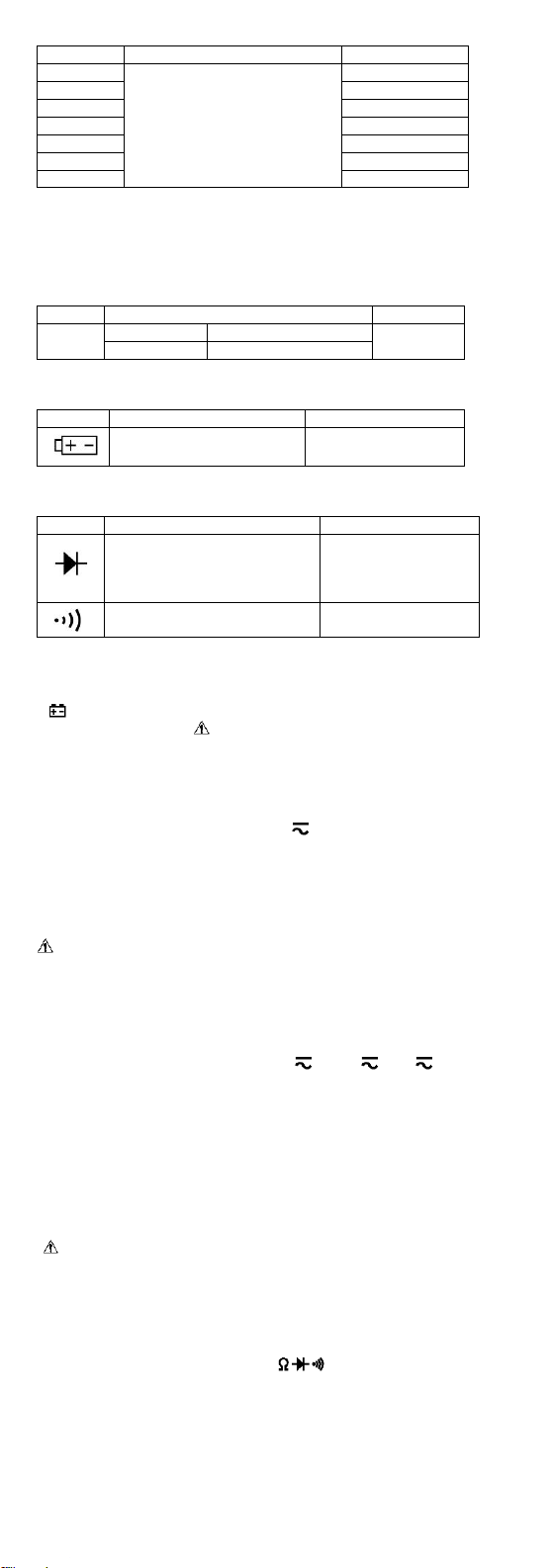

6-7 Frequency

Range Accuracy Resolution

5.12Hz

± (0.1% of rdg + 5 digits)

0.001Hz

51.2Hz 0.01Hz

512Hz 0.1Hz

5.12kHz 1Hz

51.2kHz 10Hz

512kHz 100Hz

5.12MHz 1kHz

-- Sensitivity: sine wave 0.6V rms (5.12MHz: 1.5V rms)

-- Overload protection: 250V DC or AC rms

6-8 Duty cycle

0.1%~99.9%: ± ( 2.0% of rdg + 2 digits ), Frequency lower than 10kHz

-- Sensitivity: sine wave 0.6V rms

-- Overload protection: 250V DC or AC rms

6-9 Temperature

Range Accuracy Resolution

℃-20~150℃± ( 3℃+ 1digit ) 1℃

150~1000℃± ( 3% of rdg + 2digits )

-- NiCr-NiSi sensor

-- Overload protection: 400mA/250V PPTC Resettable Fuse

6-10 Battery test

Range Accuracy Test Condition

±(5.0% of rdg + 5 digits) Loading Current:

Approx. 25mA

-- Battery voltage range: 1.5V~12V

-- Overload protection: 400mA/250V PPTC Resettable Fuse

6-11 Diode and Audible continuity test

Range Description Test Condition

Display read approximately

forward voltage of diode

Forward DC current

approx. 0.4mA

Reversed DC voltage

approx. 1.5V

Built-in buzzer sounds if

resistance is less than 100Ω

Open circuit voltage

approx. 0.5V

Overload protection: 250V DC or AC rms

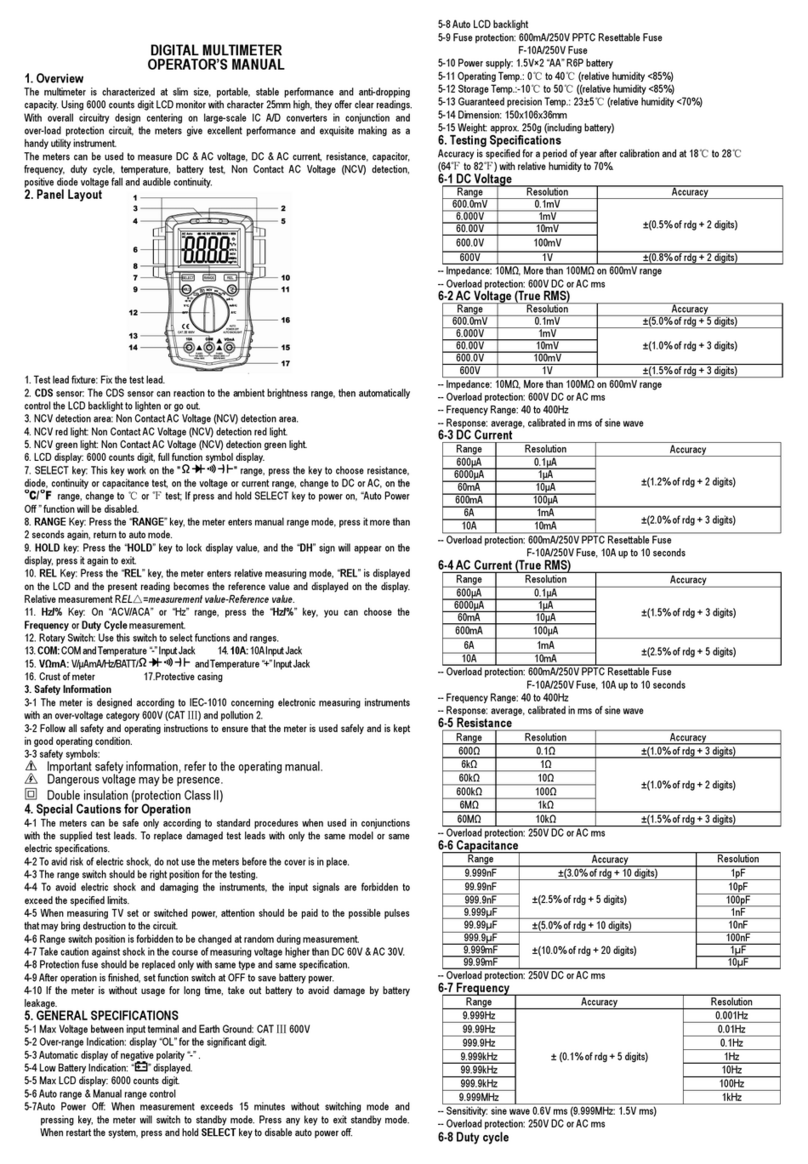

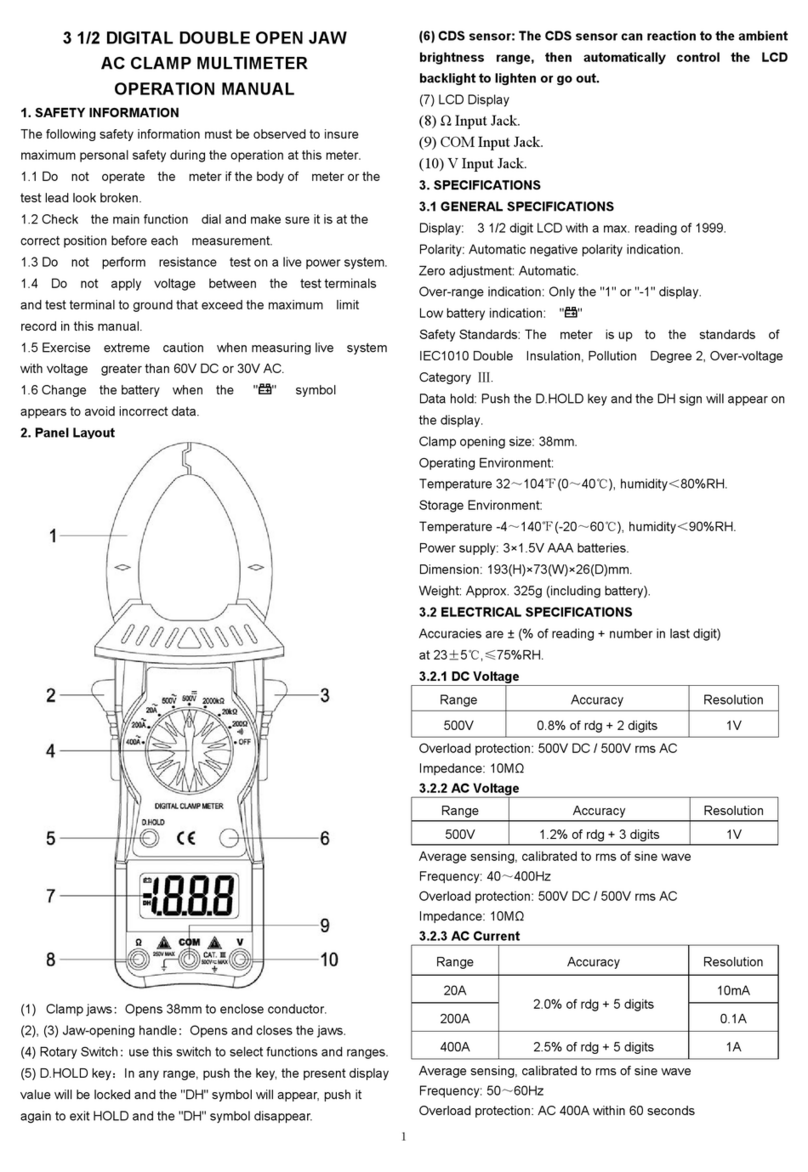

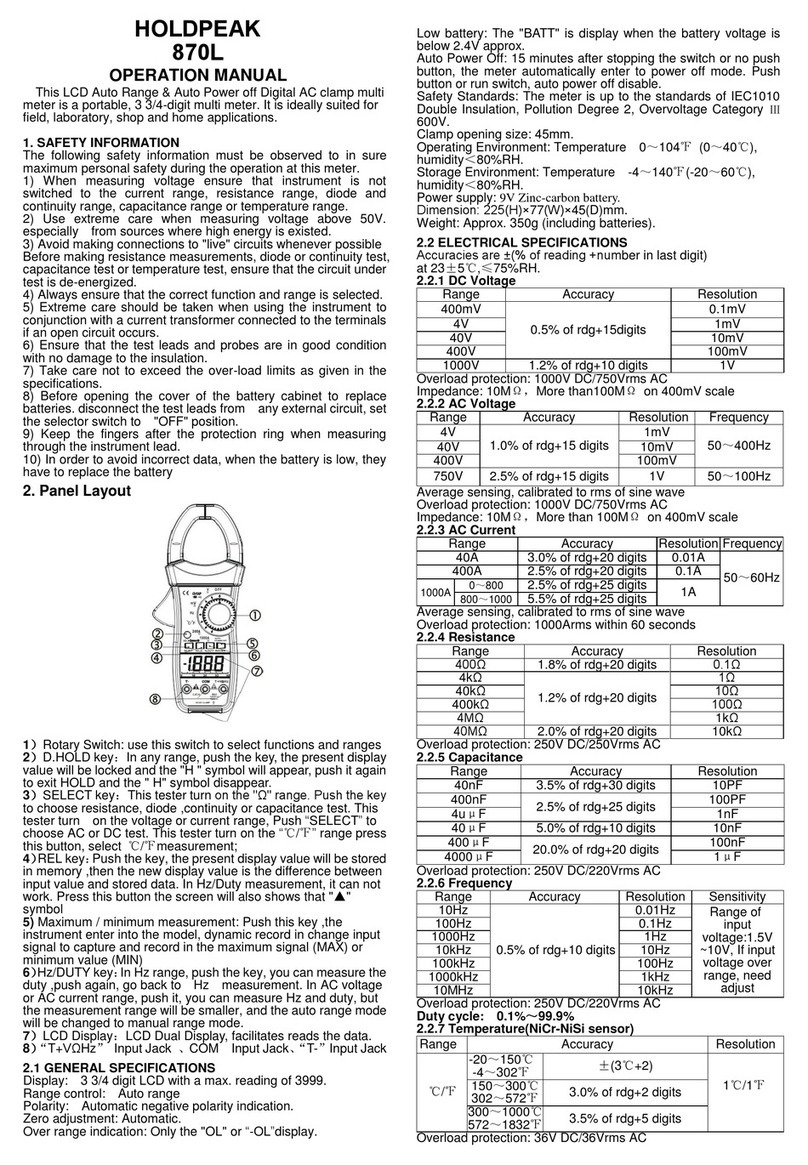

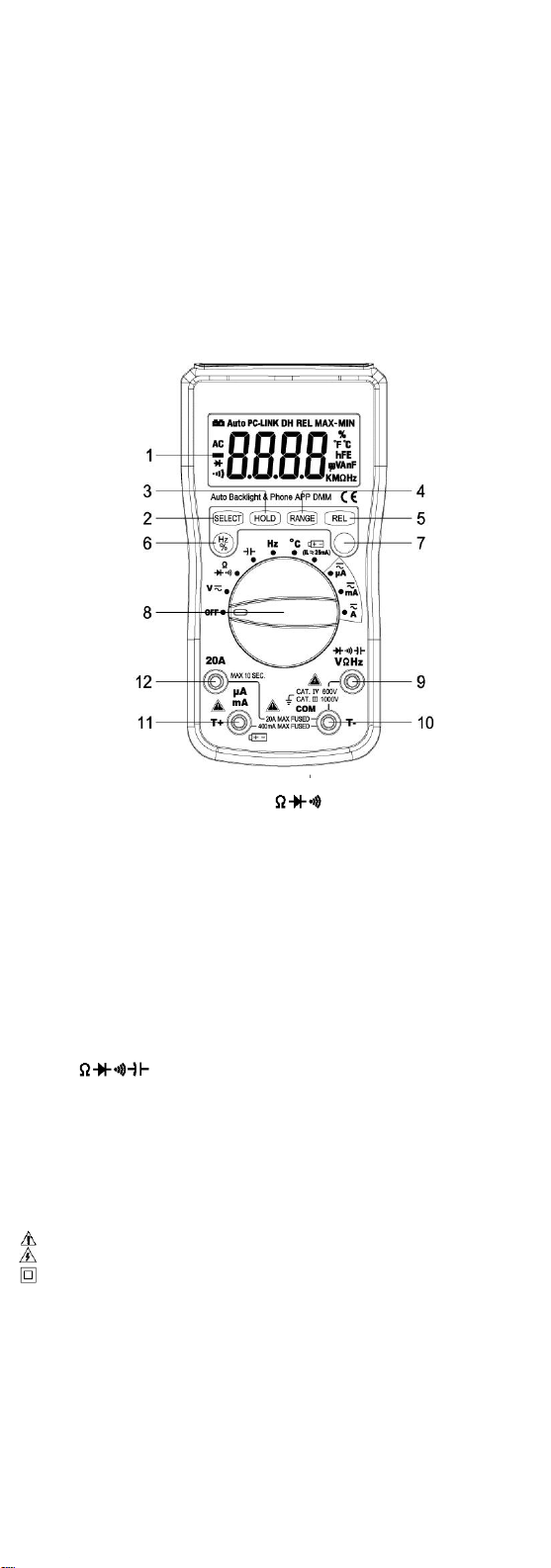

7. OPERATING INSTRUCTIONS

7-1 Attention before operation

7-1-1 Check battery. When the battery voltage drop below proper operation range,

the “ ” symbol will appear on the LCD display and the battery need to changed.

7-1-2 Pay attention to the “ ” besides the input jack which shows that the input

voltage or current should be within the specified value.

7-1-3 The range switch should be positioned to desired range for measurement

before operation.

7-2 Measuring DC & AC Voltage

