Hirschmann iVISOR mentor QVGA User manual

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 1

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

iVISOR

mentor QVGA

Service Manual

Edition 2/2009 Rev. A

The order code for this document is

24 183 69 1012e (Generic)

Contents

General information

Important notes

Service menus

Troubleshooting

Appendix:

Wiring Diagrams …

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 2

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

TABLE OF CONTENTS

1. General information ........................................................................... 3

2. Important notes .................................................................................. 5

3. Sensor calibration.............................................................................. 6

3.1 Zero-setting the pressure signals......................................................... 8

3.2 Zero-setting the slewing signal........................................................... 10

3.3 Length sensor calibration procedure.................................................. 12

3.4 Angle sensor calibration procedure.................................................... 15

4. Troubleshooting............................................................................... 19

4.1 General information............................................................................ 19

4.2 Error code list ..................................................................................... 20

Revision History ................................................................................. 26

Appendix: Wiring, Drawings, Spare Parts

The manufacturer reserves the right to modify the contents of this manual without notice. Hirschmann will not be liable for

errors contained in this manual or for incidental or consequential damages in connection with the furnishing, performance, or

use of this manual. This document contains proprietary information, which is protected by copyright, and all rights are

reserved. No part of this document may be photocopied, reproduced, or translated to another language without the prior

written consent of Hirschmann. Hirschmann reserves proprietary rights to all drawings, photos and the data contained

therein. The drawings, photos and data are confidential and cannot be used or reproduced without the written consent of

Hirschmann. The drawings and/or photos are subject to technical modification without prior notice.

All information in this document is subject to change without notice..

Configuration Setup

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 3

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

1. GENERAL INFORMATION

This manual describes the service menus of the iVISOR mentor QVGA load moment indicator (LMI)

and assists a service or maintenance person in identifying system malfunctions.

NOTE: Knowledge of system and CAN bus wiring is assumed.

REFERENCE: Refer to Operator’s manual 24 183 19 1012e (Generic) for detailed operation of

the mentor QVGA.

The iVISOR mentor QVGA load moment indicator system comprises a central microprocessor unit

with an integrated display and control console together with various sensors to record the measured

values. The system components are connected via CAN bus.

Components of the iVISOR mentor QVGA LMI system

Configuration Setup

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 4

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

Components:

CPU/Console: The iVISOR mentor QVGA load moment indicator comprises a central

microprocessor unit with an integrated display and operating console together with various

sensors to record measured values. The system components are connected via CAN bus.

The iVISOR mentor QVGA displays all geometrical information such as length and angle

of main boom, working radius and tip height of the boom. It also displays the actual load

and the maximum load permitted by load chart. Furthermore, it has an acoustical alarm, a

warning light for overload, and a pre-warning light.

The graphic display allows for a simple interactive configuration setup, as well as sensor

calibration (zero adjustment), and troubleshooting sensor output screen. The console has

a warning light for anti-two-block conditions and an override switch for overload or anti-

block condition.

Length-Angle Transducer: The length-angle sensor gSENS LWG, often referred to as

the “cable reel”, is a combination of two transducers in one box, installed on the base

section of the boom. It measures the length and the angle of the boom. A reeling drum

drives a potentiometer, which is the length transducer. Part of the length transducer circuit

is the length cable on the drum, which is a multi-conductor cable. It is connected to the

anti-two-block switch at the boom head and to a slip ring body in the LWG. The angle

transducer is a potentiometer driven by a weighted pendulum that is oil damped. Both

length and angle transducer are connected to a CAN bus controller board, which is

connected to the bus system.

Pressure Transducer(s): A pressure transducer pSENS DAVS converts hydraulic

pressure into a CAN signal. One (or two) pressure transducer is (are) connected to the

piston side of the lift cylinder and one to the rod side.

Slew Angle Sensor: The gSENS DWG sensor converts the circular motion of the upper

structure of the crane into a CAN signal.

Configuration Setup

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 5

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

2. IMPORTANT NOTES

The LMI is an operating aid that warns the crane operator of imminent overloading or of the approach

of the hook block to the boom head, in order to avoid possible property damage or injury to personnel.

The device is not, nor is it intended to be, a substitute for good operator judgment and/or experience,

nor does it remove the need for utilizing only recognized safe procedures during crane operations.

The crane operator continues to bear ultimate responsibility for safe operation of the crane.

He must ensure that he fully understands and follows the displayed notes and instructions

in their entirety.

The LMI is not able to provide aid to the crane operator unless it has been properly adjusted

and unless the correct load capacity chart and the correct operating code have been

entered for the respective rigging configuration. The correctness of the LMI settings must

be guaranteed before beginning crane work in order to avoid damage to property and

severe or even fatal injuries to personnel.

This system can be equipped with an external key-operated switch located in the crane

operator's cab. This key-operated switch overrides control lever function switch-off by the

LMI or by the hoist limit switch system. This switch may only be used during emergency

situations, and even then only by authorized personnel. Failure to observe these

instructions could result in damage to property and severe or even fatal injuries to

personnel.

