PRS 80 Wind Speed Operator’s/Service Manual

© Hirschmann ECS, 2006; PRS 80 Wind Speed Rev.C 05/23/06 190184_C

TABLE OF CONTENTS

1GENERAL INFORMATION.............................................................................................................1

2WARNINGS .................................................................................................................................... 1

3FEATURES ..................................................................................................................................... 2

4SYSTEM DESCRIPTION................................................................................................................ 2

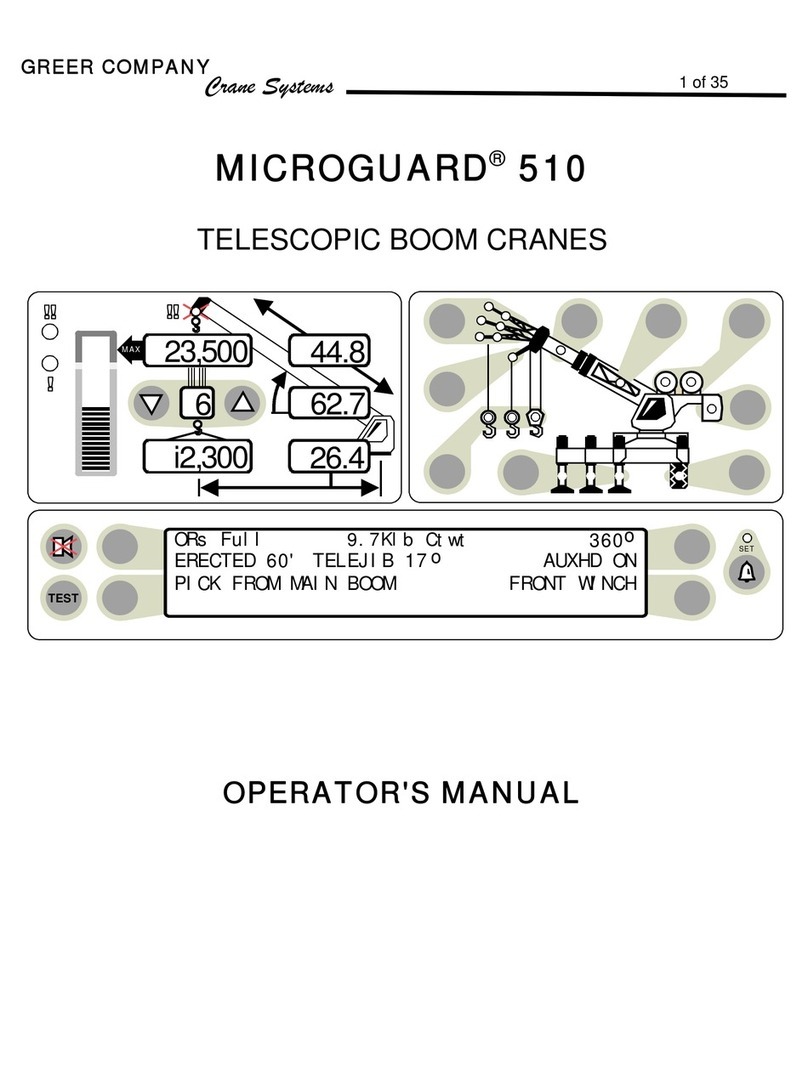

4.1 OPERATING CONSOLE ................................................................................................................... 2

