AUMA FQMEx 05.1 User manual

Fail safe unit

FQMEx 05.1 –FQMEx 12.1

FM version (Class/Division System)

Assembly, operation, commissioningOperation manual

Read operation manual first.

●Observe safety instructions.

●This operation manual is part of the product.

●Store operation manual during product life.

●Pass on manual to any subsequent user or owner of the product.

●Proposition 65:This product may contain one or more substances or chemicals known to the state of

California to cause cancer.

Target group:

This document contains information for the mounting, commissioning, and maintenance staff.

Table of contents Page

41. Safety instructions................................................................................................................. 41.1. Prerequisites for safe handling of the product 41.2. Range of application 51.3. Warnings and notes 51.4. References and symbols 61.5. Safety instructions for the handwheel

72. Identification........................................................................................................................... 72.1. Name tag 92.2. Short description

103. Transport, storage and packaging........................................................................................ 103.1. Transport 113.2. Storage 113.3. Packaging

124. Assembly................................................................................................................................ 124.1. Mounting position 134.2. Actuators for fail safe units 134.3. Mounting the fail safe unit to the valve 144.3.1. Overview on coupling variants 144.3.1.1. Fail safe unit to valve: mount

185. Electrical connection............................................................................................................. 185.1. Basic information 185.2. Electrical connection of actuator/actuator controls 185.3. Electrical connection for fail safe unit 195.3.1. Connect cables with KES type electrical connection 195.3.1.1. Open terminal compartment 205.3.1.2. Cable connection 215.3.1.3. Terminal compartment: close 225.4. Initialization

236. Commissioning...................................................................................................................... 236.1. End stops in part-turn actuator 236.2. End stops in the fail safe unit 246.2.1. End stop CLOSED: set 246.2.2. End stop OPEN: set 246.3. Actuator settings (for initial commissioning)

2

FQMEx 05.1 –FQMEx 12.1

Table of contents FM version (Class/Division System)

267. Fail safe operation and standard operation.........................................................................

278. Indications.............................................................................................................................. 278.1. Indications on display 278.1.1. Indications during and after initialization 278.1.2. Indications during fail safe operation 288.2. Indication lights of local controls 288.2.1. Indication lights (indications): modify

299. Signals (output signals)......................................................................................................... 299.1. Status signals via output contacts (digital outputs) 299.1.1. Assignment of outputs 299.1.2. Direct feedback signals from the fail safe unit

3010. Servicing and maintenance................................................................................................... 3010.1. Maintenance intervals

3111. Technical data......................................................................................................................... 3111.1. Technical data Fail safe unit

35Index........................................................................................................................................

3

FQMEx 05.1 –FQMEx 12.1

FM version (Class/Division System) Table of contents

1. Safety instructions

1.1. Prerequisites for safe handling of the product

The end user or the contractor must ensure that all legal requirements, directives,

guidelines, national regulations and recommendations with respect to assembly,

electrical connection, commissioning and operation are met at the place of installation.

Safetyinstructions/warn-

ings All personnel working with this device must be familiar with the safety and warning

instructions in this manual and observe the instructions given. Safety instructions

and warning signs on the device must be observed to avoid personal injury or property

damage.

Proposition 65: This product may contain one or more substances or chemicals

known to the state of California to cause cancer.

Qualification of staff Assembly, electrical connection, commissioning, operation, and maintenance must

be carried out exclusively by suitably qualified personnel having been authorized by

the end user or contractor of the plant only.

Prior to working on this product, the staff must have thoroughly read and understood

this manal and, furthermore, know and observe officially recognized rules regarding

occupational health and safety.

Work performed in potentially explosive atmospheres is subject to special regulations

which have to be observed.The end user or contractor of the plant are responsible

for respect and control of these regulations, standards, and laws.

Commissioning Prior to commissioning, it is important to check that all settings meet the requirements

of the application. Incorrect settings might present a danger to the application, e.g.

cause damage to the valve or the installation.The manufacturer will not be held

liable for any consequential damage. Such risk lies entirely with the user.

Operation Prerequisites for safe and smooth operation:

●Correct transport, proper storage, mounting and installation, as well as careful

commissioning.