The LMI cannot perform correctly unless it has been properly adjusted. The prerequisite for

this is making conscientious and correct entries during the set-up procedure, in

accordance with the actual configuration of the crane. The correctness of the LMI settings

must be ensured before beginning crane work in order to avoid damage to property and

severe or even fatal injuries to personnel.

Sensor Calibration

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 6

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

3. Sensor Calibration

In this code-protected area, settings affecting system precision can be made by trained service

personnel. For access to the calibration menus it is necessary to input a matching 5-digit code.

To start the function:

▼Info screen

Actuate the INFO key.

to service menus

back

▼Entry to calibration menus

abort input of service code

increase marked numeric value

reduce marked numeric value

mark the next figure, access after the last valid figure

If an invalid service code is entered, you are prompted to enter it again or to abort the input.

Sensor Calibration

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 7

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

After entering the service menu you can follow the calibration procedure step by step or can select

the type of calibration by scrolling with function key . Press "ESC" to finish calibration procedure:

3.1) pressure

signal piston side

… and rod side 3.2) slewing angle

signal

3.3) boom length

signal

3.4) boom angle

signal

Sensor Calibration

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 8

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

3.1 Zero-setting the pressure signals

NOTE: The only thing adjustable for the pressure transducers is the zero point, which is the signal the

transducer outputs when there is no (zero) pressure sensed.

Ensure there is no pressure in the hydraulic line when

disconnecting the hoses from pressure transducers!

The display shows which transducer (piston-side, rod-side or force) is being zeroed and a horizontal

dial marks the present pressure (or force) difference in %.

NOTE: there are two calibration screens: for piston and for rod transducer.

NOTE: The operating range for zero-setting this value is from -1% to +1%.

Press and release the “AUTO >CAL<” key multiple times until the zero-setting starts.

The indicator line must move to zero on the dial, otherwise the zero-setting of this value is not

correct!

▼Zero point adjustment, pressure piston side:

leave the service menu

carry out zero point setting

skip calibration step / go to next menu

Sensor Calibration

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 9

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

▼Zero point adjustment, pressure rod side:

leave the service menu

carry out zero point setting

skip calibration step / go to next menu

Sensor Calibration

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 10

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

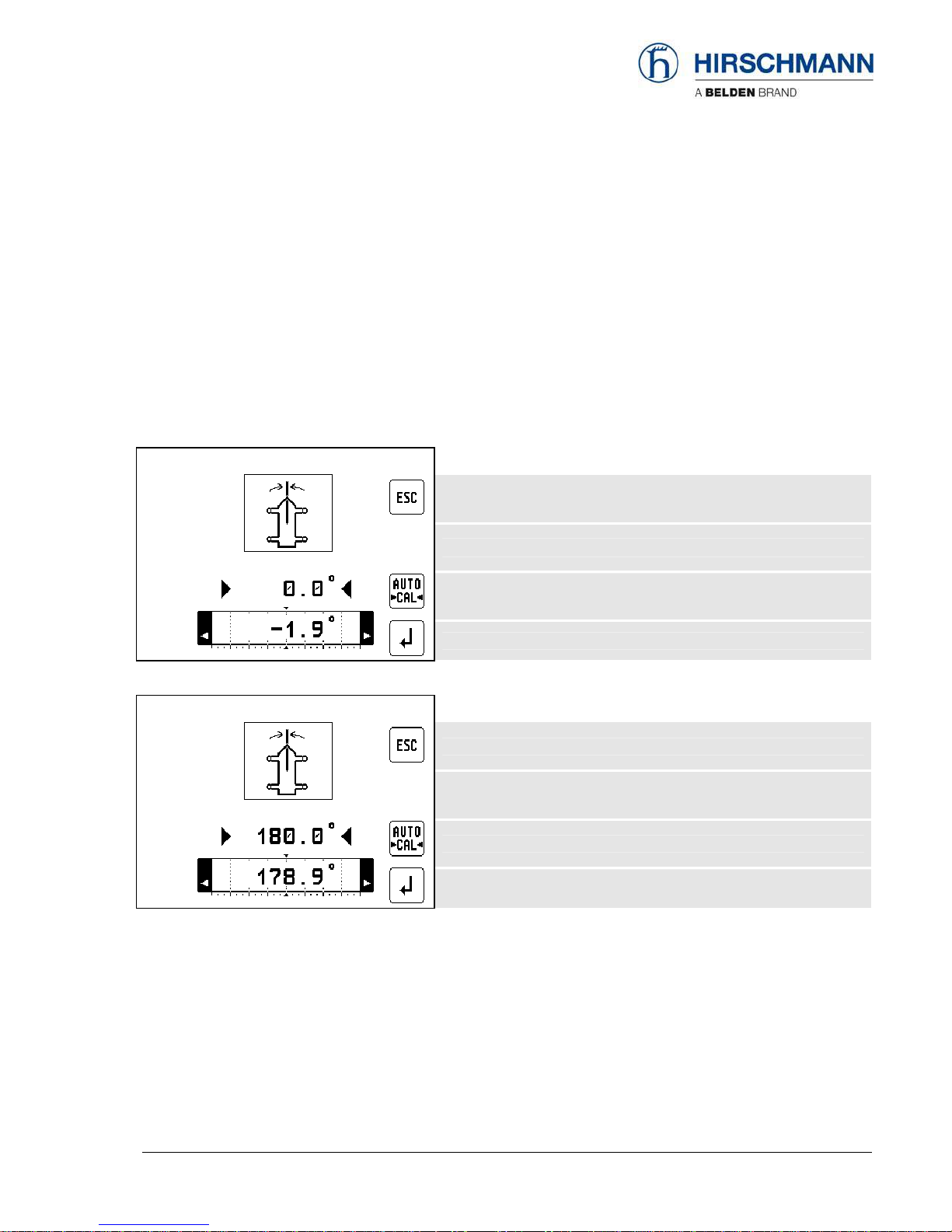

3.2 Zero-setting the slewing signal

NOTE: The only thing adjustable for the slew potentiometer is the zero point, which is complete when

the boom is at the 0°and 180° position of the crane.

NOTE: The range for zero-setting this value is from -10° to +10°./ ±170° to 190°

Press the “AUTO >CAL<” key until the zero-setting starts. The indicator line must move to zero

on the dial, otherwise the zero-setting of this value is not correct!

▼Zero point setting, slewing angle 0° position:

leave the service menu

carry out zero point setting slewing angle for 0° position

skip calibration step / go to next menu

▼Zero point setting, slewing angle 180° position:

leave the service menu

carry out zero point setting slewing angle for 180° position

skip calibration step / go to next menu

Sensor Calibration

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 11

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

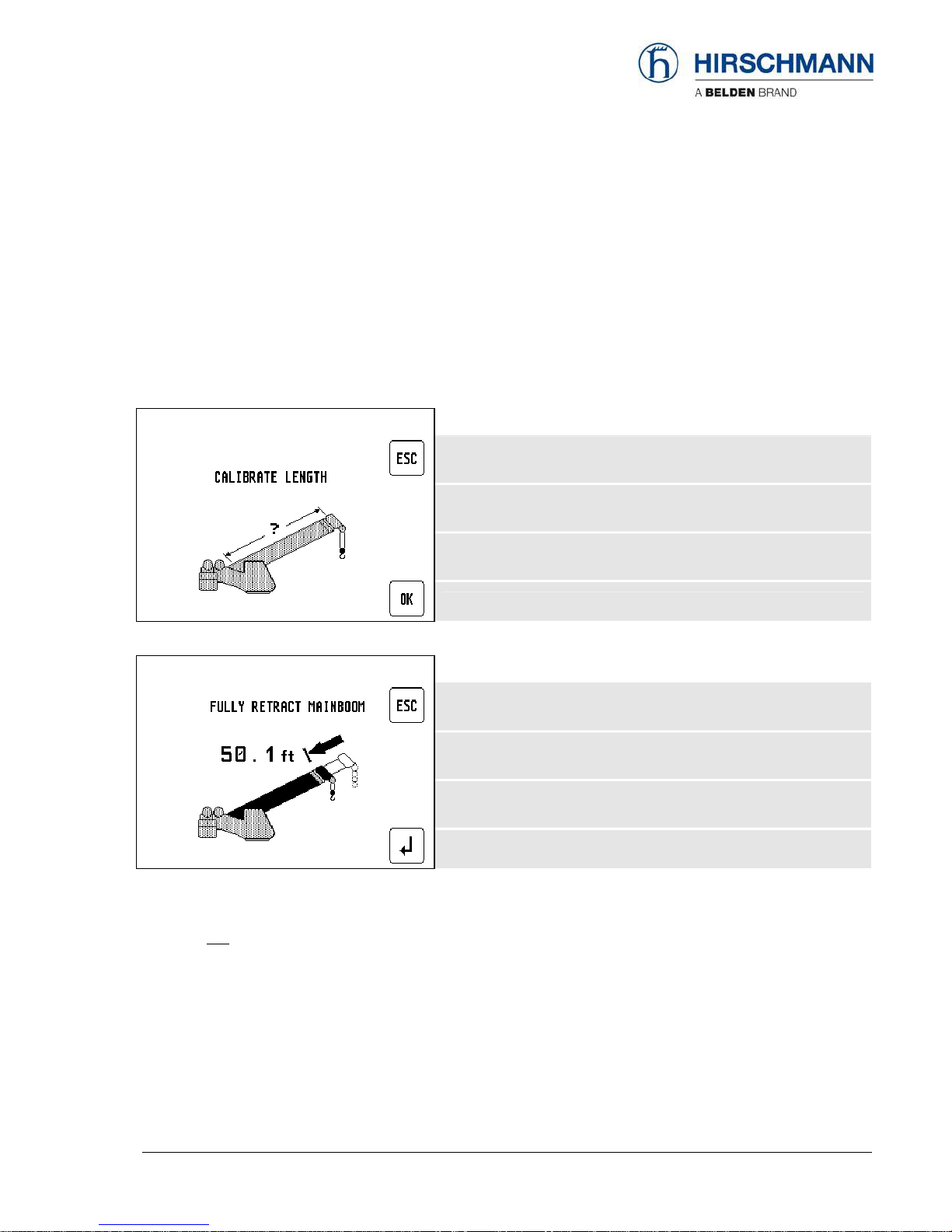

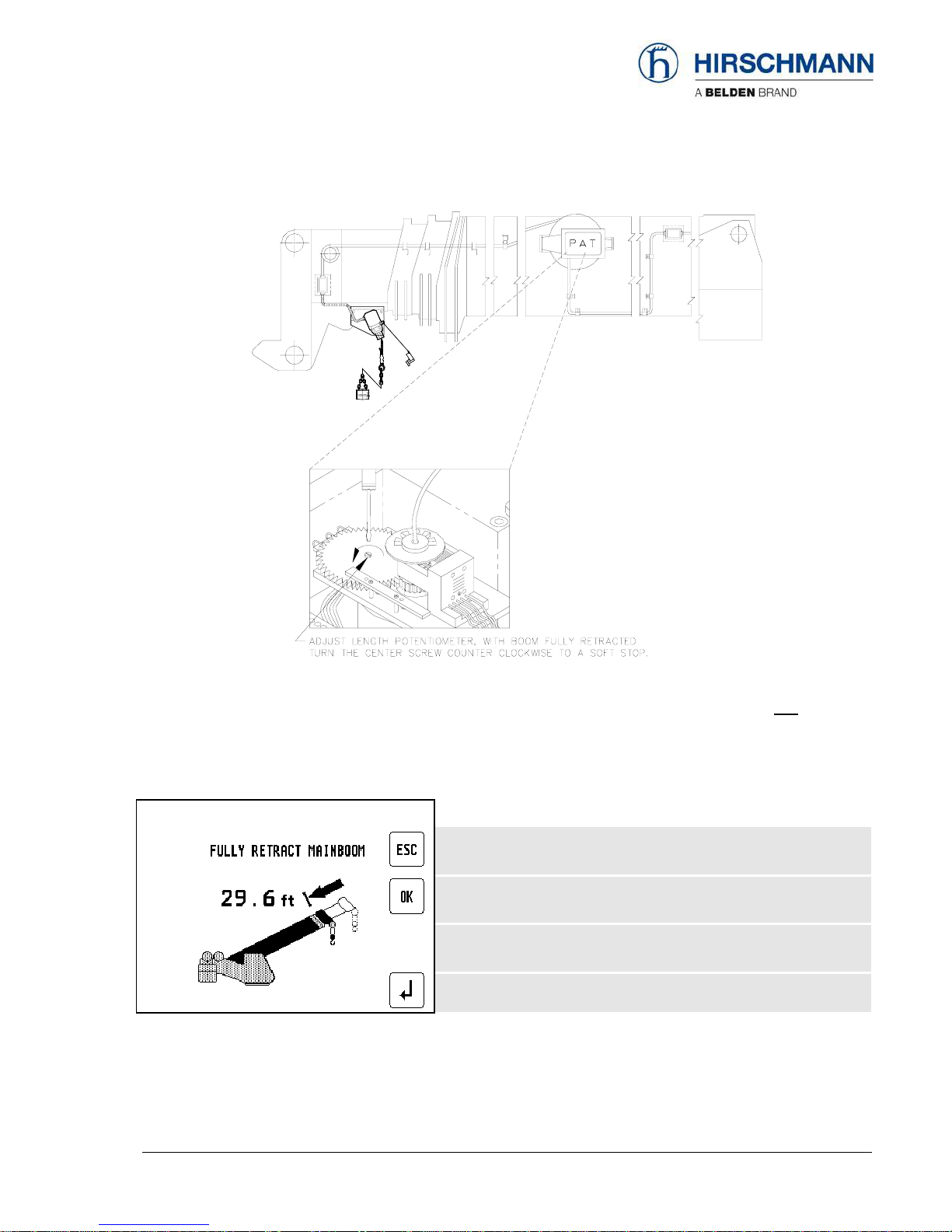

3.3 Length sensor calibration procedure

NOTE: The length sensor can be calibrated for its zero point and its full range.

With retracted boom, the potentiometer of the length sensor has to be at its 0 position, which is all the

way counter-clockwise. For extended boom, the adjustment is done by software as described below.

The length should be calibrated to be about 0.1 feet (or 0.05m for metric) accurate for retracted and

extended lengths. Perform the following steps:

▼Start screen zero point adjustment, boom length:

leave the service menu

Start length calibration

▼Start screen min. boom length:

leave the service menu

skip calibration step / go to next menu

•Fully retract the main boom and check if indicated length is within 0.1 feet (or 0.05m for metric) of

actual retracted boom length.

•If it is not, adjust length potentiometer mechanically as described below:

Sensor Calibration

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 12

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

•With boom fully retracted turn the center screw of the length pot unit counter clockwise to a soft stop.

•During adjustment an additional button "OK" appears. Check value and set actual length as fully retracted

length by pressing OK.