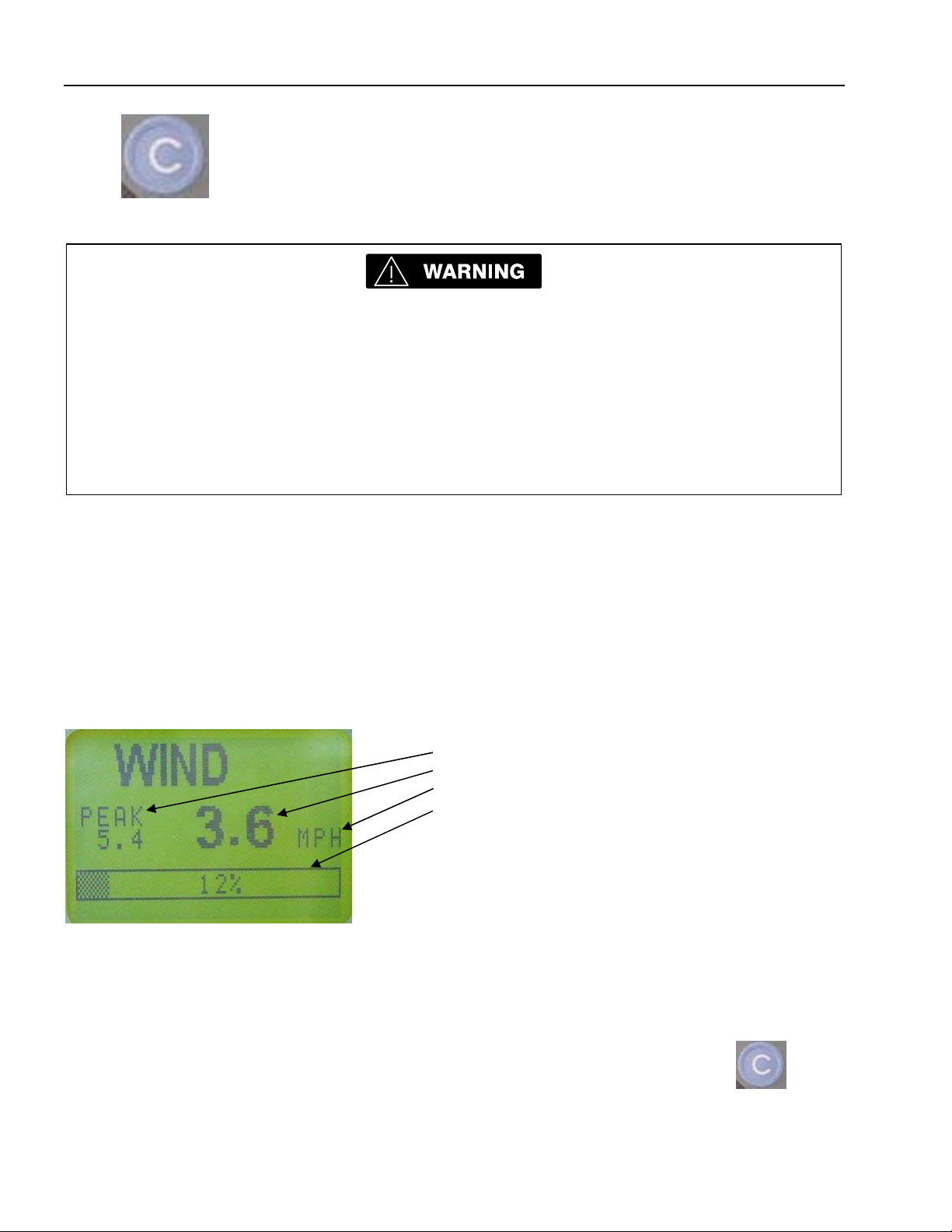

4.1.1 Liquid Crystal Display ...........................................................................................................................2

4.1.2 Control Identification .............................................................................................................................3

5SYSTEM OPERATION ................................................................................................................... 4

5.1 MENU'S ....................................................................................................................................... 5

5.2 MENU SELECTION INSTRUCTIONS .................................................................................................. 5

5.3 LIMITS........................................................................................................................................... 5

6INSTALLATION AND SETUP ......................................................................................................... 6

