HITROL HCC-95P-Ex Series User manual

HCC-95P-Ex Series

HITROL CO.,LTD. 1

HITROL CO., LTD.

HEAD OFFICE.FACTORY.R&D INSTITUDE

HITROL CO., LTD 141, Palhakgol-gil, Jori-eup

Paju-si, Gyeonggi-do, Korea

TEL. : (+82)-31-950-9700

FAX. : (+82)-31-943-5600

www.hitrol.com

INSTRUCTION MANUAL

CAPACITANCE TYPE LEVEL SWITCH

HCC-95P-Ex Series

Doc. no.: HCC95P-Ex(IECEx)_IM_Eng_Rev.0

Issue date: 2020. 10

IECEx KSCP 21.0019X

2021-04-27

HCC-95P-Ex Series

HITROL CO.,LTD. 2

You should be careful where CAUTION is marked to carry

out the work.

You should be well-informed of the contents where

WARNING is marked before carrying out the work.

You should be aware of where NOTICE is marked to carry

out the work.

Table of Contents

Overview

·

· · · · · · · · · · · · · · · · · ·

· ·

·

·

·

·

·

·

·

·

·

·3

Mechanism

and Components

· · · · · · · · · · · · · · ·

3

Features · · · · · · · · · · · · · · ·

· · · · · · · · · · · · · · · · 3

Specifications

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

4

Dimension and Technical Data

·

·

·

·

·

·

·

·

·

·

·

·

·

·

5

Installation

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

7

Attachment and Cautions

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

7

Cautions for Removal

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

8

Wiring

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

8

Precautions for

Use

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

9

Safety and Environment

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

9

Cautions for Inserted External Wire

·

·

·

·

·

·

·

·

·

10

Failure Check and Maintenance

·

·

·

·

·

·

·

·

·

·

·

·

10

Label

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

11

Product Notation

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

11

User Training

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

12

Warranty and Contact

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

12

APPENDIX E · · · · · · · · · · · · · HCC-95P Setting Guide

APPENDIX H · · · · · · · · · · Serial USB Terminal Install Guide

HCC-95P-Ex Series

HITROL CO.,LTD. 3

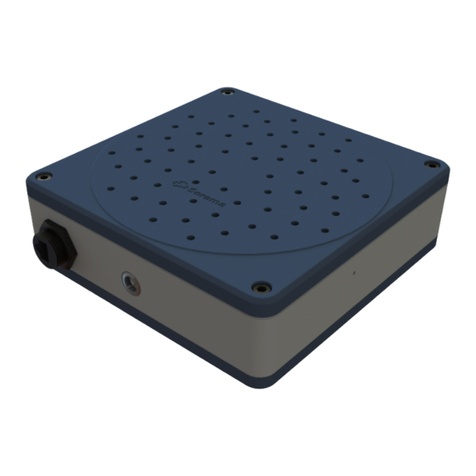

Overview

Mechanism

and

Components

Features

■ The level of different types of liquid and power can be detected.

■ It has a solid structure and is semi-permanent, because it does not have any

mechanically moving part.

■ It can be used with a corrosive liquid (aqueous solution).

■ Wiring facilitates installation (HCC-95PW).

■ Operation state can be checked.

■ Different shapes of probes are offered for different purposes.

HCC-95P Series can be installed on the top and side of the tank, and it is a

Capacitance Type Level Switch device that converts, measures and senses the inherent

dielectric constant of the measured object into a capacitance value, and outputs the

water level.

When the level between the electrode probe and wall increases, the air around electrode

probe is replaced with another dielectric substance (object to be measured) to change the

capacitance value. Initially, the electrode probe has a low capacitance value in the air, but the

value increases when the object to be measured rises and covers the electrode probe. This

change is sensed to detect the object to be measured.

C: Capacitance of object to be measured.

C1: Initial capacitance.

R : Conductivity of object to be measured.

Module

Housing

Process Conn.