●Only operate the device if it is in perfect condition while observing this manual.

●Immediately report any faults and damage and allow for corrective measures.

●Observe recognized rules for occupational health and safety.

●Observe the national regulations.

●During operation, the housing warms up and surface temperatures > 60 °C

(140 °F) may occur.To prevent possible burns, we recommend checking the

surface temperature using an appropriate thermometer and wearing protective

gloves, if required, prior to working on the device.

Protective measures The end user or the contractor is responsible for implementing required protective

measures on site, such as enclosures, barriers, or personal protective equipment

for the staff.

Maintenance Maintenance and service actions must be exclusively performed by appropriately

trained and authorized staff.

During maintenance intervention on fail safe unit, the references regarding

maintenance specified in the operation instructions pertaining to actuator must be

obeyed.

Any device modification requires prior written consent of the manufacturer.

Opening covers or unfastening screws is only permitted if the pertaining description

is available in the operation instructions.

1.2. Range of application

The FQM fail safe unit is designed for emergency operation of industrial valves, e.g.

globe valves, butterfly valves, and ball valves.The unit is operated in combination

with an AUMA part-turn actuator.

4

FQMEx 05.1 –FQMEx 12.1

Safety instructions FM version (Class/Division System)

Other applications require explicit (written) confirmation by the manufacturer.

The following applications are not permitted, e.g.:

●Buried service

●Continuous submersion (observe enclosure protection)

●Radiation exposed areas in nuclear power plants

●pulling loads (such as shutter weirs, fish-belly flap gate, and sluice gates, etc.)

No liability can be assumed for inappropriate or unintended use.

Observance of this operation manual is considered as part of the device's designated

use.

Information This operation manual is only valid for the “clockwise closing”standard version, i.e.

driven shaft turns clockwise to close the valve.

1.3. Warnings and notes

The following warnings draw special attention to safety-relevant procedures in this

operationmanual, eachmarkedbytheappropriatesignalword (DANGER,WARNING,

CAUTION, NOTICE).

Indicates an imminently hazardous situation with a high level or risk. Failure

to observe this warning results in death or serious injury.

Indicates a potentially hazardous situation with a medium level of risk.Failure

to observe this warning could result in death or serious injury.

Indicates a potentially hazardous situation with a low level of risk. Failure to

observe this warning could result in minor or moderate injury. May also be

used with property damage.

Potentially hazardous situation. Failure to observe this warning could result

in property damage. Is not used for personal injury.

Safety alert symbol warns of a potential personal injury hazard.

The signal word (here: DANGER) indicates the level of hazard.

1.4. References and symbols

The following references and symbols are used in this manual:

Information The term Information preceding the text indicates important notes and information.

Symbol for CLOSED (valve closed)

Symbol for OPEN (valve open)

➥Result of a process step

Describes the result of a preceding process step.

5

FQMEx 05.1 –FQMEx 12.1

FM version (Class/Division System) Safety instructions

1.5. Safety instructions for the handwheel

Turning handwheel at actuator following a fail safe operation!

Risk of hand injury for handwheels equipped with ball handle.

→Following a fail safe operation, do NOT activate manual operation.

→This means, for all interventions, the push button at the actuator handwheel

must NOT be pressed prior to initialization.

Information Successful initialization is indicated with FQM FS ready on the actuator display.The

symbol is displayed in the status bar (top). Further information on initialization: ➭

page 22, Initialization

6

FQMEx 05.1 –FQMEx 12.1

Safety instructions FM version (Class/Division System)

2. Identification

2.1. Name tag

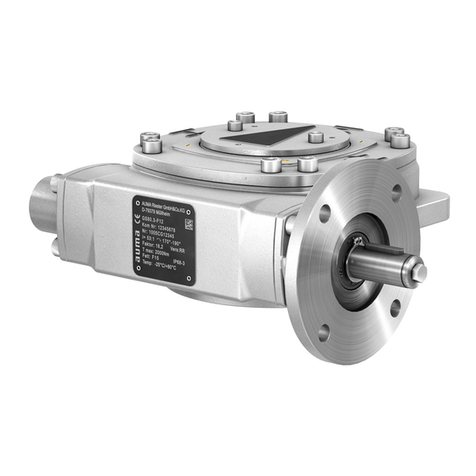

Figure 1: Arrangement of name tags

[1] Fail safe unit name tag

[2] Additional tag, e.g.KKS tag (Power Plant Classification System)

