HLU HF R 48 R Series User manual

These operating instructions are valid for the standard and ATEX versions.

Operating manual

Centrifugal fans

HF R ...-15 / 17 D / R

Size 125 up to 500

HF R ...-13 D / R

Size 450 up to 1250

HF R ...-16 R

Size 160 up to 400

HF R ...-48 R

Size 50 up to 200

RV 20

Size 80 up to 140

RV 28

Size 200 up to 800

RV 45/63

Size 160 up to 1250

MRV 45/63

Size 160 up to 355

www.hlu.eu

2

06.2019

These operating instruction are part of the fan and must be available

to the operating personnel at all times. The safety information given

in these instructions must be followed. In the event of a fan resale,

these operating instructions must be included with the equipment

supplied.

Translation

In the event of supply or subsequent sale into the countries

of the EEA, the operating instructions must be translated into

the language of the user country accordingly.

If the translated text contains divergences, always refer to

the wording of the original (German) operating instructions,

or contact the manufacturer.

Operating manual

Centrifugal fans

HF R | RV | MRV

www.hlu.eu

3

www.hlu.eu 06.2019

1.1 Index

1. Content

Operating manual

Centrifugal fans

HF R | RV | MRV

1. Content 3

1.1 Index 3

1.2 EC-/EU-Declarations of conformity 4

2. Construction and correct use for the intended application 6

2.1 Construction of the fan 6

2.2 Correct use for the intended application and eld of application 10

3. Product specic data 12

3.1 General data 15

3.2 Power supply (see motor type label) 16

4. Safety 16

4.1 Signs and explanations 16

4.2 Fan marking 17

4.3 Built-in safety systems (to be implemented by the user) 18

4.4 Interfaces of the fan 19

4.5 Safety measures (to be implemented by the user) 19

4.6 User‘s responsibilities 19

5. General warning symbols 20

5.1 Hazards 20

5.2 Operating and hazardous areas on the fan 20

5.3 Installation of spare and wear parts 21

6. Installation 22

6.1 Scope of supplies 22

6.2 Transport and packing 22

6.3 Delivery (also with spare and substitute parts) 22

6.4 Intermediate storage 22

6.5 Transport to the place of installation (at the customer‘s site) 23

6.6 Installation, mounting, Initial commissioning 24

6.7 Operating modes 25

7. Operation 25

8. Maintenance / Cleaning 26

8.1 Cleaning 27

8.2 Lubrication 28

8.3 Tensioning of V-belts 31

8.4 Inspection interval / Function checking 33

8.5 Vibrations 34

8.6 Tightening torques for bolt connections 34

8.7 General hints for maintenance 35

8.8 Checks 35

9. Troubles, causes and measures 36

10. Emergency 37

11. Dismantling / Disposal 37

4

06.2019

1.2 EC-/EU-Declaration of Conformity

www.hlu.eu

EC-/EU-

Declaration of Conformity

Page 1of 2Konformitätserklärung

Name and address of the persons, who are authorized, to assort the technical documents:

J Anne-Christin Vögl-Schmitt, Hürner Luft- und Umwelttechnik GmbH, Ernst-Hürner-Straße,

35325 Mücke-Atzenhain, Germany

J Marcel Pfeifer, HLU Systemtechnik GmbH, Sälzerstraße 20a, 56235 Ransbach-Baumbach, Germany

precluding responsibility for components provided or mounted by the customer. It the fan is modied without prior

agreement with HLU, this declaration is void.