Inactive Rod

Insulation

Sensing Probe

HCC-95P-Ex Series

HITROL CO.,LTD. 4

Specifications

Model HCC-95P-Ex-XX HCC-95PH-Ex-XX HCC-95PW-Ex-X HCC-95PWH-Ex-X

Probe Type Rod(Flat) Rope

Mounting Flange & Screw

Ambient Temperature -20°C ~ +60°C

Process Temperature -40°C~+80℃ -40°C~+150℃

-40°C~+80℃ -40°C~+150℃

Process Pressure Vacuum~ 20kg/cm2(300#)

Power Source AC 90~240V(0.03A), 50Hz/60Hz / DC 24V(0.06A)

Contact Rating AC 250V 5A, DC30V 5A

Enclosure Ex d IIC T5/T6(*) Gb Ex d IIC T3/T4(*) Gb Ex d IIC T5/T6(*) Gb

Ex d IIC T3/T4(*) Gb

Wetted Parts Material 304 SS, 316L SS with Teflon(Peek)

Process Connection PT 1”(M) Screw, 25A JIS 10K RF

Housing ; Cable Entry AL. ; PF 1/2”(F)

Electric Specifications

Model M-95P

Microprocessor 16 Bit Microprocessor

Oscillation Frequency 1MHz @ ±50KHz

Sensitivity (Adjustment) 5pF ~ 100pF @ 10pF Step

Dielectric Constant 0.2 @ Min

Relay Delay Time (Adjustment) 1Sec. @ Min. ~ 60Sec. @ Max.

Relay Return Time (Adjustment) 1Sec. @ Min. ~ 60Sec. @ Max.

Relay Contact Out Control Normal Close @ Default.

Relay Contact Rating DPDT : AC250V/5A, DC30V/5A

Status Indicator Bi-Color LED [Green / Red / Orange]

Detection Indicator Red LED

Relay Control Indicator Green LED

Function

- Activation Point Adjustment

- Measurement Range Adjustment

- Relay Delay Time Adjustment

- Relay Return Time Adjustment

- Relay Out Control (Normal/Reverse)

(*)Process Temperature for “T Grade” Max. 70℃ for T6

Max. 80℃ for T5

Max. 120℃ for T4

Max. 150℃ for T3

HCC-95P-Ex Series

HITROL CO.,LTD. 5

Dimension and Technical Data

The dimensions on the following pages are indicated in [mm].

Active Rod

material:

316L with

Teflon

Rod Type

Rod Type

Rope

material: 316

Connection Type

-Screw: PT 1” (Std.), NPT 1”, PF 1”, Others

-Flange: ANSI, JIS, DIN

-Tri-Clamp

Material

-304, 316L, Others

Active Rod

material:

316L with

Teflon

Weight material:

C.S, 316L

[Housing]

[Connection]

[Probe]

High Temp. Version

Material: Aluminum

Active Rod

material: 316L

For Liquids

For Solids

Inactive Rod

material: 316L

Inactive Rod

material:

316L with

Teflon

Inactive Rod

material: 316L

Rod Type

(Fully insulated w/ TEFLON)

Insulation

material:

Teflon

Insulation

material:

Teflon

Active Rod

material: 316L

Rope Type Flat Type

Actual product may have a tolerance slightly.

* In the case of flat type, in can also be used in liquid.

(However, as a test sample, it must be separately verified

at the manufacturer.)

HCC-95P-Ex Series

HITROL CO.,LTD. 6

For Liquids For Solids

Rod Probe

Rod Probe

Fully insulated

w/ TEFLON

Rod Probe Rope Probe

Total length(L) 100~2,500 300~1,000 100~2,500

Min. 1,000, Max. 10,000

≤2,500

≤4,500

>4,500

Active Rod Length

(L-L1) 100~1,000 150~500 100~1,000 -

Inactive Rod

Length(L1) ~1,500 150~500 ~1,500 -

Active Rod dia. Ф15

(including Teflon)

Ф30

(including Teflon)

Ф15

(including Teflon)

-

Inactive Rod dia. Ф25.4 Ф30

(including Teflon)

Ф25.4 -

Weight A - - - 170 300 300

B

-

-

-

Ф28

Ф28

Ф40

For acid liquids - O - -

For high-viscosity

liquids O O - -

HCC-95P-Ex Series

HITROL CO.,LTD. 7

Installation

Attachment

and

Cautions

A capacitive level switch can be attached using screws (PT, NPT, PF), flanges (ANSI, JIS, DIN),

or Tri-Clamp. Pay attention to the following for installation.

