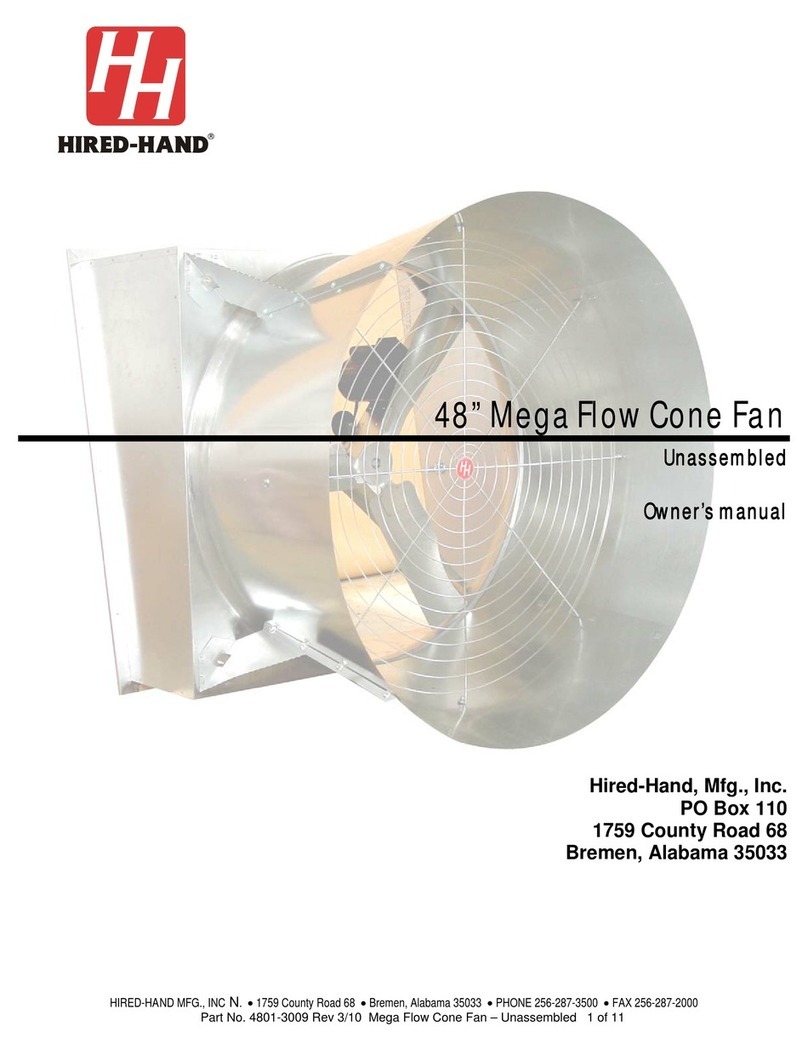

HIRED-HAND MEGA-FLOW CONE FAN User manual

HIRED-HAND MFG., INC. •1733 County Road 68 •Bremen, Alabama 35033 •PHONE 256-287-1000 •FAX 256-287-2000

