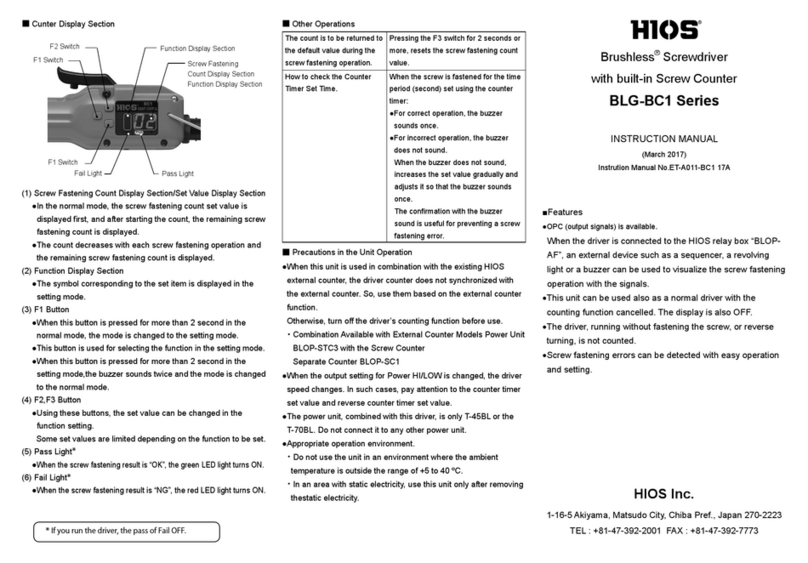

■ Names of main components of the screwdrivers

Combination table between the screwdrivers for automatic operation and the power supplies

for them

Model Convertible power supplies Number of controllable screwdrivers

BLF-2000 BLT-AY-61 1

BLF-5000

BLF-7000

BLT-AY-71 1BLF-7000X

BLF-7025X

* About the dierence between overseas specications and domestic specications of the power supply panels

The overseas specications conform to CE standard. Therefore, the POWER SW is located on the rear panel. The

ON/OFF indication lamp of the POWER SW is on the front panel side.

● For details of the power supply, please refer to the "Operation Manual" attached to the

power supply for automatic operation.

For BLF-2000 For BLF-5000 & 7000, 7000X, 7025X

Joint Shaft

Collar

Torque Adjustment nut

(BLF-2000 adopts double lock nut

mechanism)

Torque

control scale Flange Connector

About ange

2

6

4

8

Brushless

Driver

Made in Japan

BLF-5000

R

R

Power supply

BLT-AY-61/BLT-AY-71 (for controlling one screw driver)

- 10 -

■ Specications of the screwdrivers

Model

BLF series BLF-2000 BLF-5000 BLF-7000 BLF-7000X BLF-7025X

BLFQ series BLFQ-2000 BLFQ-5000 BLFQ-7000 - -

BLFR series - BLFR-5000 - BLFR-7000X BLFR-7025X

Controlled

Torque

Range

N・m 0.03 - 0.35 0.3 - 1 0.7 - 2 0.7 - 2 1.2 - 2.5

Ibf・in 0.26 - 3.0 2.6 - 8.8 6 - 17 6 - 17 9 - 22

(kgf・cm) (0.3 - 3.5) (3 - 10) (7 - 20) (7 - 20) (10 - 25)

Torque Switching Stepless adjustment

Unloaded

Rotation Speed

(r.p.m)

±

10%

11steps

switching

LOW rotation

05 - 15 120 - 345

r.p.m 115 - 320

r.p.m 150 - 450

r.p.m 150 - 450

r.p.m 120 - 350

r.p.m

HI rotation

20 - 30 690 - 975

r.p.m 660 - 940

r.p.m 495 - 735

r.p.m 495 - 735

r.p.m 400 - 600

r.p.m

Available

screws (mm)

Machine screw 1.0 - 2.3 2.0 - 3.0 3.0 - 4.0 3.0 - 4.0 3.0 - 4.0

Tapping screw 1.0 - 2.0 2.0 - 2.6 3.0 - 4.0 3.0 - 4.0 3.0 - 4.0

Bit Drive*1

BLF series HIOS H4(∅4) HIOS H5 and

5HEX (both can

be used) HIOS H5(∅5) 1/4HEX 1/4HEX

BLFQ series - -

BLFR series -

∅4(screw type)

-

∅4(screw type) ∅4(screw type)

Weight (g)*2

BLF series 315g 470g 700g 700g 700g

BLFQ series 390g 560g 830g - -

BLFR series - 700g - 1,070g 1,070g

Included

Accessories

Driver

cord

Cord length (m) 3m (10P)

Weight (g) 320g

Order Code BLF7-0611

Spring Silver - - - -

*1 Bit drive "1/4" is HEX 6.35mm, 5HEX is HEX 5mm.

