Hirschmann PAT EI65/0005 User manual

HIRSCHMANN

LENGTH-ANGLE-RADIUS-LOAD

INDICATING SYSTEM

EI65/0005

OPERATOR’S MANUAL

P/N 056-065-190-005, Rev. C, 6/15/00

Operator’s Manual EI65 / 0005

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

NOTICE

The information in this document is subject

to change without notice.

PAT makes no warranty of any kind with regard

to this material, including, but not limited

to the implied warranties of merchantability

and fitness for a particular purpose.

PAT shall not be liable for errors contained herein

or for incidental or consequential damages in

connection with the furnishing, performance

or use of this manual.

This document contains proprietary information

which is protected by copyright. All rights are

reserved. No part of this document may be

photocopied, reproduced, or translated to

another language without prior consent of PAT.

© 1996 PAT GmbH, D-76275 Ettlingen / Germany © 1999 PAT America, Chambersburg, PA 17201, USA

Operator’s Manual EI65 / 0005

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

Table of Contents

1. GENERAL INFORMATION ........................................................................................................... 1

2. WARNINGS................................................................................................................................... 1

3. SYSTEM DESCRIPTION .............................................................................................................. 2

3.1 System Function ........................................................................................................ 2

3.2 Operating Console ..................................................................................................... 5

3.3 Control Identification .................................................................................................. 6

4. PROGRAMMING PROCEDURE................................................................................................... 9

4.1 Startup Procedure ...................................................................................................... 9

4.2 Setting Operating Configuration of the Crane .......................................................... 10

4.2.1 Setting of Reevings ........................................................................................... 13

4.2.2 Selecting the Hoist Winch.................................................................................. 13

4.3 Activating and Setting of Preset Limits..................................................................... 14

4.3.1 Setting of Boom Length Presets ........................................................................ 14

4.3.2 Setting of Boom Angle Presets.......................................................................... 15

4.3.3 Setting of Boom Radius Presets........................................................................ 16

4.3.4 Setting of Boom Height Presets......................................................................... 16

4.3.5 Setting of Boom Load Presets ........................................................................... 17

4.3.6 Exit Limit Presets............................................................................................... 17

4.3.7 Default Limit....................................................................................................... 17

5. PRE-OPERATION INSPECTION................................................................................................ 18

6. OPERATION ............................................................................................................................... 19

7. SERVICE AND MAINTENANCE ................................................................................................. 20

8 TROUBLESHOOTING ................................................................................................................. 20

Malfunction Table........................................................................................................... 21

General Information

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

1

1. GENERAL INFORMATION

The PAT Length-Angle-Radius-Load Indicator System EI65 has been designed to provide the crane

operator with the essential information required to enable the machine to be used within its design

parameters. The EI65 System indicates the length and angle of the boom, tip height, working radius

and the total calculated weight being lifted by the crane.

Using various sensing devices, the EI65 System warns the crane operator of certain approaching

hazardous conditions, which could occur during the operation of the crane.

The purpose of this Operator’s Manual is to provide information to help the crane operator operate,

maintain and troubleshoot the PAT System.

The manual contains the system description, operating, and calibration information.

Always refer to operational instructions and load charts provided by the crane manufacturer

for specific crane operation and load limits.

2. WARNINGS

•The EI65 is an operational aid that warns a crane operator of certain approaching hazardous

conditions, which could cause damage to equipment and personnel.

•The device is not, and shall not be, a substitute for good operator judgment, experience and use of

accepted safe crane operating procedures.

•The responsibility for the safe operation of the crane shall remain with the crane operator who shall

ensure that all warnings and instructions supplied are fully understood and observed.

•Prior to operating the crane, the operator must carefully and thoroughly read and understand the

information in this manual to ensure that he knows the operation and limitations of the indicator

and crane.

•Proper functioning is dependent upon proper daily inspection and observations of the operating

instructions set forth in this manual.

