HIRED-HAND Mega-Flow Butterfly User manual

Table of contents

Other HIRED-HAND Fan manuals

HIRED-HAND

HIRED-HAND Econo-Flow User manual

HIRED-HAND

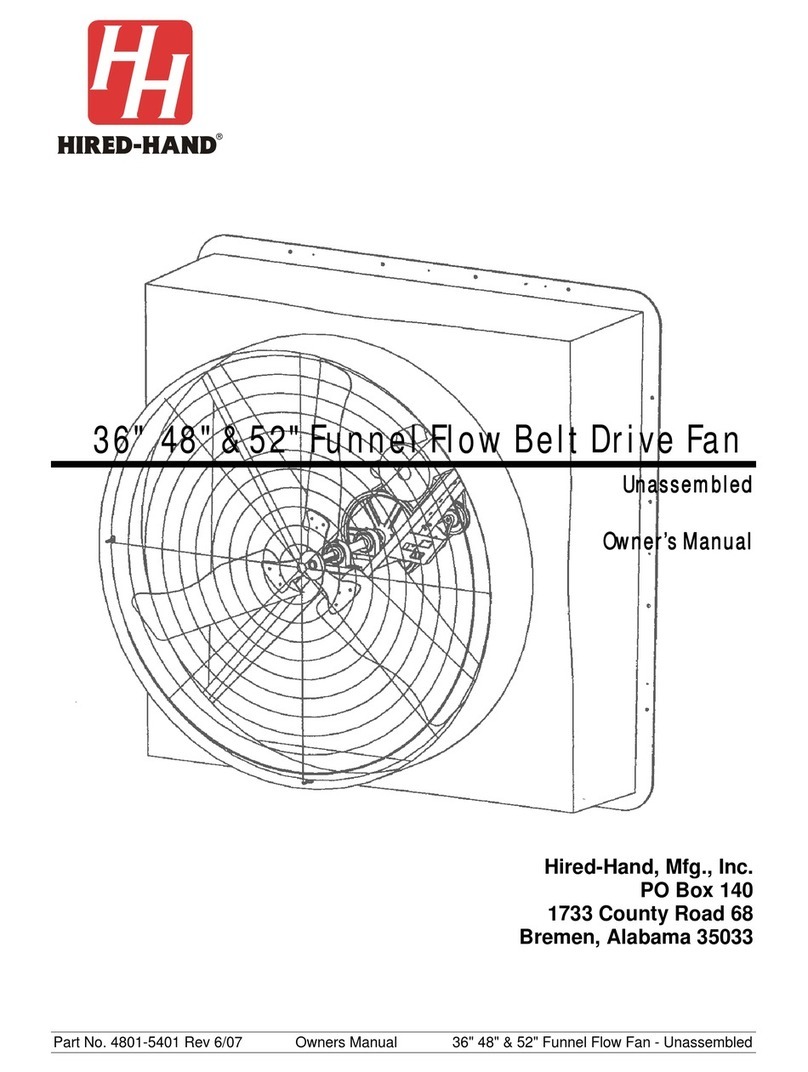

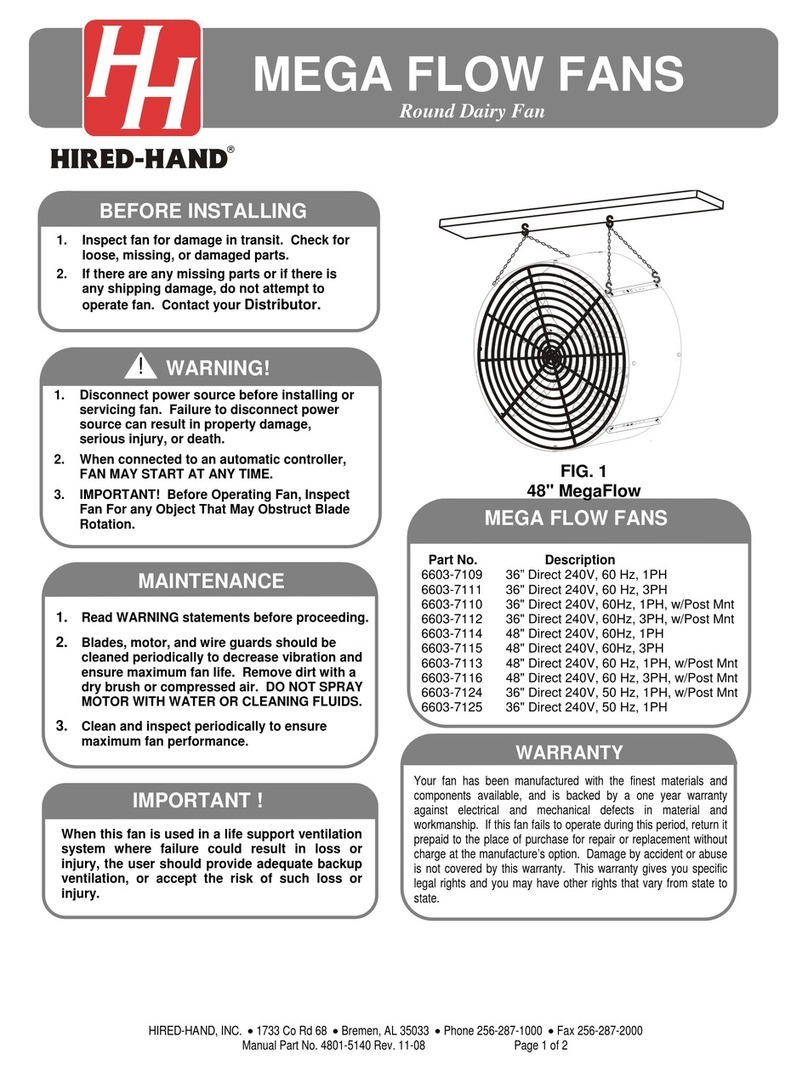

HIRED-HAND MEGA FLOW 48" User manual

HIRED-HAND

HIRED-HAND Mega Flow 6603-7109 User manual