7-2-1 Connect the black test lead to COM jack and the red to VΩHz jack.

7-2-2 Set the rotary switch at the desired “V”range position, it shows symbol for

testing DC voltage, if you want to test AC voltage, push “SELECT” button switch,

then if you want to test AC 400mV, push “RANGE”to choose.

7-2-3 Connect test leads across the source or load under measurement.

7-2-4 You can get reading from LCD. The polarity of the red lead connection will be

indicated along with the DC voltage value.

NOTE:

1.“” means you can’t input the voltage more than 1000V, it’s possible to show

higher voltage, but it may destroy the inner circuit or pose a shock.

2.Be cautious against shock when measuring high Voltage.

7-3 Measuring DC & AC Current

7-3-1 Connect the black test lead to COM jack and the red to the μAmA jack for a

maximum 400mA current , for a maximum 2A or 20A current, move the red lead to

the 20A jack.

7-3-2 Set the rotary switch at the desired “uA ”& “mA ”& “A”range position,

it shows symbol for testing DC current, if you want to test AC current, push

“SELECT”button switch.

7-3-3 Connect test leads in series with the load under measurement.

7-3-4 You can get reading from LCD. The polarity of the red lead connection will be

indicated along with the DC current value.

NOTE:

1. When the value scale to be measured is unknown beforehand, set the range

selector at the highest position.

2. When only “OL”is displayed, it indicates over-range situation and the higher

range has to be selected.

3. “ ” means the socket mA’s maximum current is 400mA and 20A’s maximum

current is 20A, over 400mA current can be protected by the PPTC resettable fuse,

but over 20A current will destroy the fuse. On the 20A range, the measuring time

should be less than 10 seconds to prevent precision from affecting by circuit

heating.

7-4 Measuring Resistance

7-4-1 Connect the black test lead to COM jack and the red to VΩHz jack.

7-4-2 Set the rotary switch at the desired “”range position.

7-4-3 Connect test leads across the resistance under measurement.

7-4-4 You can get reading from LCD.

NOTE:

1. For measuring resistance above 1MΩ, the mete may take a few seconds to get

stable reading.

2. When the input is not connected, i.e. at open circuit, the figure ‘OL’ will be

displayed for the over-range condition.

3. When checking in-circuit resistance, be sure the circuit under test has all power

removed and that all capacitors have been discharged fully.

7-5 Measuring Capacitance

7-5-1 Connect the black test lead to COM jack and the red to VΩHz jack.

7-5-2 Set the rotary switch at the desired “”range position.

7-5-3 Connect test leads across the capacitance under measurement.

7-5-4 You can get reading from LCD.

NOTE: Max. input overload: 250V rms<10sec

1. Capacitors should be discharged before being tested.

2. When testing large capacitance, it will take longer time before the final indication

(For 100uF, it will take about approx. 15 seconds).

3. When testing small capacitance (≤100nF), to assure the measurement accuracy,

first press "REL", then go on measuring.

7-6 Measuring Frequency & Duty cycle

7-6-1 Connect the black test lead to COM jack and the red to VΩHz jack.