Operator’s Manual EI65 / 0005

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

2

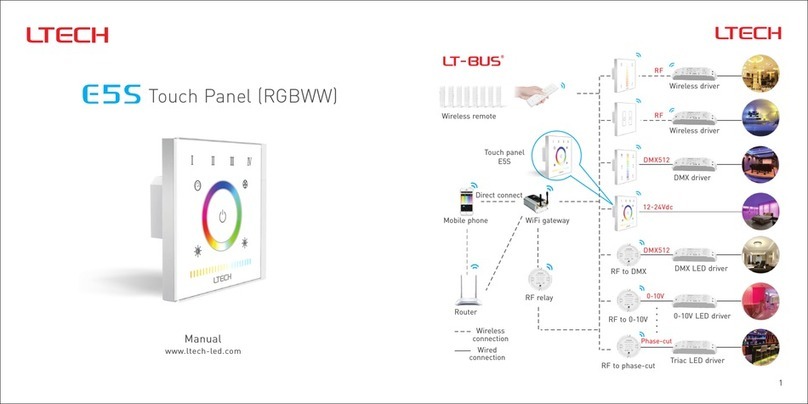

3. SYSTEM DESCRIPTION

The PAT EI65 System consists of an operating console with a central microprocessor unit,

length/angle sensor, force transducers and anti-two block switches.

Boom length and boom angle is registered by the length/angle sensor mounted inside the cable reel,

which is mounted on the boom. The boom length is measured by the cable reel cable, which also

serves as an electrical conductor for the anti-two block switches.

The crane load is measured by running line tensiometers attached to the upper side of the boom.

3.1 System Function

After ignition of the engine, the system starts with an automatic test of all lamps, the audible alarm and

the complete system.

After the system has passed through the system test without errors, the system will request the

operator to confirm the boom and jib configuration data. This allows the operator to compare the

system configuration with the actual crane configuration (Refer Section 4.1). After the operator

confirms the system configuration, the console will indicate on the display (13), the actual load, tip

height, boom length, boom angle, and radius. If an error occurs, refer to Section 8 and the error code

list.

In case of a lattice boom crane or if the crane is equipped with a jib, the operator has to confirm the

boom and jib configuration data after the system test and before normal operation (refer to Section 4

Programming Procedure

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

3

Figure 1: PAT System EI65 Components of the Telescopic Crane

1. Console

2. Cable Reel

3. Linerider or Force Transducer *

4. A2B Switch

* The load sensor depends on the system

and crane options. Refer to Installation

Manual 031-300-190-008 for system kit

options.