▼Adjustment, min length:

leave the service menu

carry out min. boom length setting

skip calibration step / go to next menu

Afterward next calibration screen appears:

Sensor Calibration

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 13

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

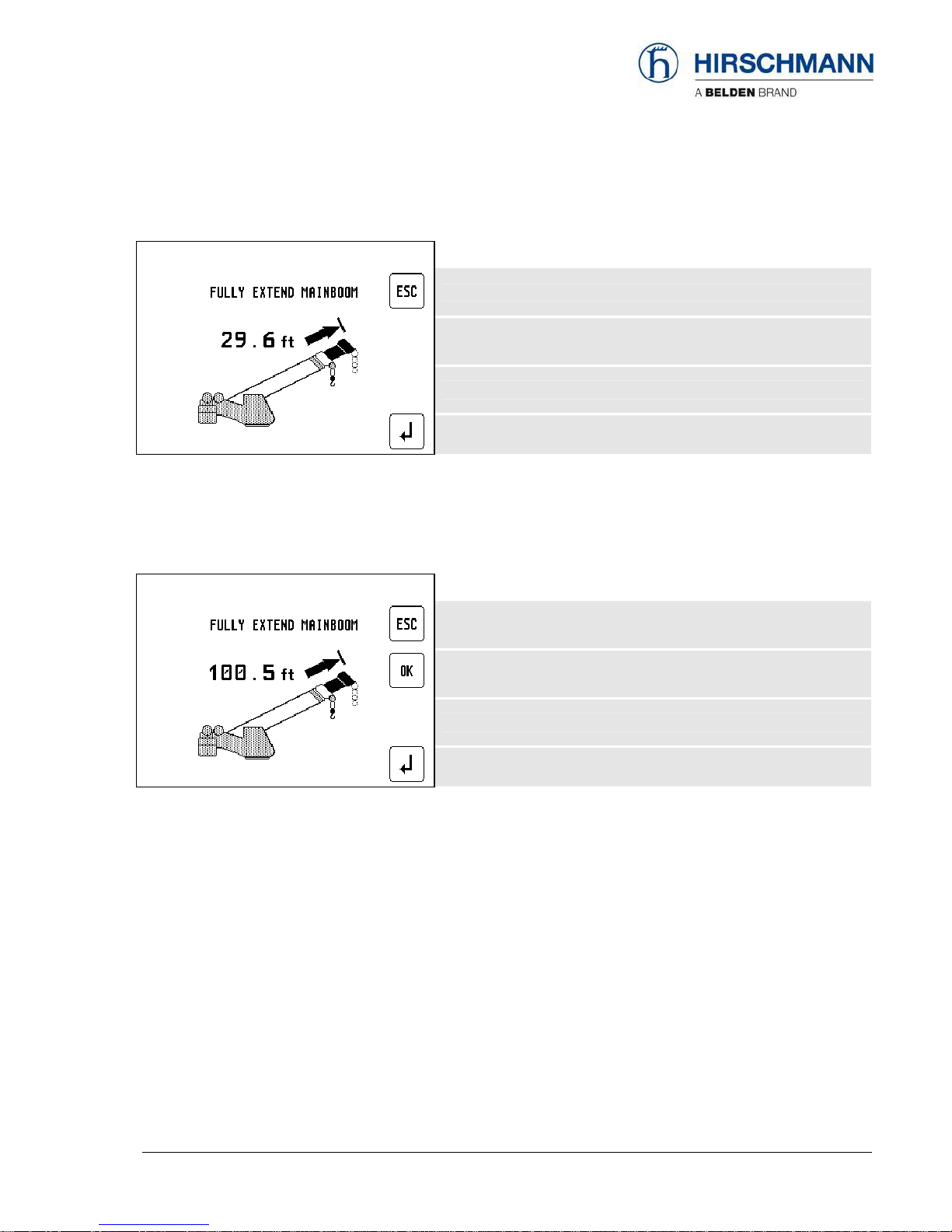

▼Start screen maximum. boom length:

leave the service menu

skip calibration step / go to next menu

•Now extend main boom all the way out. Make sure you are within the allowed operating range

(especially maximum radius).

•During telescoping out the boom an additional button "OK" appears.

▼Adjustment, maximum length:

leave the service menu

carry out max. boom length setting

skip calibration step / go to next menu

•Check whether boom is fully extended, then press "OK". Afterward next calibration step (angle)

appears.

