2

© Öhlins Racing AB. All rights reserved.

Any reprinting or unauthorized use without the written

permission of Öhlins Racing AB is prohibited.

General Warnings

Note!1

When working with the Öhlins product, always read the Vehicle Service Manual.

Note!1

The shock absorber/front fork/steering damper is an important part of the vehicle

and will affect the stability.

Note!1

Read and ensure you understand the information in this manual and other

technical documents provided by Öhlins, before using or servicing the product.

Note!1

Öhlins Racing AB can not be held responsible for any damage to the shock

absorber/front fork/steering damper, vehicle, other property or injury to persons, if

the instructions for mounting, usage and maintenance are not followed exactly.

Warning!⚠

After installing the Öhlins product, take a test ride at low speed to ensure your

vehicle has maintained stability.

Warning!⚠

If the suspension makes an abnormal noise, or the function is irregular, or if you

notice any leakage from the product, stop the vehicle immediately and return the

product to an Öhlins Service Centre.

Warning!⚠

The product warranty shall only apply if the product has been operated and

maintained in accordance with recommendations in this manual. If you have any

questions regarding usage, service, inspection and/or maintenance please contact

Öhlins.

Note!1

Before working on the product make sure that the vehicle is washed and cleaned

properly. Do not use alcobased products on the outside or inside of the product.

Product Specic Warnings

Warning!⚠

This product was developed and designed exclusively for a specic vehicle model

and shall only be installed on the intended vehicle model in its original condition as

delivered from the vehicle manufacturer.

Warning!⚠

This product is pressurized. Do not open, service or modify this product without

proper education (authorized Öhlins dealer/distributor) and proper tools.

Caution!✋

Do not use a pressure washer or a power washer when cleaning the fork.

SAFETY SYMBOLS

In this manual, mounting instructions and other technical documents,

important information concerning safety is distinguished by the following

symbols:

The Safety Alert Symbol means: Warning! Your safety is involved.

Warning!⚠

The Warning Symbol means: Failure to follow warning instructions can result

in severe or fatal injury to anyone working with, inspecting or using the shock

absorber/front fork, or to bystanders.

Caution!✋

The Caution Symbol means: Special precautions must be taken to avoid

damage to the shock absorber.

Note!1

The Note Symbol indicates information that is important regarding procedures.

Table of Contents

Tools ...................................................................................................3

Overview - General layout..................................................................3