Manual Part No. 4801-5323 Rev 6-08 Page 1 of 10

MEG

A

-FLO

W

CON

E

FAN

Fan&ConeInstallation

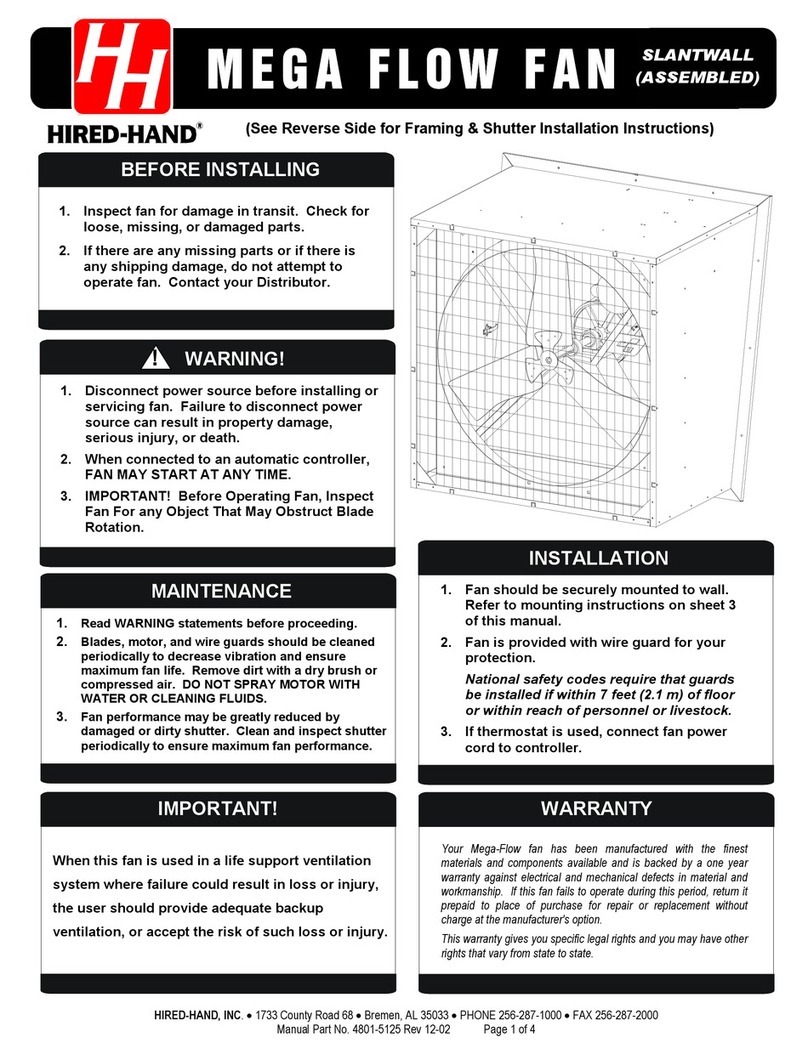

1. Disconnect power source before installing or

servicing fan. Failure to disconnect power

source can result in property damage,

serious injury, or death.

2. When connected to an automatic controller,

FAN MAY START AT ANY TIME.

3. IMPORTANT! Before Operating Fan, Inspect

Fan For any Object That May Obstruct Blade

Rotation.

! WARNING!

BEFORE INSTALLING

1. Inspect fan for damage in transit. Check for

loose, missing, or damaged parts.

2. If there are any missing parts or if there is

any shipping damage, do not attempt to

operate fan. Contact your Distributor.

MAINTENANCE

1. Read WARNING statements before proceeding.

2. Blades, motor, and wire guards should be cleaned

periodically to decrease vibration and ensure

maximum fan life. Remove dirt with a dry brush or

compressed air. DO NOT SPRAY MOTOR WITH

WATER OR CLEANING FLUIDS.

3. Fan performance may be greatly reduced by

damaged or dirty shutter. Clean and inspect shutter

periodically to ensure maximum fan performance.

When this fan is used in a life support ventilation

system where failure could result in loss or injury,

the user should provide adequate backup

ventilation, or accept the risk of such loss or injury.

IMPORTANT! WARRANTY

Your Mega

-

Flow fan has been manufactured with the finest

materials and components available and is backed by a one year

warranty against electrical and mechanical defects in material and

workmanship. If this fan fails to operate during this period, return it

prepaid to place of purchase for repair or replacement without

charge at the manufacturer's option.

This warranty gives you specific legal rights and you may have other

rights that vary from state to state.

Mega-Flow Fan & Cone

1. Fan should be securely mounted to wall. Refer to

mounting instructions on sheet 3 of this manual.

2. The cone and wire guard must always be installed for

your protection.