[3] Approval plate for explosion-proof version

Actuator name tag

Figure 2: Fail safe unit name tag (example)

[1] Name of manufacturer

[2] Address of manufacturer

[3] Type designation

[4] Order number (commission number)

[5] Actuator serial number

[6] Nominal operating time in [s] for 90° swivel movement

[7] Max. torque in direction OPEN/CLOSE

[8] Type of lubricant

[9] Permissible ambient temperature

[10] Mains voltage, mains frequency

[11] Control

[12] Can be assigned as an option upon customer request

[13] Power

[14] Enclosure protection Type

[15] FQM fail safe direction

7

FQMEx 05.1 –FQMEx 12.1

FM version (Class/Division System) Identification

Approval plate in explosion-proof version

Figure 3: Approval plates in explosion-proof version (examples)

[1] Ex symbol

[2] Classification

Division 1 (frequency or duration of occurrence of hazardous substances)

Class I = Gases or vapors (groups C, D)

Test certificate (certificate number)

[3] Protection type of housing

[4] Temperature class / max. surface temperature

[5] Permissible ambient temperature

Description referring to name tag indications

Type designation Figure 4:Type designation (example)

1. Type and size of fail safe actuator

2. Flange size

3. Ex marking

Type and size

This manual applies to the following device types and sizes:

Fail safe unit of FQMEx type, sizes 05.1, 07.1, 10.1, 12.1

Ex marking

Table 1:

Marking for explosion protection (example of /––4 ––)

––4––/

Not used–

Not used–

Protection type of electrical connection

4 = Terminal compartment Ex dflameproof enclosure

4

Not used–

Not used–

Order number The product can be identified using this number and the technical data as well as

order-related data pertaining to the device can be requested.

Please always state this number for any product inquiries.

On the Internet at http://www.auma.com> Service >Support >myAUMA, we offer

a service allowing authorized users to download order-related documents such as

wiring diagramsand technical data (bothinGerman and English),inspectioncertificate

and the operation manual when entering the order number.

8

FQMEx 05.1 –FQMEx 12.1

Identification FM version (Class/Division System)

Serial number fail safe

unit Table 2:

Description of serial number (example of 0518WQ12345)

WQ123451805

Assembly in week;05 = week 505

Year of production; 18 = 201818

Internal number for unambiguous product identificationWQ12345

FQM fail safe direction Direction of rotation of FQM output drive shaft or the driven valve shaft when safety

function is triggered.

●CW = Clockwise rotation

●CCW = Counterclockwise rotation

Fail safe OPEN and fail safe CLOSE safety functions result from the overall

combination of actuator (gearbox), FQM and valve.

Table 3:

Safety function

Safety functionFQM fail safe directionValve closing direction (actuator)1)

Fail safe CLOSEClockwise

CW

Clockwise closing

Fail safe OPENCounterclockwise

CCW

Clockwise closing

Fail safe OPENClockwise

CW

Counterclockwise closing

Fail safe CLOSECounterclockwise

CCW

Counterclockwise closing

For identical closing direction of valve and actuator1)