Installation on the side of a tank (horizontal)

As level is detected with an entire electrode, very sensitive measurement is available.

However, build-up causes malfunction. As such, the electrode needs to be installed at a slant

with its tip horizontally at the bottom.

Installation on top of a tank (vertical)

This installation reduces the effect of build-up, but level is detected only with the tip of an

electrode. As such, it has relatively lower sensitivity and may thus be inadequate for an object

to be measured with low dielectric constant.

■ To install 2 or more level switches in one container, keep 300m or more between probes.

(If the gap is smaller between probes, they may interfere each other causing instability.)

■ For the side installation, the inactive road must be exposed by 50mm or more in the tank

with the probe slanted by 15° to the horizontal plane. (Foreign substance between a nozzle

and probe may cause malfunction.)

■ Keep the probe away from the inlet of measure object, and install a protector to protect

the probe.

■ Keep the wire inlet facing the ground to maintain its rainproof feature.

■ When installing it in low level, be careful with dead stock and material bridge.

■ If the measure object is fluid in the tank, set adequate time delay for the output relay.

■ Install a sun cover for outdoor installation so as to avoid the influence of temperature rise.

■ If there is an agitator, keep safety distance between the agitator and probe.

■ When installing the sensor, avoid places with a lot of vibration or obstacles.

■ The fluid flow is severe near the outlet, and it is easy to cause mechanical damage or

chattering, so installation near the outlet should be avoided.

■ It is necessary to check if the temperature and pressure generated inside the tank meet the

specifications.

■ If the temperature of the housing is significantly different from the ambient temperature, a

solvent filling or Gortex (Ventilation) shall be applied prior to use, as condensation may

occur.

■ Use the same standard flange or screw.

■ Make sure to insert gaskets between flanges.

The user shall determine if the product involved is an Ex-proof zone and

install the appropriate product.

HCC-95P-Ex Series

HITROL CO.,LTD. 8

Cautions

For

Removal

Wiring

■ Check the level and presence of liquid in the tank before removing it.

■ The product may be overheated so wear gloves to prevent burns.

■ If there is explosive gas in the atmosphere, do not open the cover.

■ To open the cover of an ex-proof product, release the SET SCREW (ex-proof key) first.

■ Disconnect the power first.

■ Make sure that any O-ring or gasket is not damaged while opening or closing

the product cover.

Make sure that it is not subject to any high impact when moving it.

In the case of explosion-proof products, apply power after fastening the cover

after wiring.

■ Connect AC (90–240 V) or DC (24 V) according to the power specifications.

■ Make sure to connect the power with the correct polarity (+, -).

■ Do not connect the wire with the power connected.

■ This product provides DPDT. Wire it with COM and NO terminal to use HIGH contact.

■ Make sure to connect it to an external ground.

If there is an atmosphere of explosive gas and explosive dust, do not open the product cover.

HCC-95P-Ex Series

HITROL CO.,LTD. 9

Precautions

for Use

Safety and

Environment

■ Users should use appropriate products by judging the explosion-proof area of the related

products.

■ Do not bend the sensor, which is the measurement part, or cut or expand it arbitrarily.

■ Apply power after installation is completed and cover of product is fastened.

■ Do not use when the ambient temperature range (-20~+60℃) is exceeded.

■ Do not use when the degree of protection is higher than the IP66 condition.

■ It should not be used where there is vibration.

■ Precautions for Use

- Make sure to connect the product and vessel using required tools for sure.

- Keep the lock key safe and make sure that it is locked.

- Do not apply high impact to the product.

■ Precautions for Wiring

- Make sure to wire contacts correctly (refer to Wiring)

- Internal ground (inside product housing) and external ground shall be connected.

- Pay attention to prevent electric shock.

■ Disposal of Product

- Make sure to separate the amplifier and main unit from housing before disposing the products. Also, the

amplifier shall be detached and discard the metal and non-metallic materials. No part (ex. Mercury

switch) has influence on the environment, so no special attention is required.

HCC-95P-Ex Series

HITROL CO.,LTD. 10

Cautions

for

Inserted

External Wire

Failure Check

And

Maintenance

■ Use the cable gland connection or metal pipe line lead-in on the wire inlet, and use

a product with an equivalent ex-proof certificate to connect it using the external line

lead-in method.