National safety codes require that guards be installed

if within 7 feet (2.1 m) of floor or within reach of

personnel or livestock.

3. If thermostat is used, connect fan power cord to

controller.

INSTALLATION

HIRED-HAND MFG., INC. •1733 County Road 68 •Bremen, Alabama 35033 •PHONE 256-287-1000 •FAX 256-287-2000

Manual Part No. 4801-5323 Rev 6-08 Page 2 of 10

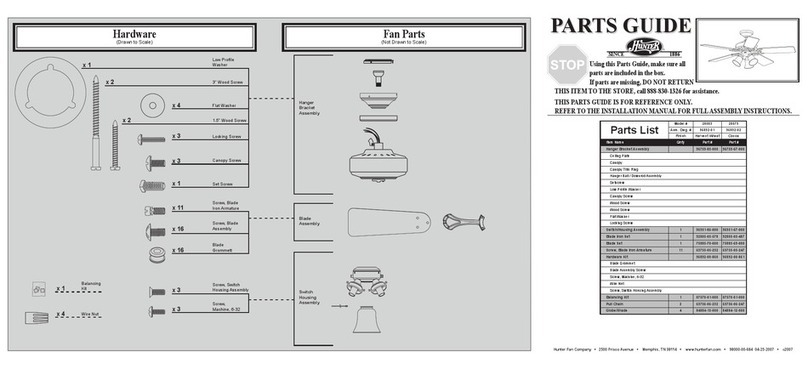

FRAMING

INSTRUCTIONS

FAN SPACING WITH CONE

Fan Housing

Cone

Center-to-Center

Spacing

Fan Size Spacing

36" 49.75" (126.4 cm)

48" 63.0" (160.0 cm)

52" 67.0" (170.2 cm)

54" 74.0"

(

188.0 cm

)

Rough Opening

Fan Size Fan Model Width Height

36" Mega-Flow Cone Fan 42.75" (108.6 cm) 43.75" (111.1 cm)

48" Mega Flow Cone Fan 54.75" (139 cm) 55.75" (141.6 cm)

52" Mega Flow Cone Fan 56.75" (144.2 cm) 57.75" (146.7 cm)

54" Mega Flow Cone Fan 60.63" (154.0 cm) 61.75" (156.8 cm)

FRAMING DIMENSIONS

FRAMING DIAGRAM

Width (W)

Height (H)

See Framing

Dimensions Below

Rough Opening

INTAKE

SHUTTER

SIDE

EXHAUST

ORIFICE

SIDE

HIRED-HAND MFG., INC. •1733 County Road 68 •Bremen, Alabama 35033 •PHONE 256-287-1000 •FAX 256-287-2000

Manual Part No. 4801-5323 Rev 6-08 Page 3 of 10

MOUNTING

INSTRUCTIONS

1. Carefully lift fan into position.

2. Securely attach fan to wall with screws (not provided).

NOTE: Route power cord through access port in top of cabinet as shown.

CAUTION!

Fan Is Heavy!

Do Not Attempt To Lift Fan Without Sufficient Workers And Equipment.

Power Cord

Install screws to firmly

attach fan to wall

Latch

See next page for

instructions on

latching shutter.

Mega-Flow

Fan Mounting

HIRED-HAND MFG., INC. •1733 County Road 68 •Bremen, Alabama 35033 •PHONE 256-287-1000 •FAX 256-287-2000

Manual Part No. 4801-5323 Rev 6-08 Page 4 of 10

CONE INSTALLATION 36″,48″52″

Packing List For One (1) Cone Kit Tools Required

Four (4) Cone Sections Four (4) Corner Brackets

One (1) Wire Guard Five (5) 3/8"-16 x 1 Cap Screws 7/16 in. (11 mm) Wrench Ratchet

Sixteen (16) ¼-20 Nuts Ten (10) 3/8" Washers

Sixteen (16) ¼-20 x 3/4 Bolts Five (5) 3/8"-16 Nuts 7/16 in. (11 mm) Socket

Sixteen (16) #14 x 1” TEK Screws

Cordless drill and bit

(For Installing TEK screws)

Marker or Scribe

WARNING!