*2 The weight (g) does not include the driver cord.

· The suction (vacuum attachment) for BLFR-7025X is available as a custom-made item. Please

feel free to ask us.

(Caution)

The controlled torque range of BLF-7000 series may be different from the value in the table

according to the working conditions.

- 11 -

Output torque guide (HI)

* BLF-2000 includes two Torque Adjustment springs. The silver spring is for high torque, while the black spring

installed to the main body is for low torque.

Please use the right spring according to your work.

・The above show the measurement results with a rotation speed of 30. Please use it as a reference.

・The torque values were measured by HIOS Torque Meter HP with a Fidaptor.

■

Exterior dimensions and details of the screwdrivers

See the details for each machine type.

2

6

4

8

Brushless

Driver

Made in Japan

BLF-5000

R

R

∅ 20a

b

L

Exterior dimensions ● Driver Cord Dimensions

Model

Total Length

(mm)

Diameter of

body(∅)

Connector

height (mm)

L a b

BLF-2000 124mm ∅ 38 7mm

BLF-5000 148mm ∅ 40 6.7mm

BLF-7000

160mm ∅ 42 6.7mmBLF-7000X

BLF-7025X

* The concavity and convexity are not considered for the dimensions.

Part Number: BLF7-0611

40mm

Cord Length 3m 16mm

BLF-2000*

Torque scale

Silver

Black

(Installed)

Torque scale Torque scale

BLF-5000 BLF-7000 series

- 12 -

■ Figure of installation dimensions

● BLF-2000 (H4)

● BLF-5000 (H5)

● BLF-7000 (H5)

●

BLF-7000X / BLF-7025X (1/4HEX)

ȍ

5

5

ȍ㸲

ȍ

03

5LJKWKDQGHG㻌VFUHZ

ȍ

ȍ

s

* The ange can be removed by

rotating it counterclockwise.

* The ange can be removed

by rotating it clockwise.

KROHVȍ

ȍ

5

ȍ

03

/HIWKDQGHG㻌VFUHZ

ȍ

ȍ

ȍ

s

KROHVȍ

ȍ

5

ȍ

s

ȍ

ȍ

ȍ

03

/HIWKDQGHG㻌VFUHZ

ȍ

ȍ

+(;

s

03

/HIWKDQGHG㻌VFUHZ

KROHVȍ

ȍ

5

㻌+(;

(Note) General tolerance is applied to the external dimensions with-

out tolerance indication above.

* The ange can be removed

by rotating it clockwise.

- 13 -

■ Suction (Vacuum) Attachment BLFQ series

As for vacuum pick up screwdriver, we deal with BLFQ (standard) and BLFR (custom-made)

Exterior view of BLFQ

BLFQ accessories list

Model

Mouthpiece Bit Suction Attachment

ASSY Accessories

Model

number Length Length

(L) Diameter Model number

BLFQ-2000 F3 18mm 60mm HIOS H4( ∅ 4) BLFQ2-SET With Hose (Hose size:

Inner diameter ∅ 4 ×

Outer diameter ∅7;

Length: 3.5m)

BLFQ-5000 F6 31mm 100mm HIOS H5( ∅ 5) BLFQ5-SET

BLFQ-7000 F6 31mm 100mm HIOS H5( ∅ 5) BLFQ7-SET

* When you use BLFQ series, please attach the mouthpiece / bit / Suction Attachments in the table (optional

parts).

・

Please contact us about the bit type of 1/4 HEX (hex bit with distance across the ats is 6.35 mm) for BLFQ-

7000.

Mouthpiece

The model numbers of the mouthpieces holding the screws are as follows:

F3 (supports BLFQ-2000) F6 (supports BLFQ-5000 and BLFQ-7000)

Adjustment of mouthpiece (Only the mouthpieces of BLFQ

series are adjustable.)

The length of the screw protrudes from the mouthpiece can

be adjusted.

1. Rotate both the A part and B part at the same time to loosen.

2. Rotate the A part to open the holder; you can then adjust the length of the screw protrudes

from the mouthpiece.