Operator’s Manual EI65 / 0005

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

4

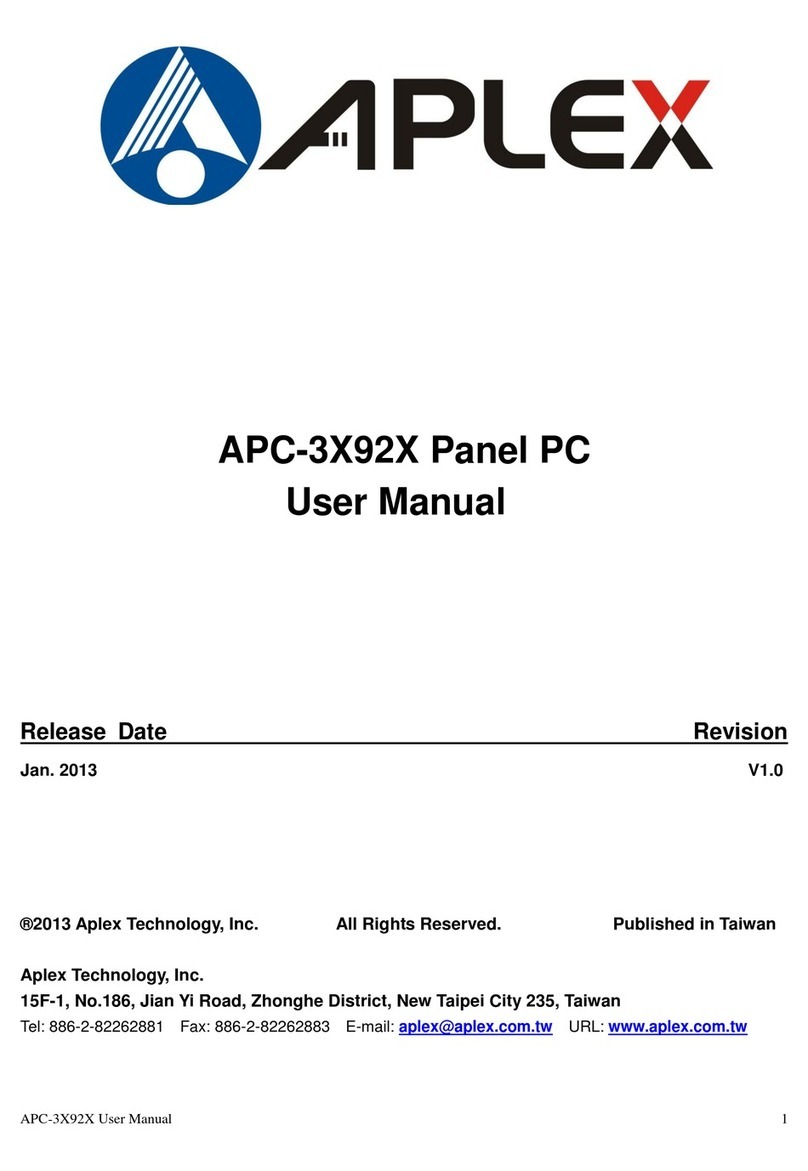

Figure 2: PAT System EI65 Components of the Lattice Crane

1. Console

2. Cable Reel

3. Linerider or Force Transducer*

4. A2B Switch

5. Angle Sensor

* The load sensor depends on

the system and crane options.

Refer to Installation Manual 031-300-

190-008 for system kit options.