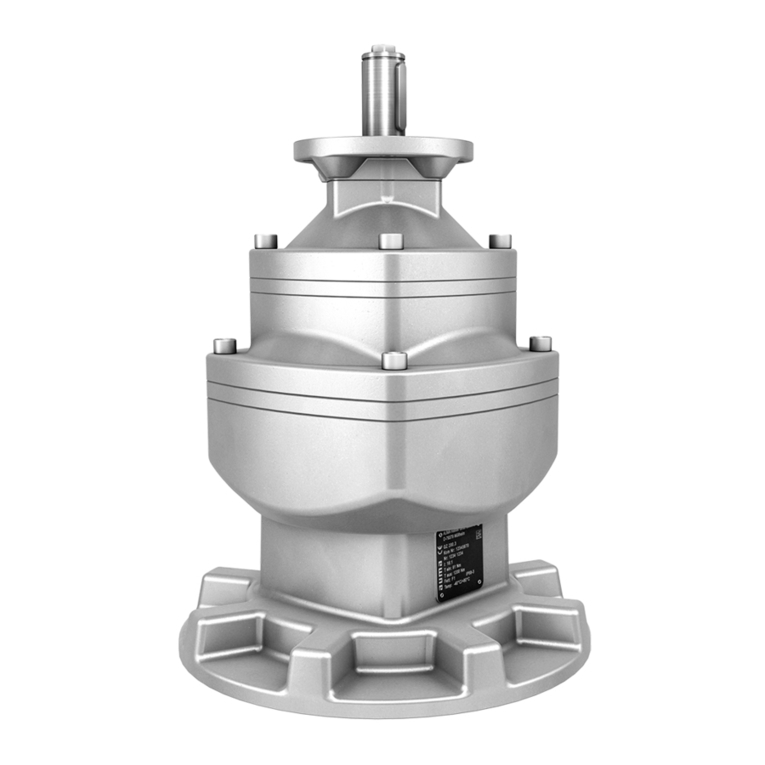

2.2. Short description

In emergencies, the fail safe unit is capable of closing or opening the valve

autonomously relying on mechanical functions.No electrical power is required for

such a fail safe operation.The torque required for opening or closing the valve is

generated by a constant force spring motor, providing a constant torque across the

total travel during fail safe operation.Consequently, the torque value for a fail safe

operation is determined by the available torque of the fail safe unit and is independent

of the actuator torque range.

For standard valve operation, the FQM fail safe unit is combined with an AUMA SQ

part-turn actuator.The required torque is transmitted directly from the actuator through

the fail safe unit to the valve. During standard operation, the constant force spring

motor of the fail safe unit is disengaged and is not operated.

The operating speed for the fail safe operation can be set in the factory.Furthermore,

the actuator operates the valve into the defined end position at reduced speed.This

avoids pressure peaks within the pipeline and protects the valve.

9

FQMEx 05.1 –FQMEx 12.1

FM version (Class/Division System) Identification

3. Transport, storage and packaging

3.1. Transport

For transport to place of installation, use sturdy packaging.

Hovering load!

Death or serious injury.

→Do NOT stand below hovering load.

→Attach ropes or hooks for the purpose of lifting by hoist only to housing and NOT

to handwheel.

→Check eyebolts for tight seat in housing (verify reach of the screw).

→Observe manufacturer specifications for fixing lifting straps and round slings.

→Heed total weight of arrangement.

Figure 5: Example, fixing FQMEx 07.1 with actuator and actuator controls

Table 4:

Weights for fail safe unit

approx. lbs [kg]Type

134 [61]FQMEx 05.1

141 [64]FQMEx 07.1

298 [135]FQMEx 10.1

302 [137]FQMEx 12.1

Table 5:

Weights for actuators and actuator controls1)

approx. lbs [kg]Type

Part-turn actuator

64 [29]SQEx 05.2

64 [29]SQEx 07.2

75 [34]SQEx 10.2

93 [42]SQEx 12.2

Actuator controls

26 [12]ACExC 01.2

Indicated weights apply to actuators with 3-phase AC motors, standard output drive and standard

electrical connection.Weights for actuator controls with standard electrical connection.

1)

10

FQMEx 05.1 –FQMEx 12.1

Transport, storage and packaging FM version (Class/Division System)

3.2. Storage

Corrosion due to inappropriate storage!

→Store in a well-ventilated, dry room (maximum humidity 70 %).

→Protect against floor dampness by storage on a shelf or on a wooden pallet.

→Cover to protect against dust and dirt.

→Apply suitable corrosion protection agent to uncoated surfaces.

Risk of damage due to excessively low temperatures!

→Actuator controls may only be stored permanently down to –22 °F (–30 °C).

→On request, actuator controls may be transported in specific cases and for short

duration at temperatures down to –76 °F (–60 °C).

Long-term storage For long-term storage (more than 6 months), observe the following points:

1. Prior to storage:

Protect uncoated surfaces, in particular the output drive parts and mounting

surface, with long-term corrosion protection agent.

