HIOS DCD-40L User manual

Current-Controlled Screwdriver

DCD-40L (115W)

Instruction Manual

ET-A070 19A

HIOS Inc.

2/ 52

■ Introduction

This manual describes the touch panel operations and functions of the screwdriver.

■ Abbreviations and terminology

The abbreviations and terminology used in this manual are defined in the table below.

Abbreviation/terminology Definition

SVC or controller SV-NET Controller

SVD or driver SV-NET compatible driver

Servo motor or motor AC servo motor

3/ 52

Contents

■Introduction..........................................................................................................................................................................2

■Abbreviations and terminology ............................................................................................................................................2

Contents ...................................................................................................................................................................................3

1. Startup screen.......................................................................................................................................................................5

2. Main screen ..........................................................................................................................................................................6

3. [Program Preview] screen.....................................................................................................................................................7

3.1 Screen display items .......................................................................................................................................................7

■Screen display items (buttons) .....................................................................................................................................7

■Screen display items (numeric values).........................................................................................................................8

4. [Operate] screen ...................................................................................................................................................................9

4.1 Screen display items .......................................................................................................................................................9

■Screen display items (buttons) .....................................................................................................................................9

■Screen display items (numeric values, lamps) ...........................................................................................................10

5. [Monitor Operate] screen .................................................................................................................................................... 11

5.1 Screen display items ..................................................................................................................................................... 11

■Screen display items (buttons) ................................................................................................................................... 11

■Screen display items (numeric values).......................................................................................................................12

■Screen display items (lamps) .....................................................................................................................................12

6. [Edit] screen........................................................................................................................................................................13

6.1 Password input..............................................................................................................................................................13

■Screen display items (numeric input) .........................................................................................................................14

■Screen display items (buttons) ...................................................................................................................................15

7. [HIOS] setting screen..........................................................................................................................................................16

7.1 Password input..............................................................................................................................................................17

■Screen display items (numeric input) .........................................................................................................................18

8. Operation parameters .........................................................................................................................................................20

■Parameter settings for each operation pattern...............................................................................................................20

■Parameter setting range for operation patterns..............................................................................................................21

■Parameter setting range for special settings..................................................................................................................23

9. Operation pattern timing charts...........................................................................................................................................26

■Pattern 1 ........................................................................................................................................................................26

■Pattern 2 ........................................................................................................................................................................27

■Pattern 3 ........................................................................................................................................................................28

■Pattern 4 ........................................................................................................................................................................29

10. Manual/auto mode ............................................................................................................................................................30

■Manual mode .................................................................................................................................................................30

■Auto mode......................................................................................................................................................................31

11. I/O .....................................................................................................................................................................................31

11.1 I/O allocation table.......................................................................................................................................................31

4/ 52

■I/O input signals..........................................................................................................................................................31

■I/O output signals .......................................................................................................................................................32

11.2 I/O input signal reception time table ............................................................................................................................32

■I/O input signals..........................................................................................................................................................32

11.3 I/O input signal sequence ............................................................................................................................................34

■Sequence of each input control signal........................................................................................................................34

■Output status signals..................................................................................................................................................35

11.4 I/O input timing charts..................................................................................................................................................36

■Timing chart for normal operations when torque judgment is OK...............................................................................36

■Timing chart for normal operations when torque judgment is NG...............................................................................37

■Timing chart when emergency stop signal is input .....................................................................................................38

12. Message window ..............................................................................................................................................................39

■Displayed messages......................................................................................................................................................39

■Message list...................................................................................................................................................................43

13. System settings.................................................................................................................................................................44

■Displaying the system settings screen ...........................................................................................................................44

■Checking the screw tightening OK judgment count........................................................................................................44

■Checking the total number of screw tightening OK judgments.......................................................................................44

■You can check the total number of times that the screw tightening OK judgment has been counted. ...........................44

14. Button touch operations ....................................................................................................................................................45

15. Holding time......................................................................................................................................................................46

■Holding time setting .......................................................................................................................................................46

16. Detailed pattern diagrams.................................................................................................................................................47

■Chattering judgment.......................................................................................................................................................47

17. Alarms...............................................................................................................................................................................49

17.1 Error list (motor driver errors) ......................................................................................................................................49

17.3 Error list (SVC errors) ..................................................................................................................................................52

■Startup screen

5/ 52

1. Startup screen

The title screen is displayed when the touch panel first starts up.

