- 2 -

CONTENTS

1 Symbols used in this service manual ..............................................................................4

2 Safety information ...........................................................................................................4

3 Maintenance, repair and safety-related check ...............................................................5

3.1 Maintenance.....................................................................................................................5

3.1.1 Maintenance schedule .....................................................................................................5

3.2 Repairs.............................................................................................................................6

3.3 Hygienic preparation.........................................................................................................6

3.4 Safety-related check.........................................................................................................6

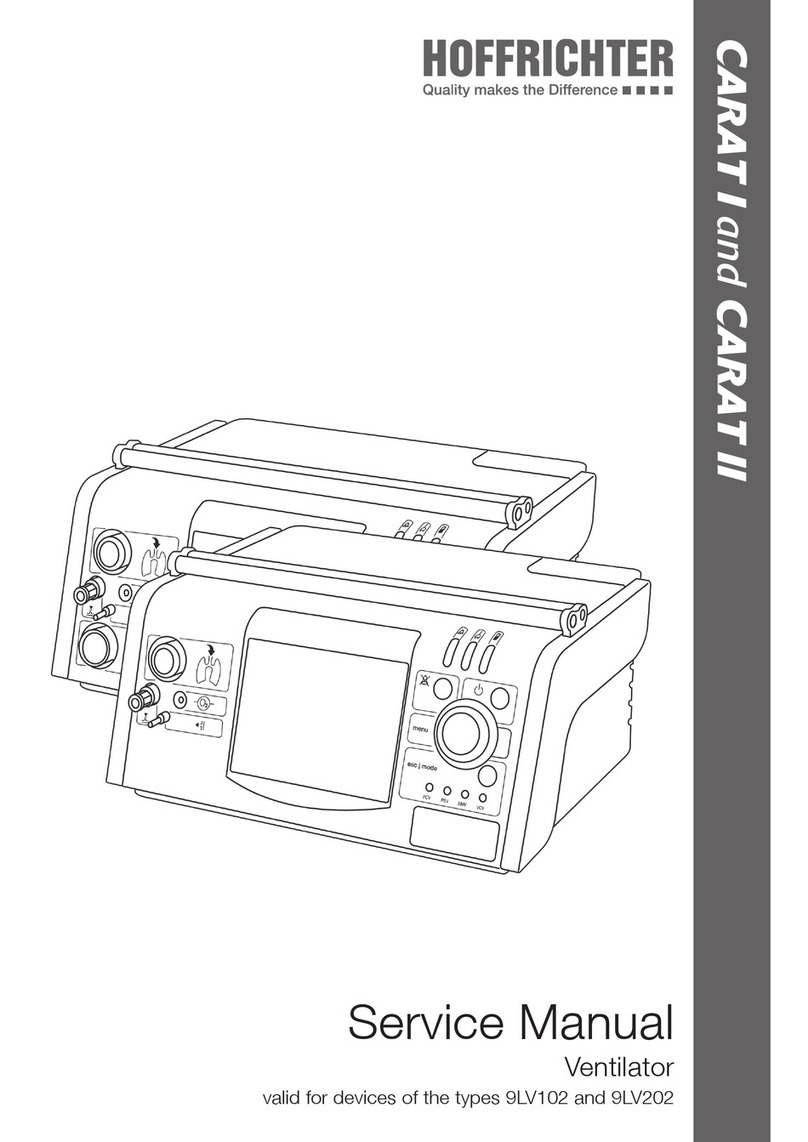

4 Description of device.......................................................................................................7

4.1 Housing, display and control elements..............................................................................7

4.2 Operating unit...................................................................................................................9

4.3 Exploded view - General layout.......................................................................................10

4.4 Exploded view - Housing upper part ...............................................................................11

4.5 Exploded view - Front panel ...........................................................................................12

4.6 Exploded view - Back part..............................................................................................12

4.7 Exploded view - Air outlet unit.........................................................................................13

4.8 Exploded view - Battery pack .........................................................................................13

4.9 Cable connecting plan PCB controller.............................................................................14

4.10 Tube connecting plan .....................................................................................................15

5 Important components ..................................................................................................16

5.1 Block diagrams ..............................................................................................................16

5.1.1 Block diagram of compressed air distribution..................................................................16

5.1.2 Block diagram of entire device ........................................................................................17

5.2 Blower............................................................................................................................17

5.3 PCB DC-communication ................................................................................................17

5.4 Sensors / Valves (distribution of the compressed air)........................................................17

5.5 Power supply .................................................................................................................18

5.6 PCB controller (Control- and operating unit) ....................................................................18

5.7 Operating unit / Display ...................................................................................................18

5.8 Interfaces .......................................................................................................................18

6 Servicing .......................................................................................................................19

6.1 Preliminary steps ............................................................................................................19

6.1.1 Tools and measuring equipment .....................................................................................19

6.1.2 Unpacking and disinfecting.............................................................................................20

6.1.3 Checking for external damage ........................................................................................20

6.1.4 Data backup...................................................................................................................20

6.2 Opening and disassembling the device ...........................................................................20

6.3 Cleaning.........................................................................................................................21

6.4 Check the silicone tubes.................................................................................................21

6.5 Check the cables and connections .................................................................................21

6.6 Changing the 9V rechargeable battery ............................................................................21

6.7 Changing the batteries....................................................................................................22

6.8 Changingthelters.........................................................................................................22

6.9 Exchanging the blower box.............................................................................................22

6.10 Assembling and closing the device .................................................................................24