Chapter I purchase inspection .......................... 1

1.1 Check item ..............................................................1

1.2 Nameplate description .......................................... 2

1.2.1 Nameplate description .................................2

1.2.2 Frequency inverter model description ...... 2

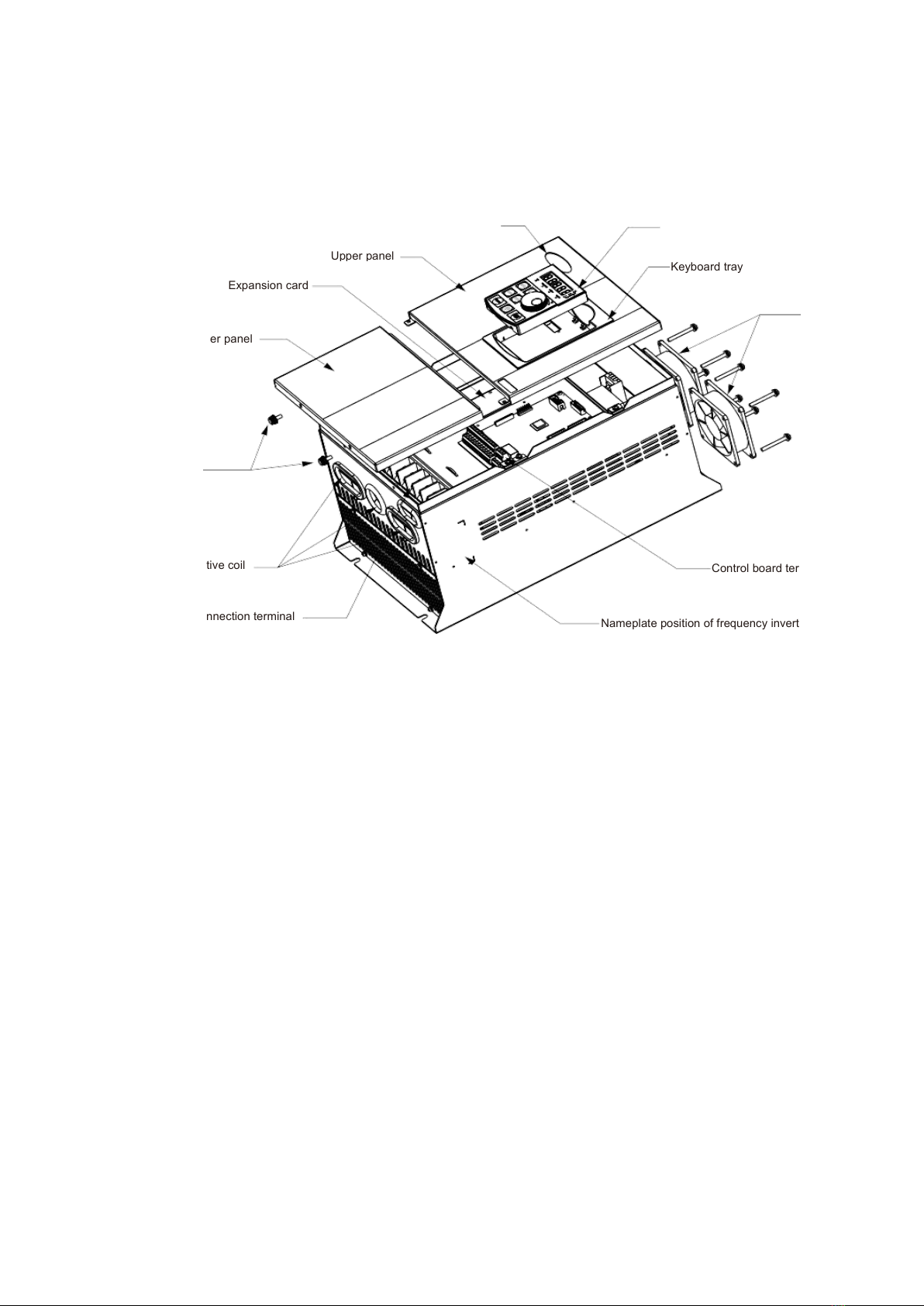

1.3 Description of parts of HV610 inverter ...............3

Chapter II Installation wiring ...............................4

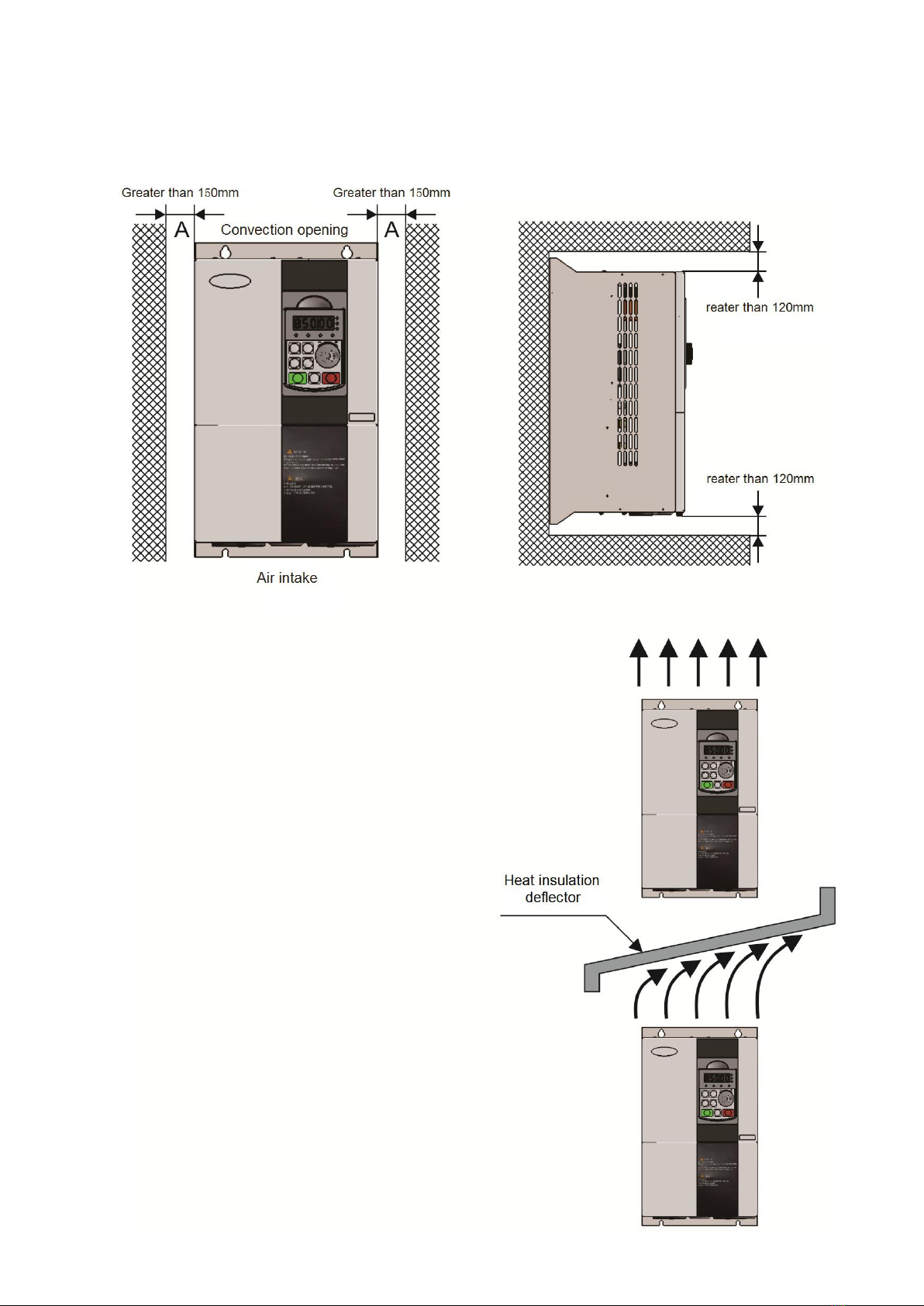

2.1 Mechanical installation ......................................... 4

2.1.1 Installation Conditions ................................. 4

2.1.2 Installation Space .........................................5

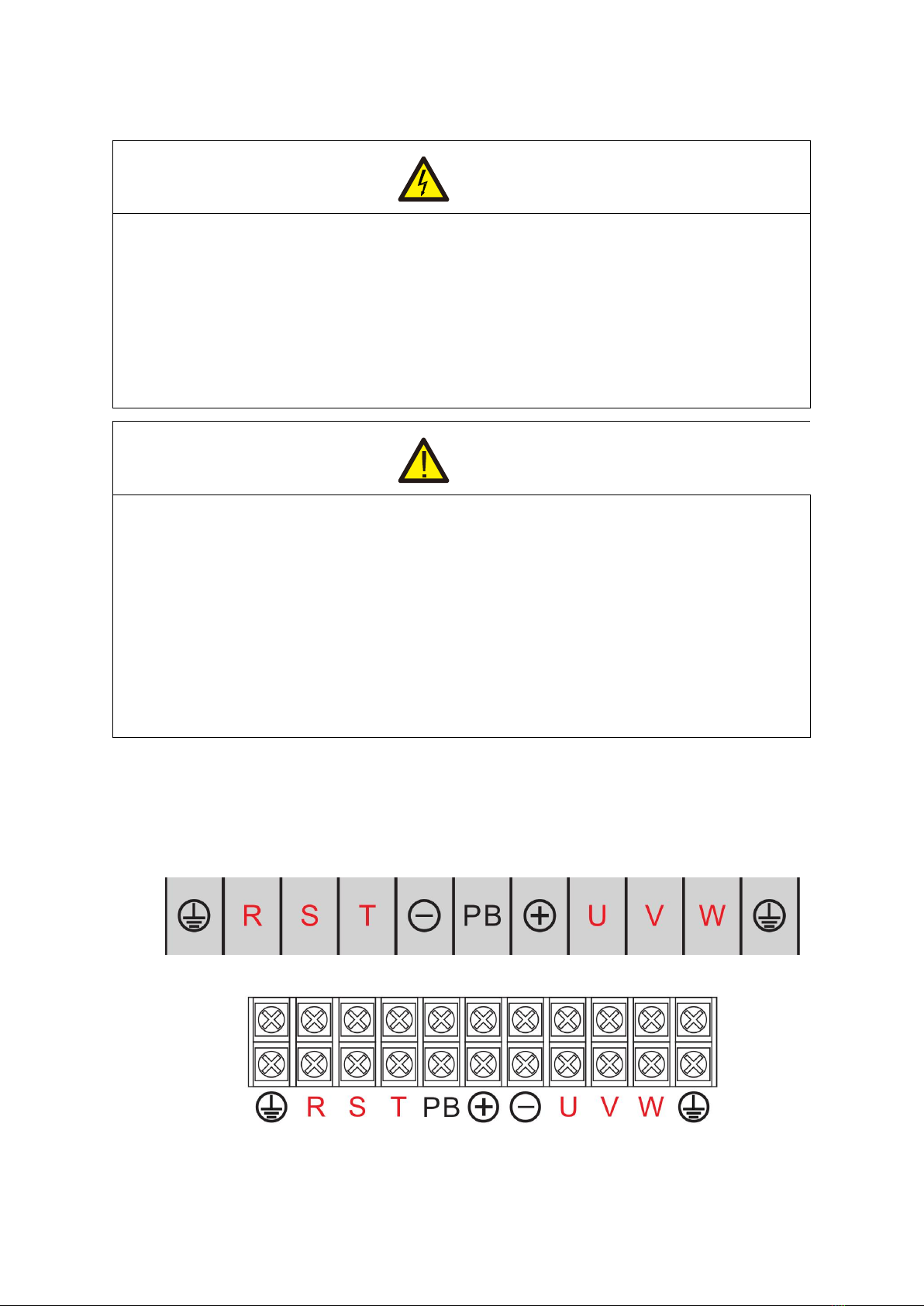

2.2 Electrical Installation ............................................. 6

2.2.1 Frequency inverter main circuit terminal

description ............................................................... 6

2.2.2 Main circuit wiring method and wiring

precautions ..............................................................7

2.2.3 Frequency inverter control loop terminal

description ............................................................... 8

2.2.4 Standard wiring diagram of frequency

inverter ..................................................................... 12

2.2.5 Control loop connection mode ................... 13

Chapter III Process operation ............................ 16

3.1 operating keyboard and display interface ......... 16

3.2 indicator light description ......................................16

3.3 key function description ........................................ 17

3.4 methods for viewing and modifying function codes