Programming Procedure

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

5

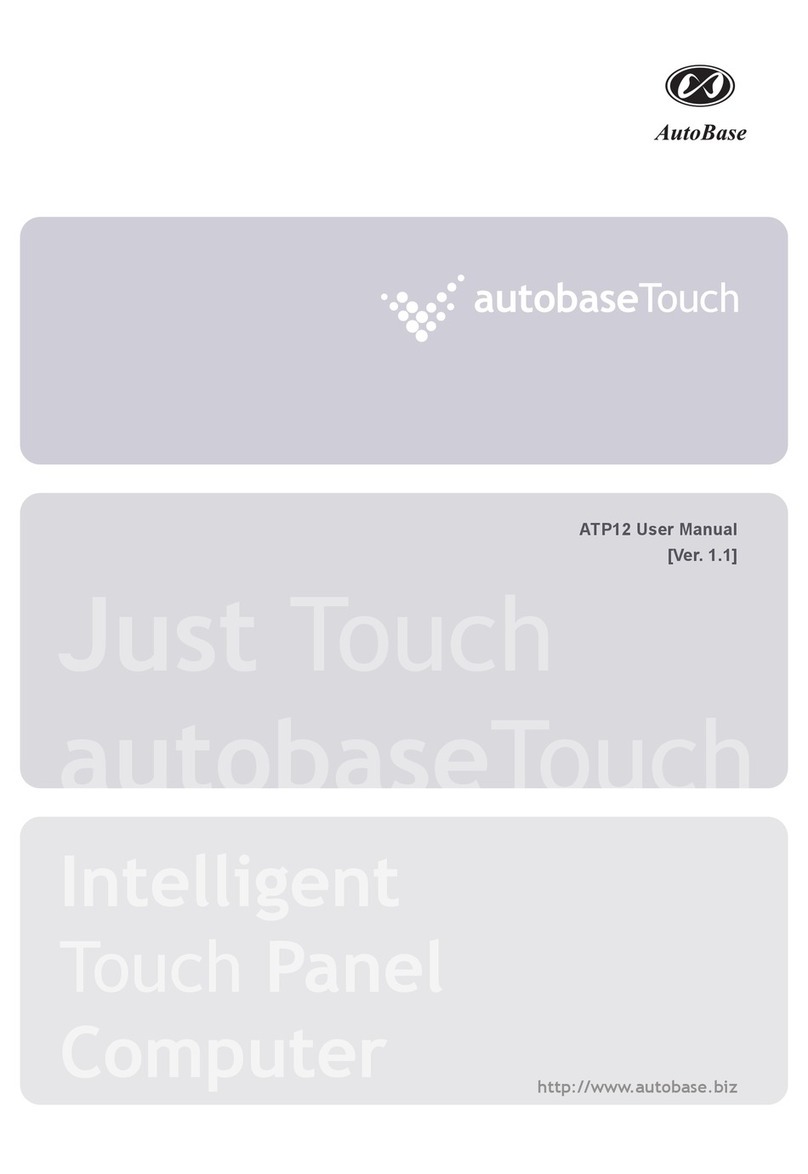

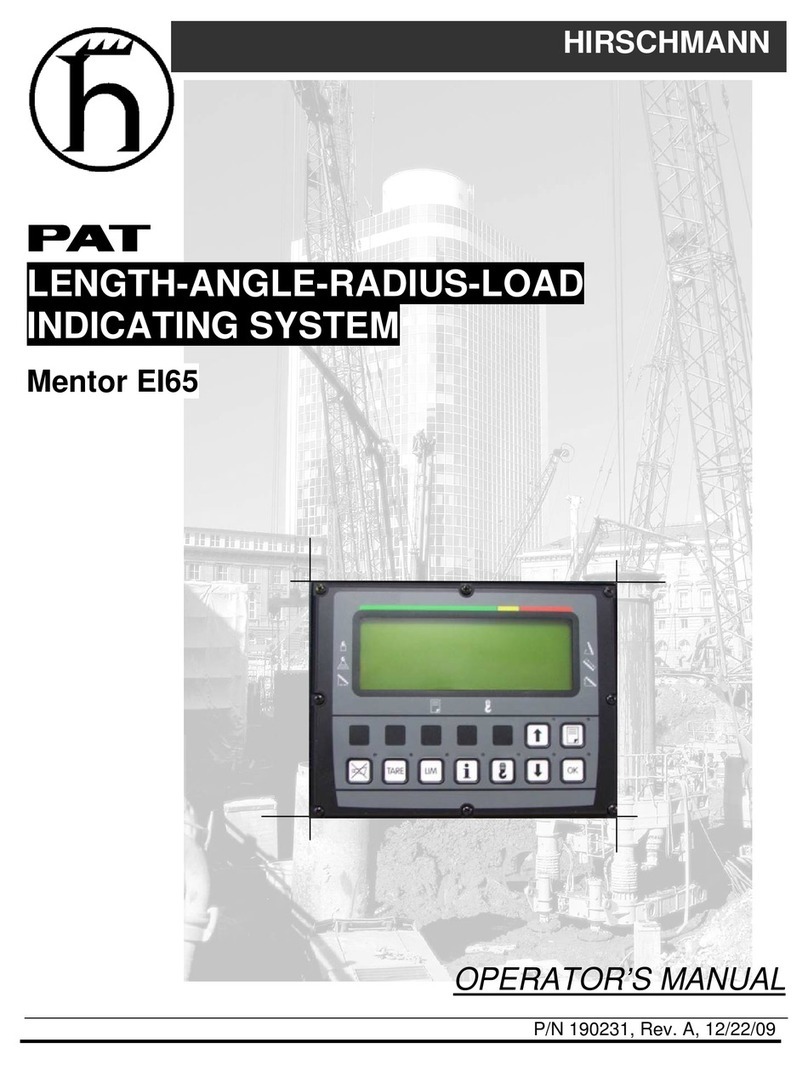

3.2 Operating Console

The console has 2 functions:

•terminal for input of instructions and information to the system by the crane operator

•display of crane data and information

The operating console is located in the operator’s cabin in front of the operator. This unit contains

different displays and controls, which are described in Section 3.3.