Sensor Calibration

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 14

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

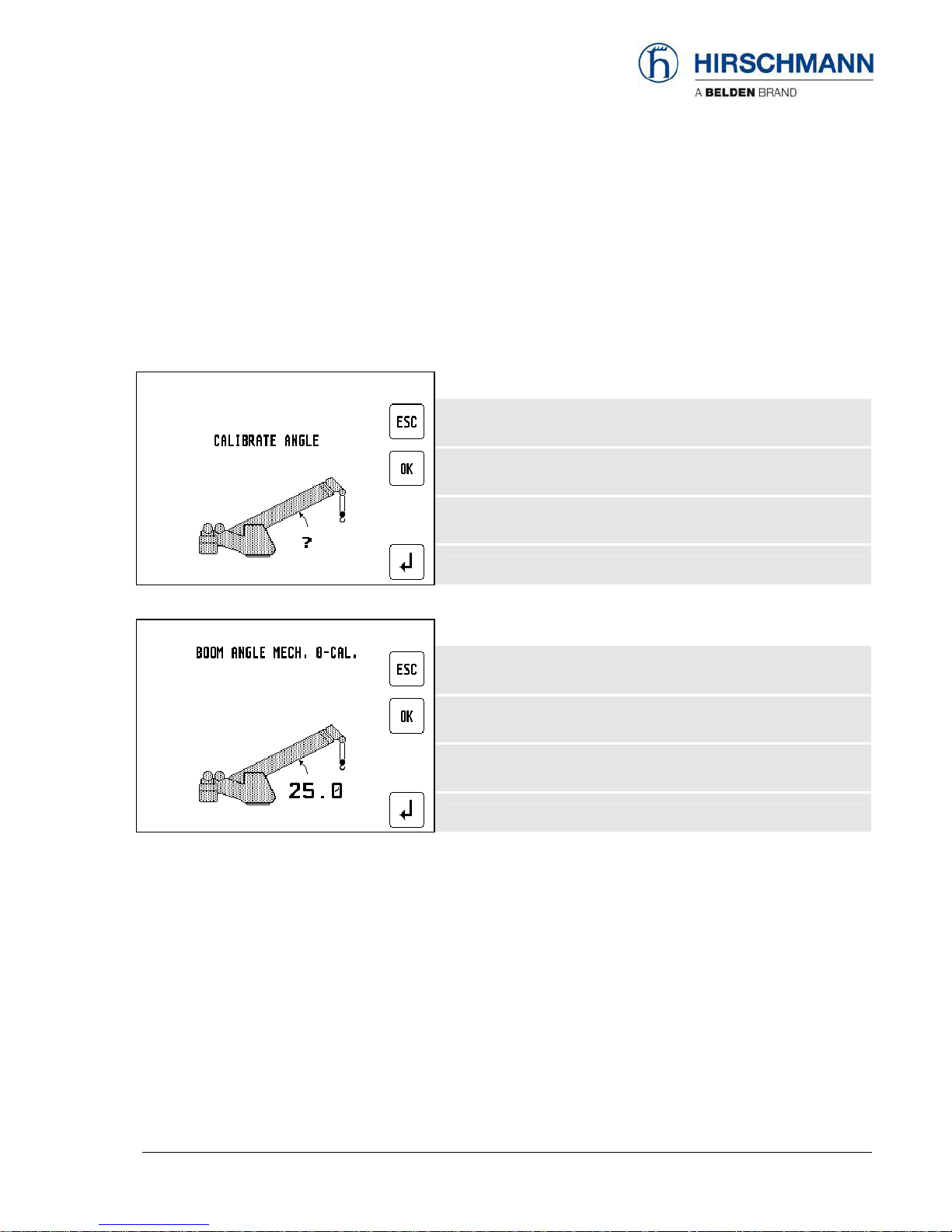

3.4 Angle sensor calibration procedure

The angle sensor can be calibrated for its zero point, with steep boom (75°) and one or two additional

angle values (40° / 65°)

Material required: calibrated inclinometer

▼Start screen adjustment, boom angle:

leave the service menu

Start angle calibration procedure

▼Start calibration for "zero degree" angle:

leave the service menu

skip calibration step / go to next menu

Sensor Calibration

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 15

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

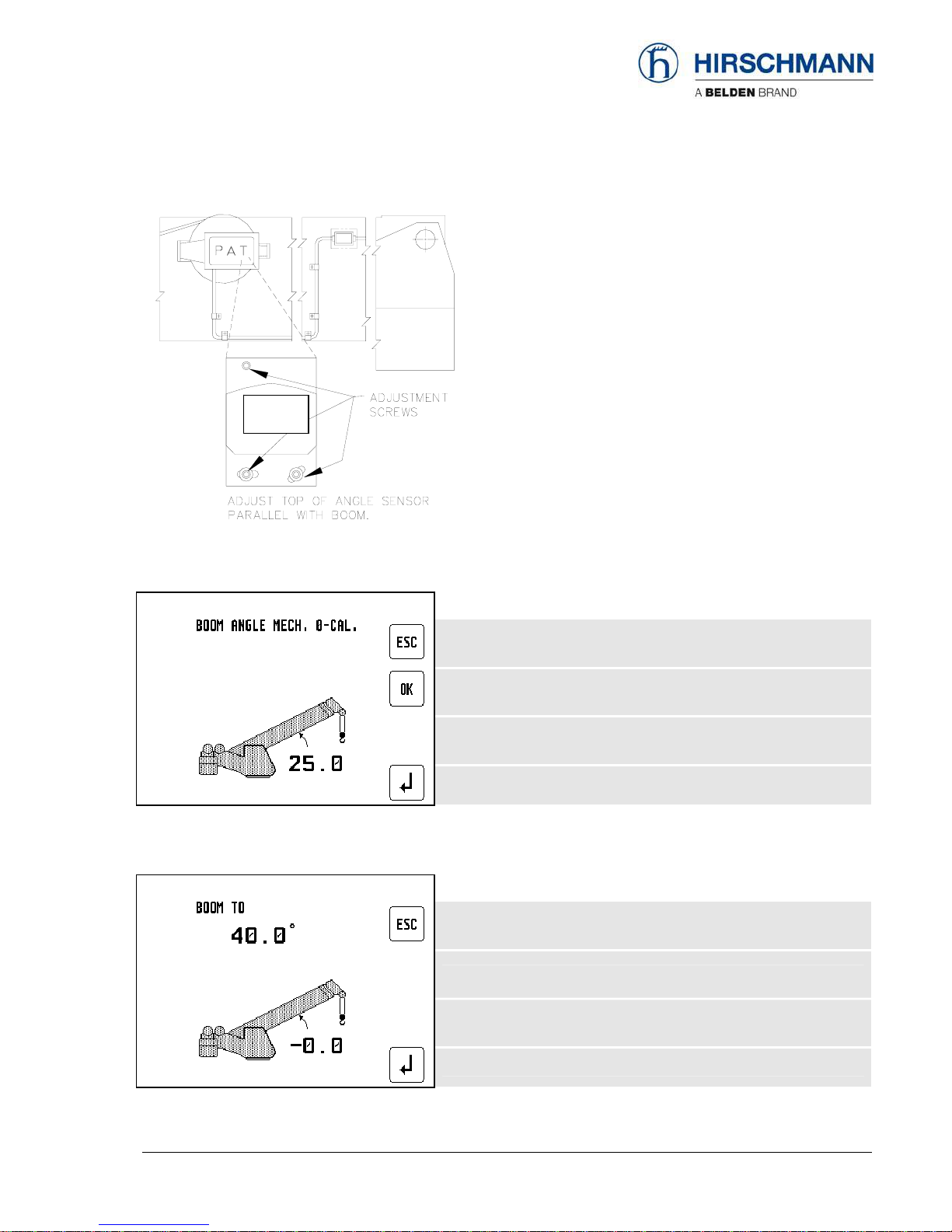

•Boom down.

•Release adjustment screws of the angle

sensor.

•Mechanically adjust top of angle sensor

housing exact parallel with boom by help of

inclinometer.

•Fix adjustment screws of the angle sensor.

Having adjusted the angle sensor mechanically check value and press "OK" for the next step.

▼Calibration for "zero degree" angle:

leave the service menu

calibrate next angle

skip calibration step / go to next menu

•Now boom up to 40°, (range is 35°- 45°)

▼Calibration for "40°" angle:

leave the service menu

calibrate next angle

skip calibration step / go to next menu

angle

sensor

Sensor Calibration

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 16

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

When the boom angle is within the calibration range, the screen will add the

‘CHANGE ?’ / ‘SET’ and ‘OK’ text as shown below:

▼Calibration for "40°" angle:

leave the service menu

adjust actual angle

set current angle to defined angle

•Measure the boom angle with the inclinometer and when the boom is positioned in the calibration

range, compare the measured angle to the displayed angle.

•If the indicated angle is within +/- 0.1 degrees of the measured angle, confirm with ‘OK’.

Otherwise, select ‘SET’ to adjust the angle.

▼Adjust "40°" angle:

leave the service menu

increase angle value by 0.1°

Confirm

decrease angle value by 0.1°

•Once you push ‘SET’ , the screen is going to change to the angle adjustment screen. Use the ‘+’

and ‘-‘ buttons to adjust the indicated angle to match the measured angle.

•When the display shows the correct angle, press ‘OK’.

Press ESC to leave sensor adjustments and return to normal LMI screen.

•Now repeat procedure as shown for the boom angle 65° and 75°.

If values were modified a confirmation screen appears at the end:

Sensor Calibration

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 17

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

▼Confirmation screen

leave the service menu

YES, I confirm

NO, go to next menu

•When you are sure to save this calibration, press ‘OK’. Normal LMI screen appears. Otherwise

press "Return" for restart the calibration procedure

Press ESC to leave sensor adjustments and return to normal LMI screen.

Troubleshooting

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 18

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

4. TROUBLESHOOTING

4.1 General information

In the event of a malfunction, if the range is not reached or is exceeded or if an operating error is

detected by the system, a message appears on the data display (1) starting with an “E” followed by a

two-digit code which indicates the reason for the malfunction.

The error codes listed in the following table describe the various error codes which can be displayed

in this system.

Faults in the microprocessor system must be dealt with only by the manufacturer’s trained customer

service personnel. If faults occur, please contact Hirschmann Service USA:

www.hirschmann.com > USA > Electronic Control Systems > Contact - ECS.