After a few moments, the main window is displayed.

Fig.1-1 Title screen

■Main screen

6/ 52

2. Main screen

On the main screen, select the screen that you want to display.

Touch a button to display the corresponding screen.

Fig.2-1 Main screen

If the external I/O is set to auto operation mode input, operation starts when the external I/O start signal is ON, even while the

main window is displayed.

* If the external I/O channel No. and pattern No. are not selected, an operation error (103) occurs.

The [Program Preview] screen and [Edit] screen cannot be opened in auto operation mode.

■[Operate] screen

7/ 52

3. [Program Preview] screen

On the [Program Preview] screen, you can select the tightening operation pattern, load the saved parameters, and check the

parameters.

Fig.3-1 [Program Preview] screen (1/2)

Fig.3-2 [Program Preview] screen (2/2)

3.1 Screen display items

■ Screen display items (buttons)

Screen display

button

Description

Select the channel No. Touch the [▲] button to increase the number, and touch the [▼] to decrease

it.

A value from 1 to 8 can be selected.

Select the pattern No. Touch the [▲] button to increase the number, and touch the [▼] to decrease

it.

A value from 1 to 4 can be selected.

Load the saved parameters for the combination of channel No. and pattern No.

When loading is complete, the [Data loaded] message window is displayed.

Display the next or previous page to check the parameters.

Return to the main screen.

■[Operate] screen

8/ 52

■ Screen display items (numeric values)

Numeric value

display item

Description

Angle 1

(Rotation angle 1)

Rotation angle setting for temporary tightening. The unit is ° (degrees).

Angle 2

(Rotation angle 2)

Rotation angle setting for loosening. The unit is ° (degrees).

Angle 3

(Rotation angle 3)

Rotation angle setting for additional tightening. The unit is ° (degrees).

Rotation 1

(Rotation speed 1)

Rotation speed setting for temporary tightening. The unit is rpm.

Rotation 2

(Rotation speed 2)

Rotation speed setting for full tightening, loosening, and additional tightening. The unit is rpm.

Trq 1

(Torque 1)

Torque setting that is applied when switching from temporary tightening to full tightening. The unit is

N.m.

Trq 2

(Torque 2)

Limit torque setting for full tightening. The unit is N.m.

Trq 3

(Torque 3)

Limit torque setting for tightening. The unit is N.m.

Cycle TM

(Cycle time)

Time setting for the full set of screw tightening operations. The unit is sec.

An error is displayed if the specified time is exceeded.

Hold TM

(Holding time)

Holding time setting for screw tightening judgment. The unit is ms. * See Chapter 15 "Holding time".

Torque allowance

(Torque judgment

range)

Setting range value for when motor torque value judgment is performed in screw tightening judgment.

The unit is ±%.

Example: When the torque judgment range is ±10% for a torque setting of 1 N.m, the judgment is OK

if the torque is from 0.9 N.m to 1.1 N.m. * See Chapter 16.

Counter (Torque

judgment counter)

Setting for number of times that normal motor torque value is detected, for screw tightening judgment.

The judgment is OK if the number of times that the normal motor torque value is detected is within the

range.

The judgment is NG if the number of times that the normal motor torque value is detected is outside

the range. * See Chapter 16.

■[Operate] screen

9/ 52

4. [Operate] screen

On the [Operate] screen, start the screw tightening operations using the parameters that have been set.

Fig.4-1 [Operate] screen

4.1 Screen display items

■ Screen display items (buttons)

Screen display button

Description

When button is

enabled

Start the screw tightening operation for the specified channel No. and pattern

No.

- In manual mode

- Before starting

operation

- When alarm

reset IN (IN 12) is

OFF

Stop the screw tightening operation while it is being performed. - In manual mode

[CW] (Clockwise)/[CCW] (Counterclockwise)

Select the rotation direction for screw tightening.

This setting cannot be changed while screw tightening operation is being

performed.

- In manual mode

- Before starting

operation

When an error occurs, the [Error No.] and [Error Reset] buttons are

displayed.

After removing the cause of the error, touch the [Error Reset] button to clear

the error display.

- Always enabled

Return to the main screen. - Always enabled

[Rev] (Reverse)

The screwdriver rotates in the screw loosening direction while this button is

touched.

- In manual mode

- Before starting

operation

■[Operate] screen

10 / 52

■ Screen display items (numeric values, lamps)

Screen display item Description

The currently selected channel No. and pattern No. are displayed.