Figure 3. Operating Console

1. Overload Alarm Light

2. Anti-Two Block Alarm Light

3. Limit Alarm Light

4. “Horn OFF” and Alarm Light Button

5. Audible Alarm

6. “SELECT” Button

7. “Reevings/Hoist” Button

8. “LIMIT” Button

9. “TARE” Button

10. “OK” Button

11. “DOWN” Button

12. “UP” Button

13. Data Display

Operator’s Manual EI65 / 0005

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

6

3.3 Control Identification

The above figure illustrates the controls and displays of the EI65 Operating Console. The numbers of

the illustration correspond to the numbers in the following list, which describes the function of each

control.

1 Overload Alarm Light

The red Overload Alarm Light (1) will light up when the preprogrammed load limit is

reached. At the same time the Audible Alarm (4) will sound and the Limit Alarm Light

(3) and the alarm light in the button Horn-Off (5) will light up.

The corresponding crane movements will be stopped (Option).

2 Anti-Two Block Warning Light

The red Anti-Two Block Warning Light (2) will light up when the anti-two block limit

switch contacts open, indicating that a two-blocking condition is approaching. At the

same time the Audible Alarm (4) will sound and the alarm light in the button Horn-Off

(5) will light up.

The following crane movements will be stopped simultaneously: hoist up, telescope

out, boom down (Option).

3 Limit Alarm Light

The Limit Alarm Light (3) will light up when one of the preprogrammed limits are

reached. The limits defined by the operator as minimum and maximum limits for boom

angle, boom length, boom height, working radius. At the same time the Audible Alarm

(4) will sound and the alarm light in the button Horn-Off (5) will light up.

The corresponding crane movements will be stopped (Option).

4 “Horn Off” and Alarm Light Button

The Button “Horn Off” (5) allows the audible alarm to be silenced for approx. 15

seconds by pressing this button. At the same time the corresponding Alarm Light (5)

goes out.

5 Audible Alarm

The Audible Alarm (4) is located on the bottom side of the console. It sounds

during the following conditions:

•approaching two-block condition

•preset angle, height, length or radius limits are reached

•preset load limit is reached

•system error.

The alarm can be silenced for 15 seconds by pushing button (5).

STO

P

LIMI

T

Programming Procedure

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

7

6 “Select” Button

The button “Select” (6) is used for indicating and setting the values of the Operating

conditions.

After pressing this button the display indicates a part of the “Select Menu”. It is possible

to move through the different points and pages of the menu step by step by pushing the

“DOWN” (11) button.

The procedure for indicating and setting the Operating Conditions is described in Section 4.2

7 “Reevings/Hoist” Button

The button “Reevings/Hoist (7) is used for setting the number of reevings (parts of line)

and selecting the hoist winch.

After pressing the button one time the operator is requested to enter the actual number

of parts of line by using the button “Up” (12) and “Down” (11).

After pressing the button two times the operator can select the actual hoist winch by using the button

“Up” (12) and “Down” (11).

The procedure for setting the reevings and selecting the hoist winch is described in Section 4.2

8 “Limit” Button

The button “Limit” (8) is used for activating the setting procedure of the preset limits.

The limits are defined by the operator as minimum and maximum limits for boom length,

boom angle, boom height, working radius and maximum limit of load.

The procedure for setting the limits is described in Section 4.3

9 “Tare” Button

The button “Tare” (9) is used to indicate the net load on the display. Net load is the

actual load, less lifting tackle and hook block. The button “Tare” has to be activated

before lifting.

After pushing the button “Tare” (9) and before lifting the load display will be set to zero

(tare) and the lamp in the button lights up. After lifting a load the load display shows the net load

(payload).

The net load display will return to the normal load display when the button “Tare” (9) is pressed a

second time.