3. Once adjustment is completed, tighten the B part to lock while holding the A part.

Bits

The bits used in the Suction (Vacuum) Attachment are required to be longer (L length) than

standard.

L length

Mouthpiece

Suction (Vacuum) Attachment ASSY

A part

The bottom part of

the screw

B part

}

- 14 -

■ Suction (Vacuum) Attachment BLFR series

Outline

This attachment is designed to be installed in robots and makes torque adjustment and bit re-

placement easier. Because replacement is not required, it is optimal for robots.

This attachment can be eectively used for dicult screw fastening positions including deep

holes where normal attachment interferes with fastening.

(Note) If you use the BLFR screwdriver in a reverse rotation, be careful about loosening the

bit because it is screwed on.

● Features of BLFR screwdriver

・ The BLFR Mouthpiece is double mouthpiece structure with a spring. There are 2 types of

those. One is a self-adjustable inner mouthpiece type.

The other one is a self-adjustable outer mouthpiece type.

There is another special mouthpiece that does not touch work piece which prevents work

piece from damaging.

・ Compared with the existing HIOS Mouthpiece, the ultimate vacuum of the BLFR Mouthpiece

is higher which helps to reduce vacuum screw errors.

・ The edge of the BLFR Mouthpiece touches parallel to the screw head which improves

uprightness of the screw.

・ The long Bit Holder prevents cross threaded screws.

2

6

Bit holder

Bit Holder ASSY

Screw-on type bit

Bit can be replaced by reversing itself.

Tip shape

Bit socket

(2) Bit

(screw type)

Length

(3) Mouthpiece with spring

(Refer to "P.16-17.”) Torque Adjustment nut

・Torque can be adjusted without

removing the cover.

(1) Suction Attachment ASSY

Exterior view of BLFR

<Interior structure>

- 15 -

BLFR accessories list (Table 1)

Model

(1) Suction At-

tachment ASSY (2) Bit (screw type) Bit Holder ASSY

Order Code Tip

Shape Order

Code Length Diameter Order Code Length Bit drive

BLFR-5000 BLFR5-SA + #1 RBP4140S 40mm ∅4 BLFR5-3060 122.8

mm 5HEX

#2 RBP4240S

BLFR-7000X BLFR7-SA + #1 RBP4140S 40mm ∅4 BLFR7-3060 122.8

mm 1/4HEX

#2 RBP4240S

BLFR-7025X BLFR7-SA + #1 RBP4140S 40mm ∅4 BLFR7-3060 122.8

mm 1/4HEX

#2 RBP4240S

* The hose is optional. (Hose size: Inner diameter ∅ 4.6 × Outer diameter ∅ 6; Hose length: 3.5m)

・

Please refer to the cross recess size and screw size below.

#0 (M1.4 - M1.7) #1 (M2.0 - M2.6) #2 (M3.0 - M5.0)

● Please check below before purchasing the BLFR series:

BLFR accessories list (Table 1): (1) Suction Attachment ASSY, and (2) Bit, and

Size of spring-loaded mouthpiece suitable for operation (Table 2) need to be selected.

Please refer to pages 16 and 17 for the type of spring loaded mouthpiece and appli-

cable screws to select the most suitable size for your work.

(Accessories are optional.)

* If you have any questions, please contact us.

- 16 -

■ Identication of the BLFR Mouthpiece Order Code

Symbol of Mouthpiece: F (F6, F3)

Spring: S → with spring

Classications of driver torque range: 6 (Only 6 is available at this moment)

Type of Mouthpiece:

1 → Self-adjustable inner mouthpiece type

0 → Self-adjustable outer mouthpiece type

Mouthpiece Inner Diameter: e.g. 80 →φ 8.0

Material/Shape:

J → POM / A→ Aluminum / S→ Stepped

FS60-80J

■ Types of spring loaded mouthpiece (attachable to BLFR-5000 and BLFR-7000 series)

● Self-adjustable inner mouthpiece type

Order Code: FS61-68

Φ6.8

Φ8

17.5

as vacuuming

a screw

Order Code: :FS61-68S

Φ5.6 Φ4

as vacuuming

a screw

Order Code: FS61-74

Φ9 Φ7.4

as vacuuming

a screw

* Neither the inner mouthpiece (FS61-68S) nor the outer mouthpiece damage the workpiece

during operation, because they can pick up screws without touching the workpiece.