The start and finish status of the screw tightening operation is indicated.

[Strt] (Start): Lights up while screw tightening operation is being performed.

[Fin] (Finish): Lights up for 100 ms after screw tightening operation is complete.

The status of the screw tightening operation is indicated.

[Tmp] (Temporary tightening): The screw is being temporarily tightened.

[Full] (Full tightening): The temporary tightening operation has finished, and the

screw is being fully tightened.

[Add] (Additional tightening): The full tightening operation has finished, and the

screw is being additionally tightened.

The direction of the screw tightening operation is indicated.

[CW] (Clockwise): Screw tightening direction

[CCW] (Counterclockwise): Screw loosening direction

The current mode is indicated.

[Manl] (Manual): Manual mode

[Auto] (Auto): Auto mode

When an error occurs, the [Error No.] and [Error Reset] buttons are displayed.

The error No. of the current error is displayed.

The status of the screw tightening operation is indicated.

[START OUT]: Lights up while screw tightening operation is being performed.

[FINISH OUT]: Lights up for 100 ms after screw tightening operation is complete.

■[Monitor Operate] screen

11 / 52

5. [Monitor Operate] screen

On the [Monitor Operate] screen, start the screw tightening operations using the parameters that have been set.

Various information about the motor can be checked.

Fig.5-1 [Monitor Operate] screen

5.1 Screen display items

■ Screen display items (buttons)

Screen display button Description

When button is

enabled

Start the screw tightening operation for the specified channel No. and

pattern No.

- In manual mode

- Before starting

operation

- When alarm reset

IN (IN 12) is OFF

Stop the motor while operation is being performed. - In manual mode

[Manual]

[Auto]

Switch between manual mode and auto mode.

The mode cannot be changed when auto ON is input from the external

I/O.

* These buttons can be used to switch the mode only while the [Monitor

Operate] screen is open.

When you return to the main screen, the mode automatically switches to

manual mode.

- Before starting

operation

[Clockwise]

[Counter-

clockwise]

Select the rotation direction for screw tightening.

These buttons are enabled only in manual mode.

The direction cannot be changed while the screw tightening operation is

being performed.

- In manual mode

- Before starting

operation

Clear the current error from the error display. - Always enabled

Return to the main screen. - Always enabled

[Rev] (Reverse)

The screwdriver rotates in the screw loosening direction while this button

is touched.

- In manual mode

- Before starting

operation

■[Monitor Operate] screen

12 / 52

■ Screen display items (numeric values)

Screen display

item

Description

The currently selected channel No. and pattern No. are displayed.

Rotation

(Rotation speed)

The motor rotation speed is displayed in units of rpm.

Motor trq

(Motor torque)

The motor torque is displayed in units of N.m.

Angle

(Rotation angle)

The current rotation angle is displayed in units of ° (degrees).

Hold time

(Holding time)

The holding time for the screw tightening operation is displayed in units of ms.

* See Chapter 15 "Holding time".

Error No. The error No. of the current error is displayed. For details, see the "Error list" sections.

■ Screen display items (lamps)

Screen display item Description

The start and finish status of the screw tightening operation is indicated.

[Strt] (Start): Lights up while screw tightening operation is being performed.

[Fin] (Finish): Lights up for 100 ms after screw tightening operation is complete.

The status of the screw tightening operation is indicated.

[Tmp] (Temporary tightening): Temporary tightening is being performed on the

screw.

[Full] (Full tightening): The temporary tightening operation has finished, and full

tightening is being performed.

[Add] (Additional tightening): The full tightening operation has finished, and

additional tightening is being performed.

The direction of the screw tightening operation is indicated.

[CW] (Clockwise): Screw tightening direction

[CCW] (Counterclockwise): Screw loosening direction

The status of the screw tightening operation is indicated.

[START OUT]: Lights up while screw tightening operation is being performed.

[FINISH OUT]: Lights up for 100 ms after screw tightening operation is complete.

■[Edit] screen

13 / 52

6. [Edit] screen

Configure the various parameter settings that are necessary for the screw tightening operations.

Configured settings can be saved or loaded for each channel No. and pattern No.

Touch a numeric value input field to enter a value using the numeric keys. For details about each numeric value input field

and each button, see the screen display item descriptions below.