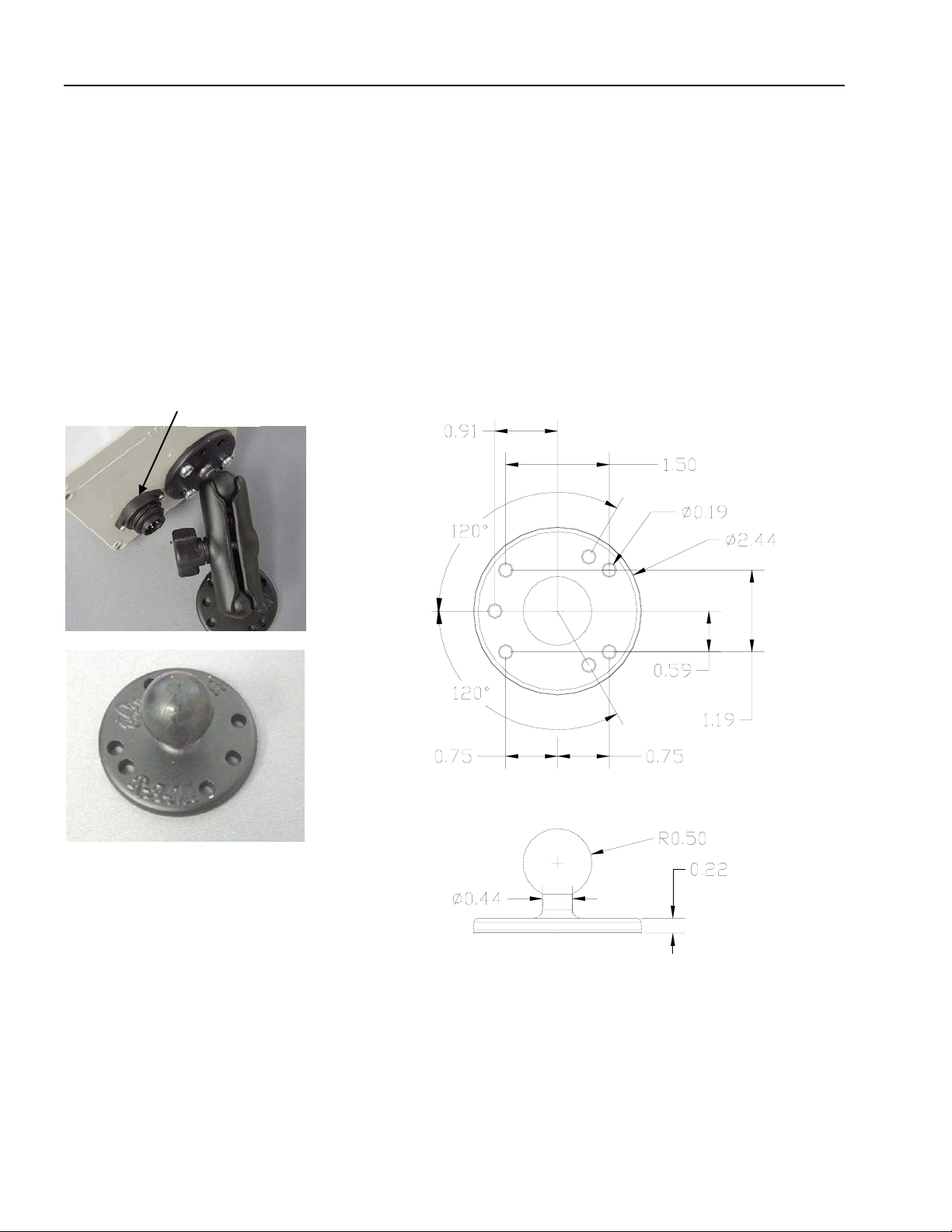

6.1 CONSOLE MOUNTING .................................................................................................................... 6

6.2 WIRING ......................................................................................................................................... 7

6.3 ADDING SENSORS.......................................................................................................................... 8

6.4 WIND SPEED SENSOR ................................................................................................................... 9

7SERVICE / TROUBLESHOOTING ............................................................................................... 10