Directive / Standard Title

DIN EN ISO 12100:2011 Safety of machinery - General principles for design – Risk assessment and

risk reduction

Reference to the following standards is made additionally in the DIN EN ISO 12100:

DIN EN ISO 13857:2008, DIN EN 349:2009, DIN EN ISO 14120:2016, DIN EN ISO 13732-1:2008,

DIN EN 60204-1:2014

DIN ISO 21940-11:2017 Procedures and tolerances for rotors with rigid behaviour

DIN EN 61000-6-4:2011 Electromagnetic compatibility, Generic standards - Immunity for industrial en-

vironments

DIN EN 61000-6-2:2011 Electromagnetic compatibility, Generic standards; Emission standard for indus-

trial environments

DIN EN 82079-1:2013 Preparation of instructions - Structuring, content and presentation

VDMA 24167:1994 Fans - Safety requirements

For the purpose of

J EC Machine Directive 2006/42/EC, Annex II A for Machines

J EC Low Voltage Directive 2014/35/EU, Annex III

J EMC Directive 2014/30/EU, Annex I and II

We hereby declare that the construction type of the supplied version of:

HF R …, HF D …, HF A …, AX 58 …, RV …, MRV …, SDR …

Manufacturer: Hürner Luft- und Umwelttechnik GmbH

Ernst-Hürner-Straße

35325 Mücke-Atzenhain

Germany

HLU Systemtechnik GmbH

Sälzerstraße 20a

56235 Ransbach-Baumbach

Germany

in the delivered version, as a separate component within an installation, complies with the above regulations and

the following standards or normative documents:

Operating manual

Centrifugal fans

HF R | RV | MRV

www.hlu.eu

5

www.hlu.eu 06.2019

www.hlu.eu

EC-/EU-

Declaration of Conformity

Page 2of 2Konformitätserklärung

Name and address of the persons, who are authorized, to assort the technical documents:

J Anne-Christin Vögl-Schmitt, Hürner Luft- und Umwelttechnik GmbH, Ernst-Hürner-Straße,

35325 Mücke-Atzenhain, Germany

J Marcel Pfeifer, HLU Systemtechnik GmbH, Sälzerstraße 20a, 56235 Ransbach-Baumbach, Germany

precluding responsibility for components provided or mounted by the customer. It the fan is modied without prior

agreement with HLU, this declaration is void.

Directive / Standard Title

DIN EN 1127-1:2011 Explosion prevention and protection - Part 1: Basic concepts and

methodology

DIN EN 13237:2013 Terms and denitions for equipment and protective systems intended for

use in potentially explosive atmospheres

DIN EN 14986:2017 Design of fans working in potentially explosive atmospheres

DIN EN 15198:2007 Methodology for the risk assessment of non-electrical equipment and compo-

nents for intended use in potentially explosive atmospheres

DIN EN ISO 80079-36:2016 Part 36: Basic method and requirements

DIN EN ISO 80079-37:2016 Part 37: Protection by constructional safety „c“

For the purpose of

J EC Directive 2014/34/EU (ATEX) concerning equipment and protective systems

intended for use in potentially explosive atmospheres

We hereby declare that the construction type of the supplied version of:

HF R …, HF D …, HF A … PTB 03 ATEX D089

RV …, MRV … PTB 04 ATEX D097

SDR … PTB 04 ATEX D098

AX 58 … PTB 04 ATEX D099

Manufacturer: Hürner Luft- und Umwelttechnik GmbH

Ernst-Hürner-Straße

35325 Mücke-Atzenhain

Germany

HLU Systemtechnik GmbH

Sälzerstraße 20a

56235 Ransbach-Baumbach

Germany

conrm in exclusive responsibility to produce solely in combination with the ATEX-name plate and the

individual test report 2.2 according DIN EN 10204:2004 in the delivered version, as a separate component

within an installation, complies with the standards / regulations of the general declaration of conformity, the

above regulations and the following standards or normative documents:

Operating manual

Centrifugal fans

HF R | RV | MRV

6

06.2019

2.1 Construction of the fans

2. Construction and correct use for the intended application

Operating manual

Centrifugal fans

HF R | RV | MRV

www.hlu.eu

Fig. 1a| Overview of the fan HF R ...-15 / 17 D | Direct drive

Motor

Impeller

Housing

Housing cover with

inlet adapter

Frame

Condensate drain

Outlet adapter

Vibration absorber

Fig. 1b| Overview of the fan HF R ...- 16 / 13 D | Direct drive

Impeller

Housing cover with

inlet adapter

Outlet adapter Motor

Frame

Vibration absorber

Condensate drain

Housing

Sleeve

Sleeve

Sleeve

Sleeve

7

www.hlu.eu 06.2019

Operating manual

Centrifugal fans

HF R | RV | MRV

Fig. 1c| Overview of the fan HF R ...-48 R | Belt drive

Motor

Housing

Impeller

Housing cover with

inlet adapter

Frame

Outlet adapter

Vibration absorber

Sleeve

Sleeve Flange bearing

Condensate drain

Belt drive

drive cover

8

06.2019

Operating manual

Centrifugal fans

HF R | RV | MRV

www.hlu.eu

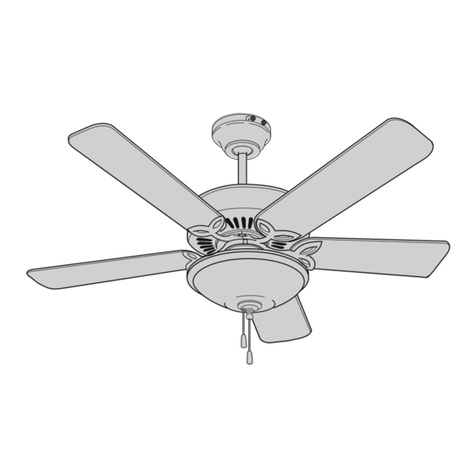

Fig. 1d| Overview of the fan HF RV / MRV | Direct drive

Designation Designation

1 Frame 5 Housing

2 Vibration dampers 6 Support

3 Motor 7 Housing cover with inlet adapter

4 Motor cover (opt.) 8 Impeller

9

www.hlu.eu 06.2019

Operating manual

Centrifugal fans

HF R | RV | MRV

Fig. 1e| Overview of the fan HF RV / MRV | Belt drive

Designation Designation

1 Frame 9 Belt pulley, Motor

2 Motor-clamp 10 V-Belt

3 Support 11 Shaft cover

4 Vibration dampers 12 Driver cover

5 Motor 13 Housing

6 Bearing 14 Housing cover with inlet adapter

7 Shaft 15 Impeller

8 Belt pulley, Fan

10

06.2019

2.2 Correct use for the intended application and eld of application

The fans are suitable for exhausting aggressive, dust-free, low-aerosol gases and clean air.

Explosive atmosphere can be exhausted only using fans designed specially for this application.

The permissible gas temperatures for the most frequently used plastics materials are generally

with PVC: 0 °C bis 50 °C,

with PE, PE-FR (PEs) -20 °C to 60 °C,

with PP, PP-FR (PPs): 0 °C to 70 °C,

and with PVDF: -10 °C to 100 °C.

These temperatures must not be exceeded.

Depending on gas composition and impeller speed, these temperature ranges must be check

and restricted, if necessary. With particularly aggressive media, the reductions must be checked

and determined individually in each case. The max. ambient temperature is 40 °C.

Sucient cooling can be ensured regardless of the volume ow, in accordance with the

above-mentioned conditions.

The fan was developed, designed and built exclusively for industrial and commercial use. Using

the fan for domestic purposes is excluded.

Operating manual

Centrifugal fans

HF R | RV | MRV

www.hlu.eu

Centrifugal fans consist of the following main assemblies: Frame, housing, impeller and

drive motor. They are delivered with direct drive (impeller on motor shaft) (except for the type

HF R …-48 R), as well as with belt drive (transmission motor-belt-impeller shaft).

The housings of the series HF R …-15 / 17 D R are sintered with polyethylene (PEs. RAL7036)

as standard. The housings of the other series are manufactured in self-supporting welded cons-

truction with dierent thermoplastics adapted to the particular conditions of use. They have a

housing cap on the inlet side, which allows the mounting / dismounting of the impeller after

demounting. For the production series RV 45 and RV 63 optionally also moulded casings made

from PVC and PPs are used. These consist of two shells in which the impellers are laid before

welding. Demounting of the impellers is not possible.

The housing is performed with a splinter protection, has on its deepest point (lateral) condensa-

te drain drillings and it can be delivered with revision opening if requested.