During Cone Installation Be Sure That Fan Motor Is Not Plugged Into Any Power Source.

Always Double Check Power Sources.

1. Lay cone pieces flat with their flanges pointed up.

Refer to Figure 1.

2. For each panel, bend tabs upward in same direction

as flange.

NOTE: Bend tabs by hand. See Inset Figure 1.

3. Arrange panels with flanges and tabs contacting as

shown in Figure 1. Align holes of flanges and

tabs.

Assembly and Installation of Cone 36

″

,48

″

& 52″

(See Page 7 for 54″Cone)

OutsideEdge

InsideEdge

Arrange panels for assembly

with flat sides down, flange

sides up. The bent tabs of

one panel should contact the

flange of adjacent panel.

Tab before

bending

Bend tab upward

Flange

Tabs

Joints

Mounting

Hole For

Wire guard

Figure 1:

Cone Assembly

!

HIRED-HAND MFG., INC. •1733 County Road 68 •Bremen, Alabama 35033 •PHONE 256-287-1000 •FAX 256-287-2000

Manual Part No. 4801-5323 Rev 6-08 Page 5 of 10

48/52" Cone Fan Bracket (0404-5640)

48

″

Fan

52

″

Fan

Holes to Mount Bracket

4. Four corner support brackets are supplied as flat

perforated metal sheets with flanges. Bend each

sheet along perforations as shown in Figure 2 to

form support brackets.

5. Figure 3 shows the three different corner support

brackets and the correct attachment holes for

mounting to the specific cone size.

6. Install three corner brackets to joints of panel

assembly as shown in Figure 4. Attach each

corner bracket to two holes in the cone nearest the

small cone opening with 1/4" bolts and nuts. To

install bolt, insert bolt through hole of bracket, then

through hole of flange, and into hole of tab as

shown in Figure 4. NOTE: Start nuts onto bolts.

Leave nuts and bolts loose until cone is installed in

unit.

Flat sheet

Bend along

perforations

Support ready

for installation

Figure 2: Form Support Brackets

Guard Mounting Hole

Corner Support

Bracket

Tab fits to side o

f

flange opposite

bracket

Flange

Figure 4: Install Bracket to Cone

Figure 3: Support Bracket

Mounting Holes

36" Cone Fan Bracket (0404-4834)

Holes to Mount Bracket

HIRED-HAND MFG., INC. •1733 County Road 68 •Bremen, Alabama 35033 •PHONE 256-287-1000 •FAX 256-287-2000

Manual Part No. 4801-5323 Rev 6-08 Page 6 of 10

7. Carefully lift the attached panels and wrap panels

into cone shape as shown in Figure 5. Attach

final corner bracket with 1/4" bolts and nuts to

fasten cone together. The assembled cone with

corner brackets should now appear as in Figure 5.

8. Disconnect all electrical power from fan.

9. Carefully lift and support cone assembly. Fit cone

into position over outside of fan orifice on exhaust

side of fan. At this point, tighten bolts and nuts as

required to achieve a tight fit of cone around

orifice.

10. While supporting cone assembly, attach a top

corner bracket to fan housing. Position bracket,

install 1" TEK screws into fan housing through

holes in bracket. See Figure 6.

11. Repeat Step 10 to attach corner bracket to

opposite corner of fan housing. Cone assembly

should now hang in place.

12. Attach two remaining corner brackets of cone to

fan housing with 1" TEK screws.

13. Install wire guard (supplied) to cone. Align wire

guard with four mounting holes in cone. Install

cap screws, washers and nuts to guard.

14. Reconnect power to fan.

15. Cone installation complete.

A

ttach corne

r

bracket with

TEK screws.