2. At an interval of approx. 6 months:

Check for corrosion.If first signs of corrosion show, apply new corrosion protec-

tion.

3.3. Packaging

Our products are protected by special packaging for the transport ex works.The

packagingconsists of environmentallyfriendly materialswhichcan easily be separated

and recycled.We use the following packaging materials: wood, cardboard, paper,

and PE foil. For the disposal of the packaging material, we recommend recycling

and collection centers.

11

FQMEx 05.1 –FQMEx 12.1

FM version (Class/Division System) Transport, storage and packaging

4. Assembly

4.1. Mounting position

The product described in this document can be operated in vertical and horizontal

mounting position.The mounting position pointing downward is not permitted. For

horizontal mounting position, the fail safe unit requires reinforcement to relieve the

flange connection to the valve.

Figure 6: Reinforcement for horizontal mounting position (example)

The reinforcement is made at both threads provided for transport. For FQMEx

05.1/07.1 = 5/8”UNC thread (M10 metric thread); for FQMEx 10.1/12.1 = 1/2”UNC

thread (M12 metric thread).

We recommendapplyingliquid threadsealingmaterialtothe screwsto avoidcontact

corrosion in the thread.

To compensate for vibration, we recommend using additional all-metal dampers as

available with Stop-Choc ®.

Support by AUMA AUMA offers an own support.The support is fixed at the output drive flange using

suitable fastening clamps.It includes all-metal dampers to compensate for vibration.

12

FQMEx 05.1 –FQMEx 12.1

Assembly FM version (Class/Division System)

Figure 7: Support by AUMA (example)

4.2. Actuators for fail safe units

An AUMA actuator with AUMA actuator controls are required to operate the valve

via fail safe unit.On delivery, the actuator is already mounted to the fail safe unit.

Information ●The actuator is exactly aligned with regard to the fail safe unit to ensure safe

unit function. In addition, the screws are fastened in the factory with a high

torqueto avoidanylateralmovement.Assembly or disassembly of actuators

may only be performed by the AUMA Service.

●The mounted SQ part-turn actuator has no end stops.The part-turn actuator

screw plugs do not have any function and should not be opened.

4.3. Mounting the fail safe unit to the valve

The fail safe unit is mounted to the valve using a coupling placed onto the valve

shaft.

13

FQMEx 05.1 –FQMEx 12.1

FM version (Class/Division System) Assembly

4.3.1. Overview on coupling variants

Design Figure 8:Valve attachment via coupling

[1] Bore with keyway

[2] Square bore

[3] Two-flat

Application ●For valves with connections according to MSS SP 101 [EN ISO 5211]

●For rotating, non-rising valve stem

4.3.1.1. Fail safe unit to valve: mount

Unbored couplings or couplings with pilot bore must be machined to match the valve

shaft prior to mounting the fail safe unit to the valve (e.g.with bore and keyway,

two-flat or square bore).

Information ●Assemble valve and fail safe unit in the same end position (OPEN/CLOSED).

●Only mount fail safe unit with unwound constant force spring. Make sure that

unit is not live.

●While constant force spring is unwound, the fail safe unit is set to the end posi-

tion of the fail safe direction indicated on the name tag:

-CW ≙end position CLOSED (for clockwise rotating valve)

-CCW ≙end position OPEN (for clockwise rotating valve)

Assembly steps 1. Thoroughly clean and degrease the surfaces of output mounting flanges.

2. Apply a small quantity of grease to the valve shaft [2].

14

FQMEx 05.1 –FQMEx 12.1

Assembly FM version (Class/Division System)

3. Place coupling [1] onto valve shaft [2] and secure against axial slipping by using

a grub screw [3] or a washer and a screw [4].Thereby, ensure that dimensions

X,Y or L are observed (refer to figure and table <Mounting positions for cou-

pling>).

Figure 9: Examples: Fit coupling

[1] Coupling

[2] Valve shaft

[3] Grub screw

[4] Screw with washer

Figure 10: Mounting positions for coupling

Table 6: FQM 12.1FQM 10.1FQM 07.1FQM 05.1Dimensions in

[mm]

FA14FA12FA12FA10FA10FA07FA07MSS SP-101

0.24 [6]0.24 [6]0.24 [6]0.24 [6]0.20 [5]0.20 [5[0.20 [5]X max.