7-6-2 Set the rotary switch at the desired “Hz”range position.

7-6-3 Push “Hz/%” key to choose Frequency or Duty cycle test.

7-6-4 Connect the probe across the source or load under measurement.

7-6-5 You can get reading from LCD.

7-7 Measuring Temperature

7-7-1 Connect the black banana plug of the sensor to COM (T-) jack and the red

banana plug to the μAmA (T+) jack.

7-7-2 Set the rotary switch at the desired “”range position.

7-7-3 Put the sensor probe into the temperature field under measurement.

7-7-4 You can get reading from LCD.

NOTE: Max. input over-load: 250V rms<10sec

1. The accessory of the meter WRNM-010 type contact thermocouple limit

temperature is 250 ℃(300 ℃shortly), please use special probe for test higher

temperature.

2. Please don't change the thermocouple at will, otherwise we can't guarantee to

measure accuracy.

3. Please don’t importing the voltage in the temperature function.

7-8 Battery Testing

7-8-1 Connect the black test lead to COM jack and the red to μAmA jack.

7-8-2 Set the rotary switch at the desired “ ” range position.

7-8-3 Connect test leads across the source or load under measurement.

7-8-4 You can get reading from LCD. The loading current: is approx. 25mA (positive), it

is no loading current when the display is negative.

7-9 Diode & Audible continuity Testing

7-9-1 Connect the black test lead to COM jack and the red to VΩHz jack.

7-9-2 Set the rotary switch at the “”range position, push “SELECT”to

choose Diode or Audible continuity measurement.

7-9-3 On diode range, connect the test leads across the diode under measurement,

display shows the approx. forward voltage of this diode.

7-9-4 On Audible continuity range, connect the test leads to two point of

circuit, if the resistance is lower than approx. 100Ω, the buzzer sounds.

NOTE: Make sure the power is cut off and all capacitors need to be discharged

under this measurement.

7-10 Connect to mobile phone APP

The meter has serial data output function. It can be connected with mobile phone

by Bluetooth, so the measured data can be recorded, analyzed, and processed by

mobile phone APP. Before use this function, you need install the mobile phone APP

by scan the QR code.

NOTE: The mobile phone APP can be installed in iphone 4S iOS or android

4.30 system and up.

7-10-1 Make sure the “HP-90EPD”mobile phone APP successfully installed before

any measurement.

7-10-2 Open the Bluetooth of the mobile phone, Run the “HP-90EPD”mobile

phone APP to enter the main interface.

7-10-3 Turn on the meter, the meter will connect to mobile phone automatically,

when the “Start”key change to green, click the “Start”key to measure and view the

synchronic data or graph in the mobile phone APP.

7-10-4 The MAX or MIN value and corresponding time will display on the mobile

phone APP, and the average value in a period of time from start measurement will

display too.

7-10-5 Press the “Reset”key to reset measurement, the old data will be cleared

and resume data recording. Press the “Stop”key to stop connection.

7-10-6 Press the “Data”key to view the data and time, Press the “Graph”key to

view the graph, Press the “Save”key to save the data or the graph. Press the

“Home”key to return the main interface.

7-10-7 More information about the mobile phone APP, please refer to the Help topic

including in the APP.

8. Maintenance

8-1 Before attempting to remove the battery door or open the case, be sure that test

leads have been disconnected from measurement circuit top avoid electric shock

hazard.

8-2 To avoid electrical shock, remove test leads from measurement circuits before

replacing the fuse. For protection against fire, replace fuses only with specified

ratings: F-20A/250V fuse.

8-3 Your must replace the test leads if the lead is exposed, and should adopt the

leads with the same specifications as origin.

8-4 Use only moist fabric or small amount of detergent but not chemical solution for

cleaning.

8-5 Do not use the meter before the back cover is properly closed and screw

secured. Upon any abnormality, stop operation immediately and send the meter

for maintenance.

8-6 Please take out the battery when not using for a long time.