HIRED-HAND

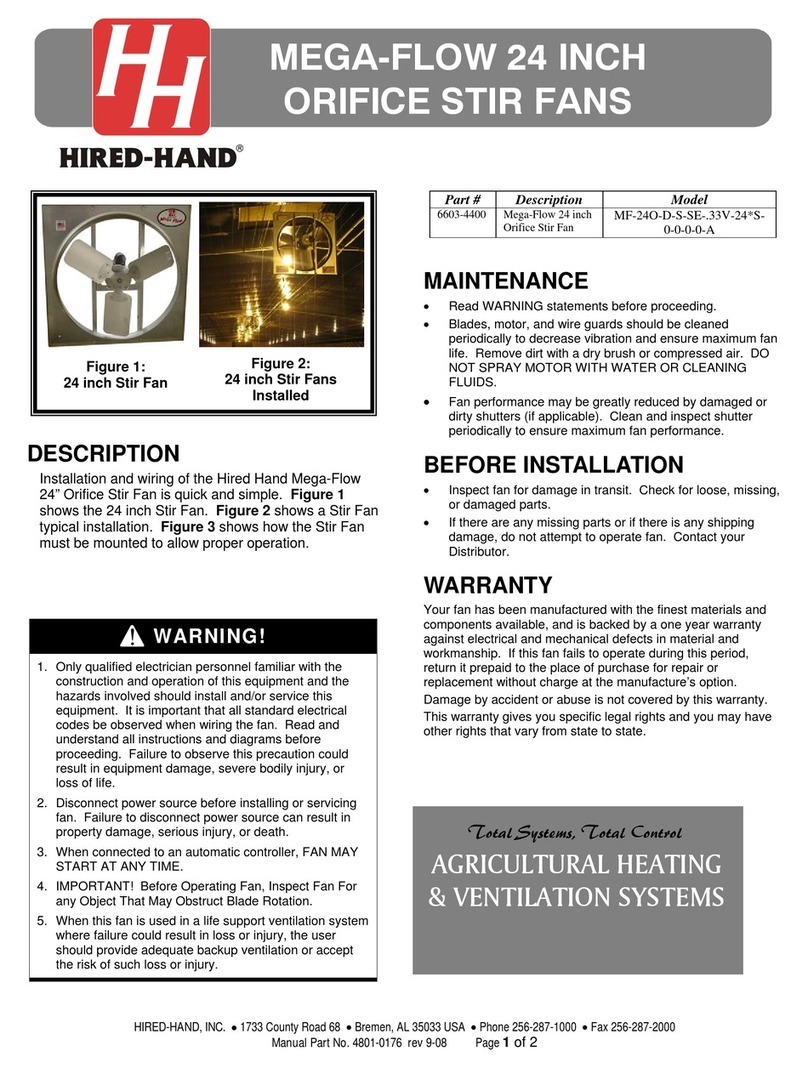

HIRED-HAND Mega-Flow MF-24O-D-S-SE Series User manual

HIRED-HAND

HIRED-HAND Econo-Flow Instruction Manual

HIRED-HAND

HIRED-HAND MEGA FLOW Use and care manual

HIRED-HAND

HIRED-HAND MEGA-FLOW MF-24O-D-S-SE Series User manual

HIRED-HAND