Fig.6-1 [Edit] setting screen (1/2)

Fig.6-2 [Edit] setting screen (2/2)

6.1 Password input

A password must be entered in order to display the [Edit] screen.

Touch the numeric keys displayed on the screen to enter the password. (The factory default setting is a four-digit password

{8104}, and a password of up to eight digits can be set.)

Touch the [BS] button to delete the last digit.

Touch the [CLR] button to delete all digits.

Touch the [ENT] button to log in with the password.

When the correct password is entered, the [Edit] screen is displayed. If the password is not correct, a warning message is

displayed. If no password is entered for one minute, the main screen is automatically displayed again.

6.3 Password input screen

Use numeric

keys to enter

Please Enter Password

1

2

3

4

5

BS

ENT

6

7

8

9

0

CLR

ESC

Level 1 or above

■[Edit] screen

14 / 52

6.2 Screen display items

■ Screen display items (numeric input)

Numeric input item Description

Angle 1

(Rotation angle 1)

Rotation angle setting for temporary tightening. The unit is ° (degrees).

Angle 2

(Rotation angle 2)

Rotation angle setting for loosening. The unit is ° (degrees).

Angle 3

(Rotation angle 3)

Rotation angle setting for additional tightening. The unit is ° (degrees).

Rotation 1

(Rotation speed 1)

Rotation speed setting for temporary tightening. The unit is rpm.

Rotation 2

(Rotation speed 2)

Rotation speed setting for full tightening, loosening, and additional tightening. The unit is rpm.

Torque 1

(Torque 1)

Torque setting that is applied when switching from temporary tightening to full tightening. The unit is

N.m.

Torque 2

(Torque 2)

Limit torque setting for full tightening. The unit is N.m.

Torque 3

(Torque 3)

Limit torque setting for tightening. The unit is N.m.

Cycle TM

(Cycle time)

Time setting for the full set of screw tightening operations. The unit is sec.

An error is displayed if the specified time is exceeded.

Hold TM

(Holding time)

Holding time setting for screw tightening judgment. The unit is ms. * See Chapter 15 "Holding time".

Torque allowance

(Torque judgment

range)

Setting range value for when motor torque value judgment is performed in screw tightening

judgment. The unit is ±%.

Example: When the torque judgment range is ±10% for a torque setting of 1 N.m, the judgment is

OK if the torque is from 0.9 N.m to 1.1 N.m. * See Chapter 16.

Counter

(Torque judgment

counter)

Setting for number of times that normal motor torque value is detected, for screw tightening judgment.

The judgment is OK if the number of times that the normal motor torque value is detected is within the

range.

The

judgment is NG if the number of times that the normal motor torque value is detected is outside

the range. * See Chapter 16.

■[Edit] screen

15 / 52

■ Screen display items (buttons)

Screen display

button

Description

Select the channel No. Touch the [▲] button to increase the number, and touch the [▼] button to

decrease it.

A value from 1 to 8 can be selected.

Select the pattern No. Touch the [▲] button to increase the number, and touch the [▼] button to

decrease it.

A value from 1 to 4 can be selected.

Load the saved parameters for the combination of channel No. and pattern No.

When loading is complete, the [Data loaded] message window is displayed.

Save the currently configured parameters for the combination of channel No. and pattern No.

If parameters have already been saved for the combination, the data is overwritten.

When saving is complete, the [Data saved] message window is displayed.

Open the screen for

configuring special settings that apply to all operation patterns, and settings that

are specific to the motor.

Since the settings are normally configured by HIOS, a password is required in order to display the

screen.

[Next]/[Prev]

Display the next or previous page of the [Edit] screen.

Return to the main screen.

■Operation parameters

16 / 52

7. [HIOS] setting screen

Open the screen for configuring special settings that apply to all operation patterns and to settings that are specific to the

motor.

Since the settings are normally configured by HIOS, a password is required in order to display the screen.

Touch a numeric value input field to enter a value using the numeric keys. For details about each numeric value input field

and each button, see the screen display item descriptions below.

Fig.7-1 [HIOS] setting screen (1/6)

Fig.7-2 [HIOS] setting screen (2/6)

Fig.7-3 [HIOS] setting screen (3/6)

Fig.7-4 [HIOS] setting screen (4/6)

Use numeric keys

to enter values

■Operation parameters

17 / 52

Fig.7-5 [HIOS] setting screen (5/6)

Fig.7-6 [HIOS] setting screen (6/6)

7.1 Password input

A password must be entered in order to display the [HIOS] setting screen.