Figure 6: Attach Bracket to Fan

Install wire guard with 90°

bend pointed toward

inside of cone.

Wire guard

Final Step

Tighten

Bolts

Figure 5: Install Guard to Cone

HIRED-HAND MFG., INC. • 1733 County Road 68 •Bremen, Alabama 35033 •Phone 256-287-1000 •Fax 256-287-2000

Manual Part No. 4801-5180 Rev 6-08 Page 7of 10

Arrange panels for assembly

with pilot hole on each panel

facing upward.

Slot for mounting top of

cone to fan housing

Joints

Install #14 x 1/2" sm

screw

Install #14 x 1/2" sm

screw

Pilot hole faces upward

Pull flanges

together to

align

mounting

holes

Mounting

Hole for

Wire Guard

Packing List For One (1) 54″Unit Tools Required

Four (4) Cone Sections Four (4) Corner Brackets 7/16 in. (11 mm) Wrench Ratchet

One (1) Wire Guard Eight (8) 5/16"-18 x 5/8 Carriage

Bolts 7/16 in. (11 mm) Socket Marker or Scribe

Five (5) 1/4"-20 Lock Nuts Ten (10) #14 x 1/2" SIM Screws Cordless drill and bit (For Installing TEK screws)

Four (4) ¼"-20 x 3/4" Bolts One (1) Installation Manual

1. Arrange panels contacting as shown in Figure 1. NOTE: The pilot hole pointing upward. Refer to Figure 7

Inset B.

2. For each panel, slide panels together. See Figure 7 Inset A.

3. Align holes of flanges. See Figure 7 Inset A. Install sheet metal screws as shown in Insets B and C.

Mounting Holes for

Damper Ring Figure 7

Inset A

Figure 7

Inset C

Figure 7:

Inset B

CONE INSTALLATION 54″

HIRED-HAND MFG., INC. • 1733 County Road 68 •Bremen, Alabama 35033 •Phone 256-287-1000 •Fax 256-287-2000

Manual Part No. 4801-5180 Rev 6-08 Page 8of 10

Pilot hole

at top

outside o

f

cone

Mounting Brackets

Top and Bottom bolts are

inserted from inside the

cone.

4. To complete the last flange

connection, roll the cone panels

so the small end is on the floor.

See Figure 8. IMPORTANT!

The four pilot holes should be at

the top end on the outside of the

cone.

5. Install the cone Mounting

Brackets to the fan housing

using two 5/16”-18x5/8” carriage

bolts in each mounting bracket.

6. Mount cone to fan. Bend the

mounting brackets back slightly

to help clear the area of the

cone edges. Hang the centered

slot in the small end of the cone

over the Pim screw mounted on

the Fan housing. See Figure 9.

Screw can be fastened with

¼”x20 lock nut, if necessary (not

included).

7. Align the cone over the

remainder of the fan housing.

Using four 1/4”x20 bolts and

lock nuts, insert the bolts from

the inside of the cone. See

Figure 10.

Cone attaches over

the top Pim screw

Figure 9: Install Cone Mounting Brackets

Figure 8: Assembled Cone

Figure 10: Mount Cone onto Fan

HIRED-HAND MFG., INC. • 1733 County Road 68 •Bremen, Alabama 35033 •Phone 256-287-1000 •Fax 256-287-2000

Manual Part No. 4801-5180 Rev 6-08 Page 9of 10

Carefull

y

lift shutter.

Note: Latch is hidden in this view. See

diagram on page 3.

Slot for latch

With shutter in place,

manually open vanes of

shutter to access latch.

Fasten latch (located

inside fan housing) into

slot in flange of shutter.

Firmly lock down latch.

Repeat procedure to

latch opposite side of

shutter.

