7

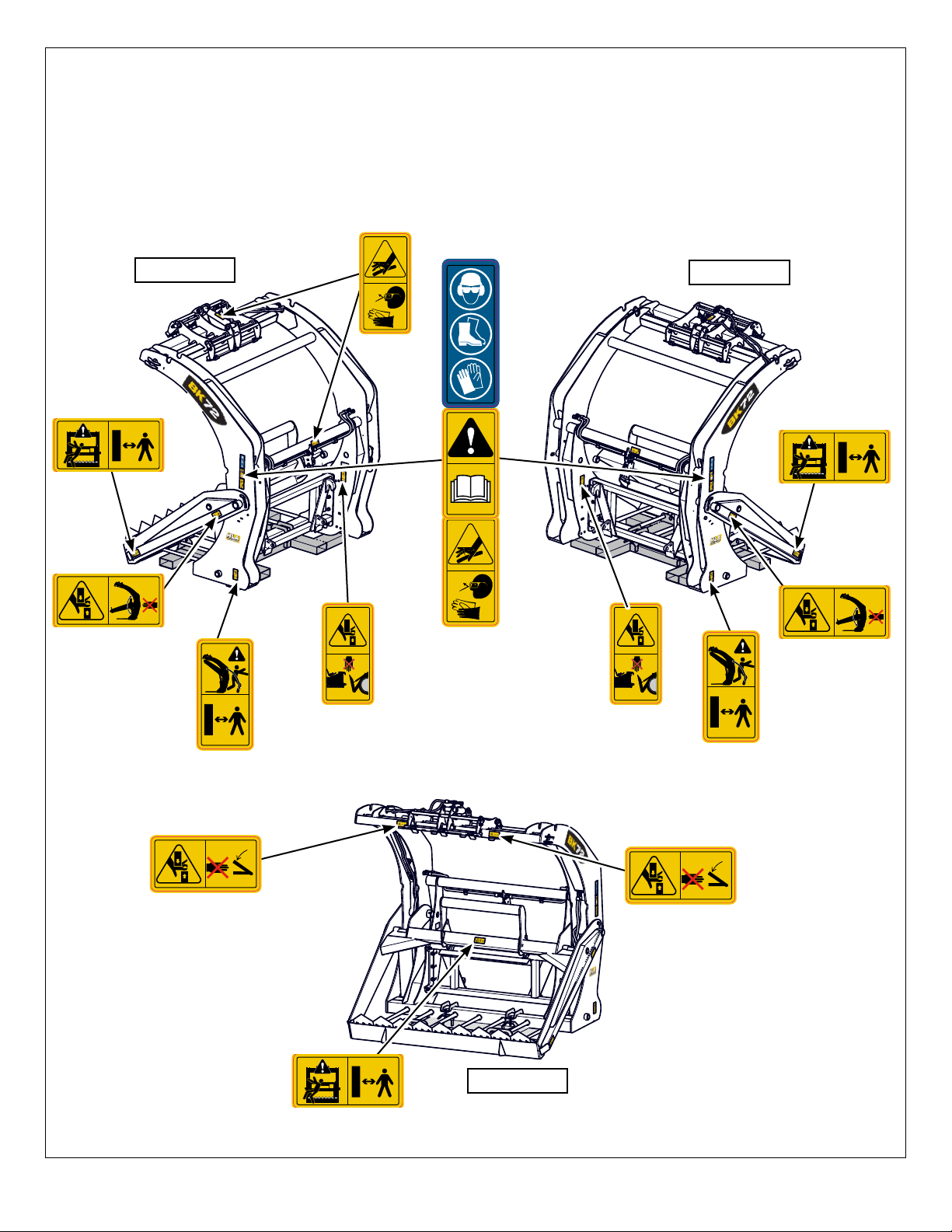

Safety Labels

Safety labeling is an important part of the overall safe use of the implement. Safety labeling alerts and warns against

potential injury or death, and is important to follow these points to help keep your implement safe for you and others who

may be using it.

If labels need to be replaced:

• Be sure that the installation area is clean and dry.

• Be sure temperature is above 50°F (10°C).

• Determine exact position before you remove the backing paper.

• Remove the smallest portion of the split backing paper.

• Align the sign over the specied area and carefully press the small portion with the exposed sticky backing in place.

• Slowly peel back the remaining paper and carefully smooth the remaining portion of the sign in place.

• Small air pockets can be pierced with a pin and smoothed out using the piece of sign backing paper.

Safety Label Descriptions

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or have become

illegible.

• Replaced parts that displayed a safety sign should

also display the current sign.

• Safety signs in Section 3 each have a part number

displayed with it. Use this part number when ordering

replacement parts.

• Safety signs are available from your authorized

Distributor or the factory order desk.

SL00008

SL00002

SL0010H

SL00004

SL00009H

SNL00001

Caution: read and understand ALL safety and

operating instructions in the manual, read and

understand ALL safety labels located on the

machine. The most important safety device on

this equipment is an informed SAFE operator.

Caution: be aware of sharp cutting arm

blades and tines. Cutting arm must aways

be stored in the up position. Use caution

and keep distance when walking around

the blades and tines. Possible tripping hazard

could result in death or serious injury from

laceration or impact.

Caution: Moving parts present a potential pinch

hazard and could result in a serious injury.

Use caution and be aware of parts as they are

being moved or adjusted. Possible pinching or

crushing hazard.

Caution: Moving cutting arm assembly

presents a potential pinch hazard and

could result in a serious injury. Use caution

and be aware of the arm as it moves up

and down. Possible pinching or amputation.

Caution: Personal Protection Equipment (PPE)

is required when operating or maintaining this

machine. Failure to wear PPE will result in

personal injury.

Caution: Hydraulic uid is under pressure, be

aware that hydraulic leaks could develop with

out warning. . Do not check for leaks with your

hand or ngers while the system is pressurized,

serious injury could result. Possible burns or

poisoning from pressurized uid injection.

SL00015

Caution: do not detach or store the bale knife

without placing it to the shipping / storage stand.

The BK is unstable in this position and could tip

without warning and serious injury could result.

Possible crushing or broken bone hazard.

SL00022

Caution: do not place your hand or any part

of your body on or near the front mount while

coupling to the power unit. Parts moving

together present a pinch point and may cause

serious injury Possible laceration, crushing,

amputation hazard.

Chassis parts lists for this product can be found online. Visit hlaattachments.com and click on the PARTS tab to be

directed to our online parts catalogue.

Parts List