- 17 -

● Self-adjustable outer mouthpiece type

Order Code: FS60-68J・FS60-68A

Φ8 Φ6.8

17.4

7.6

POM: FS60-68

Stepped: FS60-68A

as vacuuming

a screw

Order Code: FS60-80J

Φ10 Φ8

as vacuuming

a screw

Adaptive screw size indications (Table 2)

Screw Size M2.6 M3.0 M4.0

Screw Type Pan Binding Truss Pan Binding Truss Pan Binding Truss

Model

BLFR-5000

FS61-68

FS61-68S

FS61-68

FS61-68S

FS61-68S

FS61-74 FS61-74 - -

BLFR-7000X FS60-68J / FS60-68A -

FS60-80J

M4.0 or

larger

-

BLFR-7025X FS60-68J / FS60-68A -

FS60-80J

M4.0 or

larger

-

- 18 -

●Movements of the inner mouthpiece

Vacuum starts.

Sealing with a screw

Engagement with

vacuum

Sliding mouthpiece

Mouthpiece spring

Mouthpiece holder

●Movements of the outer mouthpiece

Sliding mouthpiece

Vacuum starts.

Sealing with a screw

Engagement with

vacuum

* Because the mouthpiece is thinner than the screw’s outer diameter, you can eectively fasten the

screw in a narrow space.

●Comparison in case of screw fastening at a slant:

e.g.) 4mm screw is tightened with the pilot hole deviated from the straight position by 1.5mm.

10°

1°

Fulcrum

Fulcrum

・The screw doesn’t fall because

of the high fulcrum.

・The screw falls because of the

deviation of the pilot hole.

BLFR series Normal screwdriver

* With a long bit holder, a screw doesn’t fall and slanted fastening can be prevented.

The sliding mouthpiece

moves horizontally to

hold the screw head and

keeps it straight.

The sliding mouthpiece moves hori-

zontally to hold the screw head and

keeps it straight.

- 19 -

●Variations

Length of mouthpiece + holder

Standard(85L)

2

6

85

87.4

17.4

・The standard total length of a mouthpiece and a holder is 85L. 32L, 56L, 60L, 95L and 125L

are available as customized specications.

For deeper holes

Mouthpiecestopper

Mouthpiecespring

Mouthpiece

Mouthpieceholder

85

27

22.4

・For deeper holes, the mouthpieces of 41L and 61L are available in addition to 27L.

・Furthermore, for a hole depth of 2.6 mm or smaller, we can prepare a customized mouthpiece.

However, please note that because the customized mouthpiece becomes thinner toward the

tip, the vacuum pressure tends to be weak.

* The customized mouthpieces may take longer for delivery depending on the stock status.

Please make an inquiry before placing an order.

- 20 -

■ Exterior dimensions of the suction attachments

● BLFQ-2000 (Mouthpiece: F3 Length: 18mm as standard)

● For bit H4-60mm, dimension from tip of bit to ange is 79.1mm

● Dimension of *part depends on the actual length of bit.

ȍ

ȍ

ȍ

ȍ

*

*

● BLFQ-5000 (Mouthpiece: F6 Length: 31mm as standard)

*

● For bit H5-100mm, dimension from tip of bit to flange is 117.8mm

● Dimension of *part depends on the actual length of bit.

● BLFR-5000 (installed FS60-68J)

2

6

4

102

35.1

Tilt angle 45゜360゜rotation

70

85

17

17.4

196.2

2.4

φ12

φ8

Unit: mm

This manual suits for next models

7

Table of contents

Other HIOS Power Screwdriver manuals

HIOS

HIOS VZH-1820 User manual

HIOS

HIOS CL-9000NL User manual

HIOS

HIOS JUKUREN BLG-BC2 series User manual

HIOS

HIOS VB Series User manual

HIOS

HIOS BLG-7000BC2-GT-S User manual

HIOS

HIOS DCD-40L User manual

HIOS

HIOS JUKUREN BLG-BC2 series User manual

HIOS

HIOS CL-9000 User manual

HIOS

HIOS CL-2000 Installation manual

HIOS

HIOS BLG Series User manual

Popular Power Screwdriver manuals by other brands

Würth

Würth ASS 14-1/4" Translation of the original operating instructions

EINHELL

EINHELL TE-CD 18/2 Li Original operating instructions

DeWalt

DeWalt DCF620 Original instructions

Lux Tools

Lux Tools A-BS-20-D instruction manual

Erbauer

Erbauer ECDT18-Li-2 Original instructions

Conrad

Conrad 2524385 operating instructions