HIRED-HAND Econo-Flow User manual

HIRED-HAND

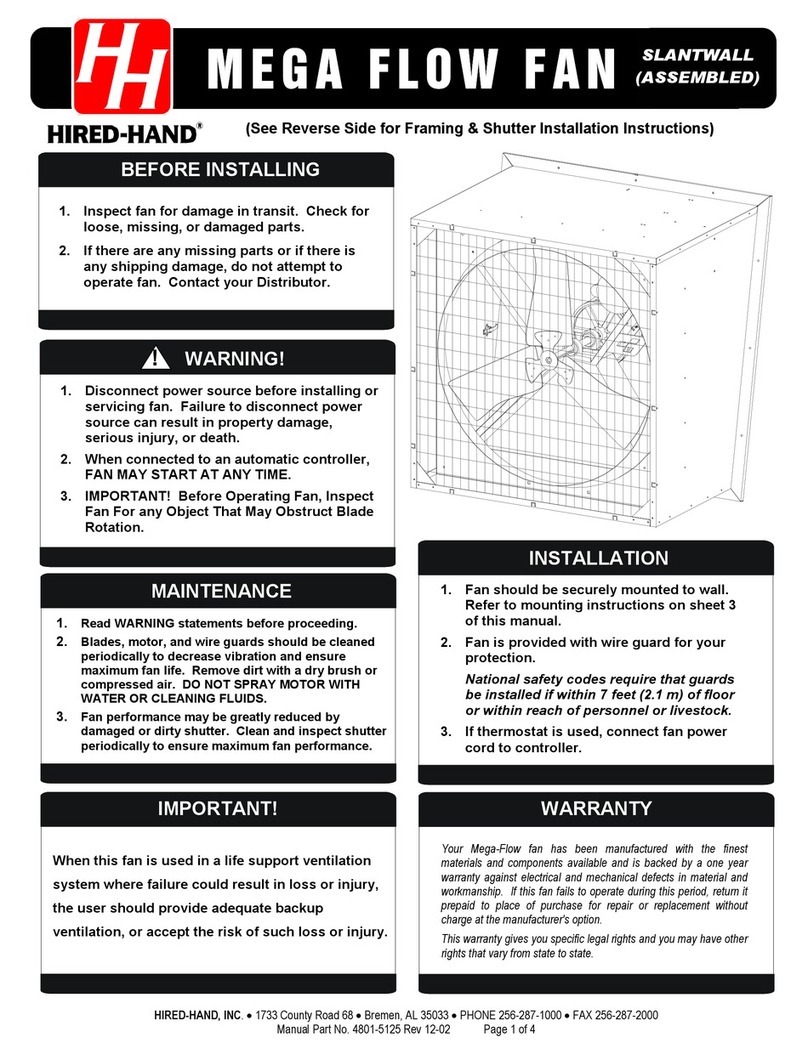

HIRED-HAND Mega Flow Slantwall User manual

HIRED-HAND

HIRED-HAND Super-Saver Bunsen Jet User manual

Popular Fan manuals by other brands

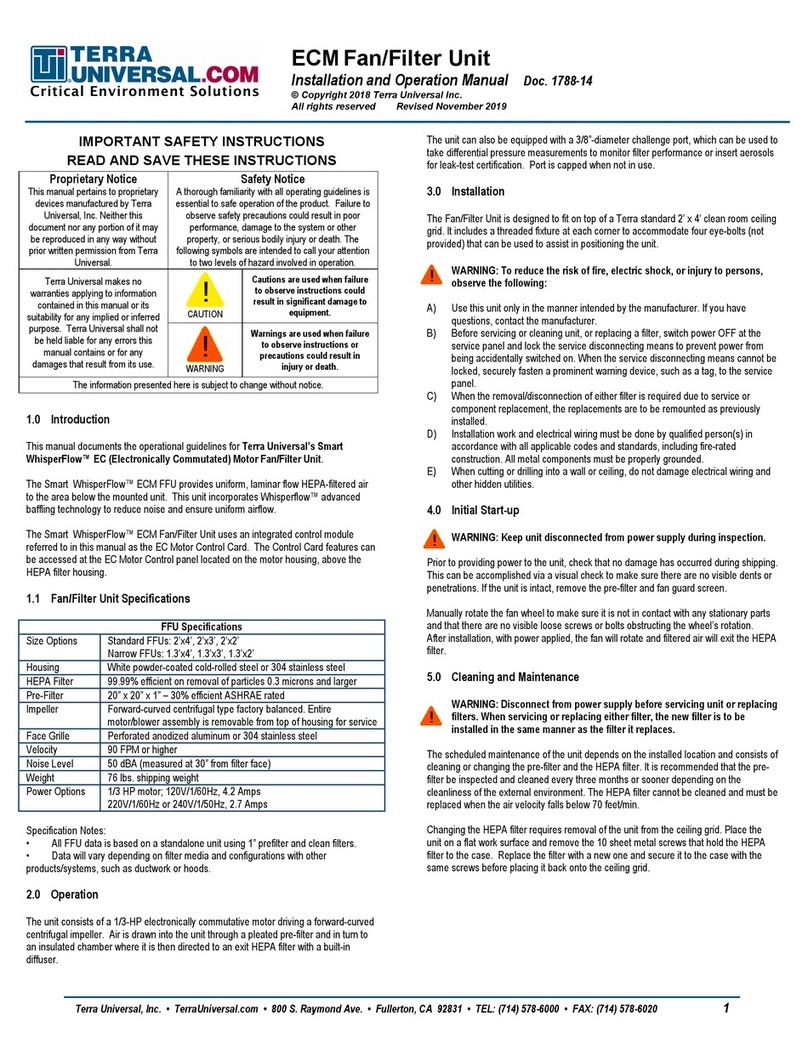

Terra Universal