Touch the numeric keys displayed on the screen to enter the password. (The factory default setting is an eight-digit password

{81040000}, and a password of up to eight digits can be set.)

Touch the [BS] button to delete the last digit.

Touch the [CLR] button to delete all digits.

Touch the [ENT] button to log in with the password.

When the correct password is entered, the [HIOS] setting screen is displayed. If the password is not correct, a warning

message is displayed. If no password is entered for one minute, the main screen is automatically displayed again.

Fig.7-4 Password input screen

Please Enter Password

1 2 3 4 5 BS ENT

6 7 8 9 0 CLR ESC

Level 2 or above

■Operation parameters

18 / 52

7.2 Screen display items

■ Screen display items (numeric input)

Numeric input item Description

1st hold time w/rev

(Holding time for first full tightening in

operation patterns that include reverse

rotation)

Set the holding time for the first full tightening in operation patterns that

include reverse rotation.

The unit is ms. * See Chapter 15 "Holding time".

Tmp chat period

(Chattering judgment period for temporary

tightening)

Set the period of one scan in the current chattering jud

gment for

temporary tightening.

The unit is ms. * See Chapter 16.

Tmp chat counter

(Chattering judgment count for temporary

tightening)

Set the number of scans to perform in the current chattering judgment

for temporary tightening.

The unit is the number of times. * See Chapter 16.

Full/Add – Specified current

(Negative current value used for judgment

of whether the specified current is reached

in full tightening and additional tightening)

This is the parameter setting to use in the calculation of the current for

the torque detection judgment, to speed up torque-up detection for full

tightening and additional tightening.

The specified percentage amount is subtracted from the full tightening

and additional tightening current.

The unit is -%.

Reverse Speed

(Reverse operation speed)

Set the speed of the reverse operation. The unit is rpm.

Motor KT (spec)

(Motor KT value (specification value))

Set the KT value of the motor that is used. (Refer to the motor

specifications.)

The unit is N.m/A.

Motor KT offset

Motor KT high/low

(Motor KT value offset

+ setting torque-down

- setting torque-up)

Set the positive and negative offset value

to apply to the motor KT

value.

This corrects for the difference between the motor torque and actual

tightening torque.

The unit is N.m/A.

Torque Coeff

(Torque command correction slope

coefficient)

This correction value is applied to the torque command to stabilize it.

(Perform calculation using the correction value calculation file.)

Torque offset Coeff

(Torque command correction offset value)

This correction value is applied to the torque command to stabilize it.

(Perform calculation using the correction value calculation file.)

Motor Torque Coeff

(Motor torque correction slope coefficient)

This coefficient corrects for the difference between the motor torque

and actual tightening torque.

■Operation parameters

19 / 52

Motor Torque offset

(Wait time for angle judgment in loosening

operation)

This setting specifies the required time, based on the angle and speed

of the driver's loosening operation. The unit is ms.

Reverse stand-by

(Wait time for angle judgment in loosening

operation)

This is the setting range of the required time, calculated from the angle

and speed of the driver's loosening operation. The unit is ms.

Add angle range

(Additional tightening angle judgment

range)

This is the range

for the angle judgment in additional tightening. The

setting range is expressed in negative (-) degrees.

Reverse angle range

(Loosening angle judgment range)

This is the range for the angle judgment in loosening. The setting range

is expressed in negative (-) degrees.

Pattern 3, Reverse torque – Full

(Torque for pattern 3 loosening operation -

Negative percentage of full tightening

torque)

This setting specifies the torque for the reverse rotation, in terms of

negative torque relative to the full tightening torque, to prevent

excessive looseness in the screw when the loosening operation in

pattern 3 is performed.

The unit is -%.

Torque down filter setting

1st step

(Torque-down filter setting -

Step 1 torque)

Set this parameter to reduce the spring-back of the bit that occurs

when the servo is turned OFF after the pattern is complete.

The torque limit setting is changed based on the parameters specified

for steps 1, 2, and 3, in that order.

The unit is %. * See Chapter 16.

Torque down filter setting

2nd step

(Torque-down filter setting -

Step 2 torque)

Set this parameter to reduce the spring-back of the bit that occurs

when the servo is turned OFF after the pattern is complete.

The torque limit setting is changed based on the parameters specified

for steps 1, 2, and 3, in that order.