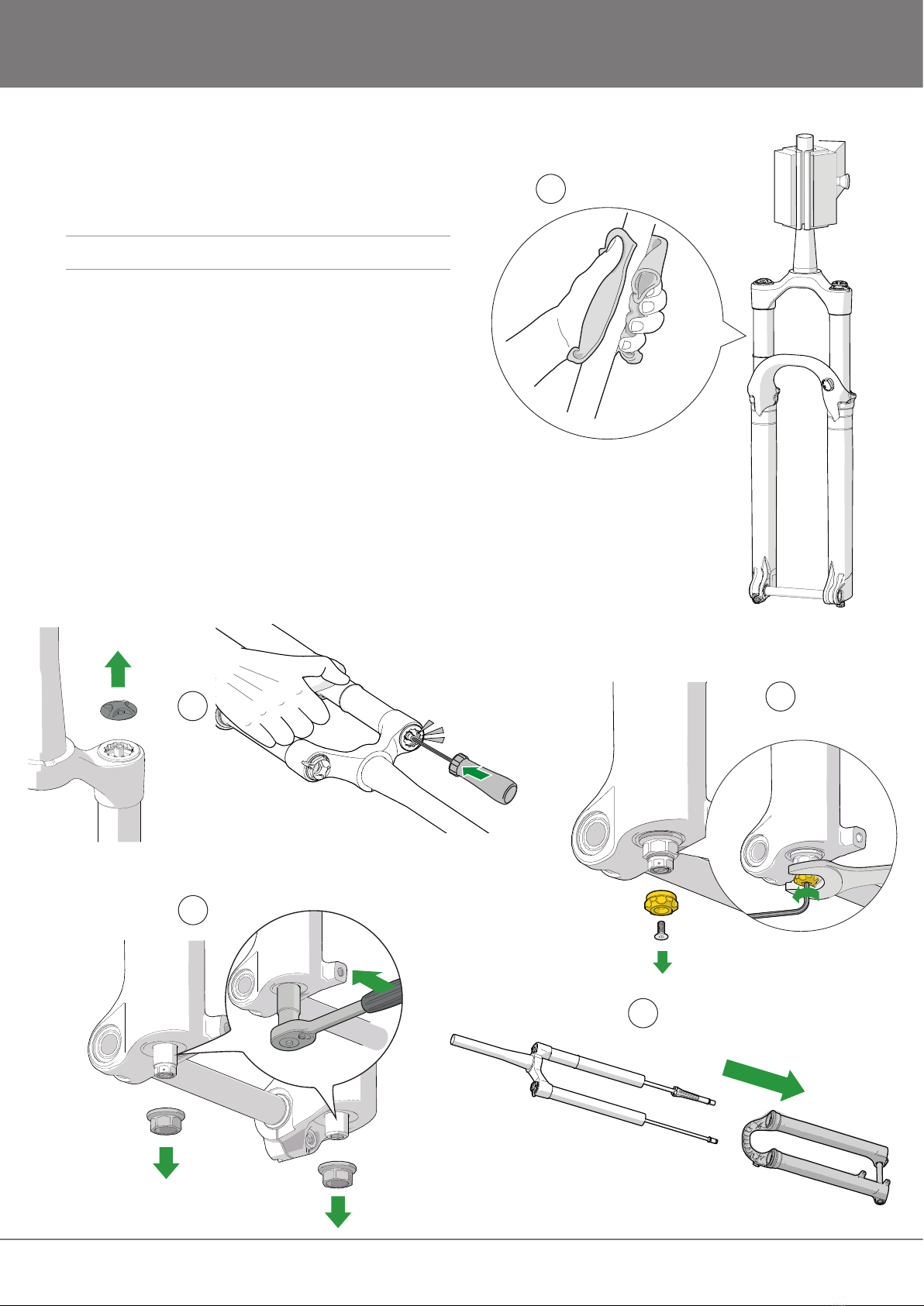

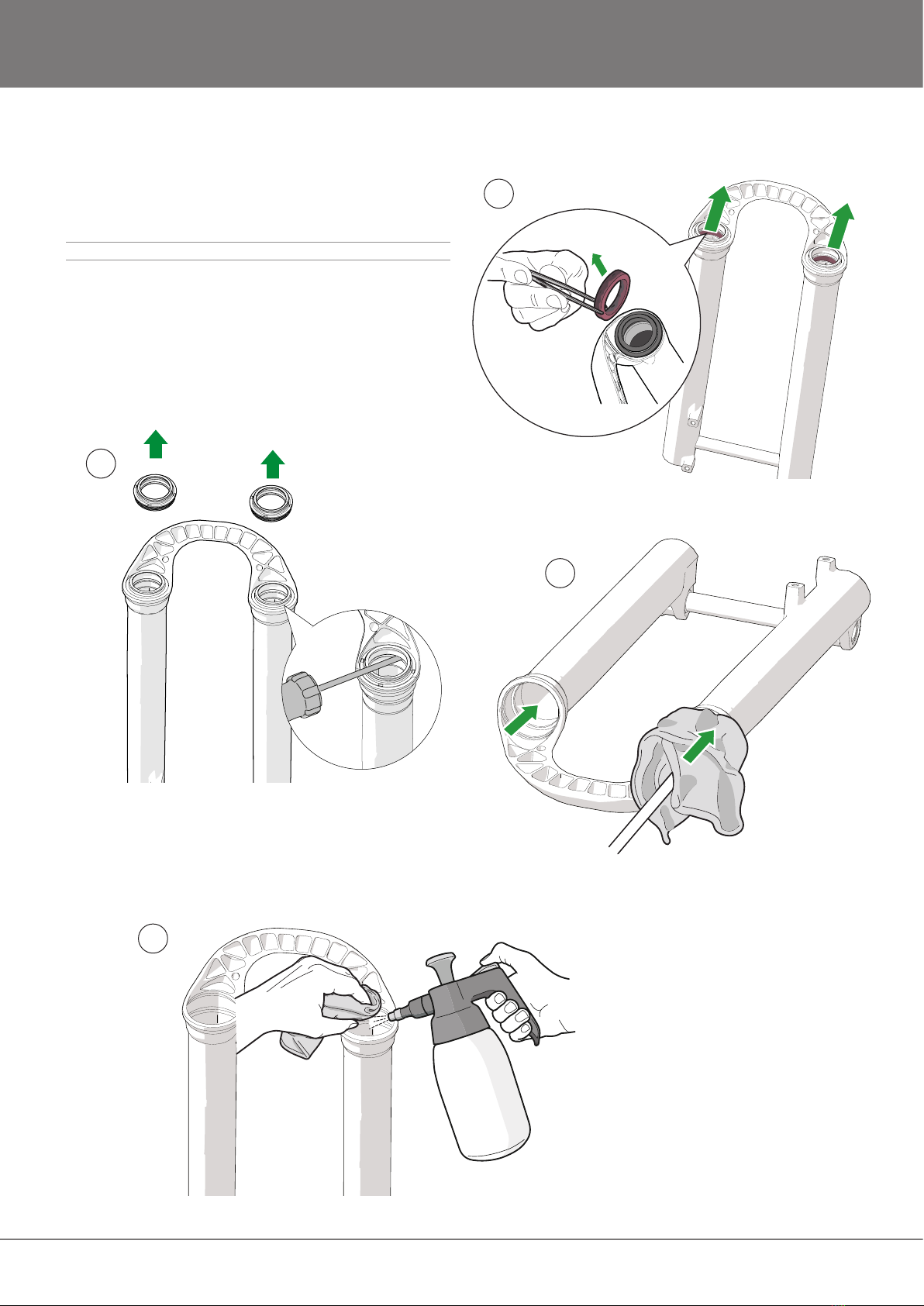

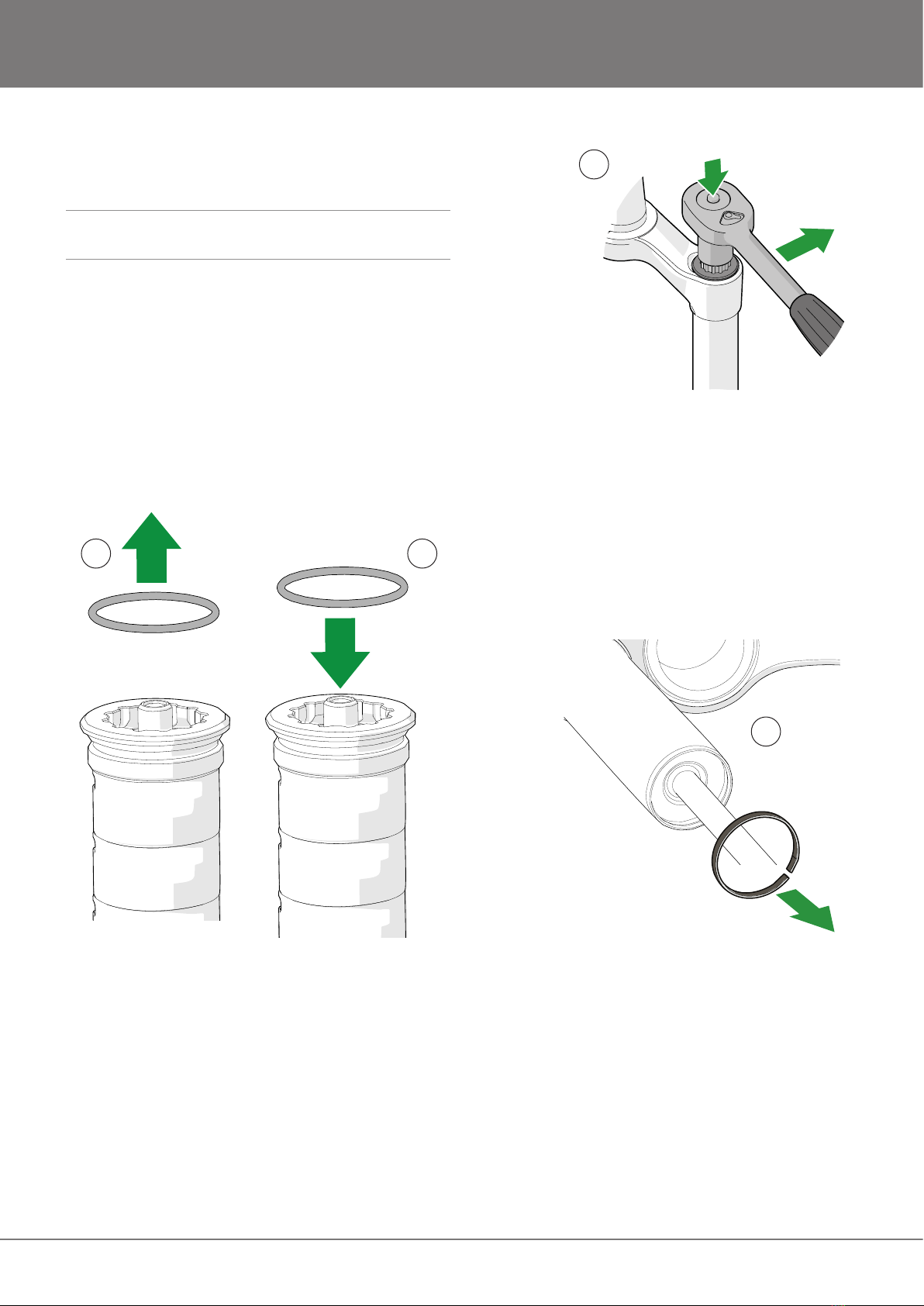

Chassis 100-Hour Service..................................................................5