10 “OK” Button

This button (10) is used to confirm values and data, which are used as input for the

system. The instruction to use this button will always be given on the display.

SELECT

LIMI

T

TAR

E

OK

Operator’s Manual EI65 / 0005

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

8

11 “Down” Button

The button “Down” (11) is used to get a decrease of a numerical value at the display

during the programming and setting procedures and to move through the different

menus in “Down” direction. The instruction to use this button will be given on the display.

12 “Up” Button

The button “Up” (12) is used to get an increase of a numerical value at the display

during the setting procedure of limits and operating conditions.

13 Data Display

The Display (13) will show technical information as well as operating information and instructions for

the operator.

120.

0

112000lb

s

88.

5

81.

0

47.

5

1

6

During crane operation the readout will display the actual load, the tip height, the boom length, the

boom angle, the working radius, the selected hoist winch and the number of reevings (parts of line). In

case of a system error an error code is displayed in place of the reevings.

During the setting procedure of the Operating Conditions and the limit setting procedure the display

shows the setting values and information for the operator.

Programming Procedure

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

9

4. PROGRAMMING PROCEDURE

During the startup phase the PAT System EI65 automatically starts with a programming procedure

which relies on the correct entry by the crane operator.

This procedure consists of three parts:

•Startup Procedure

•Setting operating configuration of the crane

•Setting the preset limits

For simple operation, the computer guides the operator through the procedure step by step. The

operator has to read the information displayed and answer questions by using appropriate buttons of

the keyboard. During each step of the procedure, particular button lights will come on to identify the

possible choices for the step.

4.1 Startup Procedure

After ignition of the engine the system starts the Startup Procedure with a self-test.

During the Startup Procedure the crane operator will confirm the preset configuration stored in system

memory as described below. The operator will compare the preset operating configuration values with

the actual crane configuration.

If there is a difference between the indicated and the actual condition, the operator must correct those

values by completing Steps 1 to 15 in Section 4.2.

The system stores the preset values for a minimum of 2 hours when the crane voltage is switched off.

After a loss of the preset values, the operator will need to reset these values.

The display shows the previously programmed boom and jib configuration.

The crane operator can compare the preset Operating Configuration

Values with the actual crane configuration. To confirm the displayed

values, push the button “OK” (10).

To change the configuration values, go to one of the following sections. If the system configurations

are correct, go to Section 5 PRE-OPERATION INSPECTION.

To change the configuration values go to one of the following sections:

•Section 4.2 will allow the operator to change all crane configurations.

•Section 4.2.1 will allow the operator to quickly change Reeving only

•Section 4.2.2 will allow the operator to quickly to change Hoist selection only.

Note: On a telescopic crane the Startup Procedure will also be skipped, when only a main boom

(without jib) is preprogrammed.

MB 115.0 J1 85.0

J2 50.0 0J 15.0 1

Operator’s Manual EI65 / 0005

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

10

4.2 Setting Operating Configuration of the Crane

Note: Only calibrated operating selections, i.e. extension and/or jibs, will appear in the following

operating configuration selection.

Step 1

To enter new values the “Select” (6) button has to be pressed.

The DOWN (11) button can be pressed to skip a step in the following procedure. When a particular

step is skipped, the configured values of that step remain the same as previously programmed.

Step 2

The operator is requested to enter the boom configuration.

Press “OK” (10) Button for next step. To continue with the previously

entered boom configuration press the DOWN (11) button.

Step 3 to 9 will be skipped, when the button “DOWN” is pressed.

Step 3

The operator is requested to press the “DOWN” (11) button if the crane

is equipped with a boom extension. If the crane is equipped only with a

main boom (without jib or boom extension) the OK (10) button has to be

pressed.

Step 5 to 9 will be skipped, when the button “OK” is pressed.

Step 4 For telescopic cranes this step will be skipped.

The display shows the previously programmed or default length of the

main boom. To enter a new main boom length, the operator has to

select the value by pressing the “UP” (12) or “DOWN” (11) buttons.