Shutter Fits Onto Intake Side Of Fan

1. Lift shutter.

2. Check that shutter is flush against housing at all points.

3. Manually open vanes of shutter to gain access to latches on fan housing. Lock shutter latches.

4. Installation complete.

SHUTTER INSTALLATION

Figure 11: Shutter Installation

Table of contents

Other HIRED-HAND Fan manuals

HIRED-HAND

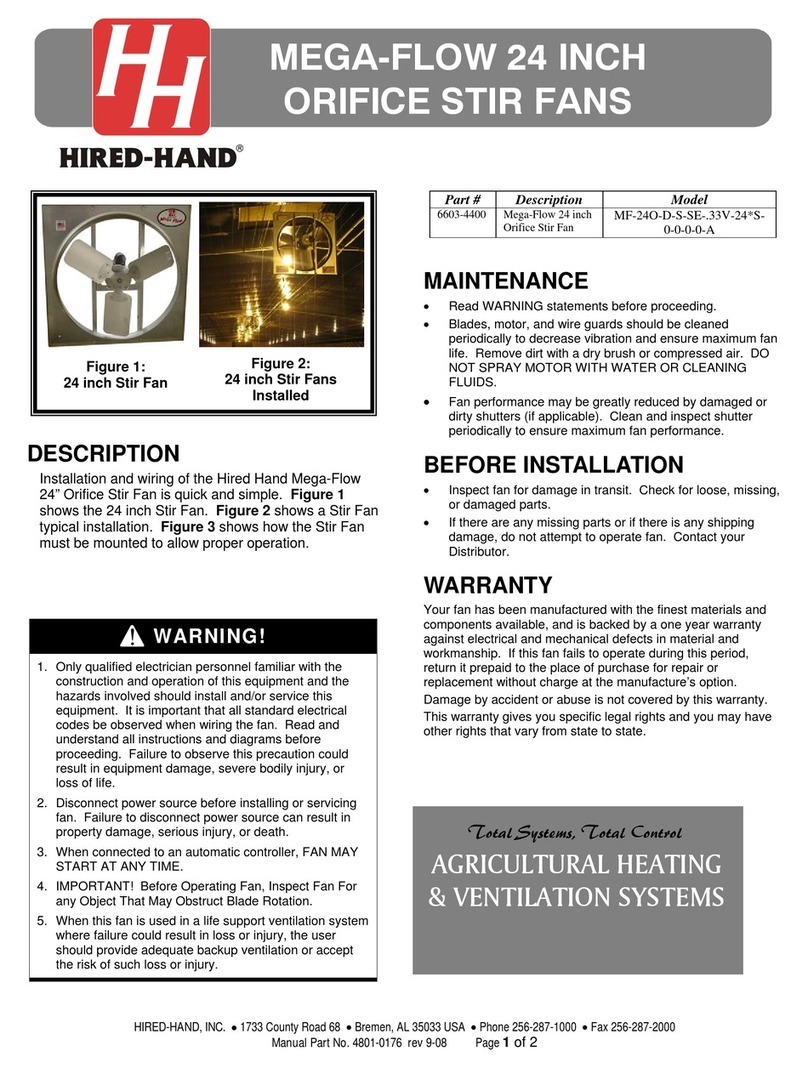

HIRED-HAND MEGA-FLOW MF-24O-D-S-SE Series User manual

HIRED-HAND

HIRED-HAND Econo-Flow User manual

HIRED-HAND

HIRED-HAND Econo-Flow Instruction Manual

HIRED-HAND

HIRED-HAND Econo-Flow User manual

HIRED-HAND

HIRED-HAND Econo-Flow User manual

HIRED-HAND

HIRED-HAND Mega Flow 6603-7109 User manual

HIRED-HAND

HIRED-HAND Mega-Flow Butterfly User manual

HIRED-HAND

HIRED-HAND Mega-Flow MF-24O-D-S-SE Series User manual

HIRED-HAND

HIRED-HAND Funnel Flow 36 User manual

HIRED-HAND

HIRED-HAND MEGA FLOW 48" User manual