0.39 [10]0.39 [10]0.39 [10]0.39 [10]0.20 [5]0.20 [5]0.20 [5]Y max.

0.39 [10]2.36 [60]2.36 [60]0.39 [10]1.77 [45]1.77 [45]1.77 [45]L max.

4. Apply non-acidic grease at splines of coupling (e.g.Gleitmo by Fuchs).

15

FQMEx 05.1 –FQMEx 12.1

FM version (Class/Division System) Assembly

5. Place fail safe unit onto valve coupling and make sure that the screws match

the bores provided.

➥For CW version, the FQM bores [ ] should overlap the bores of the valve flange

[ ] rather in clockwise direction.

Figure 11: Place FQM onto valve coupling (CW version)

[ ] FQM bore

[ ] Valve flange bore

[1] Setting screw

[2] View on valve flange and rotary movement of FQM when unfastening

the setting screw.

➥For CCW version, the FQM bores [ ] should overlap the bores of the valve

flange [ ] rather in counterclockwise direction.

Figure 12: Place FQM onto valve coupling (CCW version)

[ ] FQM bore

[ ] Valve flange bore

[1] Setting screw

[2] View on valve flange and rotary movement of FQM when unfastening

the setting screw.

16

FQMEx 05.1 –FQMEx 12.1

Assembly FM version (Class/Division System)

6. Should the bores for the screws not align:

→Remove screw plug and slightly unfasten setting screw [1] for end stop

OPEN/CLOSED at fail safe unit counterclockwise until bores [ ] line

up.When unfastening the setting screw, the FQM moves back in direction

of the valve flange bore [ ].

Risk of setting screw falling out!

→Avoid excessive unscrewing of setting screws.Observe Tmin.! Refer to:page

23, End stops in the fail safe unit

Risk of damage to end stop if setting screw is turned against the spring force!

→Do NOT unscrew setting screw clockwise against the spring force (fastening).

7. Fasten fail safe unit with screws.

Information: We recommend gluing the screws using thread sealing material

(e.g.LOCTITE 242) to avoid thread contact corrosion and to ensure vibration

resistance.

8. Fasten screws crosswise to a torque according to table.

Table 7:

Tightening torques for screws

Tightening torque ft-lb [Nm]M threadsUNC threads

Strength class A2-80/A4–80

7 [10]M61/4”

18 [24]M84/16”

35 [48]M103/8”

60 [82]M121/2”

148 [200]M165/8”

289 [392]M203/4”

Information Ifthe bores[ ]are not yetaligned fordimensionTmin.,the mounting procedure must

be aborted.The following steps must then be performed

1. Remove fail safe unit from valve.

2. Establish electrical connection and connect to power supply.

Oncethepowersupplyis connected, initializationisstartedprovided allprereq-

uisites are fulfilled. ➭page 22, Initialization

3. After initialization, screw the setting screw to dimensionT(at90) (without tolerance

margin indicated). ➭page 23, End stops in the fail safe unit

4. Then, switch off power supply again (de-energize).

The actuator performs a fail safe operation and moves to the configured fail

safe end position.

5. Now, re-place the valve onto the fail safe unit and mount to the valve as de-

scribed in the present chapter.

When mounting the fail safe unit onto the valve coupling, select splines as to

ensure that bores of the screws for the FQM and the valve flange are as close

as possible.

17

FQMEx 05.1 –FQMEx 12.1

FM version (Class/Division System) Assembly

5. Electrical connection

5.1. Basic information

Electric shock due to presence of hazardous voltage!

Death or serious injury.

→Disconnect device from the mains before opening.

→When operating in potentially explosive atmospheres:Before opening, ensure

that there is no explosive gas and no voltage.

Electric shock due to incorrect electrical connection!

Risk of death or serious injury!

→The electrical connection must be carried out exclusively by suitably qualified

personnel.

Wiring diagram/terminal

plan The pertaining wiring diagram/terminal plan (in German or English) is attached to

the device in a weather-proof bag, together with this operation manual.It can also

be requested from AUMA (state order number, refer to name tag) or downloaded

directly from the Internet (http://www.auma.com).