The impeller is statically and dynamically balanced (min. quality class G 6.3 acc. to DIN ISO

21940-11). The vibration limits correspond to the ISO 14964 standard. Depending on the speed

and other procedural parameters, various special materials are used as impeller materials in

addition to thermoplastic. Main dierentiating factor of these series are the dierent bladings of

the impellers and the housing construction.

On the type label are registered the maximum impeller r.p.m.s. For increasing the impeller

r.p.m., previous consultation of the manufacturer is indispensable.

For fans which are appropriated for the use in Ex-zone 1 the housing and the impeller are made

of electrical conductive thermoplastics. The standard thermoplastic plastic fan is not equipped

with shaft sealing.

The HF R ...- 13 D / R DS2 / DS3 series has a Kera seal as standard grown.

The exhaust uid is aspirated axially by the rotating impeller and transported radially to the

outlet in the helicoidal housing. The applied energy is converted into mass ow and pressure

increase of the exhaust uid in the impeller.

11

www.hlu.eu 06.2019

Installation inside the explosion-hazarded area:

Installation inside the explosion-hazarded area is not permissible,

unless the fan is provided explicitly for this purpose (see type label

Chapter 4.2).

If the fan for an installation with an open inlet or outlet or is provided

for an inlet-side duct connection as part of a larger installation, the

operator is obligated to prevent the penetration of foreign bodies that

can cause ignition according to DIN EN 14 986, point 4.22.

Repair and maintenance works of explosion-proof fans may only be

performed by qualied persons in the explosion protection by

using original spare parts.

If the fan has an open inlet and / or outlet (Type A, B, C according to

ISO 13349), the fan must have the same category inside and outside.

Types of connection

Residual risks

Although the fans have been constructed according to the newest

technology as well as to the security rules and they are monitored by

quality assurance (QA) system, there remains a residual risk due to

the possible rupture of the impeller. This happens especially, when

the conditions of use have not been complied. Therefore it is neces-

sary to pay attention on technically perfect conditions and on the right

case of application. The environment of the fans has to be secured

in such a way, that in case of a damage, neither persons nor objects

get harmed.

These assemblies are intended exclusively for the above purpose.

Using the assemblies for dierent purposes than described above,

or modifying them without written consent of the manufacturer are

considered as non-compliant with the intended application. The ma-

nufacturer cannot be held responsible for damage resulting from such

use. The risk is borne exclusively by the user. The fan may be started

only after checking that all safety devices are operable and that the

system in which this fan is installed complies with the EU directives.

The correct use for the intended application also implies compliance with the instructions given

in the manufacturer operating manual and with the conditions for maintenance and repair.

The plastic fans are not covered by the „Regulation No 327/2011 of the European Commission

about the implementation of Directive 2009/125/EC (ErP Directive)“ because they are intended

for the extraction of highly corrosive media.

Operating manual

Centrifugal fans

HF R | RV | MRV

12

06.2019

3. Product specic data

The materials/uids for the correct use of the fan in compliance with

the intended application are procured and applied by the manufactu-

rer. The user is responsible exclusively for correct handling of these

materials/uids and the related hazards. Information on hazards and

disposal must be provided by the user. Follow the rules given in the

manufacturer‘s safety data sheets for materials and uids.

Technical data sheet

Operating manual

Centrifugal fans

HF R | RV | MRV

www.hlu.eu

Fig. 2b| Overview of the fan HF R | Belt drive:

Belt ange bearing (RF) and Belt block bearing (RB)

Fig. 2a| Overview of the fan HF R | Direct drive

13

www.hlu.eu 06.2019

Dimensions and design can be changed | Dimensions in mm

Operating manual

Centrifugal fans

HF R | RV | MRV

Type ØD

max.

A

max.

H

max.

RFX

max.

kg

HF R 160-16 160 459 750 850 33

HF R 200-16 200 582 730 1020 41

HF R 250-16 250 710 775 1150 58

HF R 315-16 315 893 965 1350 81

HF R 355-16 355 1008 1090 1450 98

HF R 400-16 400 1126 1250 1450 149

Type ØD

max.

A

max.