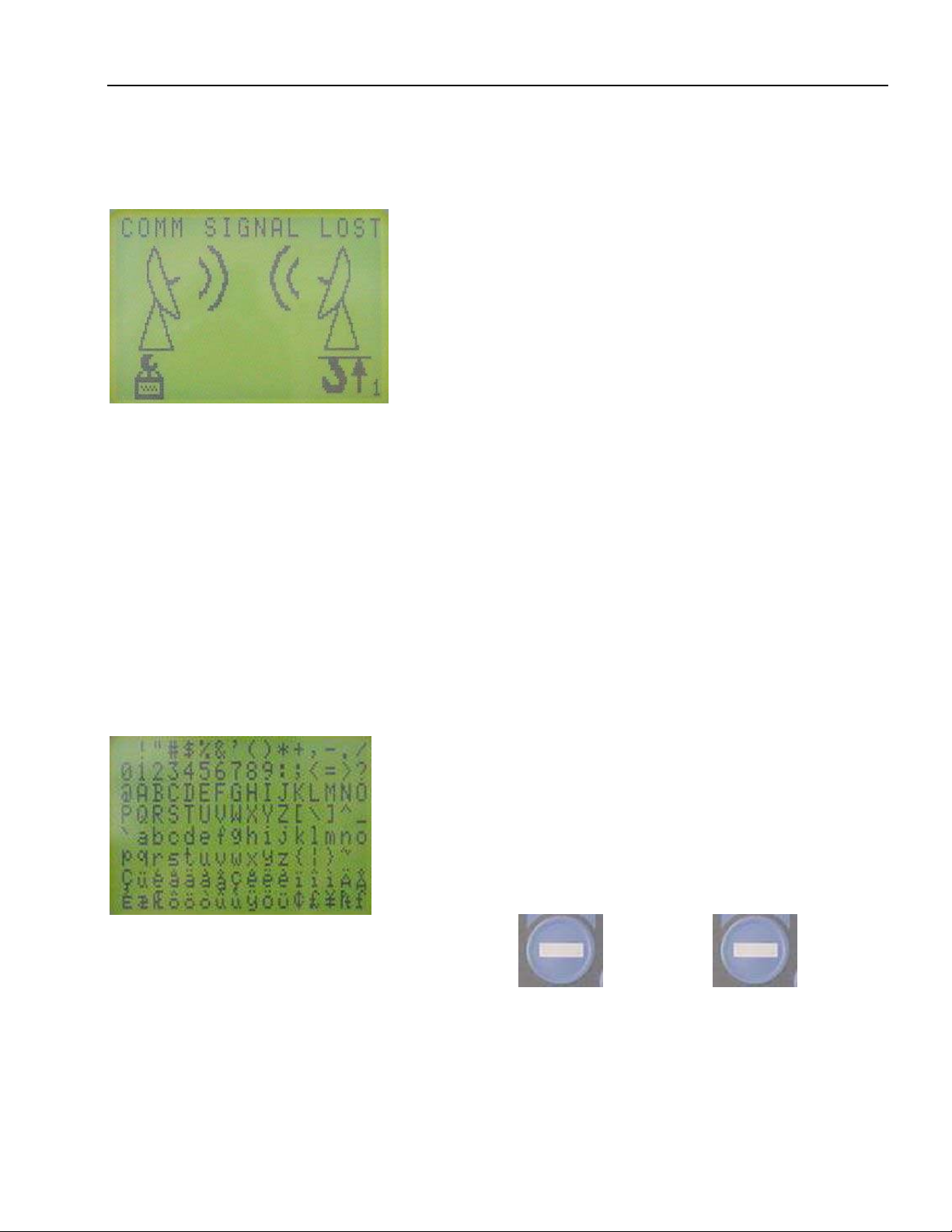

7.1 SCREENS .................................................................................................................................... 11

7.2 DIAGNOSTICS .............................................................................................................................. 11

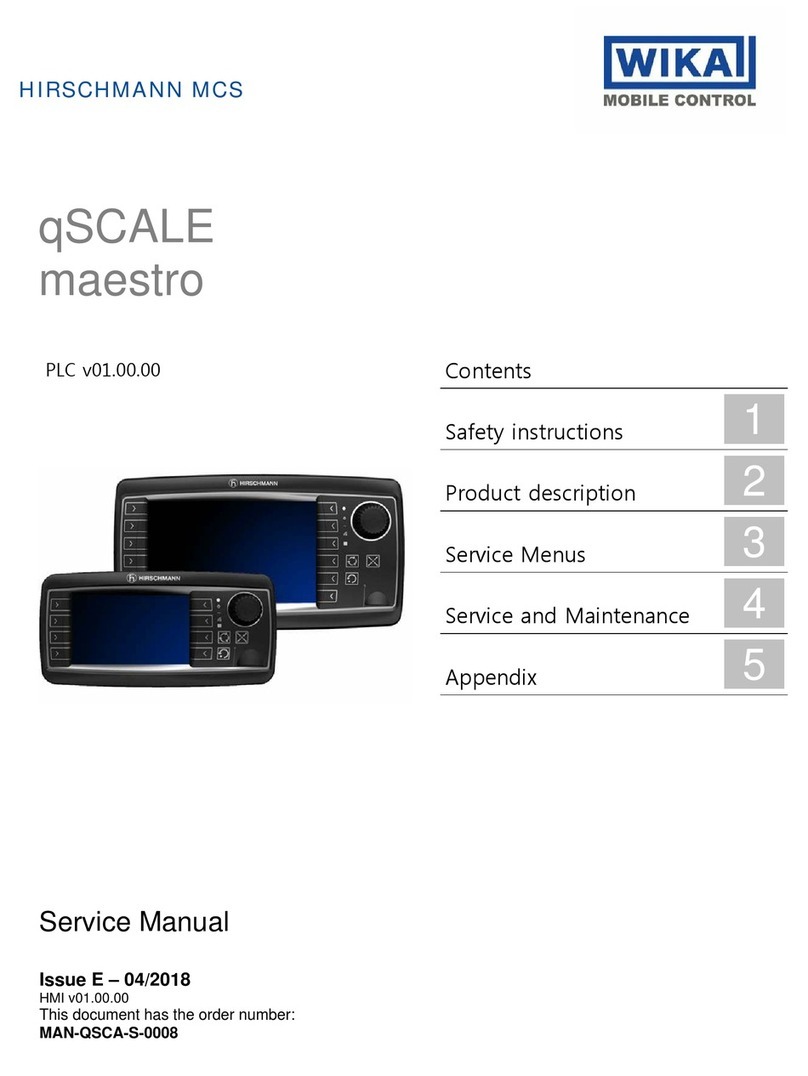

7.2.1 To Test the Display:............................................................................................................................11

7.2.2 To Test the buttons:............................................................................................................................12

7.2.3 To Test the outputs:............................................................................................................................12

7.3 NO DISPLAY ................................................................................................................................13

7.4 TROUBLESHOOTING MOISTURE.................................................................................................... 13

7.5 TROUBLESHOOTING CHART ......................................................................................................... 14

8MAINTENANCE ............................................................................................................................ 15

8.1 BATTERY REPLACEMENT ............................................................................................................. 15

9PART NUMBERS.......................................................................................................................... 16