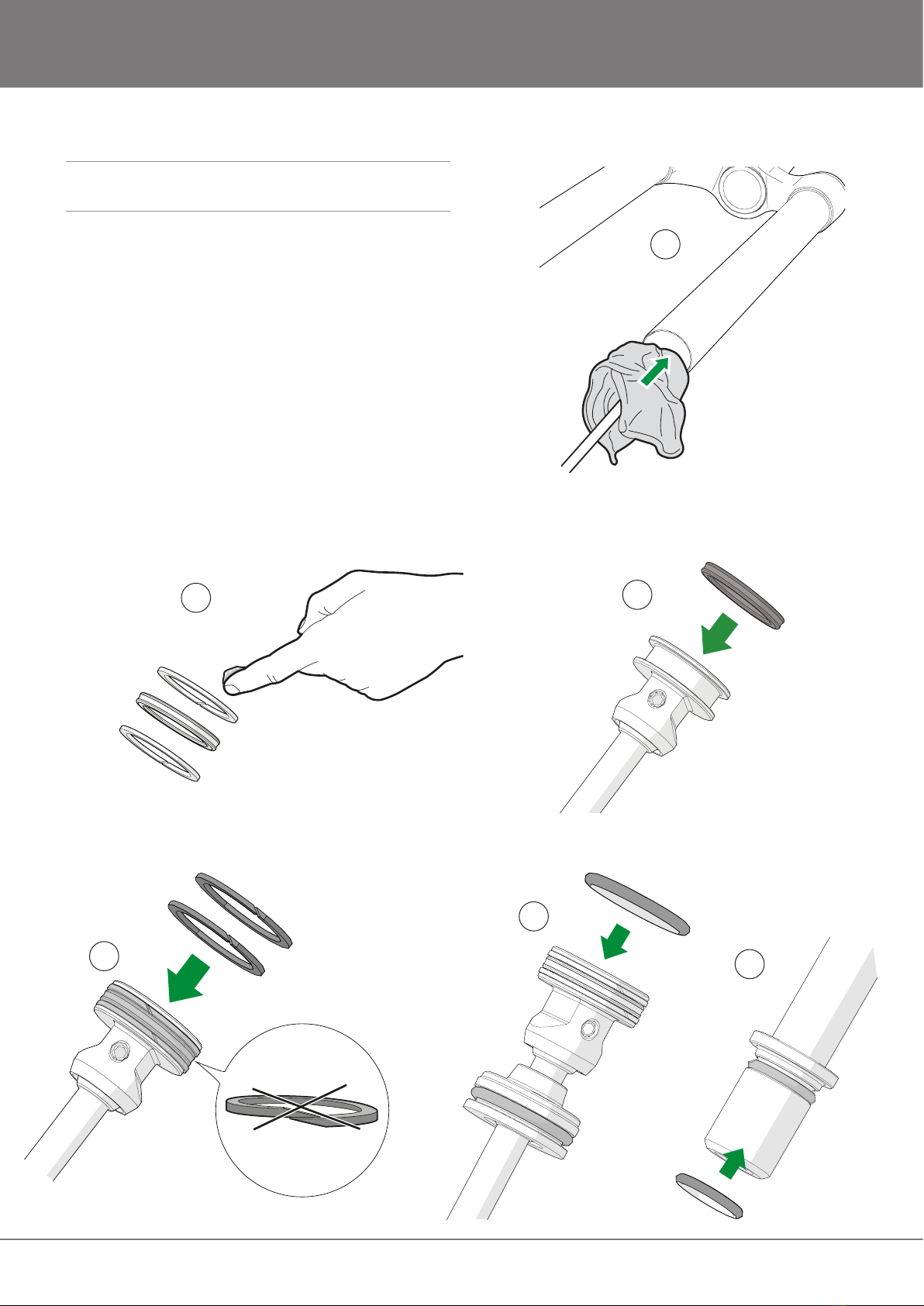

Air spring Cartridge 100-hour service.................................................8

Appendix A. RXF34 m.2 ...................................................................15

SAFETY PRECAUTIONS