HIRED-HAND Funnel Flow 36 User manual

This manual suits for next models

2

Table of contents

Other HIRED-HAND Fan manuals

HIRED-HAND

HIRED-HAND Econo-Flow User manual

HIRED-HAND

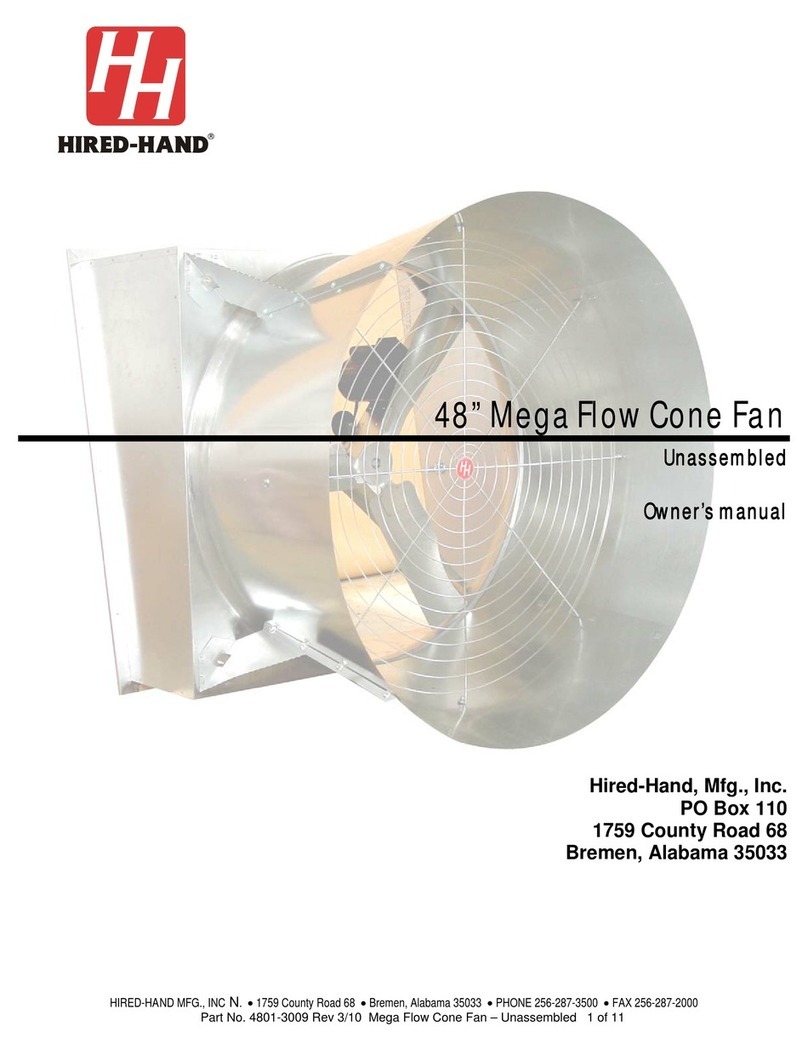

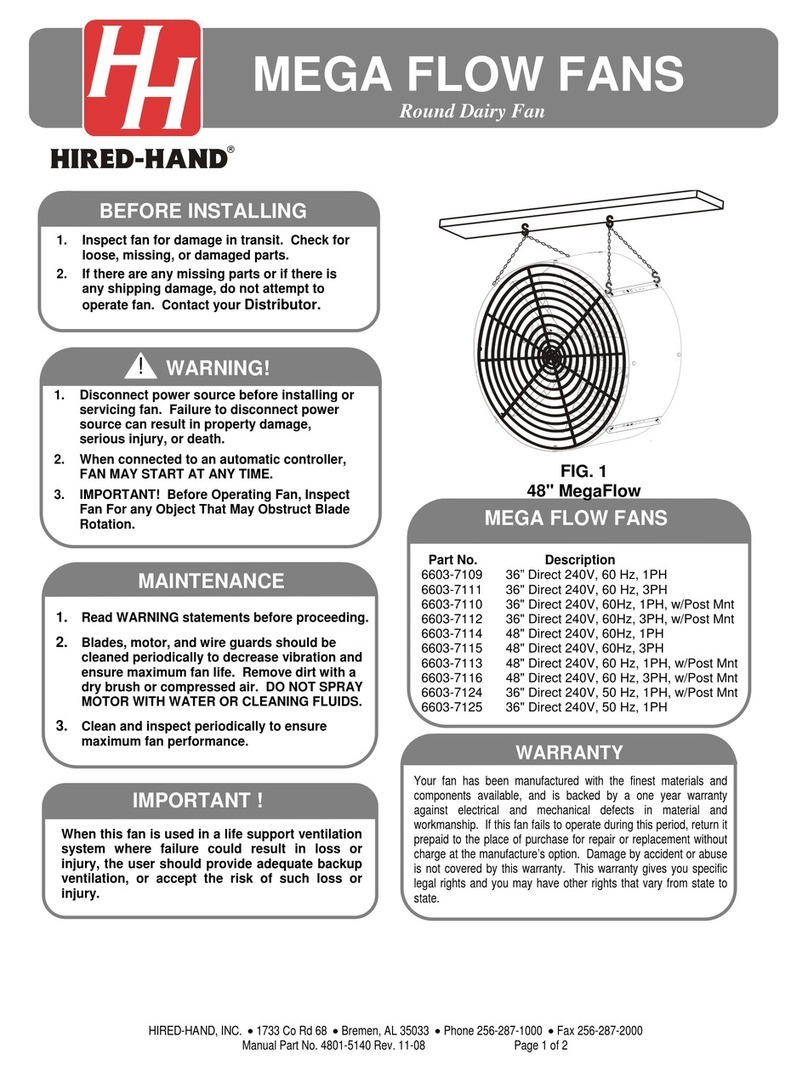

HIRED-HAND Mega Flow 6603-7109 User manual

HIRED-HAND

HIRED-HAND Mega-Flow Butterfly User manual

HIRED-HAND

HIRED-HAND MEGA-FLOW CONE FAN User manual