H

max.

X

max.

kg.

max.

RFX

max.

kg

HF R 125-15/17 125 366,5 435 504 12

HF R 140-15/17 140 409 462 518 13

HF R 160-15/17 160 464 861,5 725 91 880 99

HF R 180-15/17 180 522 558 629 27 760 28

HF R 200-15/17 200 582 945 812 110 1037 166

HF R 250-15/17 250 732 1040 925 129 1080 174

HF R 280-15/17 280 816 804 768 62 923 56

HF R 315-15/17 315 920,5 1290 1179 260 1334 351

HF R 355-15/17 355 1030 1426 1151 214 1412 352

HF R 400-15/17 400 1141 1562 1255 280 1451 402

HF R 450-15/17 450 1297 1625 1320 310 1546 552

HF R 500-15/17 500 1469 1811 1378 506 1575 691

Type ØD

max.

A

max.

H

max.

X

max.

kg.

max.

RFX

max.

kg

max.

RBX

max.

kg

HF R 450-13 450 1200 1250 1550 1950

HF R 500-13 500 1350 1400 1650 2050

HF R 560-13 560 1575 1860 1471 600 1836 650 2110 750

HF R 630-13 630 1770 2065 1635 950 1965 1000 2155 800

HF R 710-13 710 1985 2310 1710 1150 2040 1200 2405 1200

HF R 800-13 800 2235 2470 1889 1350 2249 1450 2700 1500

HF R 900-13 900 2515 2750 2223 1850 2583 1950 2895 2000

HF R 1000-13 1000 2780 3060 2343 2596 2813 2200 3220 2300

HF R 1120-13 1120 2942 3500 2621 3298 3106 2350 3410 3500

HF R 1250-13 1250 3105 3840 2900 4000 3400 4300 3600 4700

Type ØD

max.

A

max.

H

max.

RFX

max.

kg

HF R 50-48 50 372 605 622 85

HF R 63-48 63 455 640 633 100

HF R 80-48 80 566 705 719 150

HF R 100-48 100 703 805 781 200

HF R 125-48 125 860 950 929 300

HF R 160-48 160 1100 1180 1021 400

HF R 200-48 200 1353 1390 1215 550

14

06.2019

Operating manual

Centrifugal fans

HF R | RV | MRV

www.hlu.eu

Fig. 2d| Overview of the fan RV / MRV | Belt drive

Fig. 2c| Overview of the fan RV / MRV | Direct drive

Type ØD

max.

A

Direct drive Belt drive

max.

B

max.

X

max.

RB

max.

RX

max.

kg

RV 20-80 80 400 550 500 600 850

RV 20-100 100 500 600 500 650 900

RV 20-125 125 600 750 550 800 1250

RV 20-140 140 700 800 550 800 1300

RV 28-200 200 600 700 600 700 1000 53

RV 28-225 225 650 750 650 700 1050 40

RV 28-250 250 700 800 650 750 1050 46

RV 28-280 280 800 900 950 850 1350

RV 28-315 315 900 950 1000 900 1400 80

RV 28-355 355 1000 1200 1000 1100 1850

RV 28-400 400 1100 1250 1050 1150 1850 180

RV 28-450 450 1250 1500 1250 1350 1950

RV 28-500 500 1400 1550 1300 1400 1950

RV 28-560 560 1550 1600 1400 1700 2150

RV 28-630 630 1700 1800 1550 1750 2250 380

RV 28-710 710 1900 2100 2050 2100 2700

RV 28-800 800 2150 2250 2150 2250 2800

15

www.hlu.eu 06.2019

Dimensions and design can be changed | Dimensions in mm

3.1 General data

Ambient temperature range

The specications on the type label are applicable. If they are missing, the temperature range

is - 20 °C to + 40 °C.

Noise level

For the value applicable to each fan, see the manufacturer internet site, or contact us via phone.

Operating manual

Centrifugal fans

HF R | RV | MRV

Type ØD

max.

A

Direct drive Belt drive

max.

B

max.

X

max.

kg.

max.

RB

max.