Error Code List

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 19

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

4.2 Error code list (System program LSQN V 1.11)

Error Code Error Cause Elimination

E01 Fallen below radius

range or angle range

exceeded

•Fallen below the minimum

radius or gone past the

maximum angle specified in the

respective load chart due to

luffing up the boom too far

•Luff down the boom to a radius

or angle specified in the load

chart.

E02 Radius range exceeded

or fallen below angle

range

•Gone past the maximum radius

or fallen below the minimum

angle specified in the respective

load chart due to luffing down

the boom too far

•Luff up the boom to a radius or

angle specified in the load

chart.

E03 Non-permitted slewing

zone (no load area)

•The slewing zone with load is

not permitted

•Slew to permitted area

•A non existing operating mode

has been selected

•Set the correct operating mode

for the operating state in

question

E04

Operating mode not

acknowledged or non

permitted slewing zone •The boom is in a non-permitted

slewing zone

•Slew the boom to a permitted

area.

•Boom has been extended either

too far or not far enough, e.g. if

it is prohibited to go beyond a

certain maximum boom length

or with load curves for jibs

where the main boom has to be

extended to a certain length

•Extend/retract boom to the

correct length

•Length sensor adjustment has

changed, e.g. the cable slid off

the length sensor reel.

•Retract boom. Check the pre-

stress of the cable reel (cable

must be taut). Open the length

sensor and carefully turn the

length sensor pot

counterclockwise until the

detent by means of a screw

driver

E05

Prohibited length range

•Clutch between length sensor

pot and drive is defective

•Replace the complete clutch

including drive wheel and adjust

length sensor pot as described

above

E06

Radius range exceeded

or fallen below angle

range with luffing jib

operation

•Maximum radius as specified in

the load chart exceeded or

fallen below minimum angle

due to luffing down the luffing

jib too far

•Luff the jib to a radius or angle

specified in the load chart.

•Length potentiometer is

defective

•PDB variable for analog value

not supported

•Replace length potentiometer

•Setup of correct PDB variable

for analog value in DGA6.i.3

E11

Fallen below lower limit

value for measuring

channel "length main

boom" •Electronic component in the

measuring channel is defective

•Replace sensor unit

Error Code List

© 2009 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · eMail: info.ec[email protected]e · www.hirschmann.com 20

24 183 69 1012e (Generic) / 2009-02-26 / Rev. 01 / rk.

Error Code Error Cause Elimination

•Pressure transducer is

defective.

•PDB variable for analog value

not supported

•Replace pressure transducer

•Setup of correct PDB variable

for analog value in DGA6.i.3

E12

Fallen below the lower

limit value in the

measuring channel

"pressure piston side"

•Electronic component in the

measuring channel is defective.

•Replace sensor unit

E13

Fallen below lower limit

value in the measuring

channel "pressure rod

side"

•refer to E12 •refer to E12

E14

Fallen below lower limit

value in measuring

channel "force"

•Force transducer defective

•Electronic component in the

measuring channel is defective.

•Replace force transducer

•Replace sensor unit

•Angle potentiometer defective

•PDB variable for analog value

not supported

•Replace angle sensor

•Setup of correct PDB variable

for analog value in DGA6.i.3

E15

Fallen below lower limit

value in measuring

channel "angle main

boom"

•Electronic component in the

measuring channel defective.

•Replace sensor unit

•Angle potentiometer defective •Replace angle sensor

E16

Fallen below lower limit

value in measuring

channel "angle 2"

•Electronic component in the

measuring channel defective.

•Replace sensor unit

•Length potentiometer defective •Replace length sensor.

E17

Fallen below lower limit

value "length telescope I

(+II)"

•Electronic component in the

measuring channel defective

•Replace sensor unit

E18 Front outrigger

overloaded

•Front outrigger overloaded •

•Cable between the central unit

and the slewing angle sensor

defective or loose. Water inside

the plug of the angle sensor

•1-cannel slew sensor min. value

DGA 11.5.7 <> 0

•Check cable as well as plugs,

replace, if need be.

•move to allowed slew range

•Slewing angle potentiometer is

defective

•Replace slewing angle sensor

E1A

Fallen below lower limit

value in measuring

channel "slewing angle

1".

slew below allowed

range

•Electronic component in the

measuring channel defective

•Replace sensor unit

E1B

Fallen below lower limit

value in measuring

channel "slewing angle

2"

•refer to E1A

•refer to E1A

E1C Fallen below lower limit •Angle potentiometer defective •Replace angle sensor

Other manuals for iVISOR mentor QVGA

1

Table of contents

Other Hirschmann Touch Panel manuals

Hirschmann

Hirschmann PAT DS 350GM Programming manual

Hirschmann

Hirschmann PAT EI65/0005 User manual

Hirschmann

Hirschmann iVISOR mentor QVGA User manual

Hirschmann

Hirschmann PAT IFLEX5 User manual

Hirschmann

Hirschmann Mentor EI65 User manual

Hirschmann

Hirschmann PRS 80 Wind Speed User manual

Hirschmann

Hirschmann PAT DS 160 User manual

Hirschmann

Hirschmann MARK 4E/2 User manual

Hirschmann

Hirschmann qSCALE maestro User manual