Protection on site For short-circuit protection and for disconnecting from the mains, fuses and disconnect

switches have to be provided by the customer.

The current values for respective sizing are derived from the current consumption

of the motor (refer to electrical data sheet), the current consumption of the actuator

controls, plus the current consumption of the fail safe unit. Please refer to the

operation manual pertaining to the actuator for information on the current consumption

of actuator controls.

When providing joint protection for actuator, actuator controls and fail safe unit, the

maximum power consumption of 360 W for the fail safe unit has to be accounted

for. In case separate power supply for the fail safe unit is provided, 360 W have to

be accounted for FQM protection.

Consider increased power supply starting current when selecting the circuit breaker

characteristic.We recommend tripping characteristics D or K for circuit breakers in

accordance with IEC 60947-2.To avoid spurious action, fuses with values below 2

A are not recommended.

5.2. Electrical connection of actuator/actuator controls

The customer connection for valve control during standard operation (power

connection and signal cables) is made via the electrical connection of the actuator

or the actuator controls.Any procedures for opening/closing the terminal compartment

and for connecting the cables are described in the operation manual pertaining to

the actuator.

5.3. Electrical connection for fail safe unit

On delivery, the electrical connection of the fail safe unit is already equipped with

the power supply for FQM and the signal cable for actuator controls.

The tripping signal (ESD) for a fail safe operation as well as direct feedbacks (e.g.

end switch signals LSO/LSC) have to be connected in compliance with the wiring

diagram at the customer’s.

A KES-Exd type electrical connector will be provided for electrical connection.

18

FQMEx 05.1 –FQMEx 12.1

Electrical connection FM version (Class/Division System)

5.3.1. Connect cables with KES type electrical connection

5.3.1.1. Open terminal compartment

Figure 13: Open terminal compartment

[1] Cover

[2] Screws for cover

[3] O-ring

[4] Blanking plug

[5] Cable gland (example)

[6] Connection frame

Ignition of potentially explosive atmospheres caused by sparks!

Risk of death or serious injury!

→Before opening, ensure that there is no explosive gas and no voltage.

1. Loosen screws [2] and remove cover [1].

2. Insert cable glands suitable for connecting cables.

Information:When selecting cable glands observe type of protection (with Ex d

approval) and enclosure protection NEMA... (refer to name tag).

The type of protection stated on the name tag, NEMA...is only ensured if suitable

cable glands are used.

Figure 14: Name tag, example with enclosure protection NEMA

Information: For shielded cables: Use EMC approved cable glands.

3. Seal unused cable entries with approved plugs suitable for the required protec-

tion type.

19

FQMEx 05.1 –FQMEx 12.1

FM version (Class/Division System) Electrical connection

5.3.1.2. Cable connection

Table 8:

Terminal cross sections and terminal tightening torques

Tightening torquesTerminal cross sectionsDesignation

1.1 –1.3 ft- lb [1.5 –1.8 Nm]max. 10 mm² (flexible or solid)Power contacts (U, V, W)

2.2 –3.0 ft- lb [3.0 –4.0 Nm]max. 10 mm² (flexible or solid)PE connection

0.4 –0.6 ft- lb [0.6 –0.8 Nm]max. 2.5 mm² flexible, or

max. 4 mm² solid

Control contacts (1 to 50)

1. Remove cable sheathing and insert the wires into the cable glands.

2. Fasten cable glands with the specified torque to ensure required enclosure

protection.

3. Strip wires.

4. For flexible cables: Use wire end sleeves.

5. Connect cables according to order-related wiring diagram.

In case of a fault, electric shock due to presence of hazardous voltage if the

PE conductor is NOT connected!

Risk of death or serious injury!

→Connect all protective earth conductors.

→Connect PE connection to external protective earth conductor of connecting

cables.

→Start running the device only after having connected the protective earth con-

ductor.

6. Firmly tighten protective earth to PE connection (symbol: ).

Figure 15: PE connection

[1] U-bracket for PE connection

20

FQMEx 05.1 –FQMEx 12.1

Electrical connection FM version (Class/Division System)

This manual suits for next models

3

Table of contents

Other AUMA Industrial Equipment manuals