RX

max.

kg

RV 45/63-160 160 400 500 500 6 550 950 22

RV 45/63-200 200 500 600 550 9 600 1000 23

RV 45/63-250 250 650 750 680 15 700 1100 32

RV 45/63-315 315 800 900 720 25 850 1300 46

RV 45/63-355 355 900 950 780 30 900 1450 55

RV 45/63-400 400 1000 1100 1100 65 1100 1850 120

RV 45/63-450 450 1100 1150 1150 125 1150 1850 150

RV 45/63-500 500 1200 1350 1300 95 1350 2000 200

RV 45/63-560 560 1350 1400 1350 170 1400 2000 150

RV 45/63-630 630 1500 1700 1500 265 1700 2250 355

RV 45/63-710 710 1700 1750 1650 1750 2350

RV 45/63-800 800 1900 2100 2100 480 2100 2850 560

RV 45/63-900 900 2150 2200 2200 2200 2950

RV 45/63-1000 1000 2400 2650 2300 720 2650 3150 1000

RV 45/63-1120 1120 2700 2750 2450 2750 3300 1040

RV 45/63-1250 1250 3000 3050 2550 3050 3500

Type ØD

max.

A

Direct drive Belt drive

max.

B

max.

X

max.

RB

max.

RX

MRV 45/63-160 160 450 600 550 650 950

MRV 45/63-200 200 550 750 600 750 1000

MRV 45/63-250 250 650 900 700 850 1100

MRV 45/63-315 315 800 1100 1000 1050 1300

MRV 45/63-355 355 850 1150 1050 1100 1450

Others

More relevant data are given on the type label.

The service life of bearing is depending on the load at > 25 000 h.

16

06.2019

3.2 Power supply (see motor type label)

Optionally, the electric motors can be controlled continuously by means of a frequency inverter.

The maximal rotation speed at the impeller (see fan type label) must not be exceeded.

The ICA (instrumentation technology, control technology, automation technology) on site must

give protection against overspeed according DIN EN 60204-1.

In case of operation of several motors with a frequency inverter all-pole sinusoidal lters should

be used between frequency inverter and motor.

If frequency inverters are used in the explosion-hazarded area (Zone 1) these must be installed

outside the explosion-hazarded area and ameproof motors to DIN EN 60079-1 must be used.

Before connecting the fan, check the specications on the type label

and dimension the electrical control system accordingly.

With a motor power ≥ 4 kW for starting up the fan is a star-delta-con-

nection, a soft starter or a FI regulation to use to protect the impeller

and the motor bearing against premature damages.

In the case of direct involvement or frequent restart, damage or in-

creased wear may arise by the torque forces on the impeller.

4.1 Signs and explanations

Danger warnings

are marked with a warning triangle.

Notes

are marked with a hand symbol.

Warnings

are marked with a „STOP“ sign.

The information given in the operating manual is binding

is marked with a „book“.

4. Safety

Operating manual

Centrifugal fans

HF R | RV | MRV

www.hlu.eu

17

www.hlu.eu 06.2019

Hazards due to explosive atmosphere

are marked with the symbol shown opposite.

Hazards due to electric current

are marked with the symbol shown opposite.

Protective earth connection

is marked by these symbols at the connecting points.

4.2 Fan marking

Fig. 3a| Type label (normal application)

Caution

Fans without explosion protection marking are not permissible for

operation inside the explosion-hazarded atmosphere.

This applies to the environment and the exhausted uid.

Fig. 3b| Type label (explosive atmosphere)

Specications for fans without explosion protection:

Type

Order no. (AB) Construction year

Fan-specic data

Specications for fans with explosion protection:

Type Denomination of explosion

protection type

Ex-Zone Temperature

Motor explosion protection type

Order no. (AB) Construction year

Fan-specic data

Operating manual

Centrifugal fans

HF R | RV | MRV

18

06.2019

The information given in these operating instructions is only applicable to the fan type specied

on the title page. The type label with the type denomination is located on the base frame or on

the side panel of the fan housing. With all enquiries, make sure to specify the order conrmation

no. and the type label properly to ensure correct and quick handling.