■ For an unused external line inlet, use a closing plug with an equivalent ex-proof certificate.

■ Precautions for ground connection

- The location of the external ground is as follows, and when connecting to the ground

wire must be 4㎟ (4mmSQ) or more. (Internal grounding should be connected with

the same specifications as the connection cable.)

Washer must be used when reconnecting after disassembling the terminal lug to the

ground terminal. (Anti loosening)

ground

External ground

■ Inspection

The sensor and transmission parts of a capacitive-level transmitter must be inspected.

Their service lives depend on the user environment and can be optimized with regular

inspection. As such, users are advised to conduct regular inspections and maintenance at

least every year. The exterior damage will be visually inspected, and any object to be

measured and foreign substance will be regularly removed from the probe as these can

affect accuracy.

When removing them, prevent causing damage to the Teflon.

■ Failure Check

1) Is the power connected correctly?

2) Is the power voltage correct?

3) Is the cabling correct?

4) Is the green LED turned on?

During maintenance, the power to the product must be completely cut off

before inspection.

Do not disassemble while power is applied in an explosion-proof area.

Internal ground

ground

HCC-95P-Ex Series

HITROL CO.,LTD. 11

Label

Product Notation

■ Label

The label is attached on the housing to state the model, serial number, working

temperature, working pressure, and output. The serial number is a unique manufacturing

number.

■ IECEx Certification standard

IEC 60079-0 : 2017 Edition : 7.0

Explosive atmospheres – Part 0 : Equipment – General requirements.

IEC 60079-1 : 2014 Edition : 7.0

Explosive atmospheres – Part 1 : Equipment protection by flameproof enclosures “d”

IEC

The composition of the product is as follows.

HCC-95P * * - Ex- *

FR : FLANGE / ROD & F : FLANGE (ONLY WIRE TYPE)

FF : FLANGE / FLAT

SR : SCREW / ROD & S : SCREW (ONLY WIRE TYPE)

SF : SCREW / FLAT

“H” High Temperature

“W” Wire

HCC-95P-Ex Series

HITROL CO.,LTD. 12

User Training

Warranty

and Contact

■ Warranty and Service

This product is subject to a two-year warranty upon shipment and free service will be

provided for any damage found under normal operating conditions. If troubles that

occur are not due to product failure, service charge will apply.

You can request A/S from our website or by contacting our headquarters.

■ Headquarters, Factory, and Research Center (Contacts)

Address: Hitrol, 141, Palhakgol-gil, Jori-eup, Paju-si, Gyeonggi-do, Republic of Korea

(Palhakgol-gil 98)

HITROL CO., LTD. 141, Palhakgol-gil, Jori-eup, Paju-si, Gyeonggi-do, Korea

TEL.: 031-950-9700 (Headquarters and A/S)

FAX: 031-943-9796–9799 (Headquarters and A/S)

Read and understand the aforementioned and make sure that the temperature of the object

to be measured does not exceed 800℃ for general purpose. For an ex-proof type, the

maximum is 150℃. In addition, make sure that the ambient temperature of the housing is

kept at -20 – +60℃.

An ex-proof product is a pressure-resistance and ex-proof type, so do not open the cover

while using it.

Do not apply a non-ex-proof product in an ex-proof zone.

An ex-proof product can be used where the environment and containers of the

object to be measured are type 1 and 2.

Sensing Probe can be a source of ignition because it operates on the principle

of Capacitance. Therefore, the tank interior is a non-hazardous area and cannot be

used in locations containing flammable products.

HCC-95P

조정방법 설명서

Capacitance Type Level Switch

Doc. no. : Rev1.0

APPENDIX E

1. M-95P 구성 및기능

No

구성

기능

1

SET.

■Autoset

○Tank내정전용량 자동 측정 및기준

2

RANGE

■정전용량 측정 감도 범위 설정

○감도 설정 범위 : 10pF ~ 150pF

○감도 설정 방법 : BCD Dip Switch

3

SEN.

■정전용량 측정 감도 세밀 조정

○Dry Contact 감도 세밀 조정 범위 : △10pF

○Wet Contact 감도 세밀 조정 범위 : △-5pF

4

DT.