Step 5 This step will be skipped, when there is no whip extension available.

If the crane is equipped with a whip extension, press the “OK” (10)

button. If the crane is not equipped with a whip extension, press the

DOWN (11) button.

Step 6 will be skipped, when the whip extension is selected.

Step 6

If the crane is equipped with an extension or jib, press the “OK” (10)

button. If the DOWN (11) button is pushed, the system will return to

Step 3, because no extension or jib have been entered.

SELECT BOOM?

PUSH ↓OR OK

MAIN BOOM?

PUSH ↓OR OK

BOOM LGTH?

PUSH ↓↑ OR OK

WHIP EXTENSION?

PUSH ↓OR OK

FIXED EXTENSION?

PUSH ↓OR OK

Programming Procedure

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

11

Step 7

The display shows the previously programmed or default length of jib 1. Enter a

new jib length, using the “UP” (12) or “DOWN” (11) buttons. If no jib 1 is used

the value 0.0 has to be selected.

Note: Jib 1 is a boom extension with fixed length and without offset angle.

Confirm jib 1 length by pressing the “OK” (10) button.

Step 8

The display shows the previously programmed or default length of jib 2. Enter a

new jib length, using the “UP” (12) or “DOWN” (11) buttons. If no jib 2 is used

the value 0.0 has to be selected.

Note: Jib 2 is a boom extension with fixed length and with offset angle.

Confirm jib 2 length by pressing the “OK” (10) button.

Step 9

The display shows the previously programmed or default offset of jib 2.

Enter a new jib offset, using the “UP” (12) or “DOWN” (11) buttons.

Confirm jib 2 offset by pressing the “OK” (10) button.

Step 10 This step will be skipped, if the crane is not equipped with an Auxiliary Hoist.

The crane operator is requested to select hoist or winch that is currently being

used. Press Button “OK” (10) for next step. If the operator wants to continue

with the previously used or default hoist, press the “DOWN” (11) button.

Step 11 will be skipped, when the button “DOWN” is pressed.

Step 11

Use the “DOWN” (10) button to toggle between the Main Hoist or the

Auxiliary Hoist. Confirm the selection by pressing the “OK” (10) button.

JIB LGTH_1: 45

USE ↓↑ OR OK

JIB LGTH_2: 25

USE ↓↑ OR OK

JIB OFFSET_2: 15

USE ↓↑ OR OK

HOIST SELECT?

PUSH ↓OR OK

MAIN HOIST?

PUSH ↓OR OK

AUXILIARY HOIST?

PUSH ↓OR OK

Operator’s Manual EI65 / 0005

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

12

Step 12

Press Button “OK” (10) to enter the number of reevings (parts of line)

being used. If the operator wants to continue with the previously

programmed or default number of reevings, press “DOWN” (11) button.

Step 13 will be skipped, when the button “DOWN” is pressed.

Step 13

The display shows the previously programmed or default number of

reevings (parts of line). To change the parts of line, use the “UP” (12) or

“DOWN” (11) buttons. If the operator wants to continue with the

displayed number of reevings (parts of line), confirm by pressing the

“OK” (10) button.

Step 14

If you would like to review the selection made in the programming

procedure, press “OK” (10) button. The display will show jib length and

offset, check correct and press “OK”. If no jibs were selected the Exit

screen will appear.

Step 15

The Setting Procedure is completed. The crane operator has the

possibility to accept the conditions programmed on Step 1 to 13, or to

correct the values.

For correction of the preset condition press the “DOWN” (11) button and

correct the selection you have made in this programming procedure. After correcting the selection,

return to the EXIT screen to accept and exit.

Press the “OK” (10) button.

The operating screen will be displayed, which shows the measured crane data. Complete Section 5.

PRE-OPERATION INSPECTION to ensure the data shown is correct.

REEVING?

PUSH ↓OR OK

PARTS OF LINE: 1

PUSH ↓↑ OR OK

SHOW SELECTION?