4.3 Built-in safety systems (to be implemented by the user)

The built-in safety devices must be checked at regular intervals:

d = daily, w= weekly, m= monthly, j = yearly.

The following methods must be used for checking:

V= visual check, F= functional check, M = measurement.

Check

Interval Method

y F

Overcurrent protection device

To prevent overheating (re hazard) in the event of overload (e.g. due

to clogging), the fan drive has to be provided with an overcurrent pro-

tection device.

Thermal contact (optional)

For temperature monitoring, the fan is equipped with a thermal

contact. In the event of a temperature increase, the motor switches

o.

PTC resistor (optional)

Don‘t connect the PTC resistor to the mains voltage. Avoid exceeding

a max. PTC resistor test voltage of 2.5 V.

Protective claddings

All mobile fan components driven by the electric motor as well as all

other hazardous parts of the fan are covered by xed, safely fastened

protective claddings that can be removed only using tools.

Check

Interval Method

y V, F, M

Electrical connection

The electrical connections are made using a 4-wire supply cable sys-

tem, 3 phases and 1 earth conductor with three-phase motors and

using a 3-wire supply cable system, 1 phase, 1 neutral wire and 1

earth conductor with alternating current motors.

Check

Interval Method

y F

Check

Interval Method

y F

Check

Interval Method

m V

Meaning of possible device categories on the type label:

II 2G The fan is suitable for exhaustion from zone 1

and for installation in zone 1

II 2/3G The fan is suitable for exhaustion from zone 1

and for installation in zone 2

II 3G The fan is suitable for exhaustion from zone 2

and for installation in zone 2

II 3/-G The fan is suitable for exhaustion from zone 2

and must be installed outside the hazardous area

Operating manual

Centrifugal fans

HF R | RV | MRV

www.hlu.eu

19

www.hlu.eu 06.2019

Deactivating the safety devices, or changing their operating principle,

is strictly prohibited.

4.5 Safety measures (to be implemented by the user)

4.4 Interfaces of the fan

The fan has the following interfaces:

J Outlet side (connection via sleeve with tightening strap or ange)

J Terminal box or maintenance switch (electric supply)

J Inlet side (connection via sleeve with tightening strap or ange)

We point out that the user is under the duty to:

J instruct the operating and maintenance personnel on the protective devices of the fan,

J and to ensure supervision concerning compliance with the safety measures.

This operating manual must be kept for future use. The specied frequency of inspection and

control measures must be met.

J The chapters related to transport, installation and mounting, maintenance, troubles/causes/

troubleshooting must be understood by a qualied person. Work described in this chapter

may be performed only by qualied personnel.

4.6 User‘s responsibilities

In the European Economic Area, compliance with Council Directive

(89/391/EEC) and the related individual directives, especially Council

Directive 89/655/EEC Concerning the Minimum Safety and Health

Requirements for the Use of Work Equipment by Workers at Work in

the relevant national version is mandatory.

The user must obtain the local operating licence and follow the relevant rules.

Additionally, the user must ensure compliance with the national legal regulations concerning

J the personnel safety (regulations relating to accident prevention)

J the safety of work equipment (protective equipment and maintenance)

J product recycling (Waste Management Law)

J material disposal (Waste Management Law)

J cleaning (cleaning agents and disposal)

J and comply with the requirements for environment protection.

Operating manual

Centrifugal fans

HF R | RV | MRV

20

06.2019

5.1 Hazards

Pay attention to the safety devices described in this manual and follow the safety notes.

When doing setup, maintenance and repair work within the ex-

plosion-hazarded area, make sure that there isn‘t a critical gas

concentration. Use a gas detector. Always avoid handling all kinds of

ignition sources inside the explosion-hazarded area. Welding, cutting

and polishing work may be performed only, if the related permission

was granted.

During setup, maintenance and repair work, mind the squeezing

hazards.

During setup, maintenance and repair work, mind the hazard due to

electric current!

During setup, maintenance and repair work, be aware of the risk of

getting burned due to hot components.

In the event of a failure of the forced ventilation, the drive motor pre-

sents a hazard of getting burned.