...........................................................................................17

3.5 Two quick access modes for function code

parameters .................................................................... 18

3.6 trial running ............................................................. 18

3.7 motor characteristic parameter setting and

automatic tuning ........................................................... 18

Chapter IV Functional parameters ...................21

Chapter V Description of parameters ............ 54

F0 group basic function ...............................................54

F1 group motor parameters ........................................64

F2 group motor vector control parameters .............. 66

F3 group V/F control parameter .................................67

F4 group output terminal .............................................71

F5 group input terminal ............................................... 77

F6 group start-stop control ..........................................89

F7 group torque control .............................................. 94

F8 group auxiliary function .........................................95

F9 group fault and protection ...................................101

FA group PID function ...............................................106

FB group second group motor parameters ...........111

FC group multi-segment instruction, simple PLC 112

FD group communication parameters ................... 117

FE group user customized function code ..............117

FF group performance optimization parameters ..117

E0 group fault record ................................................ 117

P2 group AIAO correction group .............................119

U0 group monitoring parameter group ...................121

Chapter VI abnormal diagnosis ......................126

6.1 fault alarm and countermeasures .................... 126

6.2 matters needing attention in commissioning ..129

6.3 F0.01 = 2 V/F mode, common problem solving

methods.........................................................................130

6.4 fault analysis and countermeasures ................130

Chapter VII Maintenance .................................... 134

7.1 routine maintenance and safeguard ................134

7.2 product storage and storage .............................136

Chapter VIII Peripheral devices ...................... 137

8.1 introductions to configuration of peripheral devices

........................................................................................ 137

8.2 functional description of peripheral equipment

........................................................................................ 137

Chapter IX Quality Assurance ......................... 145

Appendix A Introduction of Communication

............................................................................................ 147

Appendix B: Technical specification for

frequency inverters ............................................... 159

Appendix I general purpose keyboard

dimensions and mounting dimensions ..... 161

Appendix II Plastic shell dimensions and

mounting dimensions............................................ 162

Appendix III dimensions and mounting

dimensions of sheet metal machines............162

Constant pressure control solution Case V0.1

for water pump and fan......................................... 170