The unit is %. * See Chapter 16.

Torque down filter setting

3rd step

(Torque-down filter setting -

Step 3 torque)

Set this parameter to reduce the spring-back of the bit that occurs when

the servo is turned OFF after the pattern is complete.

The torque limit setting is changed based on the parameters specified

for steps 1, 2, and 3, in that order.

The unit is %. * See Chapter 16.

Torque down filter setting Wait Time

(Torque-down filter setting -

Wait time)

Set this parameter to reduce the spring-back of the bit that occurs

when the servo is turned OFF after the pattern is complete.

The wait time specifies the amount of time to wait before applying

each change to the torque limit setting.

The unit is msec. * See Chapter 16.

■Operation parameters

20 / 52

■ Screen display items (buttons)

Screen display

button

Description

Save the currently configured parameters.

If parameters have already been saved, the data is overwritten.

When saving is complete, the [特殊設定データ保存完了] (Finished saving special setting

data) message window is displayed.

[Next]/[Prev]

Display the next or previous page of the [HIOS] setting screen.

Return to the [Edit] screen.

Set whether or not to use the torque-down filter.

Select [ON] to reduce the spring-back of the bit that occurs when the servo is turned OFF

after the pattern is complete.

The torque limit setting is changed before the servo turns OFF upon completion of the pattern

operation.

The torque limit setting changes based on the parameters specified for steps 1, 2, and 3, in

that order.

The wait time specifies the amount of time to wait before applying each change to the torque

limit setting.

* See Chapter 16.

8. Operation parameters

The tables in this chapter describe the parameter settings for each operation pattern, as well as the available setting ranges

for the [Edit] screen and [HIOS] screen settings.

■ Parameter settings for each operation pattern

Operation No. Pattern 1 Pattern 2 Pattern 3 Pattern 4

Angle 1

(Rotation angle 1: °)

Specified rotation angle for temporary tightening

Angle 2

(Rotation angle 2: °)

Not used

Specified rotation angle for loosening

Angle 3

(Rotation angle 3: °) Not used

Specified rotation

angle for additional

tightening

Not used

Specified rotation

angle for additional

tightening

Rotation 1

(Rotation speed 1: rpm)

Speed for temporary tightening

Table of contents

Other HIOS Power Screwdriver manuals

HIOS

HIOS JUKUREN BLG-BC2 series User manual

HIOS

HIOS CL-9000NL User manual

HIOS

HIOS VB Series User manual

HIOS

HIOS CL-9000 User manual

HIOS

HIOS BLG Series User manual

HIOS

HIOS VZH-1820 User manual

HIOS

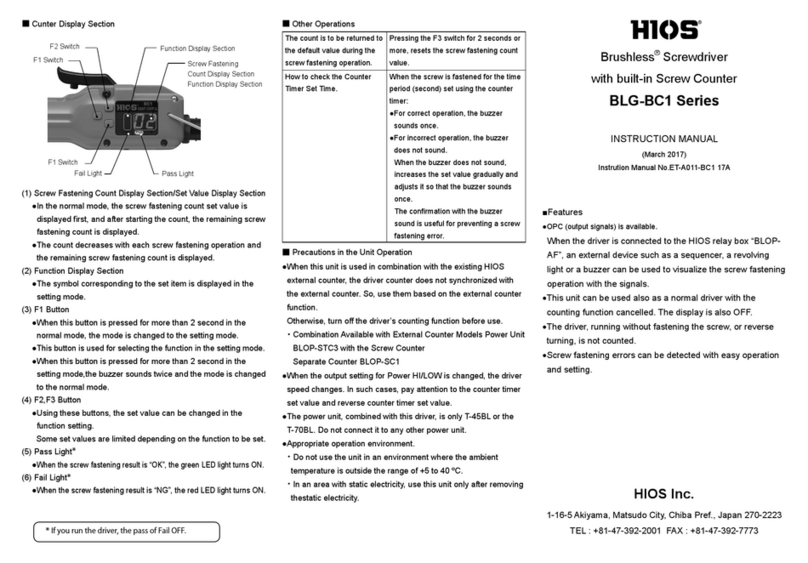

HIOS BLG-BC1 Series User manual

HIOS

HIOS JUKUREN BLG-BC2 series User manual

HIOS

HIOS BLG-7000BC2-GT-S User manual

HIOS

HIOS BLF-2000 User manual