5. General warning symbols

5.2 Operating and hazardous areas on the fan

Hazardous area

During setup, maintenance and repair work, the overall area around the fan is a hazardous

area.

To avoid the occurrence of ignition sources, the operating and main-

tenance personnel must be equipped properly and receive adequate

instructions for realization of cleaning and maintenance work, e.g.

J to avoid the use of tools giving rise to sparking,

J strict observance of the smoking ban,

J to avoid the actuation of ignition sources (e.g. lighters, etc.).

Operating manual

Centrifugal fans

HF R | RV | MRV

www.hlu.eu

This manual suits for next models

100

Table of contents

Other HLU Fan manuals

Popular Fan manuals by other brands

Costway

Costway EP24830 user manual

KDK

KDK M56XG Operating and installation instructions

Vectaire

Vectaire MBOX 125/2DC Installation, operating and maintenance instructions

ENERMAX

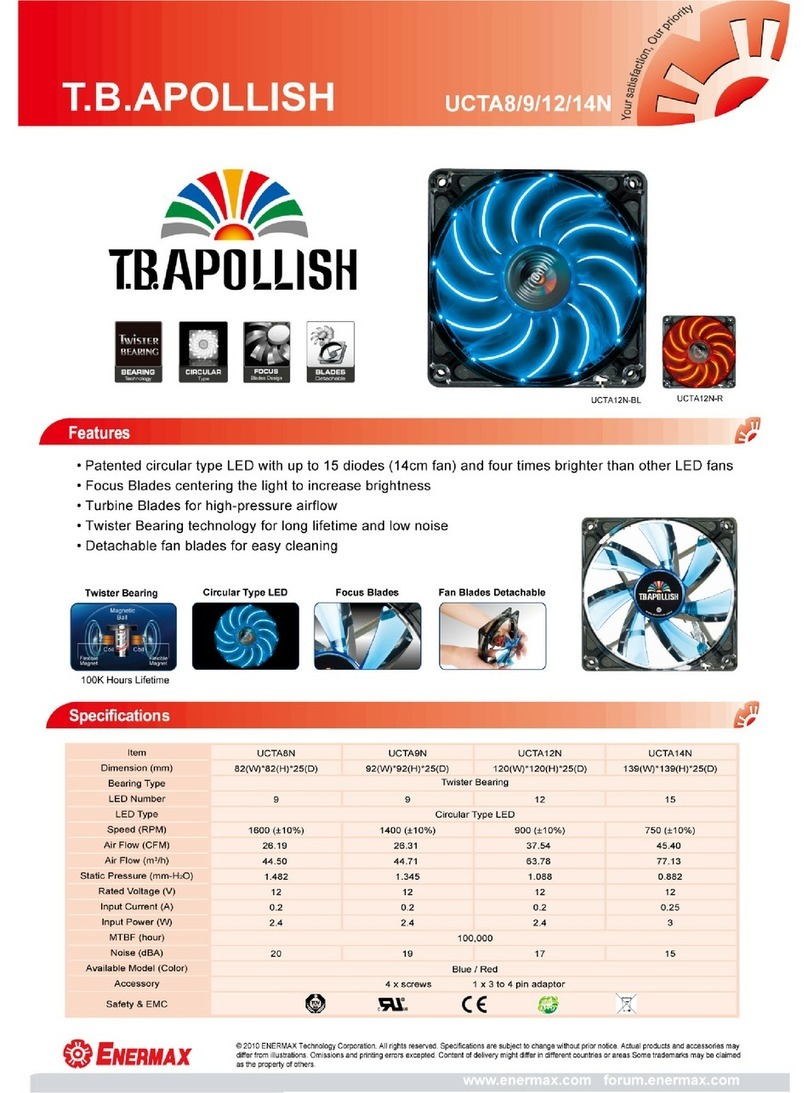

ENERMAX T.B.APOLLISH datasheet

Westinghouse

Westinghouse Marino WH20 owner's manual

Craftmade

Craftmade Builder Deluxe BLD52-3 light installation guide