HIRED-HAND

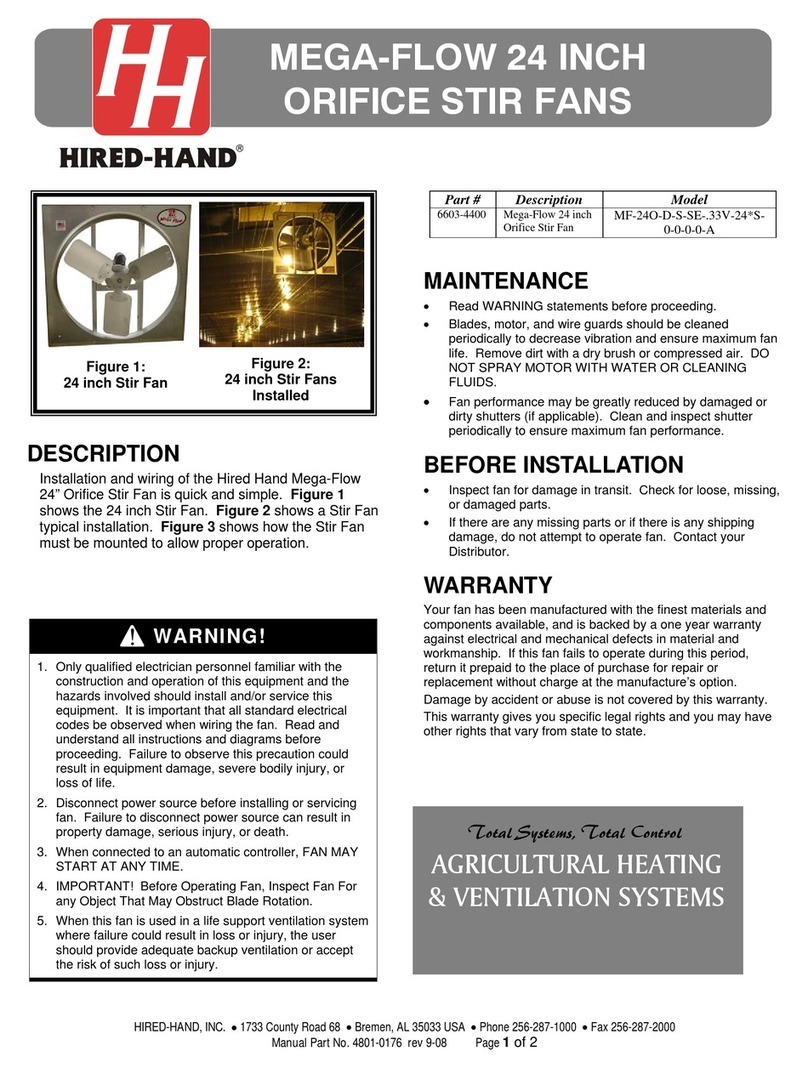

HIRED-HAND Mega-Flow MF-24O-D-S-SE Series User manual

HIRED-HAND

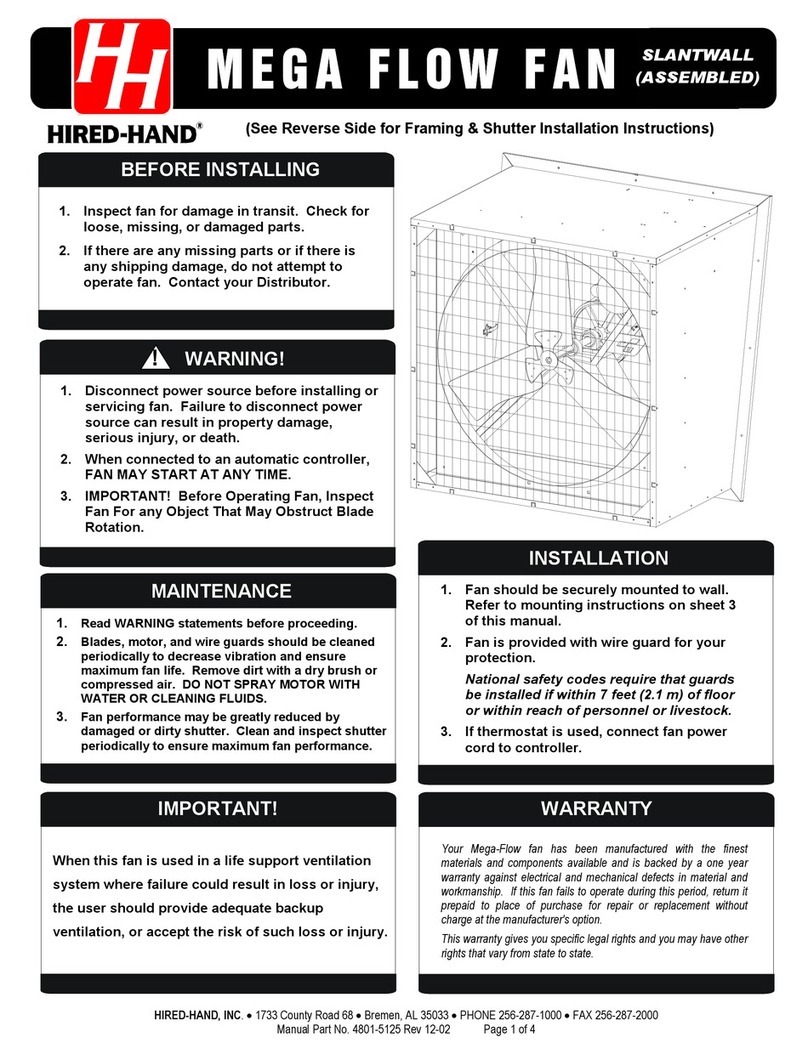

HIRED-HAND Mega Flow Slantwall User manual

HIRED-HAND

HIRED-HAND MEGA FLOW 48" User manual

HIRED-HAND

HIRED-HAND MEGA-FLOW MF-24O-D-S-SE Series User manual

HIRED-HAND

HIRED-HAND Econo-Flow User manual

HIRED-HAND

HIRED-HAND Econo-Flow User manual

Popular Fan manuals by other brands

Itho Daalderop

Itho Daalderop BTV-N200 manual

Ovente

Ovente TF87 Series instruction manual

NuAire

NuAire FAITH Series installation manual

Stelpro

Stelpro ULTRA SILENCIEUX Series installation guide

Domus Ventilation

Domus Ventilation DX Series Installation and Maintenance

Carrier

Carrier 42TW Series Installation, Start-Up and Service Instructions