PUSH ↓OR OK

EXIT!

PUSH ↓OR OK

Programming Procedure

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

13

4.2.1 Setting of Reevings

The operator can activate the setting procedure by pushing the button “Reevings/Hoist Winch” (7).

After pushing the button one time an asterisk will appear on the display beside the number

of reevings, indicating that the procedure of setting the reevings is activated. To enter a

new number of reevings the operator has to select the value by pushing the buttons “UP”

(12) or “DOWN” (11).

If the operator wants to continue with the displayed number of reevings (parts of line) he

has to confirm by pushing the button “OK” (10).

After pushing the button “OK” (10) the procedure for Number of Reevings is completed.

The operating screen will be displayed, which shows the measured crane data. Complete Section 5.

PRE-OPERATION INSPECTION to ensure the data shown is correct.

4.2.2 Selecting the Hoist Winch

The procedure for selecting the hoist winch can be activated by the operator by pushing the button

“Reevings/Hoist Winch” (7) two times.

After pushing the button two times an asterisk will appear on the display beside the

symbol for the hoist winch.

Select either the main hoist “UP” (12) or the auxiliary hoist using the button “DOWN”

(11).

Select the hoist or winch that is currently being used, and confirm by pushing the “OK” (10) button.

The operating screen will be displayed, which shows the measured crane data. Complete Section 5.

PRE-OPERATION INSPECTION to ensure the data shown is correct.

16 *

*

Operator’s Manual EI65 / 0005

© PAT Rev. C 06/15/00 // CSH 056-065 / 190005_c.doc

14

4.3 Activating and Setting of Preset Limits

The PAT System EI65 is equipped with the following presets:

•limit for maximum hook load

•limits for maximum and minimum boom angle, boom length and working radius.

The operator has the option to activate a maximum and minimum limit of one of the above

geometric dimensions.

When a limit is activated, it is identifiable by a blinking colon on the working screen for the

corresponding geometric data displayed.

The operator has to read the information displayed and is instructed to answer questions by

using appropriate buttons of the keyboard as defined in the following procedures. During the

Setting Procedure, the lamp in the particular button lights up to indicate button option.

When the system is longer than 2 hours without supply voltage, the preset values may be lost

and will reset to the to the maximum or minimum limits.

To activate a preset limit press the LIMIT (8) button.

Scroll through the following limits by pressing the “DOWN” (11) button this will allow you to

select one of the following presets:

4.3.1 Length Limit

4.3.2 Angle Limit

4.3.3 Radius Limit

4.3.4 Height Limit

4.3.5 Load Limit

4.3.6 EXIT Limit; exits the limit settings

4.3.7 Default Limits; set the all limits at a maximum and minimum

4.3.1 Setting of Boom Length Presets

Step 1

This message appears after pushing the “LIMIT” (8) button and pressing

the “DOWN” (11) button to scroll through the limits. To set a minimum

and maximum boom length limit press the “OK” (10) button.

Step 2

The minimum boom length preset value is displayed, use the “UP” (12)

and “DOWN” (11) buttons to change the displayed value to your desired

limit. Push Button “OK” (10) for next step.

LENGTH LIMIT?

PUSH ↓OR OK

MIN. LIMIT: 10

USE ↑↓ OR OK

Table of contents

Other Hirschmann Touch Panel manuals

Hirschmann

Hirschmann MARK 4E/2 User manual

Hirschmann

Hirschmann iVISOR mentor QVGA User manual

Hirschmann

Hirschmann Mentor EI65 User manual

Hirschmann

Hirschmann PAT IFLEX5 User manual

Hirschmann

Hirschmann PAT DS 350GM Programming manual

Hirschmann

Hirschmann qSCALE maestro User manual

Hirschmann

Hirschmann PRS 80 Wind Speed User manual

Hirschmann

Hirschmann PAT DS 160 User manual

Hirschmann

Hirschmann iVISOR mentor QVGA User manual