Terra Universal Smart WhisperFlow Installation and operation manual

Salda

Salda RIRS 400HE/HW EKO 3.0 Technical manual

DeWalt

DeWalt DXF2475 manual

Inverter

Inverter iV-Office installation instructions

Bestron

Bestron DFT35W User instructions

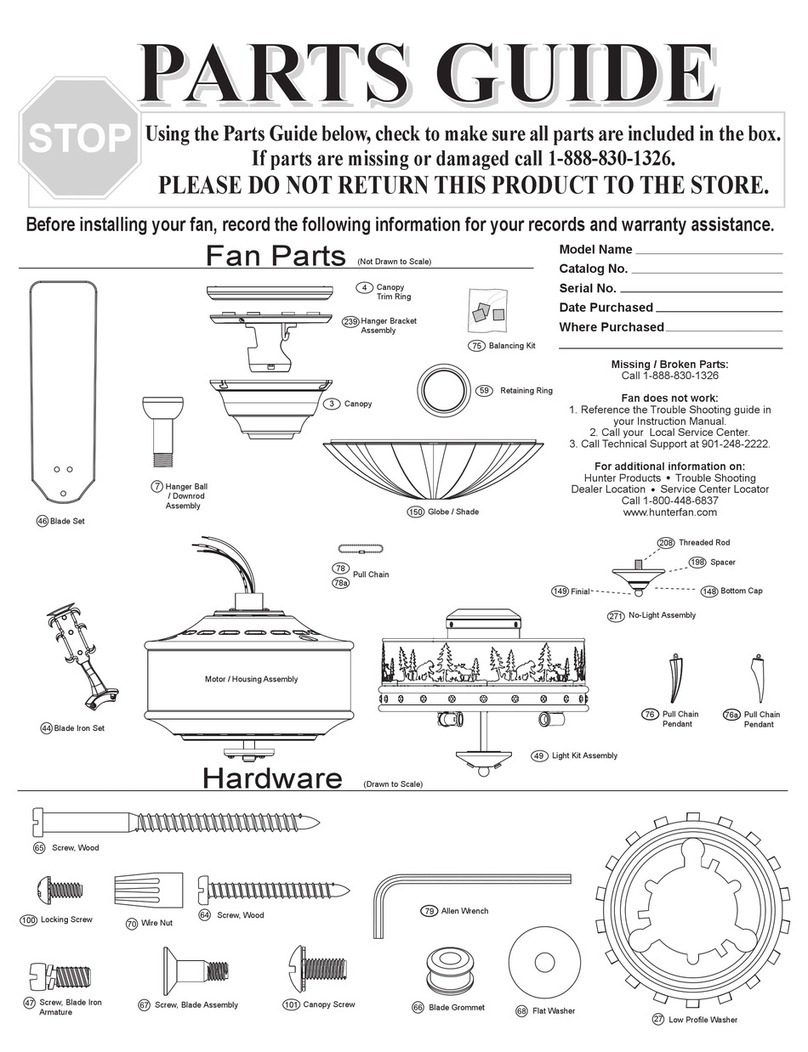

Hunter

Hunter Builder Low Profile instruction manual