■Relay Delay Time 동작 시간 설정

○시간 범위 : 0.5s, 1s ~ 10s @ Adjustment 0.1s

5

RT.

■Relay Return Time 복귀 시간 설정

○시간 범위 : 0.5s, 1s ~ 10s @ Adjustment 0.1s

6

Fail Safe Mode

■Relay 동작 변환 설정

○N.C ↔N.O

7

DET.

■매질 측정 상태 LED

○OFF →Red

8

RLY.

■Relay 동작 상태 LED

○N.C 상태 : OFF →Green

○N.O 상태 : Green →OFF

9

PWR

■전원 및상태 표시

10

UART

■M-95P 동작 상태 통신용 Port

11

Power

■공급 전원 (AC용/ DC용)

12

Relay Out

■Relay Contact Out (DPDT)

2. M-95P 세팅 및조정 방법

■초기화 세팅 방법

□Tank 설치 후빠른 응답성을 위하여 초기화 상태로 세팅합니다.

■Tuning 세팅 방법 1

□“Autoset 설정 후감도 조정”에 따른 세팅 방법입니다.

No

기능

방법

1

SET.

■“SET.” Tact Switch를 1초간 누르면 PWR LED가점.소등 됩니다.

■Tank 내의 정전용량값을 자동 측정하여 기준값을 설정합니다.

2

SEN.

■“SEN.” VR로 측정 매질의 감도 변화값을 설정합니다.

■“감도 조정 방법” 참조 바랍니다.

■Tuning 세팅 방법 2

□“감도 조정 후Autoset”에 따른 세팅 방법입니다.

No

기능

방법

1

SEN.

■“SEN.” VR로 측정 매질의 감도 변화값을 설정합니다.

■LED가켜져 있을 수도 있습니다.

■“감도 조정 방법” 참조 바랍니다.

2

SET.

■“SET.” Tact Switch를 1초간 누르면 PWR LED가점.소등 됩니다.

■Tank 내의 정전용량값을 자동 측정하여 기준값을 설정합니다.

■감도 조정 방법

□Dry Contact 환경 설치 시측정 감도를 조정할 수있습니다.

No

기능

방법

1

Dry Contact 환경

■측정 매질의 미접촉 상태입니다.

2

SET.

■“SET.”Tact Switch를누른 후조정 가능합니다.

■감도 설정 및조정 후“SET.”Tact Switch를누를 수있습니다.

3

RANGE

■RANGE : 정전용량 측정 감도 설정 범위입니다.

■측정 감도 조정 범위 : 10pF ~ 150pF

■측정 감도 조정 방법

4

SEN.

■SEN. : RANGE 측정 감도 설정 범위내에서의 세밀 조정 범위입니다.

■감도 세밀 조정 범위 : △10pF

□Wet Contact 환경 설치 시측정 감도를 조정할 수있습니다.

No

기능

방법

1

Wet Contact 환경

■측정 매질의 접촉 상태입니다.

2

SET.

■“SET.”Tact Switch를누른 후조정 가능합니다.

■감도 설정 및조정 후“SET.”Tact Switch를누를 수있습니다.

3

RANGE

■RANGE : 정전용량 측정 감도 설정 범위입니다.

■측정 감도 조정 범위 : 10pF ~ 150pF

■측정 감도 조정 방법

4

SEN.

■SEN. : RANGE 측정 감도 설정 범위내에서의 세밀 조정 범위입니다.

■감도 세밀 조정 범위 : △-5pF

□측정 감도 설정 및세밀 조정 영역.

■Relay 동작 시간 조정 방법

□측정물 감지 후Relay 동작 시간을 조정할 수있습니다.

□측정물 미감지 후Relay 복귀 시간을 조정할 수있습니다.

No

기능

방법

1

DT.

■Relay Delay Time

■시간 조정 범위 : 0.5s, 1s ~ 10s @ Adjustment 0.1s

No

기능

방법

1

RT.

■Relay Return Time

■시간 조정 범위 : 0.5s, 1s ~ 10s @ Adjustment 0.1s

Table of contents

Other HITROL Measuring Instrument manuals